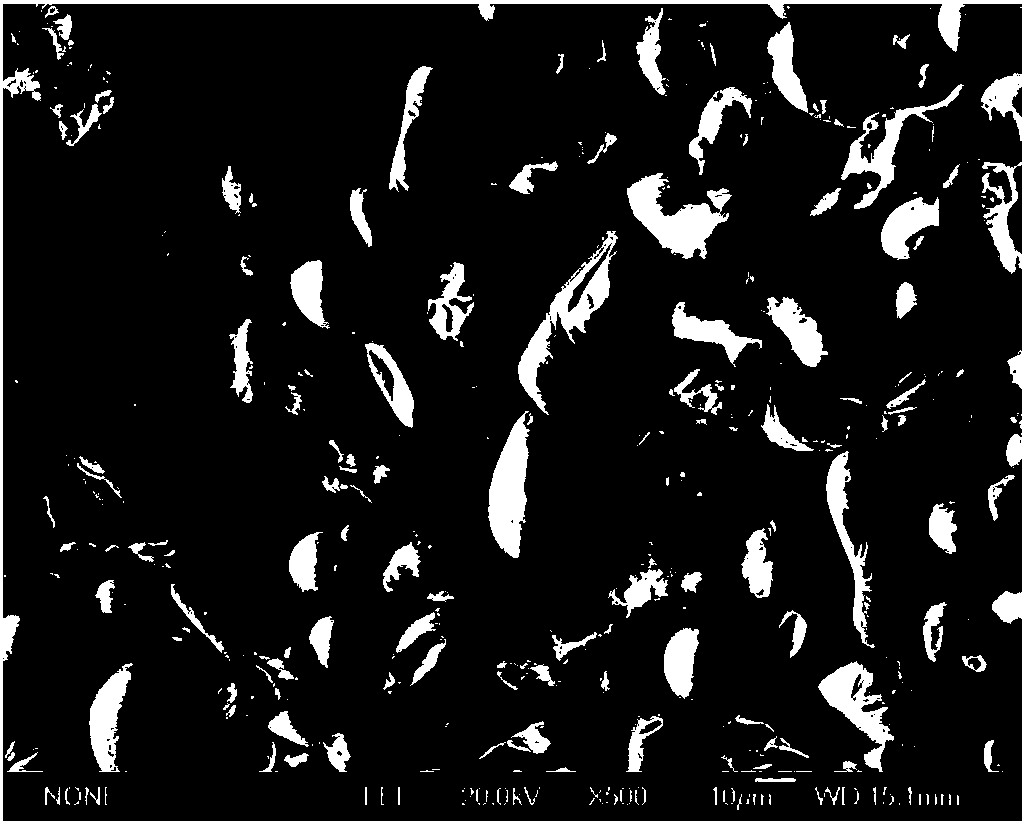

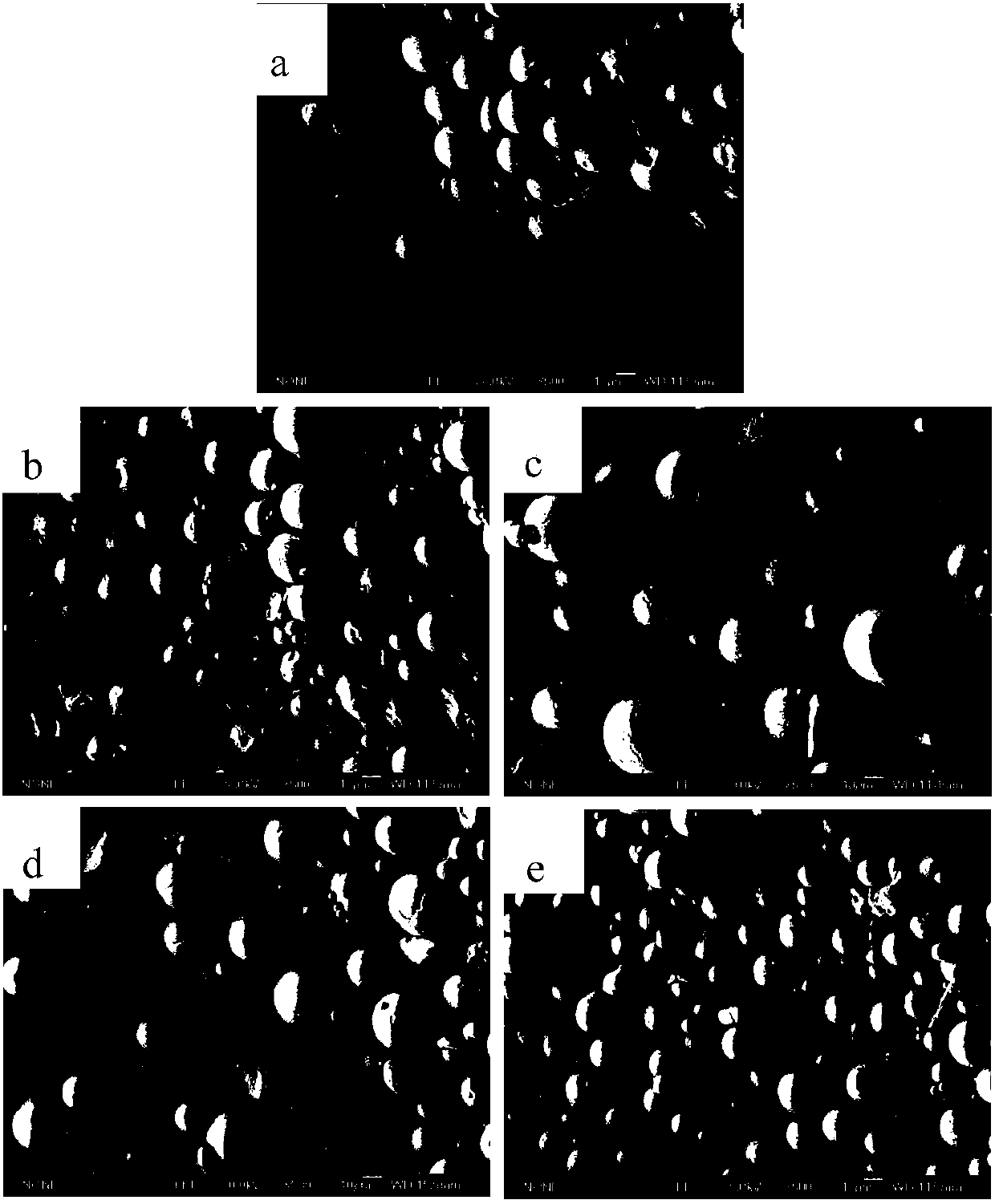

Method for preparing Cu-Cr alloy powder by means of vacuum gas atomization

A technology of alloy powder and vacuum air, which is applied in the field of preparation of copper alloy powder, can solve the serious shape and irregularity of Cu-Cr alloy powder oxidation, and achieve the effects of electrical conductivity recovery, strength improvement and oxidation avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Evacuate the melting chamber and atomization chamber in the vacuum atomization furnace to a vacuum state with a pressure of 5x10 -3 Pa;

[0024] Step 2: Put Cu and Cr into the graphite crucible in the melting chamber, and fill the melting chamber with N 2 As a protective gas, the graphite crucible is heated by high-frequency induction equipment to obtain the alloy liquid, and the heat preservation makes the superheat of the alloy liquid reach 50°C, ready to start atomization;

[0025] Step 3: Adjust the atomization pressure to 4MPa, spray the alloy liquid obtained in step 2 into the atomization chamber through a graphite nozzle, atomize and crush to obtain Cu-Cr alloy powder, wherein, open the exhaust valve after atomization for 3s to ensure The pressure in the atomization chamber will not be too high. After the atomization of the alloy liquid is completed, the exhaust valve is closed to prevent the oxidation of the alloy powder. After completion, the oxygen co...

Embodiment 2

[0027] Step 1: Evacuate the melting chamber and atomization chamber in the vacuum atomization furnace to a vacuum state with a pressure of 5x10 -3 Pa;

[0028] Step 2: Put Cu and Cr into the graphite crucible in the melting chamber, and fill the melting chamber with N 2 As a protective gas, the graphite crucible is heated by high-frequency induction equipment to obtain the alloy liquid, and the heat preservation makes the superheat of the alloy liquid reach 150°C, ready to start atomization;

[0029] Step 3: Adjust the atomization pressure to 5MPa, spray the alloy liquid obtained in step 2 into the atomization chamber through a graphite nozzle, and atomize and crush it to obtain Cu-Cr alloy powder, wherein, after atomization is carried out for 3s, open the exhaust valve to ensure The pressure in the atomization chamber will not be too high. After the atomization of the alloy liquid is completed, the exhaust valve is closed to prevent the oxidation of the alloy powder. After c...

Embodiment 3

[0031] Step 1: Evacuate the melting chamber and atomization chamber in the vacuum atomization furnace to a vacuum state with a pressure of 6x10 -3 Pa;

[0032] Step 2: Put Cu and Cr into the graphite crucible in the melting chamber, and fill the melting chamber with N 2 As a protective gas, the graphite crucible is heated by high-frequency induction equipment to obtain the alloy liquid, and the heat preservation makes the superheat of the alloy liquid reach 150°C, ready to start atomization;

[0033] Step 3: Adjust the atomization pressure to 6MPa, spray the alloy liquid obtained in step 2 into the atomization chamber through a graphite nozzle, atomize and crush to obtain Cu-Cr alloy powder, wherein, open the exhaust valve after atomization for 3s to ensure The pressure in the atomization chamber will not be too high. After the atomization of the alloy liquid is completed, the exhaust valve is closed to prevent the oxidation of the alloy powder. After completion, the oxygen c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| process yield | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com