Graphene conducting film and application of graphene conducting film to electrochemical capacitor

A conductive thin film, graphene technology, applied in graphene, hybrid capacitor electrodes, chemical instruments and methods, etc., can solve the problems of low conductivity and specific surface area, unable to meet fast charge and discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

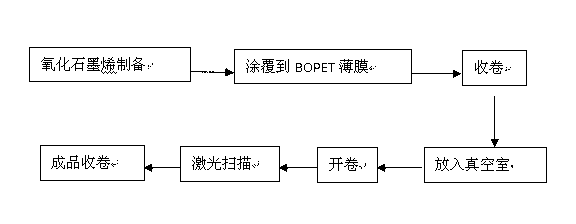

[0029] Such as figure 1 As shown, cheap graphene oxide (golden yellow) is produced by the modified Hummers method, and then the graphene oxide is made into an aqueous solution and coated on a substrate according to a certain thickness, such as biaxially oriented polyethylene terephthalate ester (BOPET) films, which were dried and then collected into rolls; the graphene oxide-coated BOPET rolls were placed in such figure 2 The vacuum chamber shown, is evacuated and uncoiled through chilled rolls while the coated graphene oxide is scanned with a laser until it becomes graphene (black), and the finished product is then rewound.

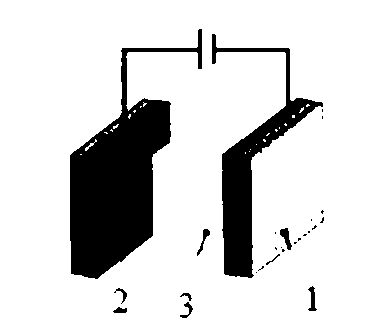

[0030] Cut the prepared graphene conductive film into 1cm 2 The electrode is prepared by adding electrolyte solution in the middle, such as image 3 The performance test of the flexible super electrochemical capacitor shown, in the figure 1-PET, 2-multilayer graphene, 3-electrolyte.

[0031] The electrolyte of the flexible super electrochemical capac...

Embodiment 2

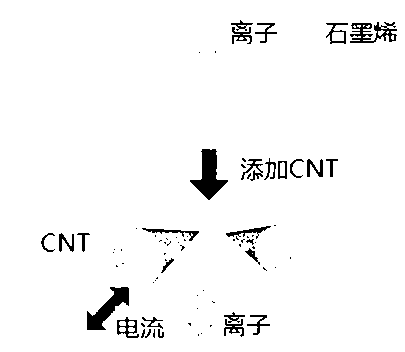

[0034] Self-assembled graphene oxide and carbon nanotubes (CNTs) to form Figure 4 The structure shown is then coated on BOPET to prepare a conductive graphene film, and then made into an electrode.

[0035] The graphene oxide is modified by polyhexamethylene cations, or other cationic materials, such as chitosan, etc.; the CNT is modified by acid oxidation treatment, or other anionic materials, such as sodium alginate, etc., and then the two or hybrid self-assembly. The basic principle of self-assembly is that the system moves spontaneously to the direction of free energy reduction, forming covalent bonds, ionic bonds, coordination bonds, etc., thereby obtaining multilayer alternating materials, graphite oxide modified by cations and acid-oxidized CNTs with anions The self-assembled material is formed by alternate stacking by using the strong electrostatic interaction between charges. Since graphene oxide has a negative charge on its untreated surface in aqueous solution, C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com