High-compressibility water atomization iron powder and preparation method thereof

A water-atomized iron powder and high-compression technology, applied in the field of powder metallurgy, can solve the problems of high quality of raw molten iron and low impurity content, and achieve the effect of increasing added value and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

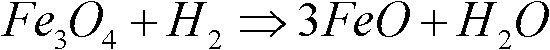

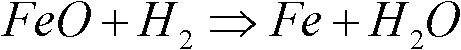

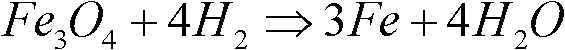

[0038] Select molten steel whose molten steel composition after smelting meets the raw material composition requirements of the present invention, and prepare raw material iron powder through water atomization, and obtain raw powder after primary reduction, primary magnetic separation, dehydration, drying, and secondary magnetic separation of raw material iron powder , then, evenly fill the raw powder in the iron boat, the material layer thickness is 30mm, push it into the high temperature zone of the molybdenum wire furnace for secondary reduction, and the reduction atmosphere is H as the furnace heats up. 2 atmosphere, h 2 The flow rate is 6~8L·min -1 , Furnace pressure: 0.02-0.03MPa, the other end of the furnace tube is always in a burning state. The holding time is 1 to 3 hours, and it is taken out after cooling to room temperature with the furnace. After the secondary reduction, the obtained powder is disintegrated, sieved, and batched to obtain high compressibility iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com