Method for manufacturing laminated core

An iron core and chip technology, which is applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the difficulty of improving the productivity of rotor laminated iron core, the decline of productivity, and the complicated product process Achieve excellent electrical performance, improved bending processing characteristics, and excellent forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

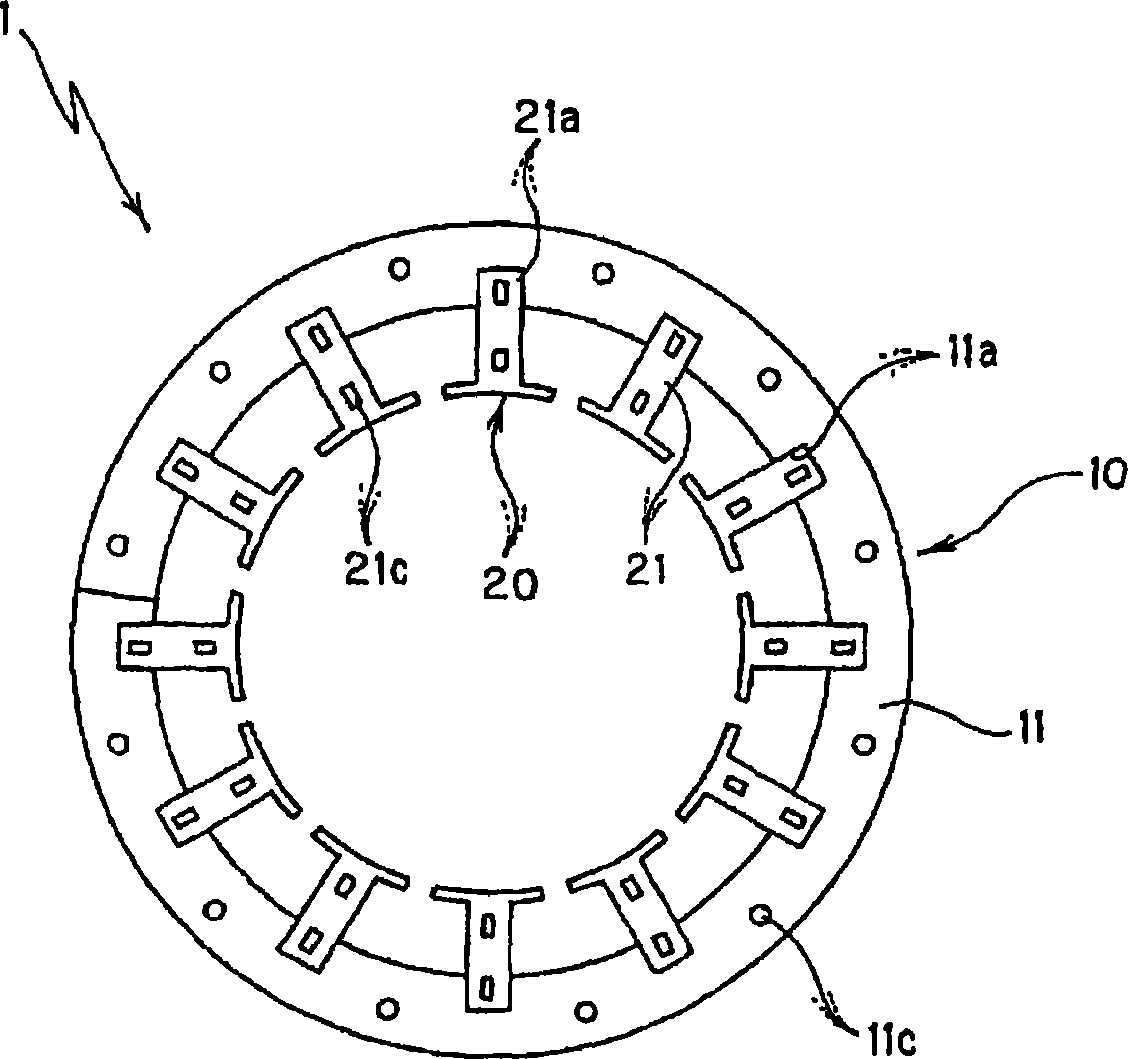

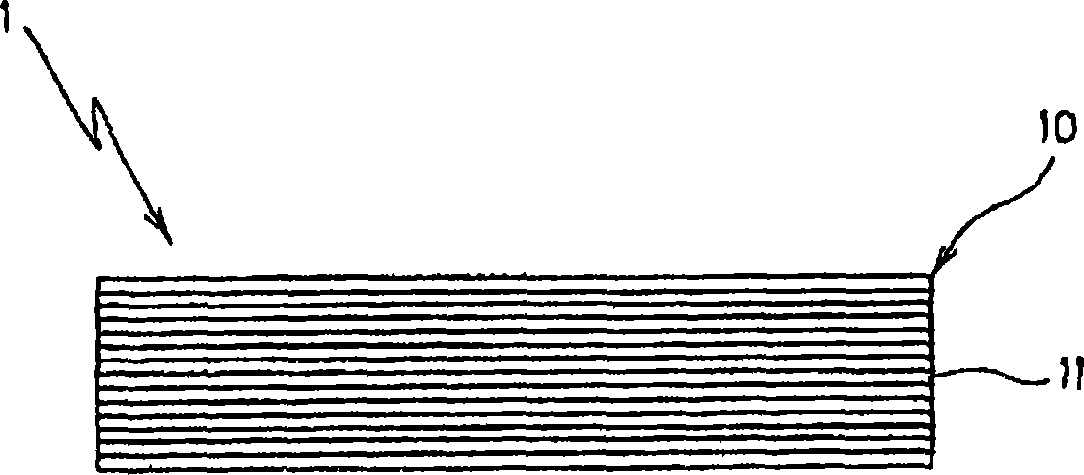

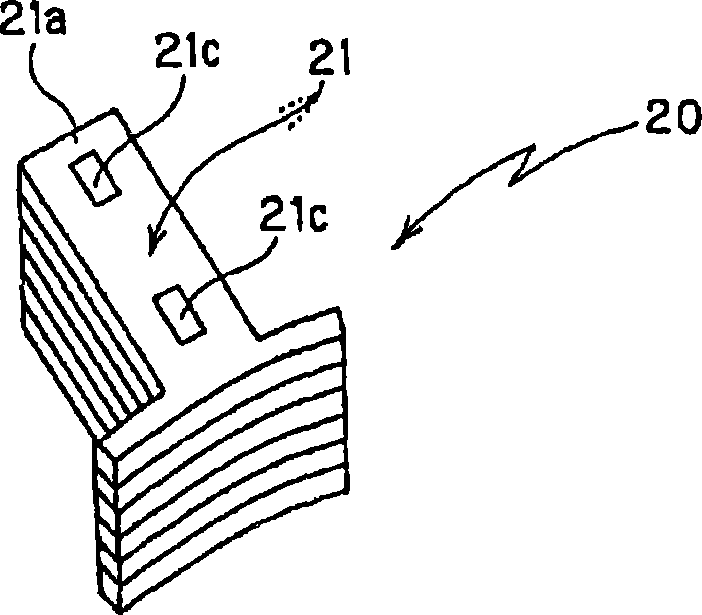

[0186] 1 to 7 show a method of manufacturing a stator laminated core according to the invention. The laminated iron core 1 manufactured according to the present invention includes a laminated yoke body 10 having a belt shape and a predetermined number of laminated magnetic bodies 20, 20 ... (12 in total in the first embodiment), which are coupled to the interior of the laminated yoke body 10. on the circumference edge.

[0187] As will be described later, the laminated yoke body 10 is constituted by winding and laminating a strip-shaped yoke core piece 11 formed by punching a strip-shaped steel plate (metal plate), which has a spiral shape and is coupled in a caulked manner (caulking lamination). Laminated strip steel plates. A predetermined number of concave connection portions 11a, 11a, . . . (12 in total in the first embodiment) are formed on the inner peripheral edge of the laminated yoke body 10. Reference numeral 11c in the figure denotes a caulking portion formed in t...

no. 2 example

[0219] 10 and 11 show a method of manufacturing a stator laminated core according to a second embodiment of the present invention.

[0220] The method according to the second embodiment is substantially similar to the method of the first embodiment described above with reference to Figs. 1 to 9, except that the details of the process of forming a laminated yoke 10' are different from those described above. The stator laminated core manufactured according to the first embodiment is basically similar to the stator laminated core 1 shown in Figs. 1 to 9, except that the partial shape of the laminated yoke 10' is different.

[0221] In the method of manufacturing a stator laminated core according to the second embodiment, first, as Figure 10A As shown, a strip-shaped yoke chip 11' is formed by punching an unshown electrical steel sheet (metal plate).

[0222] The strip-shaped yoke core piece 11' has a shape in which the yoke as a finished stator laminated core is developed in a ...

no. 3 example

[0235] 12 to 17 show a method of manufacturing a stator laminated core according to a third embodiment of the present invention. The laminated iron core 1 manufactured according to the third embodiment includes a laminated yoke body 10 having a ring shape and a predetermined number of laminated magnetic bodies 20, 20... (12 in total in the third embodiment), which are coupled to the laminated yoke body 10. on the inner circumference of .

[0236] As will be described later, the laminated yoke body 10 is constituted by winding and laminating a strip-shaped yoke core piece 11 formed by punching a strip-shaped steel plate (metal plate), which has a spiral shape and is coupled in a caulked manner (caulking lamination). Laminated strip steel plates. A predetermined number of concave connection portions 11a, 11a, . . . (12 in total in the third embodiment) are formed on the inner peripheral edge of the laminated yoke body 10. Reference numeral 11c in the figure denotes a caulking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com