Preparation method and application of modified graphene nano filling material

A nano-filling, graphene technology, applied in fibrous fillers, chemical instruments and methods, inorganic pigment processing and other directions, can solve the problems of poor graphene conductivity, difficult to meet application requirements, reduce graphene application value, etc. The effect of burning and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

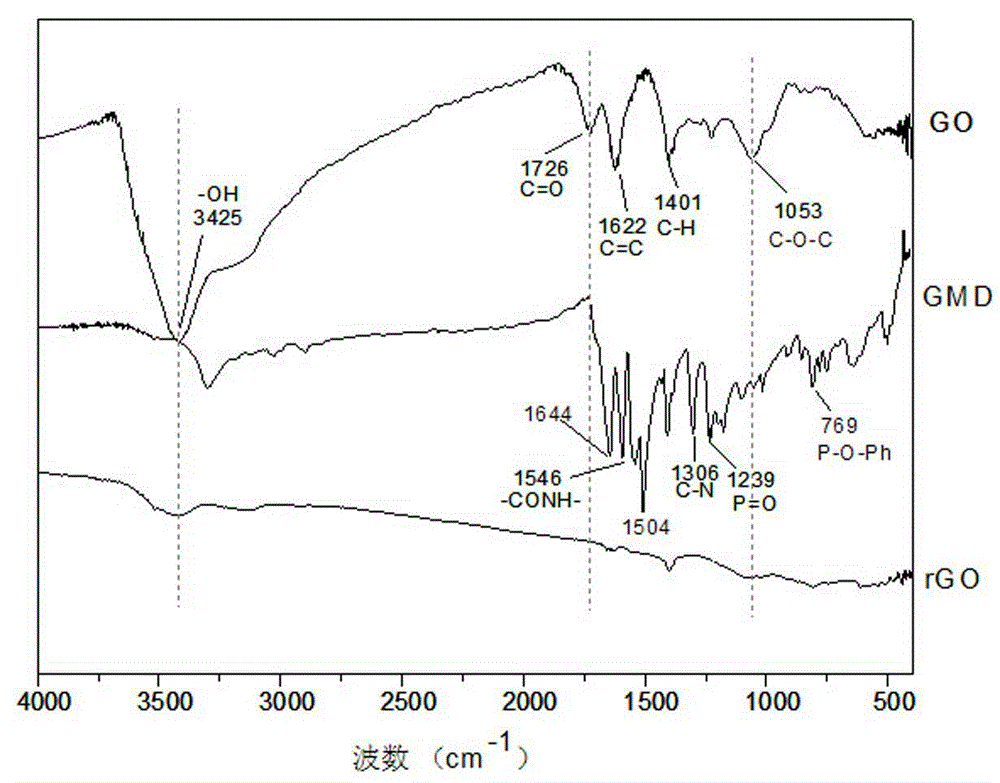

Image

Examples

Embodiment 1

[0025] The modified graphene nano-fill material of the present embodiment is prepared as follows:

[0026] (1) Preparation of graphite oxide: take 2g graphite powder, 1g NaNO 3 , 46ml concentrated H 2 SO 4 Place in a flask and stir in an ice bath; add 6g KMnO to the above system 4 , continue to stir for 30 minutes; then raise the temperature to 35°C, and after stirring for 1 hour, add 92ml of distilled water dropwise to the reaction system; then raise the reaction temperature to 98°C, continue to stir for 15 minutes, and then use warm water to dissolve the reaction solution To dilute, add 5ml H to the reaction solution 2 O 2 and stirred, the obtained product was filtered by suction, washed with water until neutral, and dried in a vacuum oven at 60°C to obtain graphite oxide; the conductivity of the obtained graphite oxide was tested to be 1.34×10 -8 S / m.

[0027] (2) Preparation of reduced graphene: Take 1g of graphite oxide prepared in s...

Embodiment 2

[0033] The modified graphene nano-fill material of the present embodiment is prepared as follows:

[0034] (1) The preparation method of graphite oxide is the same as in Example 1;

[0035] (2) the preparation method of reduced graphene is identical with embodiment 1;

[0036] (3) Preparation of modified graphene: Take 0.5g of the reduced graphene prepared in step (2) and ultrasonically disperse it in 80ml of anhydrous NMP (N-methylpyrrolidone), take 8g of 4,4'-dicyclohexyl Dissolve methane diisocyanate in NMP, under the protection of nitrogen, add 4,4'-dicyclohexylmethane diisocyanate solution dropwise to the reduced graphene dispersion, react at 70°C for 5 hours, and the obtained product is centrifuged , NMP was washed several times, and then dispersed in anhydrous NMP; 7.6g DOPO was dissolved in NMP, and under nitrogen protection, the DOPO solution was added dropwise to the above-mentioned graphene dispersion grafted with isocyanate groups, and then Add 0.3g of tr...

Embodiment 3

[0040] The modified graphene nano-fill material of the present embodiment is prepared as follows:

[0041] (1) The preparation method of graphite oxide is the same as in Example 1;

[0042] (2) the preparation method of reduced graphene is identical with embodiment 1;

[0043] (3) Preparation of modified graphene: take 0.5g of the reduced graphene prepared in step (2) and ultrasonically disperse it in 80ml of anhydrous DMF, take 9g of 4,4'-diphenylmethane diisocyanate and dissolve it in DMF , under the protection of nitrogen, 4,4'-diphenylmethane diisocyanate solution was added dropwise to the reduced graphene dispersion, and reacted at 70°C for 5 hours. The obtained product was centrifuged, washed with DMF several times, and then Disperse in anhydrous DMF; get 6.5g dimethyl phosphite and dissolve in DMF, under the protection of nitrogen, add the dimethyl phosphite solution dropwise in the above-mentioned graphene dispersion liquid grafted with isocyanate groups, Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com