Method for inducing fusion sintering of liquid metal micro-nano liquid drops by utilizing solvent evaporation

A liquid metal, evaporation-induced technology, which is used in the manufacture of conductive/semiconductive layer equipment, cable/conductor manufacturing, heat treatment equipment, etc., can solve the complicated operation, high mechanical performance requirements of the substrate, and energy consumption. advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Add 100mg of gallium-indium alloy (74.5wt% Ga and 24.5wt% In) into 10mL of deionized water, and use an ultrasonic breaker with a power of 300W to sonicate for 60min in an ice-water bath;

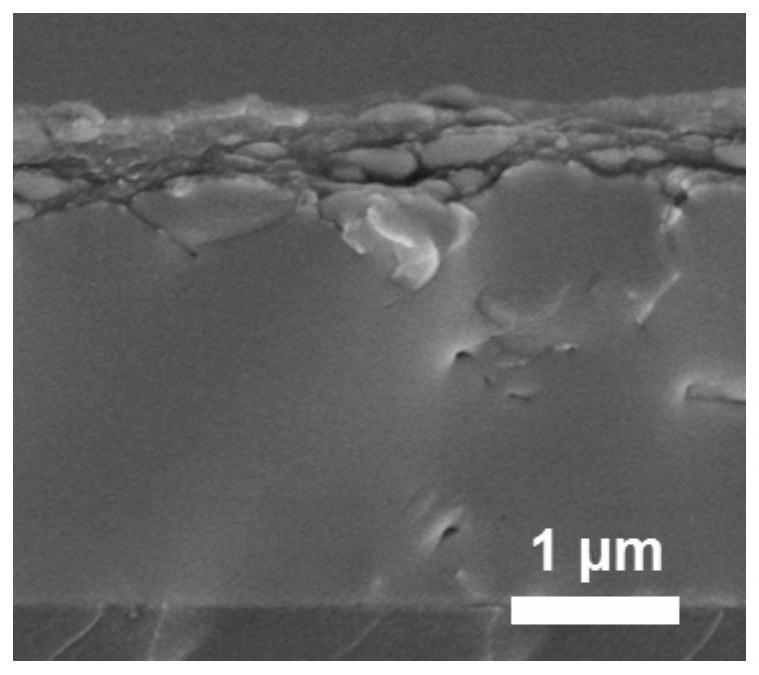

[0045] 2) Drop-coat the gray solution obtained in step 1) onto a glass substrate, dry and sinter at room temperature (25°C) under vacuum (-0.1MPa) (see figure 1 ).

[0046] By observing figure 1 It is known that water-dispersed liquid metals are used to form micro-nano droplets at room temperature (25°C) and vacuum conditions (-0.1MPa) for natural drying, and the surface tension formed under vacuum conditions increases, further increasing the capillary force generated during the drying process. The force will promote the fusion and sintering of liquid metal droplets, and a layer of liquid metal film will be formed on the glass substrate. The upper side of the film is dark gray, and the lower side close to the glass substrate is bright silvery white. This material can be used as a ...

Embodiment 2

[0048] 1) Add 100mg of gallium-indium alloy into 10mL of deionized water, and use an ultrasonic breaker with a power of 300W to sonicate for 60min in an ice-water bath;

[0049] 2) Add 5 mL of 2 mg mL to the solution obtained in step 1) –1 TEMPO oxidized cellulose (carboxyl content ~ 1.4mmol g -1 ) the nanofiber solution was stirred for 30 min to make it evenly mixed;

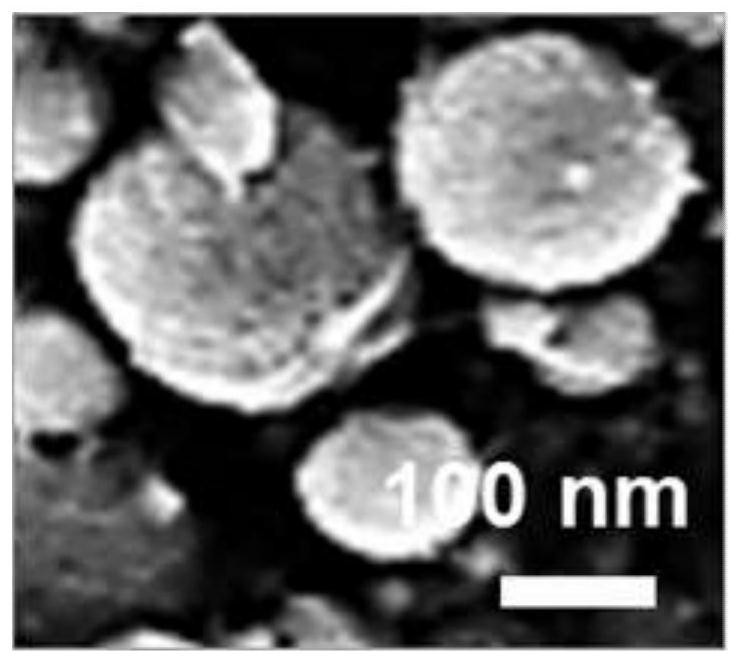

[0050] 3) The gray solution obtained in step 2) was drip-coated on a glass substrate, and dried and sintered at room temperature (25°C) and normal pressure (0.1MPa) (see Figure 2-4 ).

[0051] SEM Figure 2-4 It is known from the analysis that water-dispersed liquid metal is used to form micro-nano droplets and then cellulose nanofibers oxidized by the auxiliary agent TEMPO are added. The average diameter of the obtained uniformly mixed particles is 100nm, and the outside has fiber entanglement. The added cellulose nanofibers can be During the evaporation process, the capillary force is increased to promot...

Embodiment 3

[0053] 1) Add 100mg gallium indium alloy to 10mL with a concentration of 1mg mL –1 In the aqueous ethanol solution (water in the aqueous ethanol solution: the volume ratio of ethanol is 9:1) of the silk nanofibers, utilize the sonicator that power is 300W ultrasonic 60min under ice-water bath condition;

[0054] The preparation method of the silk nanofibers can be found in literature (ACS Nano, 2017, 11, 8178).

[0055] 2) Stir with magnetic force for 30 minutes after ultrasonication, and the stirring speed is 1000 revolutions per minute, so that the silk nanofibers and liquid metal micro-nano particles are fully mixed evenly;

[0056] 3) The resulting gray solution is drop-coated onto a patterned polyethylene terephthalate (PET) film, dried under a vacuum of 0 MPa, and formed on the PET film at a temperature of 30°C. conductive path (see Figure 5 ).

[0057] According to the scanning electron microscope analysis, the dispersion solvent containing silk nanofibers is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com