Novel wire-cutting lifting mechanism

A lifting mechanism and wire cutting technology, applied in the field of electrical processing, can solve the problems of unsuitability for mass production, slow lifting speed control, low positioning accuracy, etc., to improve cutting accuracy and slicing quality, stable operation process, and lifting speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

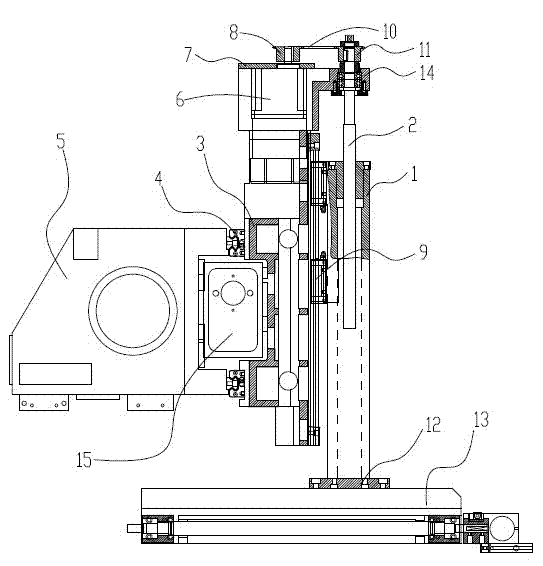

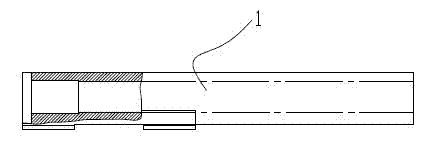

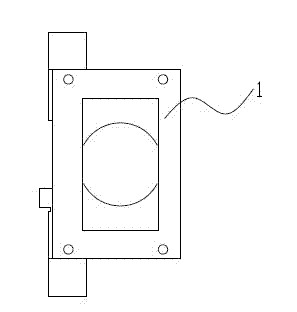

[0020] As shown in the accompanying drawings of the description, the present invention is provided with a lifting guide rail 1, the lifting guide rail 1 is an outer internal hollow structure, and the hollow part in the lifting guide rail 1 is provided with a lifting screw pair 2, and the lifting screw rod The top of the auxiliary 2 is connected to the lifting screw sprocket 11, and the lifting bearing seat 14 is arranged below the lifting screw sprocket 11, and the lifting bearing seat 14 is socketed on the periphery of the lifting screw rod; the lifting guide rail 1 is sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com