Ultrathin TiO2 coating layer of lithium battery cathode material, lithium battery cathode material and preparation method of lithium battery cathode material

A cathode material and coating layer technology, applied in the field of lithium ion battery cathode material modification, can solve the problems of unfavorable ultra-thin coating layer, difficult control of reaction process, difficult industrial production, etc., and achieve controllable hydrolysis rate of titanium salt, Good lithium ion conductivity, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

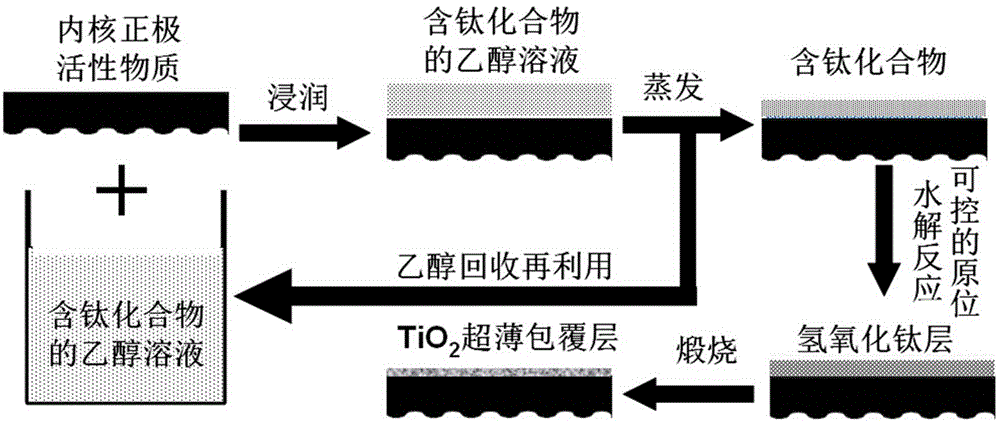

Method used

Image

Examples

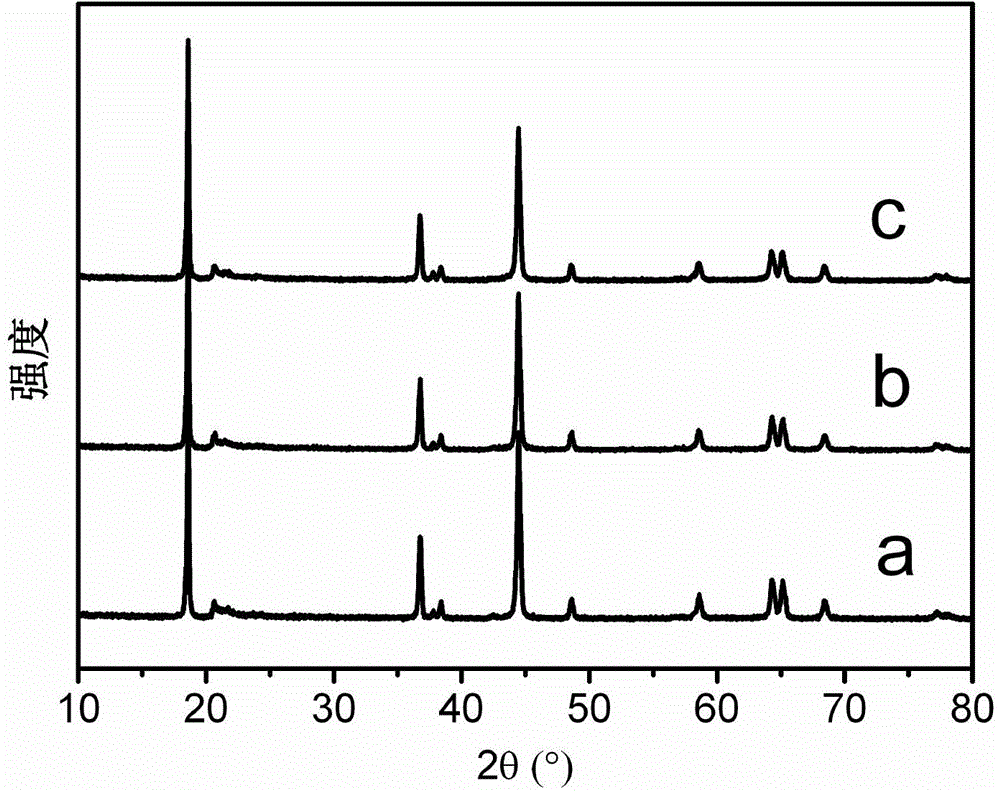

Embodiment 1

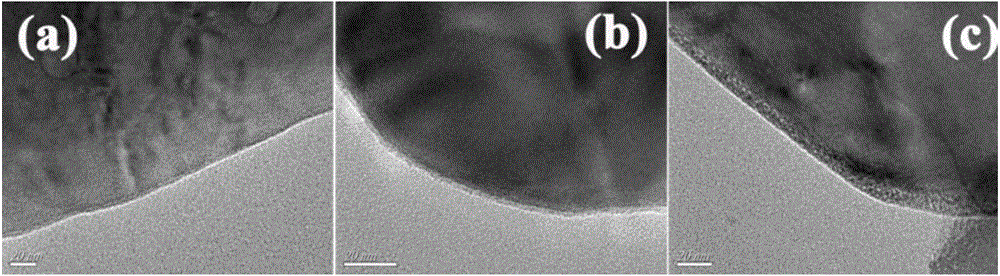

[0035] A kind of ultra-thin TiO of cathode material of lithium battery of the present invention 2 The cladding layer, whose composition is mainly TiO 2 ; and the ultra-thin TiO 2 The cladding layer is uniform and dense, and its thickness is only about 5nm.

[0036] From the above ultrathin TiO 2 A lithium battery positive electrode material of the present invention formed by a coating layer, which is a core-shell type coating structure, includes an inner core positive electrode active material, and the inner core positive electrode active material is coated with the ultra-thin TiO of the above-mentioned embodiment. 2 cladding. The core positive electrode active material is a lithium-rich manganese-based positive electrode material (Li 1.2 mn 0.6 Ni 0.2 o 2 ); Ultra-thin TiO 2 The molar ratio of Ti in the cladding layer to the transition metal element in the positive electrode active material in the inner core is 0.5%. The lithium battery cathode material ultra-thin Ti...

Embodiment 2

[0044] A kind of ultra-thin TiO of cathode material of lithium battery of the present invention 2 The cladding layer, whose composition is mainly TiO 2 ; and the ultra-thin TiO 2 The cladding layer is uniform and dense, and its thickness is only about 10nm.

[0045] From the above ultrathin TiO 2 A lithium battery positive electrode material of the present invention formed by a coating layer, which is a core-shell type coating structure, includes an inner core positive electrode active material, and the inner core positive electrode active material is coated with the ultra-thin TiO of the above-mentioned embodiment. 2 cladding. The core positive electrode active material is a lithium-rich manganese-based positive electrode material (Li 1.2 mn 0.6 Ni 0.2 o 2 ); Ultra-thin TiO 2 The molar ratio of Ti in the cladding layer to the transition metal element in the positive electrode active material in the inner core is 1%. The lithium battery cathode material ultra-thin TiO...

Embodiment 3

[0054] A kind of ultra-thin TiO of cathode material of lithium battery of the present invention 2 The cladding layer, whose composition is mainly TiO 2 ; and the ultra-thin TiO 2 The cladding layer is uniform and dense, and its thickness is only about 6nm.

[0055] From the above ultrathin TiO 2 A lithium battery positive electrode material of the present invention formed by a coating layer, which is a core-shell type coating structure, includes an inner core positive electrode active material, and the inner core positive electrode active material is coated with the ultra-thin TiO of the above-mentioned embodiment. 2 cladding. The core positive active material is a ternary positive material (LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 ); Ultra-thin TiO 2 The molar ratio of Ti in the coating layer to the transition metal element in the positive electrode active material in the inner core is 0.6%. The lithium battery cathode material ultra-thin TiO of the present embodiment 2 The coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com