Flexible and electrically insulating fluorinated graphene heat-conducting composite film as well as preparation and application thereof

A fluorinated graphene, thermally conductive composite technology, applied in chemical instruments and methods, heat exchange materials and other directions, can solve the problems of non-insulation and poor thermal conductivity of graphene films, and achieve good electrical insulation and flexibility, and production costs. Low, enhanced effect of interaction between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

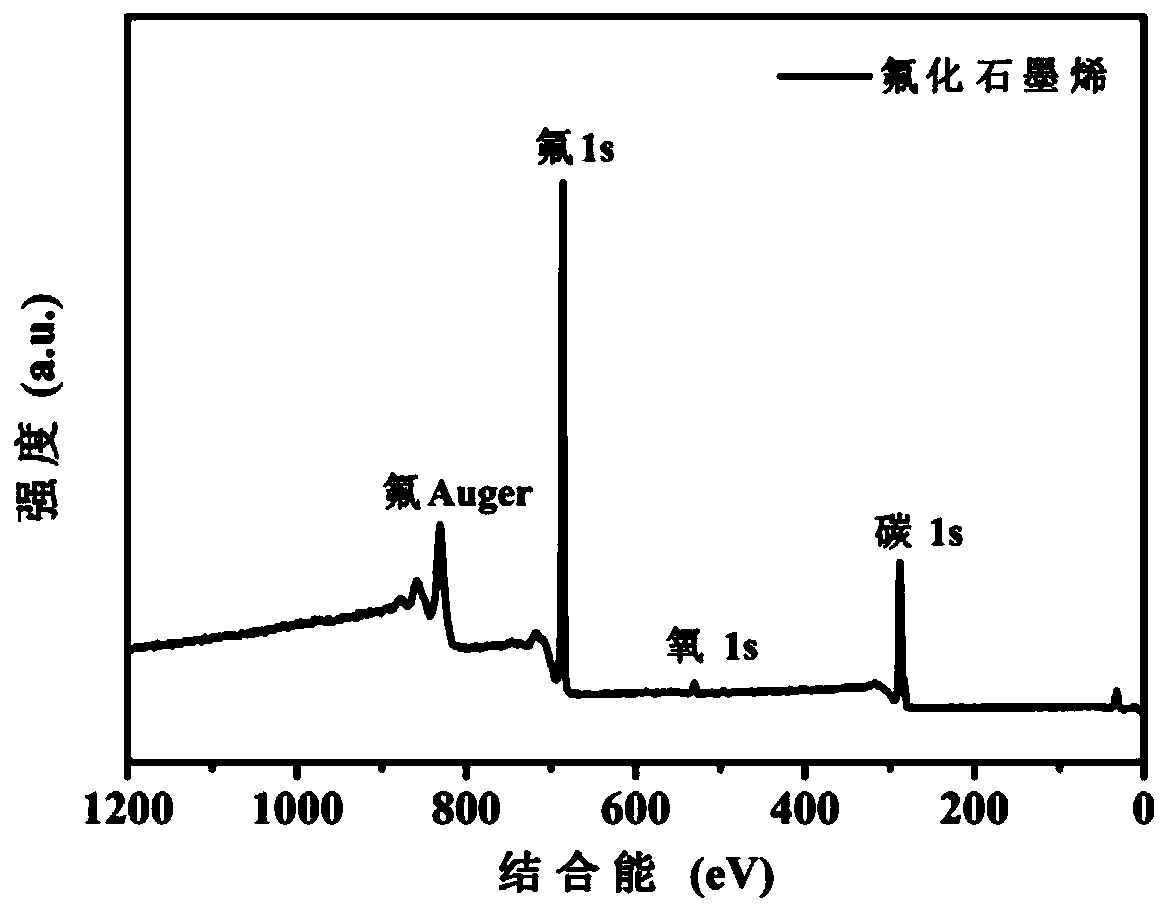

[0038] (1) Disperse commercial fluorinated graphite powder in isopropanol, ultrasonicate on a water bath ultrasonic instrument for 24h (250W), and then centrifuge the mixed dispersion at 3000rpm for 10min to obtain exfoliated fluorinated graphene nanosheets.

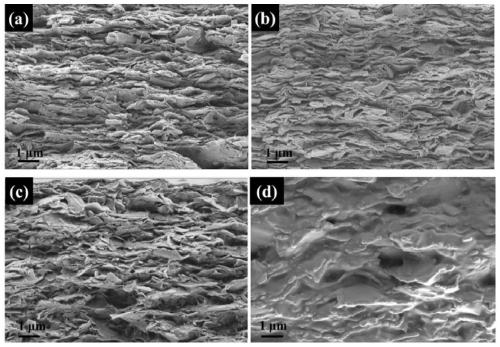

[0039] (2) Take by weighing 40mg of fluorinated graphene obtained in step (1) and disperse it in 200ml water, add 0.05ml 6wt% polyvinyl alcohol (molecular weight 145kg / mol) aqueous solution, ultrasonic 30min, obtain evenly dispersed fluorinated graphene liquid; then pour the dispersion into the vacuum filtration device mixed with cellulose acetate filter membrane, so that the fluorinated graphene nanosheets are uniformly deposited layer by layer to obtain an anisotropic composite graphene thermal film, which is estimated by thermogravimetric analysis. The fluorinated graphene content under the condition is 93wt%.

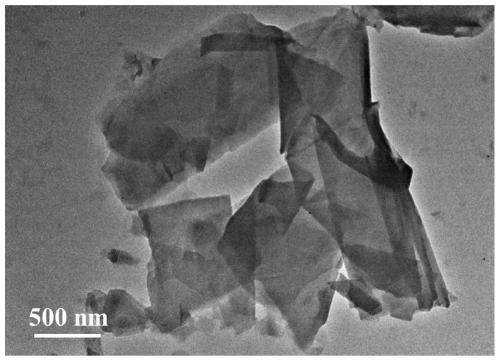

[0040] Transmission electron microscope image of fluorinated graphene figure 1 As shown, it is shown that...

Embodiment 2

[0043] (1) Disperse commercial fluorinated graphite powder in isopropanol, ultrasonicate on a water bath ultrasonic instrument for 24h (250W), and then centrifuge the mixed dispersion at 3000rpm for 10min to obtain exfoliated fluorinated graphene nanosheets.

[0044] (2) Take by weighing 40mg of fluorinated graphene obtained in step (1) and disperse it in 200ml water, add 0.1ml 6wt% polyvinyl alcohol (molecular weight 145kg / mol) aqueous solution, ultrasonic 30min, obtain evenly dispersed fluorinated graphene liquid; then pour the dispersion into a mixed cellulose acetate filter membrane decompression filtration device, so that the fluorinated graphene nanosheets are uniformly deposited layer by layer to obtain an anisotropic composite graphene thermal conductivity film, which is estimated by thermogravimetric analysis. The lower fluorinated graphene content was 88.6 wt%.

Embodiment 3

[0046] (1) Disperse commercial fluorinated graphite powder in isopropanol, ultrasonicate on a water bath ultrasonic instrument for 24h (250W), and then centrifuge the mixed dispersion at 3000rpm for 10min to obtain exfoliated fluorinated graphene nanosheets.

[0047] (2) Take by weighing 40mg of fluorinated graphene obtained in step (1) and disperse it in 200ml water, add 0.2ml 6wt% polyvinyl alcohol (molecular weight 145kg / mol) aqueous solution, ultrasonic 30min, obtain evenly dispersed fluorinated graphene liquid; then pour the dispersion into a mixed cellulose acetate filter membrane decompression filtration device, so that the fluorinated graphene nanosheets are uniformly deposited layer by layer to obtain an anisotropic composite graphene thermal conductivity film, which is estimated by thermogravimetric analysis. The lower fluorinated graphene content was 81.8wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com