Charge restraining method and apparatus for piezoelectric oxide single crystal

A single crystal, oxide technology, applied in chemical instruments and methods, vanadium oxide, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as electrode damage, electrode short circuit, etc., to improve reliability and suppress modulation. , Improve the effect of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

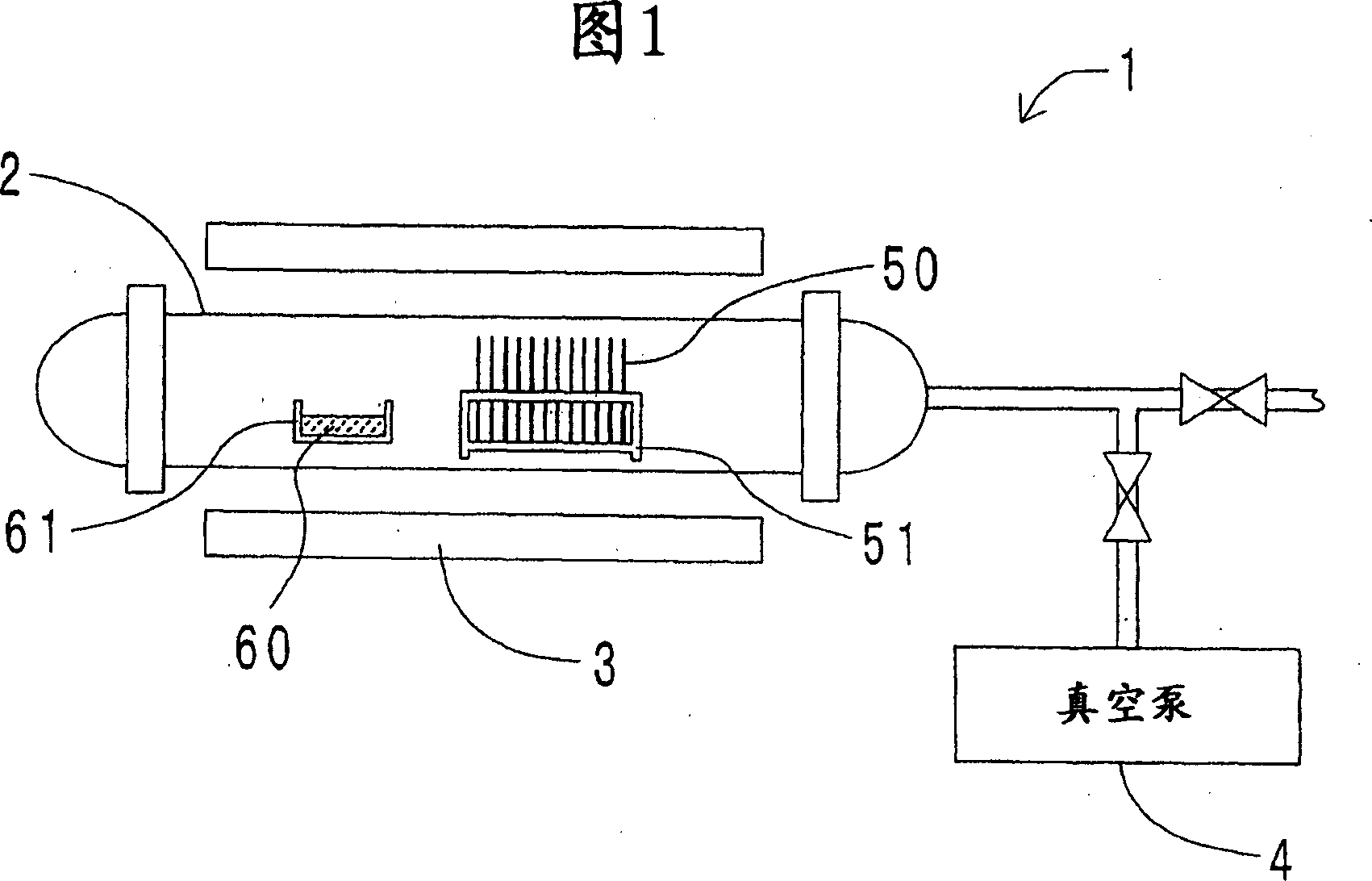

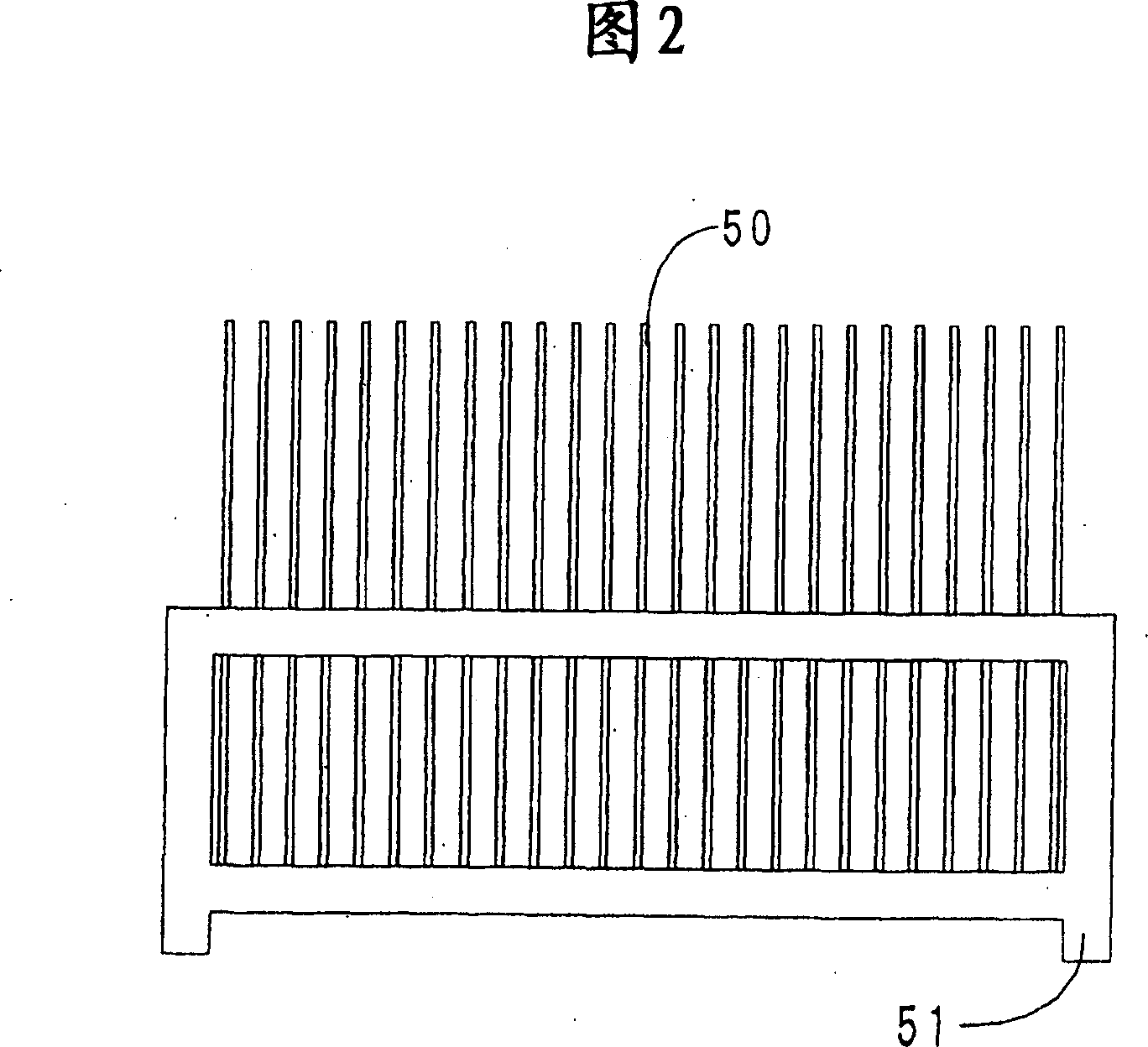

[0052] First, the configuration of the charge suppressing device in this embodiment is described. In FIG. 1 , an overview of a charge suppression device is illustrated. Also, the model shown in Figure 2 shows how the wafers are placed in the processing vessel. As shown in FIG. 1 , a charge suppression apparatus 1 includes a processing container 2 , a heater 3 , and a vacuum pump 4 .

[0053] The processing container 2 is made of quartz glass. One of the opposite ends of the processing vessel 2 is connected to a pipeline. Through this connecting line, the processing container 2 is evacuated. In the processing container 2, a wafer 50 and lithium chloride powder 60 are housed.

[0054] The wafer 50 is supported by a quartz wafer cassette 51 . The wafer 50 is composed of a 42° Y-X cut lithium tantalate single crystal. Wafer 50 has a diameter of 4 inches (approximately 10.16 cm) and a thickness of 0.5 mm. The number of wafers 50 was placed in the number of 50 pieces at a pit...

no. 2 approach

[0063] The second embodiment differs from the first embodiment in that the type and placement form of the reducing agent are changed. Since other configurations are the same as those of the first embodiment, differences will be described here.

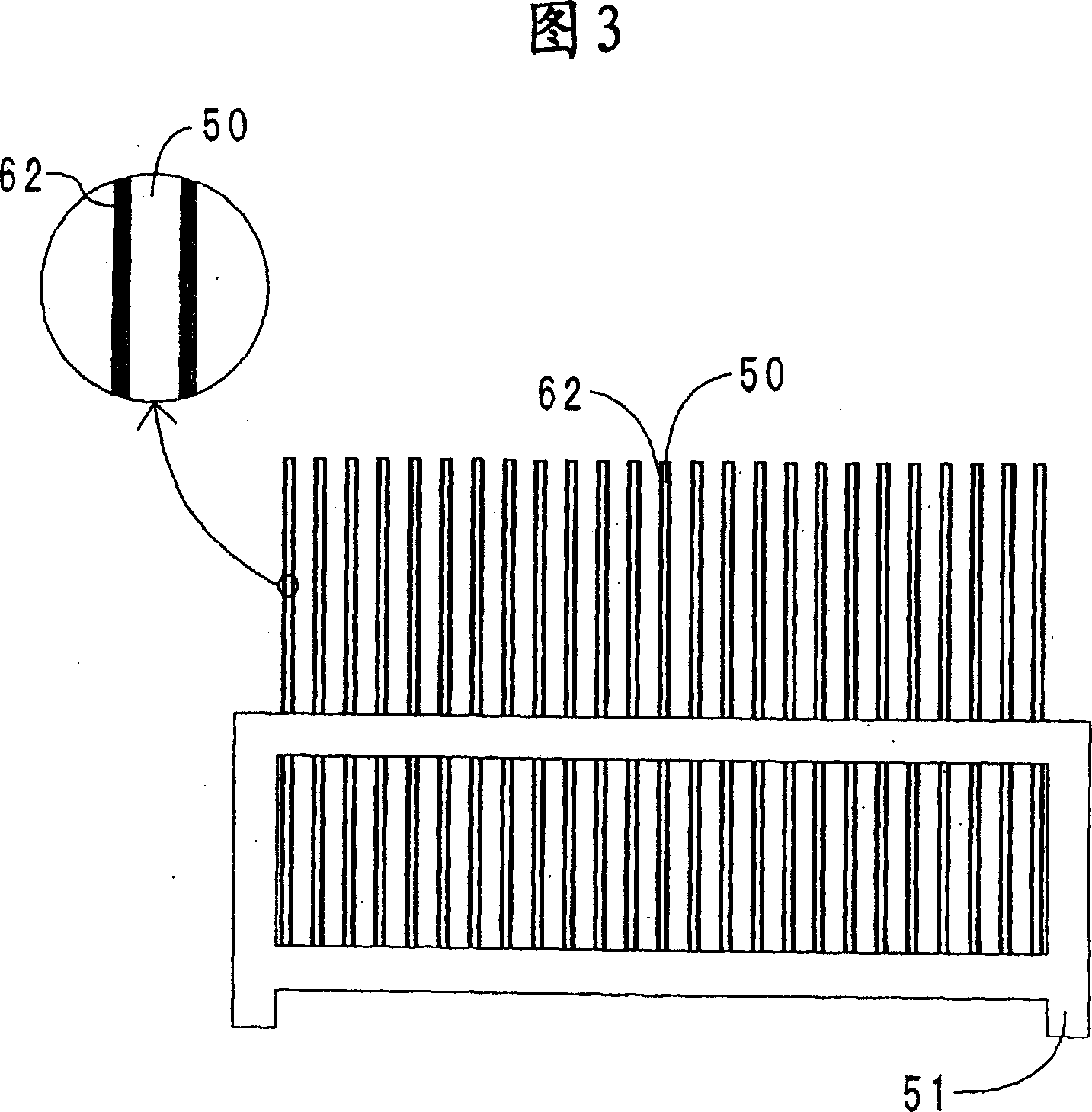

[0064] In Fig. 3, how to place the wafer and the reducing agent in this embodiment is illustrated in a model. In FIG. 3, components corresponding to those in FIG. 2 are denoted by the same reference numerals. As shown in FIG. 3 , two opposite surfaces of the wafer 50 are coated with a lithium carbonate solution 62 , and the solution 62 is to dissolve 100 g of lithium carbonate powder into polyvinyl alcohol. Lithium carbonate solution 62 is the reducing agent in the present invention. Coating of the wafer 50 was carried out by immersing the wafer 50 in a lithium carbonate solution 62, applying the lithium carbonate solution 62 to the surface of the wafer 50, and then drying them in a greenhouse at 200°C. In the processing container 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com