Method for preparing graphene

A technology of graphene and graphite, which is applied in the field of alcohol thermal reduction preparation of graphene, can solve the problems of unsuitability for large-scale industrial production, pollution, high price of reducing agent, etc., and achieve the effect of low cost, less pollution and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

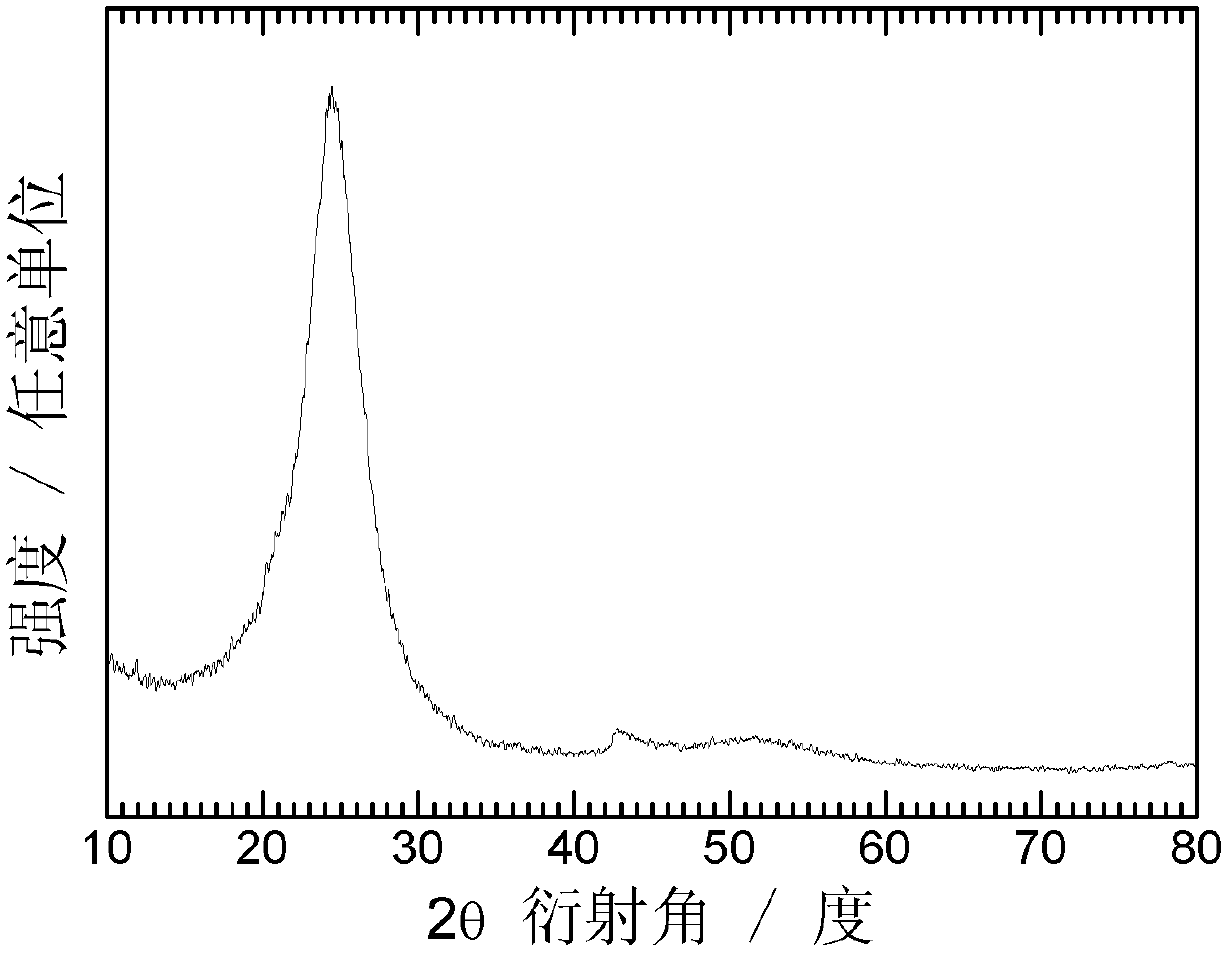

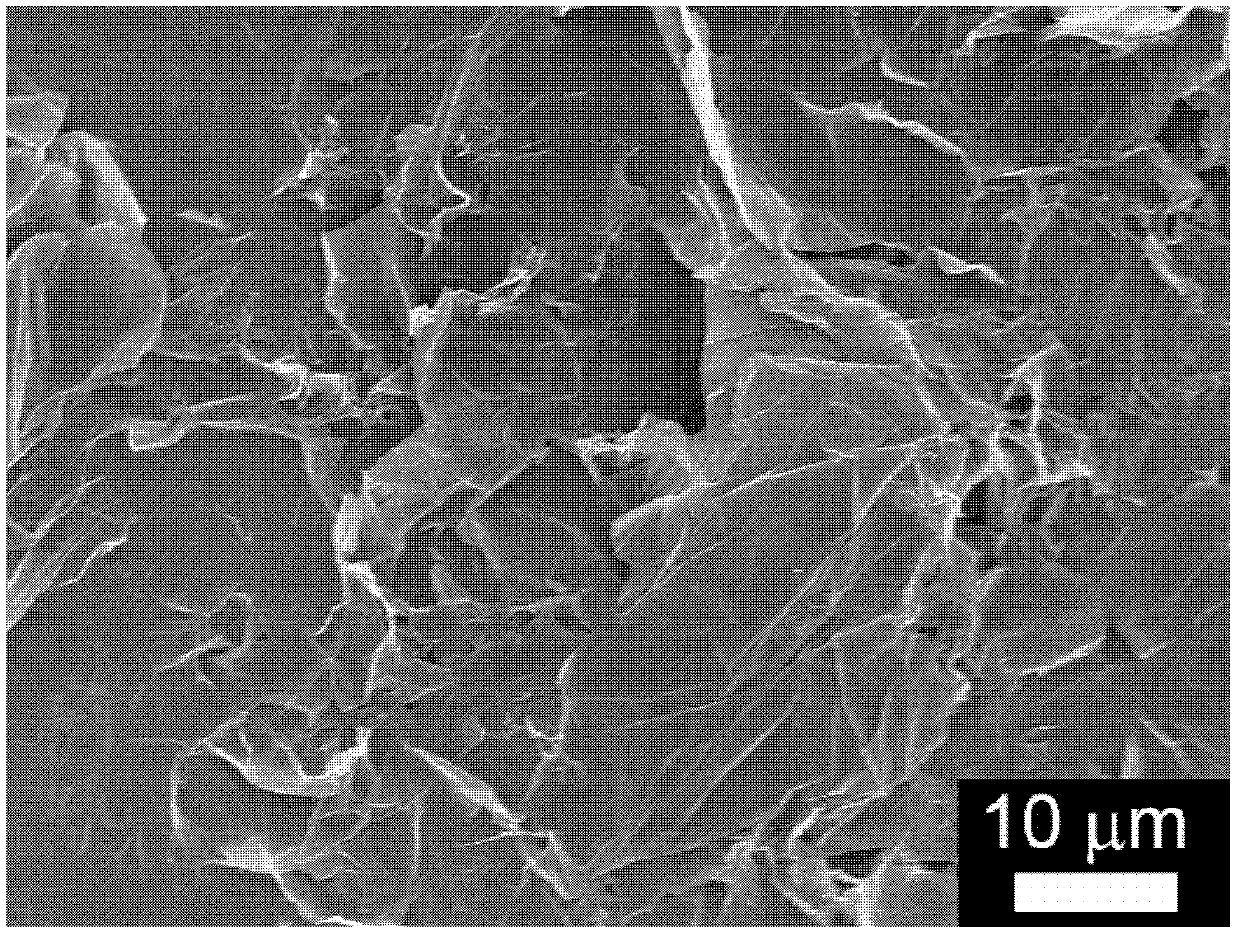

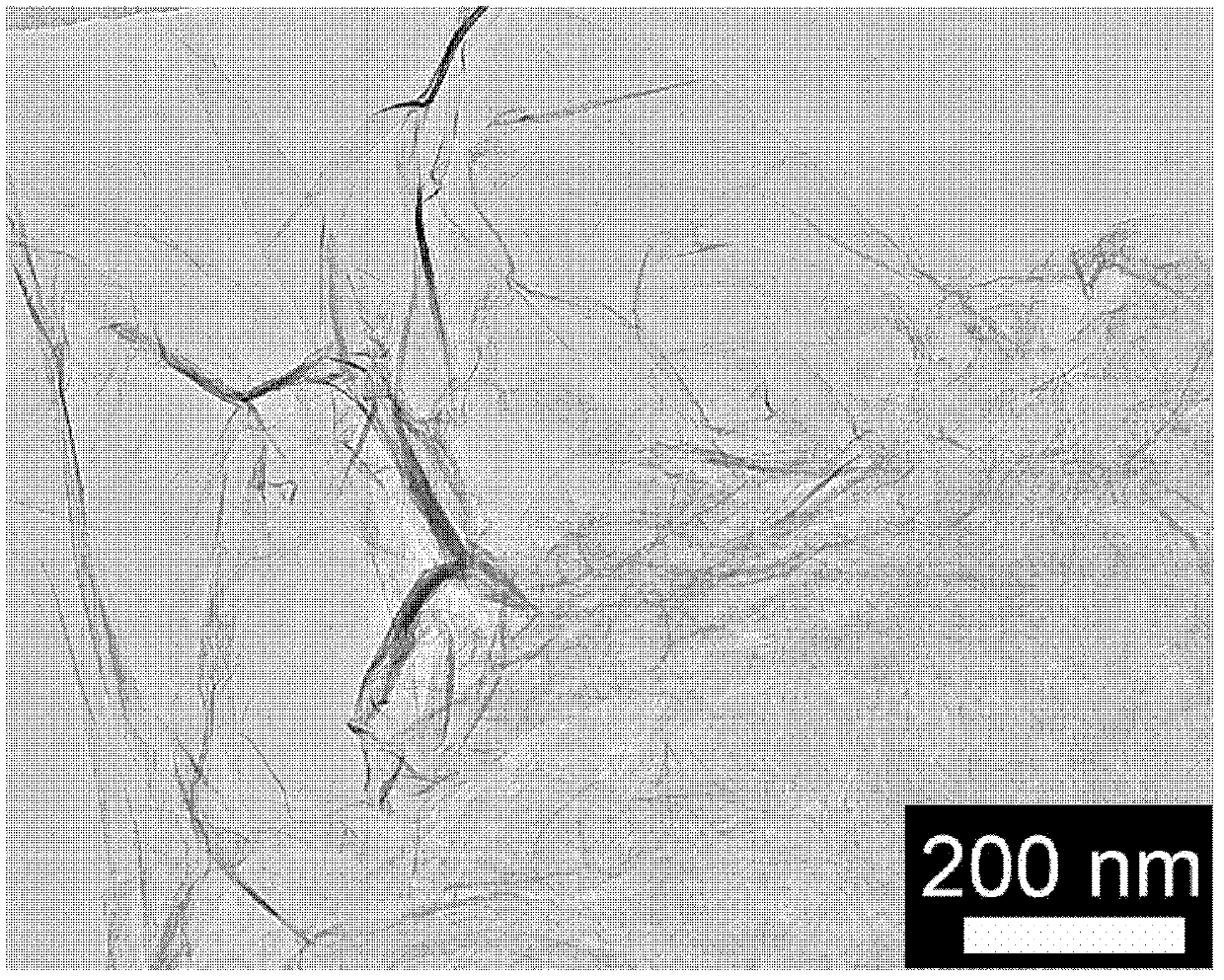

Method used

Image

Examples

Embodiment 1

[0036] 1), 5 grams of potassium persulfate, 5 grams of phosphorus pentoxide and 5 grams of natural graphite powder were added to 39 milliliters of concentrated sulfuric acid (71.8 g) with a mass percent concentration of 98%, and magnetically stirred for 6 hours at 80° C. , then add deionized water while stirring to cool to room temperature, the suspension is filtered and cleaned with deionized water to pH=7, and then vacuum-dried at 60°C for 10 hours to obtain 5.3 grams of pre-oxidized graphite;

[0037] 2), 2 grams of pre-oxidized graphite, 2 grams of sodium nitrate, and 6 grams of potassium permanganate were added to 46 milliliters of concentrated sulfuric acid (84.6 g) with a concentration of 98% by mass, stirred for 1 hour in an ice bath, and then heated up Stir at 35°C for 2 hours, then add 90 ml of warm water at 70°C, raise the temperature to 98°C and keep it for 15 minutes, then add 280 ml of warm water at 70°C, 10 ml of 30% H 2 o 2 and 24 milliliters of dilute hydroch...

Embodiment 2

[0042] 1), 15 grams of potassium persulfate, 15 grams of phosphorus pentoxide and 5 grams of natural graphite powder are added to 150 g of 90% concentrated sulfuric acid by mass percentage, magnetically stirred for 4 hours at 90 ° C, then stirred while stirring Add deionized water to cool it down to 28°C, filter and wash the suspension with deionized water to pH=6.5, and then vacuum-dry it at 80°C for 6 hours to obtain 5.5g of pre-oxidized graphite;

[0043] 2), 2 grams of pre-oxidized graphite, 6 grams of sodium nitrate, and 4 grams of potassium permanganate were added to 40 grams of concentrated sulfuric acid with a mass percent concentration of 98%, stirred for 3 hours in an ice bath, and then heated to 30° C. and stirred for 4 hours. hour, then add 90 ml of warm water at 60°C, and raise the temperature to 70°C and keep it for 40 minutes, then add 280 ml of warm water at 60°C, 10 ml of H with a concentration of 10% by mass 2o 2 and 24 milliliters of dilute hydrochloric aci...

Embodiment 3

[0048] 1), 10 grams of potassium persulfate, 10 grams of phosphorus pentoxide and 5 grams of natural graphite powder are added to 50 grams of concentrated sulfuric acid with a mass percent concentration of 70%, magnetically stirred for 10 hours at 60° C., and then stirred while stirring Add deionized water to cool it down to 20°C, filter and wash the suspension with deionized water to pH=7.5, and then vacuum-dry it at 70°C for 12 hours to obtain 5.2g of pre-oxidized graphite;

[0049] 2), 2 grams of pre-oxidized graphite, 4 grams of sodium nitrate, 12 grams of potassium permanganate were added to 100 g of concentrated sulfuric acid with a concentration of 98% by mass, stirred for 2 hours in an ice bath, then warmed up to 40° C. and stirred for 3 hour, then add 400 ml of warm water at 80°C, and raise the temperature to 100°C and keep it for 10 minutes, then add 400 ml of warm water at 80°C, 10 ml of H at a concentration of 40% by mass 2 o 2 and 24 milliliters of dilute hydroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com