Oxidized graphene based on mixed acid system and preparation method of graphene

A graphene and system technology, applied in the field of graphene oxide and graphene preparation, can solve the problems of low reaction rate, corrosion of equipment, large amount of heat release, etc., and achieve the effects of high reaction efficiency, reduced corrosion, and sufficient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

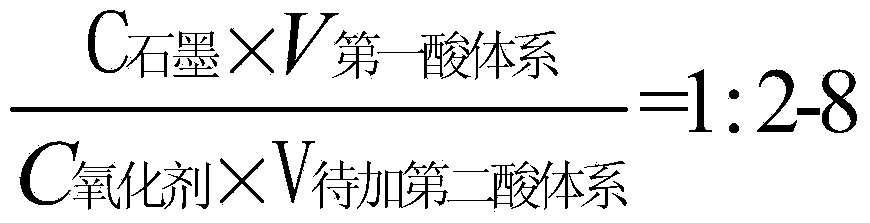

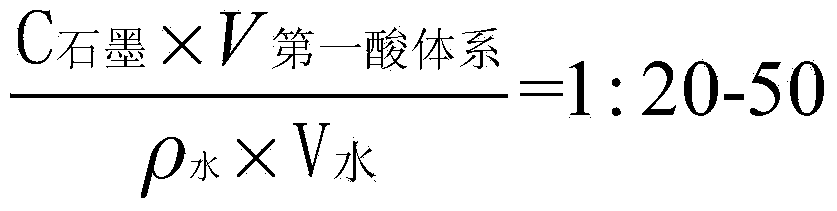

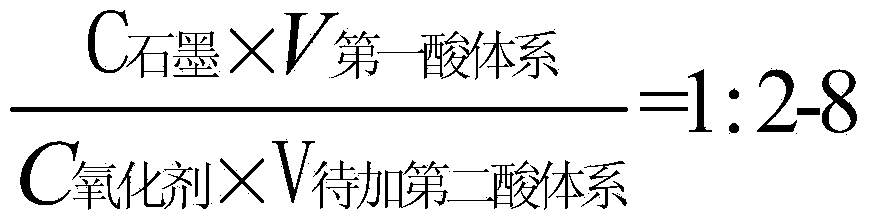

Method used

Image

Examples

Embodiment 1

[0036] The raw material flake graphite is washed with water, dried, pulverized, and passed through a 200-mesh sieve to obtain flake graphite powder with a finer particle size. Then take 1g of graphite powder and disperse it in 10ml of concentrated sulfuric acid by ultrasonic to form a graphite-concentrated sulfuric acid dispersion with a mass concentration of 0.1g / ml. After 120w ultrasonic treatment with stirring for 1.5h, the concentrated sulfuric acid can be fully inserted into the interlayer of graphite , so as to obtain a suspension of sulfuric acid intercalated graphite, that is, to obtain the first acid system. The suspension was dark gray with no obvious heat release.

[0037] Grind 4g potassium permanganate finely, add 8ml of concentrated phosphoric acid to dissolve, control the dissolution temperature between 40-60°C, form a phosphoric acid solution of potassium permanganate with a mass concentration of 0.5g / ml, and stir it ultrasonically to make it dissolve evenly ,...

Embodiment 2

[0042] The raw material flake graphite is washed with water, dried, pulverized, and passed through a 200-mesh sieve to obtain flake graphite powder with a finer particle size. Then take 1g of graphite powder and disperse it in 10ml of concentrated sulfuric acid by ultrasonic to form a graphite-concentrated sulfuric acid dispersion with a mass concentration of 0.1g / ml. After 120w ultrasonic treatment with stirring for 1.5h, the concentrated sulfuric acid can be fully inserted into the interlayer of graphite , so as to obtain a suspension of sulfuric acid intercalated graphite, that is, to obtain the first acid system. The suspension was dark gray with no obvious heat release.

[0043] Grind 4g potassium permanganate finely, add 8ml of concentrated phosphoric acid to dissolve, control the dissolution temperature between 40-60°C, form a phosphoric acid solution of potassium permanganate with a mass concentration of 0.5g / ml, and stir it ultrasonically to make it dissolve evenly ,...

Embodiment 3

[0048] Get the 1g graphite powder identical with embodiment 1, adopt traditional Hummers method to prepare graphene oxide and graphene to be compiled as comparative example 1, the concentrated sulfuric acid concentration used in comparative example is identical with embodiment 1, embodiment 2, then to its strong acid consumption , reaction efficiency, and whether precipitation occurs in the graphene oxide solution is an indicator that embodiment 1, embodiment 2 and comparative example 1 are tested, and the test results are as follows in table 1:

[0049]

[0050] Table 1: Example 1-2 and comparative example test result table

[0051] As can be seen from the above table, the amount of strong acid used to prepare graphene oxide and graphene by the scheme of the present invention is significantly lower than that of the traditional method, and the reaction efficiency is higher than that of the traditional method. The residual graphite particles in the alkene solution has a sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com