Active material reactivation method, battery regeneration method, catalyst layer, counter electrode

A catalyst layer and electrode active material technology, applied in the field of dye-sensitized solar cells, can solve the problems of increasing the manufacturing cost of dye-sensitized solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0241]

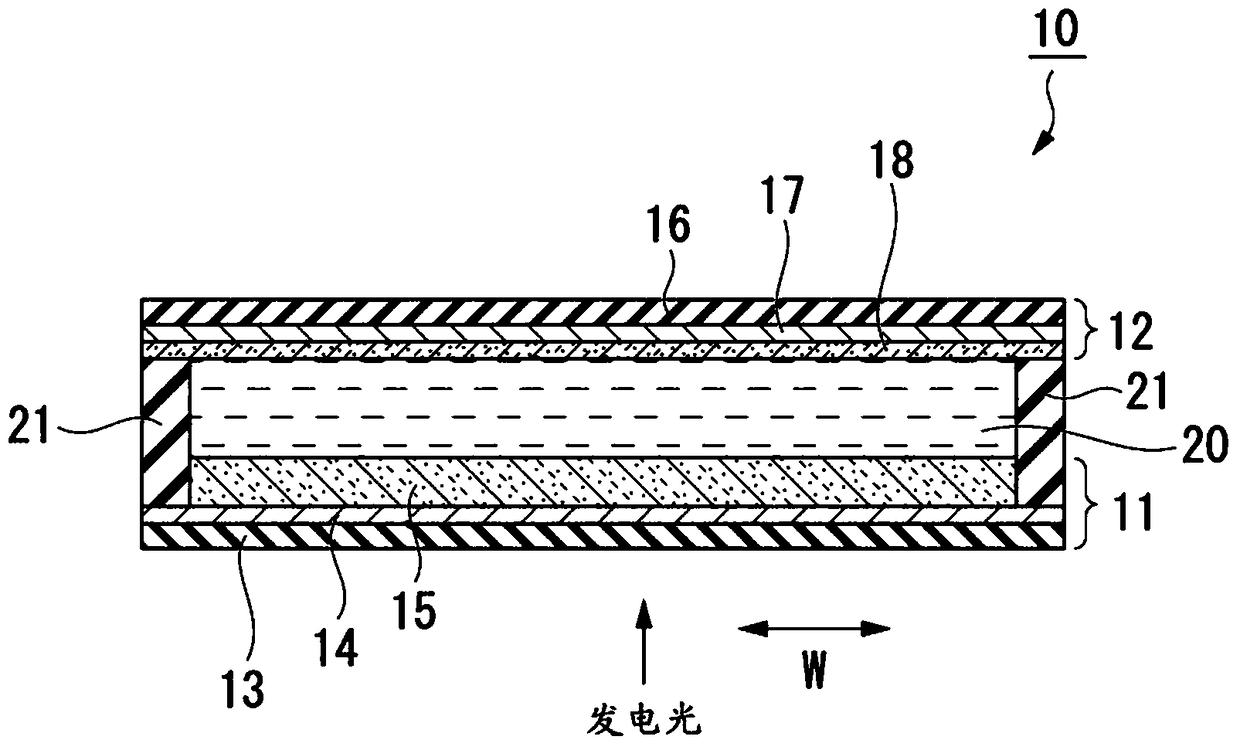

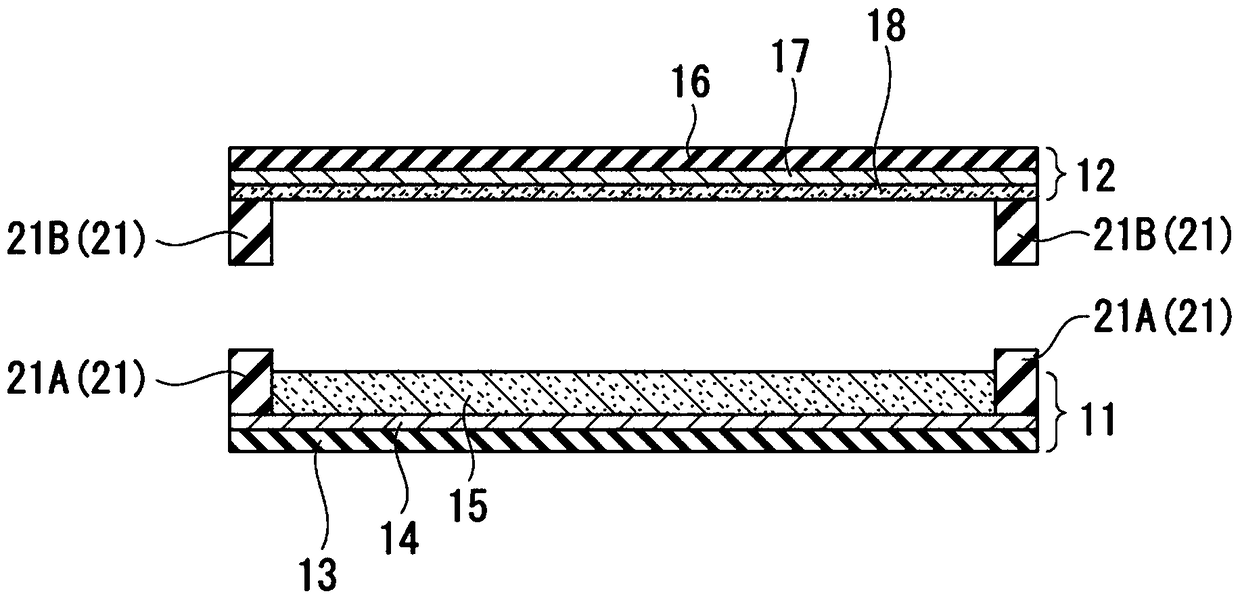

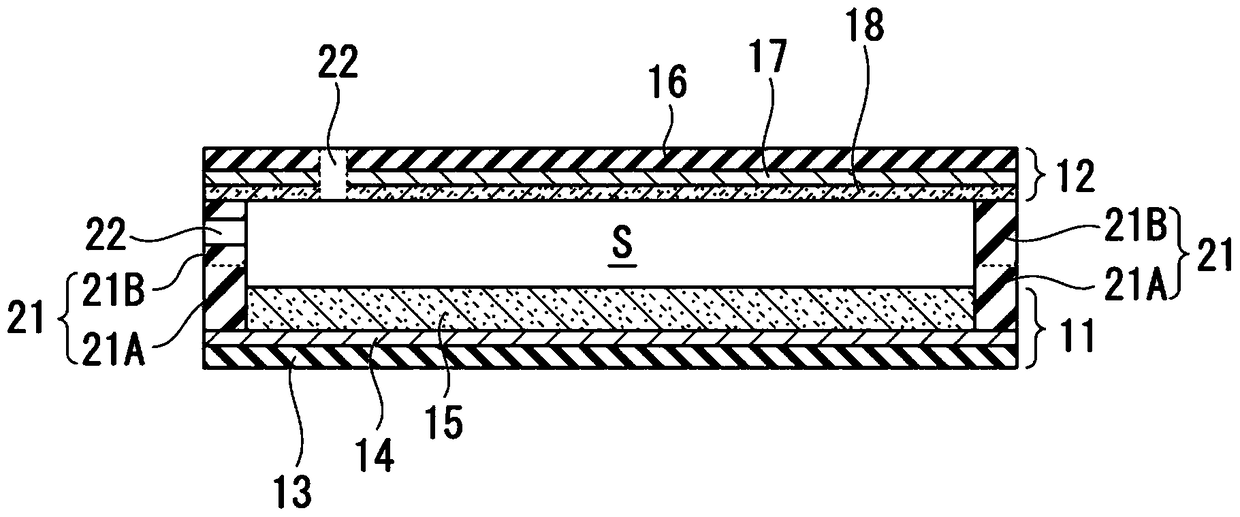

[0242] As the transparent base material 13 , a glass substrate in which an FTO film was formed on a plate surface was prepared. On the FTO film, TiO with an average particle size of 14nm 2 Particles: 19% by mass, ethyl cellulose: 9% by mass, terpineol: 72% by mass were formed into a film with a size of 4mm×4mm by screen printing, and baked at 500°C for 30 minutes in an air atmosphere , thus forming the TiO 2A porous layer of particles. Then, N719 as a sensitizing dye was dissolved at a concentration of 0.3 mM in a mixed solution prepared by mixing acetonitrile and tert-butanol at a mass ratio of 1:1, and dipped in the obtained sensitizing dye solution 2 The porous layer made of particles and the glass substrate of the FTO membrane were washed with acetonitrile for 20 hours, so that the sensitizing dye was adsorbed on the surface of the porous layer. Thus, the working electrode 11 in which the transparent conductive film 14 and the photoelectrode 15 were laminated...

Embodiment 2

[0257] The same steps as in Example 1 were carried out except that the reoxidation of the conductive polymer included in the counter electrode 12 was performed by electrochemical oxidation instead of chemical oxidation. Hereinafter, "reoxidation of the conductive polymer by electrochemical oxidation" and the subsequent "reassembly of the dye-sensitized solar cell and evaluation of power generation performance" will be described, and the same as in Example 1 other than these will be omitted. description of the process.

[0258]

[0259] Such as Figure 9 As shown, will Figure 6A ~ Figure 6D The conductive polymer catalyst layer 18 of the counter electrode 12D of the dye-sensitized solar cell 10D shown as a working electrode is impregnated with LiTFSI (lithium bistrifluoromethanesulfonylimide) as a supporting electrolyte: 10 -1 M in acetonitrile. Then, using a platinum wire and a silver wire as an auxiliary electrode and a standard electrode respectively, a voltage of 1.0 ...

Embodiment 3

[0271]

[0272] The porous membrane was formed using a slurry composed of 19% by mass of titanium oxide particles (particle size Φ14 nm), 9% by mass of ethyl cellulose, and 72% by mass of terpineol. As a transparent conductive substrate, a glass substrate with a surface resistance of 10 ohms (Ω) provided with an FTO film is used, and the above-mentioned slurry is coated on the FTO film with an area of 4 mm × 4 mm by a screen printing method, and then placed on the FTO film under an air atmosphere. Baking at 500° C. for 30 minutes formed a porous layer (thickness: 10 μm) on the transparent conductive film.

[0273] In a pigment solution in which the sensitizing dye N719 was dissolved at a concentration of 0.3 mM in a 1:1 mixture of acetonitrile and tert-butanol, the substrate with the above-mentioned porous layer was immersed for 20 hours, and then washed with acetonitrile to fabricate a substrate with a sensitizer. A photoelectrode with a power generation layer formed by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com