Charging roll used for laser printing machine and its manufacturing method

A technology of laser printers and charging rollers, applied in the direction of circuits, applications, electrical components, etc., can solve problems such as degradation and softening of the silicone rubber conductive elastic layer, and achieve good bite, clear images, and moderate elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

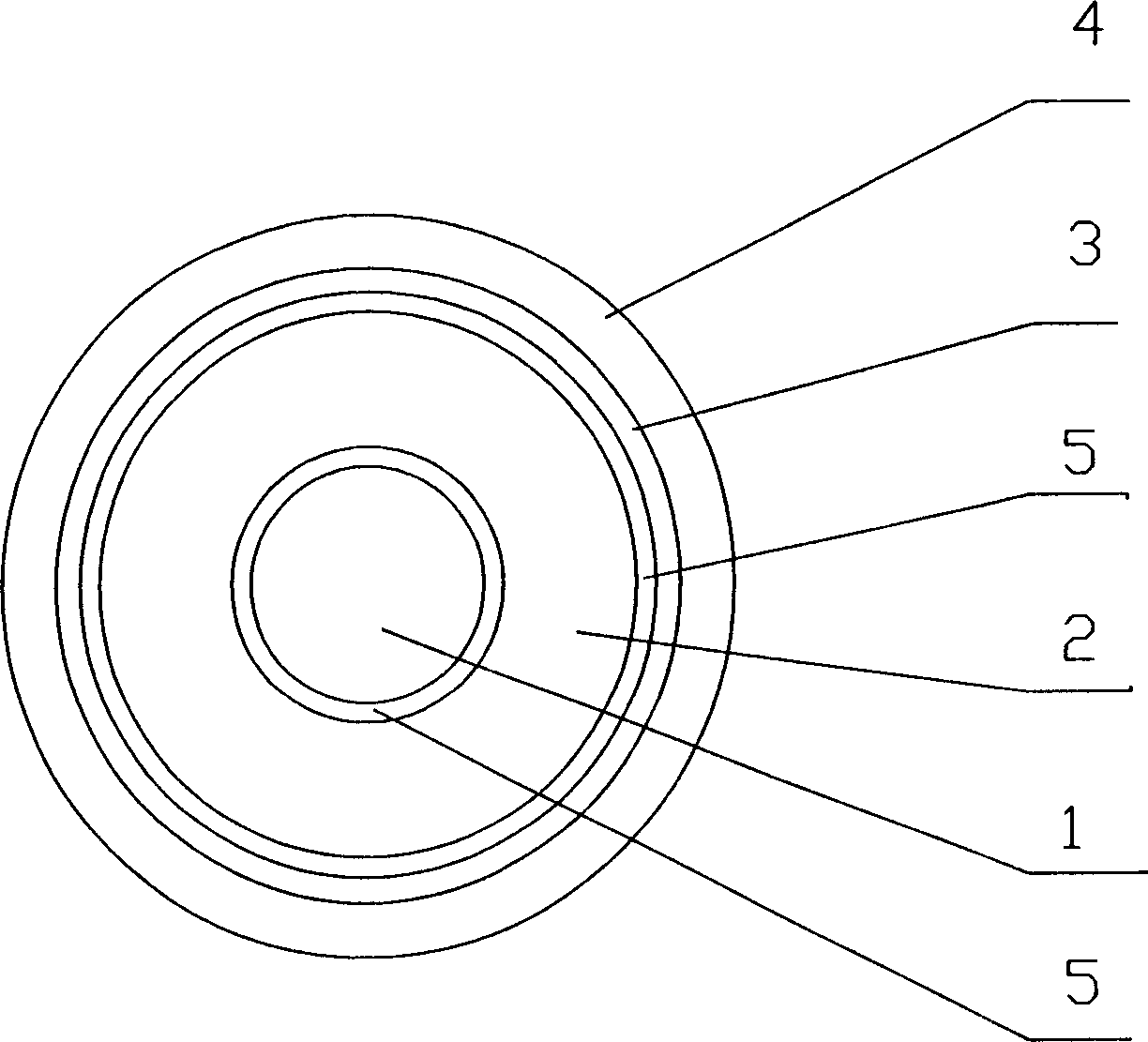

[0030] Such as figure 1 The shown charging roller for a laser printer includes a metal core 1, an adhesive layer 5 on the outer peripheral surface of the metal core 1 bonded with a low-hardness conductive silicone rubber elastic layer 2, and the low-hardness conductive silicone rubber The adhesive layer 5 on the outer peripheral surface of the elastic layer 2 adheres the conductive fluorine paint protective layer 4 .

[0031] The low-hardness conductive silicone rubber elastic layer: select 100 parts by weight of silicone rubber with a molecular weight of 500,000-600,000, reinforce with 15 parts by weight of white carbon black, use 0.6-0.8 parts by weight of 2,5-dimethyl 2, 5 bis(tert-butyl peroxy) hexane crosslinking, kneading into rubber compound; 100 parts by weight of rubber compound, plus 8-9 parts by weight of conductive carbon black, 6-10 parts by weight of graphite Refined into a low-hardness conductive silicone rubber elastic layer material, the resistance value is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com