Electromagnetic wave shielding film, printed circuit board including shielding film and preparation method of circuit board

A technology of electromagnetic shielding film and printed circuit board, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit parts, etc., can solve the problems of difficult production and processing of insulating layer and metal layer bonding force, metal lamination deformation, aging, etc. Achieve the effect of being convenient for industrial production and application, easy to operate the production process, and good shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

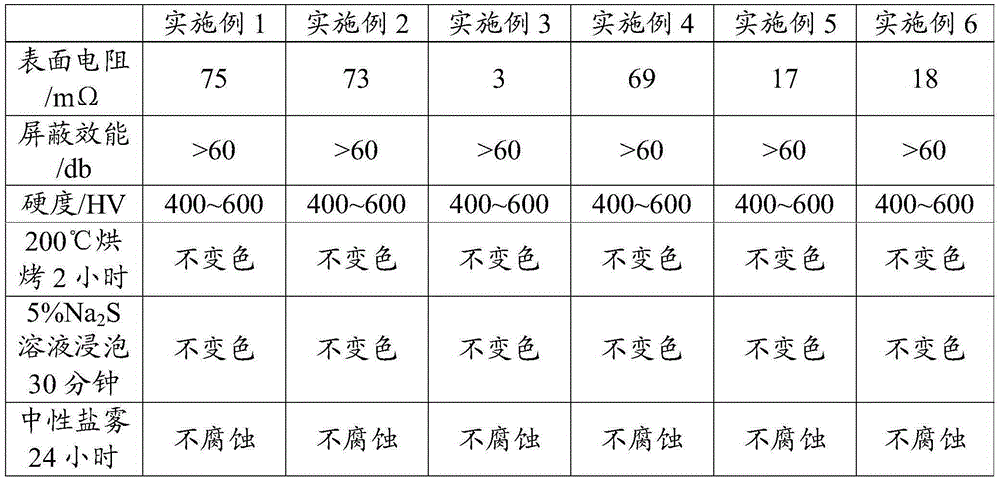

Examples

preparation example Construction

[0046] The present invention also provides the preparation method of described printed wiring board, comprises following method:

[0047] Method one: the preparation method of the printed circuit board, comprising the steps of:

[0048] a. Combining the printed circuit substrate and the adhesive layer of the electromagnetic shielding film in the thickness direction by using a hot-press curing process to obtain a printed circuit substrate comprising the electromagnetic shielding film;

[0049] b. Electrically connecting the grounding layer on the printed circuit board containing the electromagnetic shielding film obtained through step a with the shielding effect layer to obtain the product.

[0050] Method two: the preparation method of the printed circuit board comprises the following steps:

[0051] a. Combining the printed circuit substrate and the adhesive layer of the electromagnetic shielding film in the thickness direction by using a hot-press curing process to obtain a...

Embodiment 1

[0060] An electromagnetic wave shielding film, comprising a carrier film, an insulating layer, a shielding improvement layer, a shielding effect layer, a shielding protection layer and an adhesive layer compounded sequentially from bottom to top; the thickness of the carrier film is 42 microns; the insulating layer The thickness is 6 microns; the thickness of the shielding improvement layer is 0.005 microns; the thickness of the shielding effectiveness layer is 0.08 microns; the thickness of the shielding protective layer is 0.075 microns; the thickness of the adhesive layer is 7 microns.

Embodiment 2

[0062] An electromagnetic wave shielding film, comprising a carrier film, an insulating layer, a shielding improvement layer, a shielding effectiveness layer, a shielding protection layer and an adhesive layer compounded sequentially from bottom to top; the thickness of the carrier film is 25 microns; the insulating layer The thickness is 2 microns; the thickness of the shielding improvement layer is 0.001 microns; the thickness of the shielding effectiveness layer is 0.08 microns; the thickness of the shielding protection layer is 0.075 microns; the thickness of the adhesive layer is 3 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com