A kind of preparation method of high conductivity graphene

A high-conductivity, graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of insufficient stripping, unfavorable industrialization, etc., and achieve the effect of reducing the burden of reduction, reducing the degree of oxidation, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

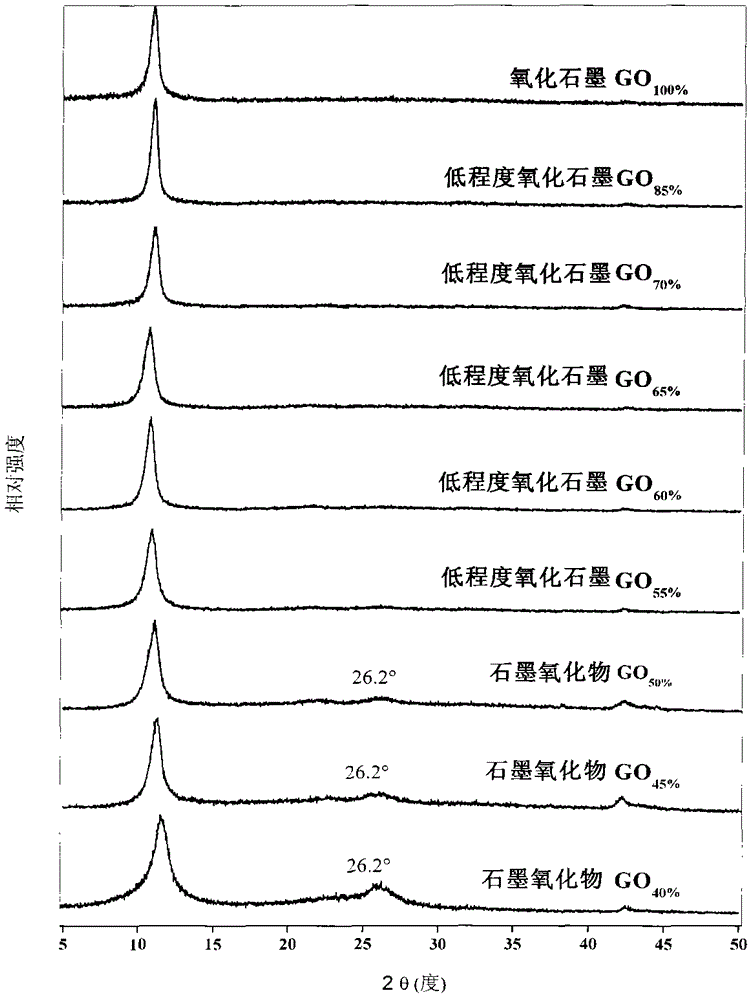

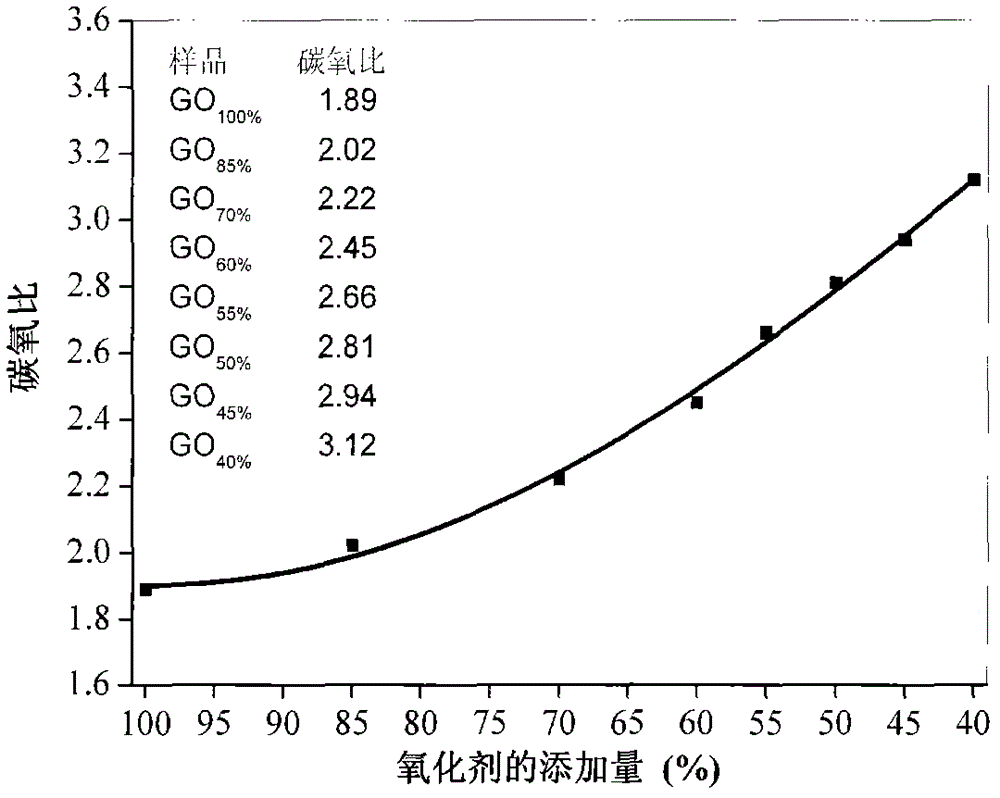

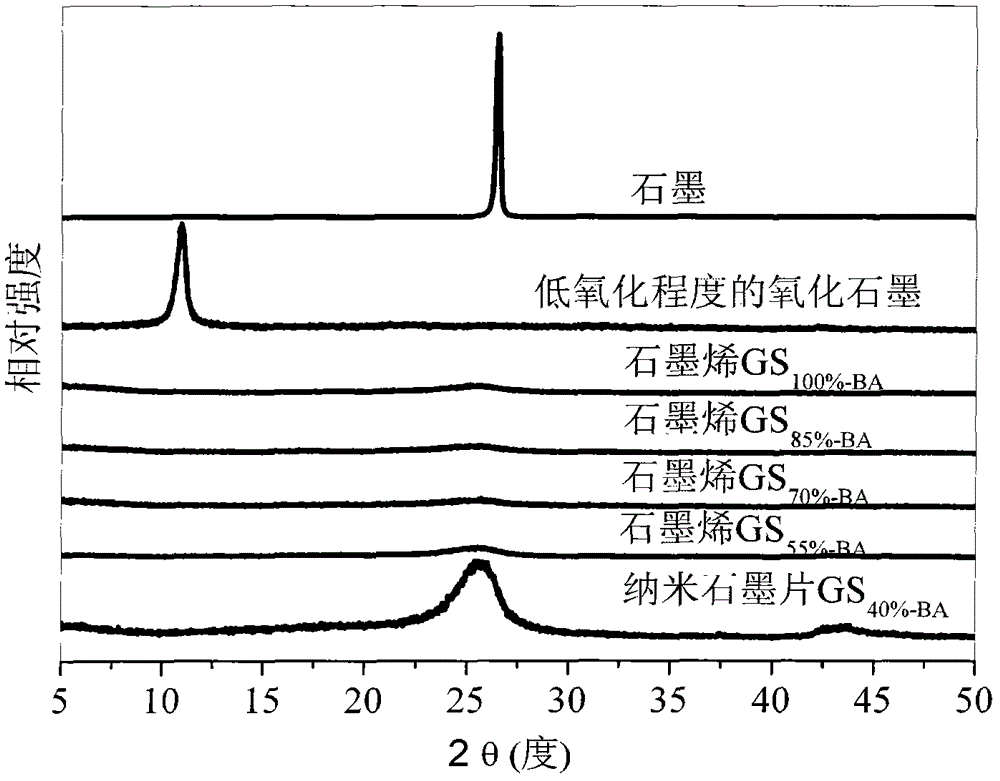

[0038] The experimental steps and conditions are the same as those of the above-mentioned graphite oxide preparation comparative example 1, except that the addition amount of sodium nitrate and potassium permanganate is changed to 85% of the corresponding substance addition amount in graphite oxide comparative example 1, and the obtained graphite oxide is recorded as GO 85% .

preparation Embodiment 2

[0040] The experimental steps and conditions are the same as those of the above-mentioned graphite oxide preparation comparative example 1, except that the addition amount of sodium nitrate and potassium permanganate is changed to 70% of the corresponding substance addition amount in graphite oxide comparative example 1, and the obtained graphite oxide is recorded as GO 70% .

preparation Embodiment 3

[0042] The experimental steps and conditions are the same as those of the above-mentioned graphite oxide preparation comparative example 1, except that the addition amount of sodium nitrate and potassium permanganate is changed to 65% of the corresponding substance addition amount in graphite oxide comparative example 1, and the obtained graphite oxide is recorded as GO 65% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com