Method for preparing graphene film through reduction of ferrous iodide acid solution

A technology of graphene film and acidic solution, which is applied in the preparation of low-temperature catalytic reduction of graphene nanomaterials and the reduction of ferrous iodide acidic solution to prepare graphene film, which can solve the problems of incomplete reduction, environmental pollution, and harsh conditions. Achieve mild and controllable reduction reaction, broaden the application range, and achieve the effect of mild and controllable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of graphene oxide used in the example is as follows: mix 3g graphite powder, 3g sodium nitrate and 138ml concentrated sulfuric acid ice bath; then slowly add 18g potassium permanganate, after magnetic stirring and mixing, heat in 35 ℃ water bath 1h; then add 240ml deionized water and heat at 90°C for 0.5h, add 600ml deionized water and 18ml hydrogen peroxide after heating.

[0033] The graphene oxide obtained after oxidation is ultrasonically dispersed, then diluted according to a certain ratio, and finally the diluted solution is centrifuged, and the upper suspension is taken, and a graphene oxide film with a certain thickness is prepared by suction filtration. Then measure the film thickness of the graphene film with a step meter, and measure its electrical conductivity with a four-probe method.

Embodiment 1

[0035] After centrifugation, 40ml of graphene oxide (GO) supernatant suspension (GO concentration 0.2mg / ml, solvent is ethanol) was suction-filtered to form a film, and dried for later use. Among them, GO refers to the single-layer graphene oxide obtained by Hamel oxidation.

[0036] Grind 5.08g of iodine particles, then add 4g of iron powder, and mix well to obtain a mixture. Put the mixture into a large beaker, drop 0.1ml of deionized water as a catalyst for the reaction; the reaction unfolds rapidly, at the same time, add 90ml of deionized water, stir quickly with magnetic force to make it fully react, and add 9ml of 12mol / L concentrated hydrochloric acid at the same time (pH value is about 0.1), obtains the ferrous iodide acidic solution of concentration about 0.2mol / L (iron powder is excessive, suppresses Lewis acid hydrolysis).

[0037] Then put the dried graphene oxide (GO) film (thickness is about 2 μm) into ferrous iodide acidic solution, heat to 100 °C, and reduce for...

Embodiment 2

[0045] Mix 1.27g of ground iodine particles and 1g of iron powder evenly, put them into a large beaker, drop in 0.1ml of deionized water as a catalyst for the reaction; the reaction develops rapidly, and add 90ml of N,N-dimethylformamide at the same time (DMF), fast magnetic stirring, make it react fully, add the concentrated hydrochloric acid 9ml (pH value is about 0.1) of 12mol / L simultaneously, make ferrous iodide acidic solution (concentration of ferrous iodide is 0.05mol / L, where excess iron). Then the dried graphene oxide (GO) film was put into ferrous iodide acidic solution and reduced at 140 °C for 1 h under magnetic stirring.

[0046] The test result is: the conductivity of the graphene film is 18351S / m.

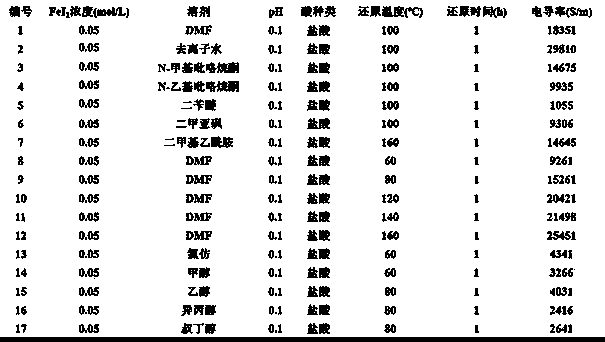

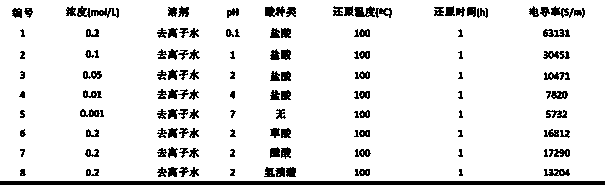

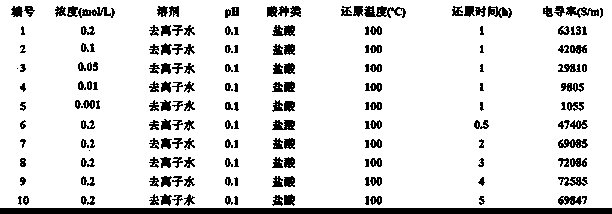

[0047] With above-mentioned ferrous iodide acidic solution as reductant, change reductant solvent type, reduction temperature and pH value and the kind of inorganic acid respectively, under the premise that other conditions are constant, the electrical conductivity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com