Regeneration method of charging roller of laser imaging processing box

A technology of laser imaging and charging roller, which is applied in optics, electrical recording, instruments, etc., can solve the problems of bottom dust, influence on insulation performance, and decline in conductivity, and achieve simple and easy process steps, recovery of conductivity, and excellent quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

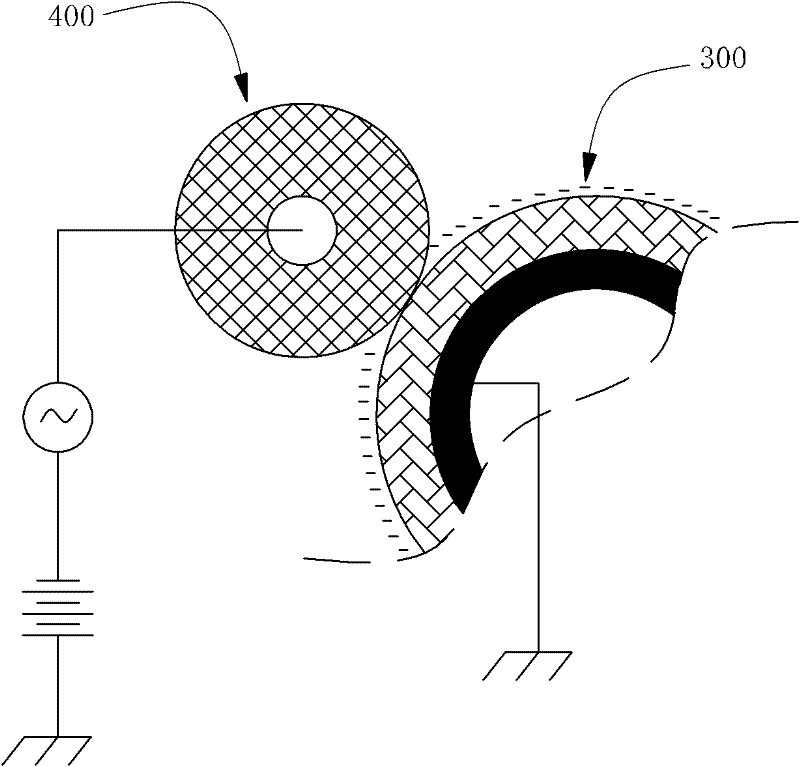

[0025] The charging roller regeneration method of the laser imaging process box of the present invention will be described in detail below in conjunction with the accompanying drawings.

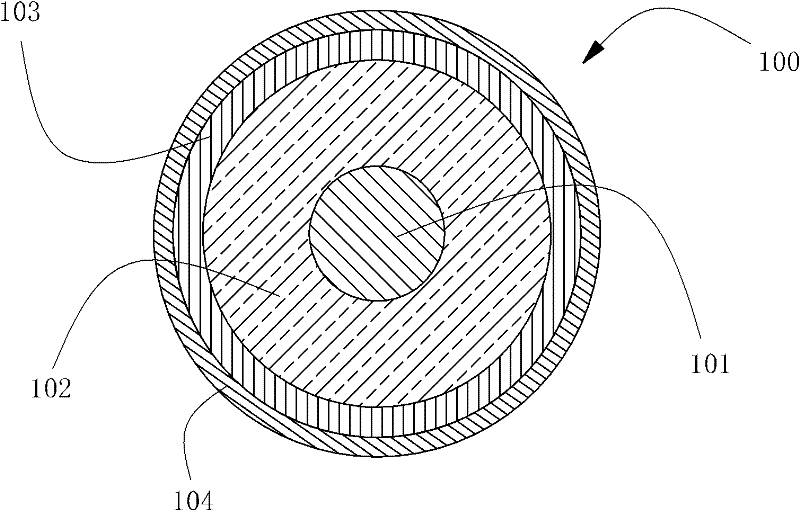

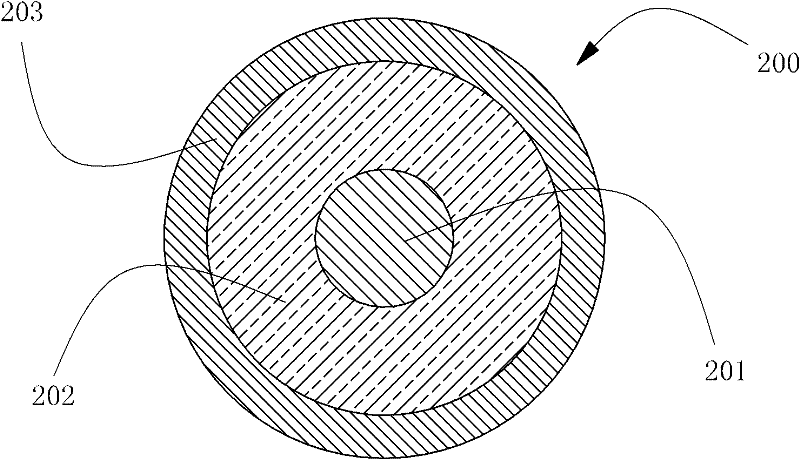

[0026] see figure 2 , 3 , respectively show the cross-sectional views of two charging rollers of the laser imaging process cartridge suitable for the regeneration method of the present invention.

[0027] figure 2 The illustrated cross-sectional structure of the charging roller 100 includes a metal mandrel 101 , an insulating layer 102 , a transition layer 103 and a conductive layer 104 . image 3 The illustrated cross-sectional structure of the charging roller 200 includes a metal mandrel 201 , an insulating layer 202 and a conductive layer 203 . The insulating layer 102 or the insulating layer 202 of the two charging rollers generally use foamed sponge as a raw material. Both the conductive layer 104 and the conductive layer 203 of the two charging rollers are usually made of conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com