Sludge dewatering container and dewatering method by adopting container

A sludge dehydration and container technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of sludge dehydration efficiency reduction, slow down the decline of electrical conductivity, prolong electricity The effect of soaking time and restoring conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

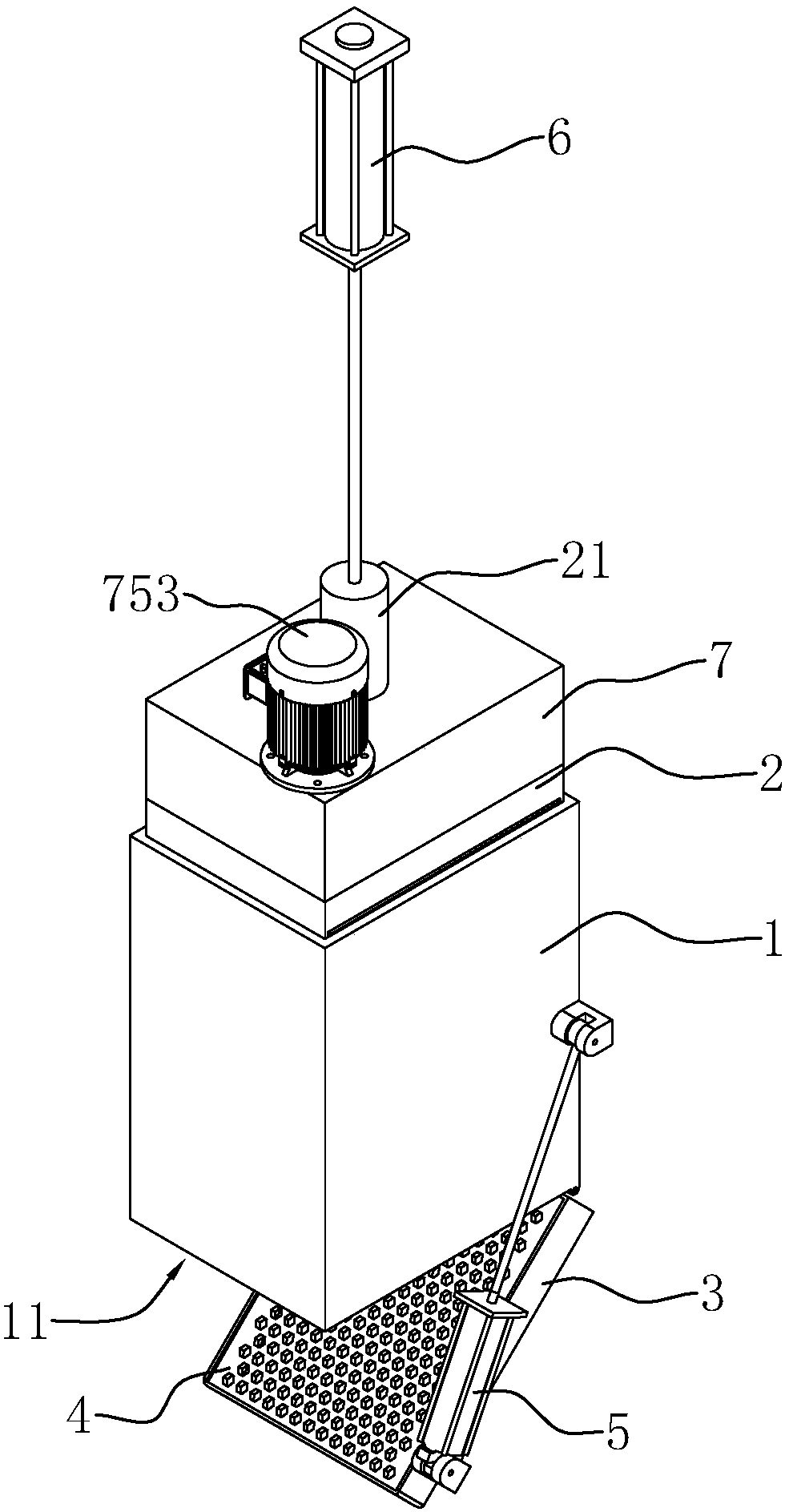

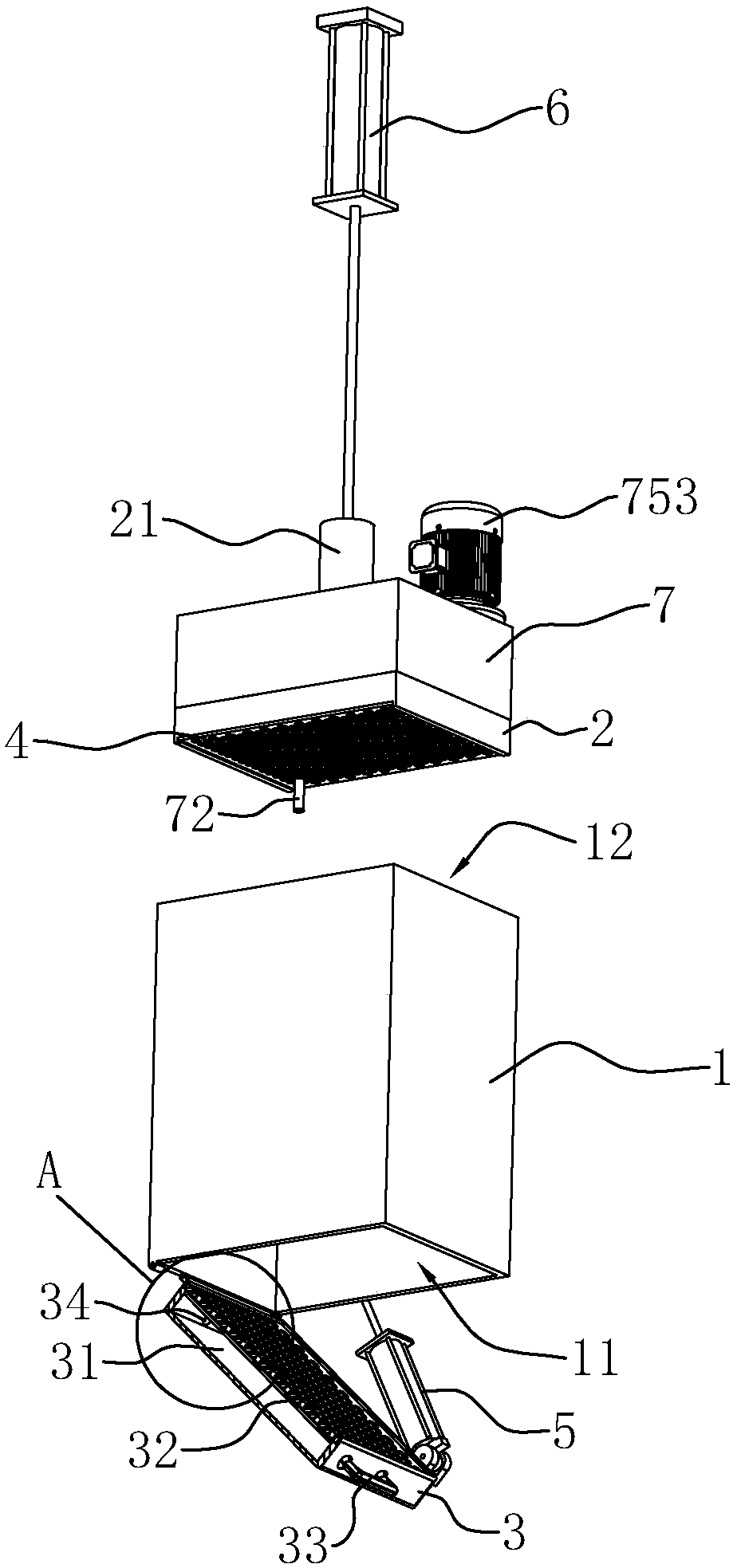

[0043] Embodiment 1: a kind of sludge dewatering container, such as figure 1 As shown, it includes an insulating container body 1, which is a cubic structure (wherein, it is not limited to a cube, it can be a cylinder, a cuboid, etc.), and the insulating container body 1 includes a container side wall, a bottom, a top, and a Two electrode materials 4 on the bottom and the top, the two electrode materials 4 are connected with the positive pole and the negative pole of the power supply to form two situations of upper yang and lower yin or upper yin and lower yang, wherein the upper yin and lower yang are used to flocculate the mud, and the upper yang is used to flocculate the mud. The lower shade is used for deep dehydration of the flocculated sludge.

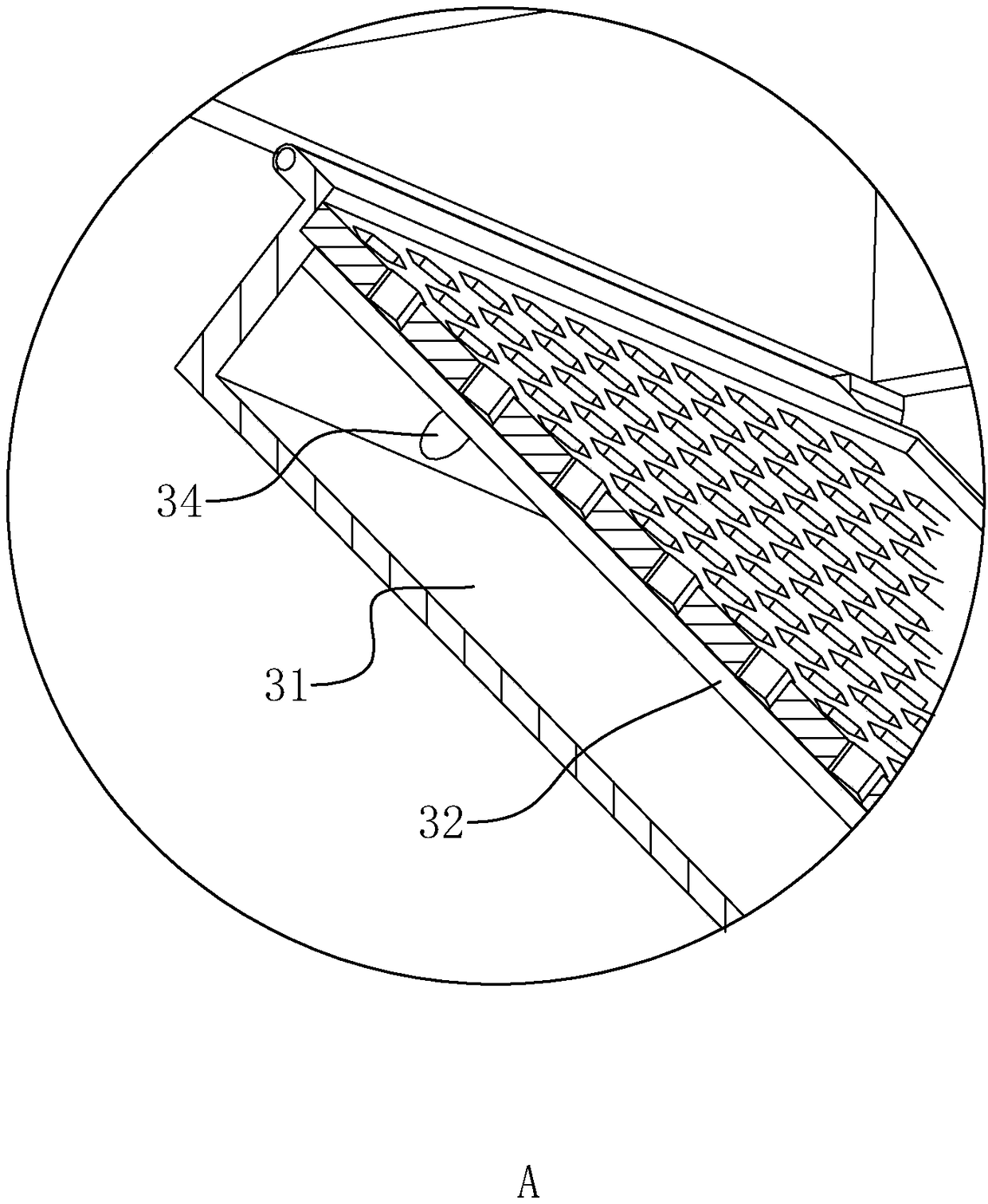

[0044] like figure 1 and 2 As shown, the bottom end of the insulating container body 1 is open to form a mud outlet 11, the bottom is a flip-type bottom cover 3 that can close the mud outlet 11, and one side of the bottom cover...

Embodiment 2

[0055] Embodiment 2: a kind of dehydration method of dehydration container, comprises the following steps:

[0056] S1, packing, close the sludge outlet 11 of the sludge dewatering container, add sludge to the sludge dehydration container from the sludge inlet 12, and seal the sludge outlet 11 with the top cover 2 after filling;

[0057] S2, energize and dehydrate, control the lifting cylinder 6 to continue to elongate, so that the counterweight block is in conflict with the sludge, continue to control the elongation of the lifting cylinder 6 at this time, shrink the telescopic rod, and release the pulling force of the lifting cylinder 6 on the counterweight.

[0058] The electrode material 4 on the top cover 2 is connected to the positive pole of the intermittent power supply equipment, the electrode material 4 on the bottom cover 3 is connected to the negative pole of the intermittent power supply equipment, and the intermittent power supply equipment is started to energize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com