Rolled copper foil

A technology of rolling copper foil and rolling surface, which is applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problem of easy deformation of copper foil, and achieve the effect of excellent bending characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

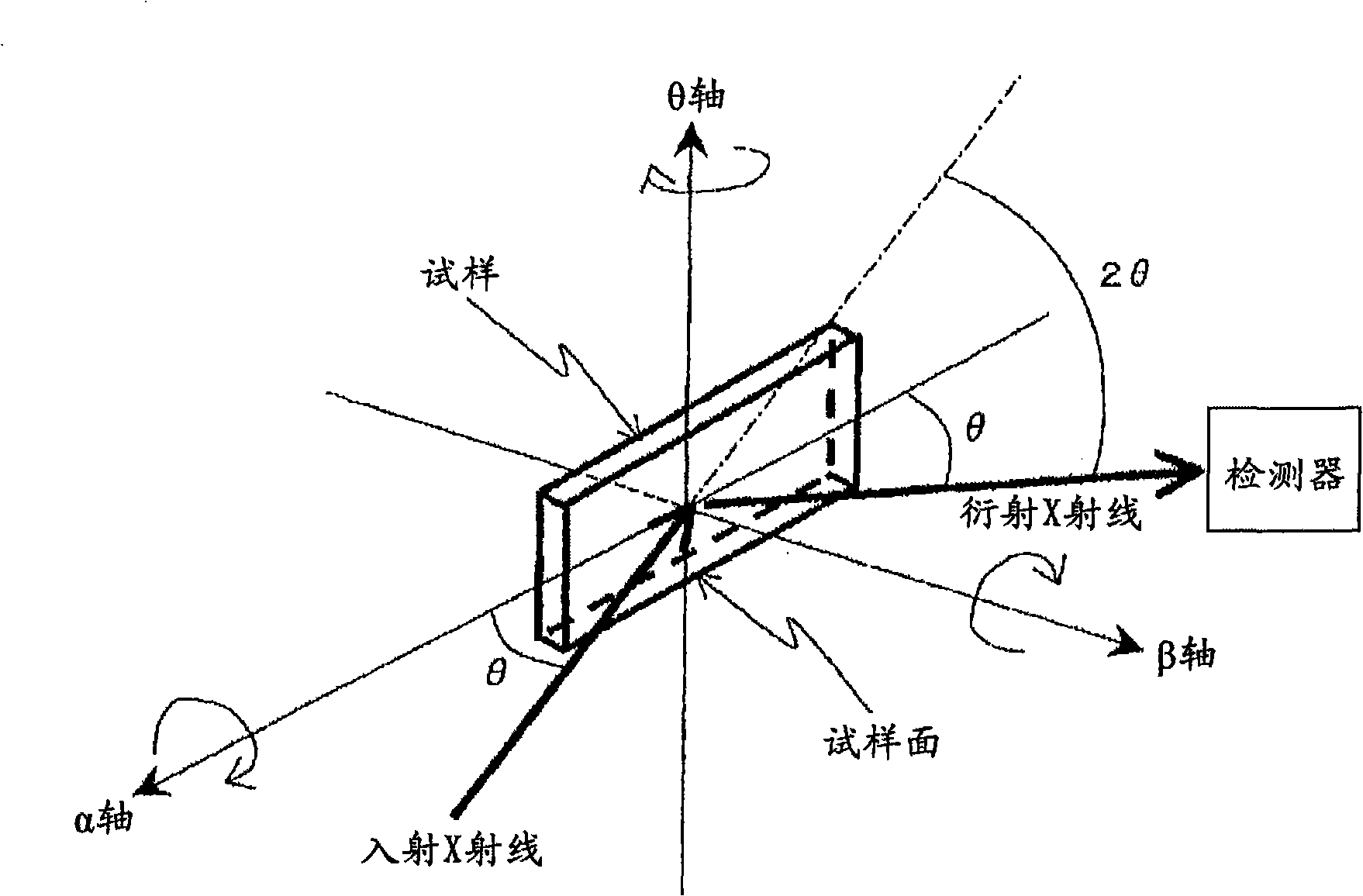

[0045] The rolled copper foil of this embodiment is a rolled copper foil after the final cold rolling process and before recrystallization annealing, and is characterized in that, based on the results obtained by X-ray diffraction polar image measurement based on the rolled surface, When the normalized intensity of the {200} Cu surface diffraction peak of the copper crystal obtained by the β scan of each α angle measured by the polar image is plotted as a graph, the maximum value A of the normalized intensity in the range of α=40-60° and α = The ratio A / B of the maximum value B of the normalized intensity in the range of 80 to 90° is greater than or equal to 4, and, within the range of the above-mentioned α angle being 25 to 45°, when the above-mentioned normalized intensity increases as the α angle increases, There are basically no regions that increase stepwise.

[0046]

[0047] The so-called normalized intensity (Rc) is the averaged count of the specified {hkl} Cu diffra...

no. 2 Embodiment approach

[0064]

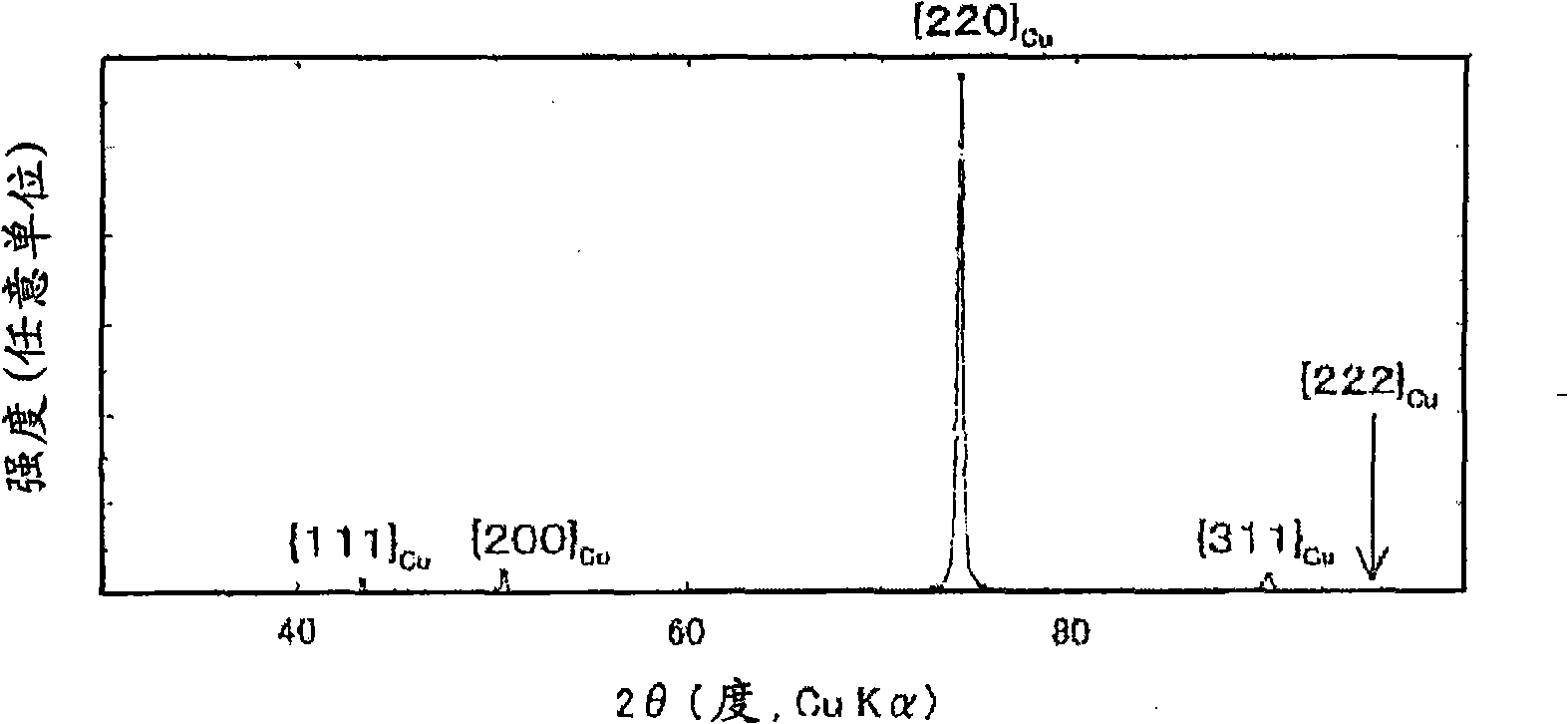

[0065] The rolled copper foil in this embodiment is characterized in that, in the state after the final cold rolling step and before recrystallization annealing, the diffraction pattern of the copper crystals is the same as the result obtained from the X-ray diffraction 2θ / θ measurement on the rolled surface. The diffraction intensity of the {220} Cu plane in the peak is strong, and the occupancy rate of the {220} Cu plane is 80% or more.

[0066] figure 2 This is an example of the results of X-ray diffraction 2θ / θ measurement of the rolled surface in the state before the recrystallization annealing after the final cold rolling process in the rolled copper foil of this embodiment. Depend on figure 2 It can be clearly seen that the diffraction intensity of the {220} Cu plane on the rolling surface is very strong, and the occupancy rate of the {220} Cu plane is more than 80%. This indicates that the copper foil is a rolled copper foil having a rolled texture in wh...

no. 3 Embodiment approach

[0076]

[0077] The rolled copper foil in this embodiment is characterized by being a copper alloy containing 0.001 to 0.009% by mass of Sn and the balance being Cu and unavoidable impurities. Next, the reasons for adding alloy components and the reasons for limiting the content of the copper alloy constituting the rolled copper foil in this embodiment will be described.

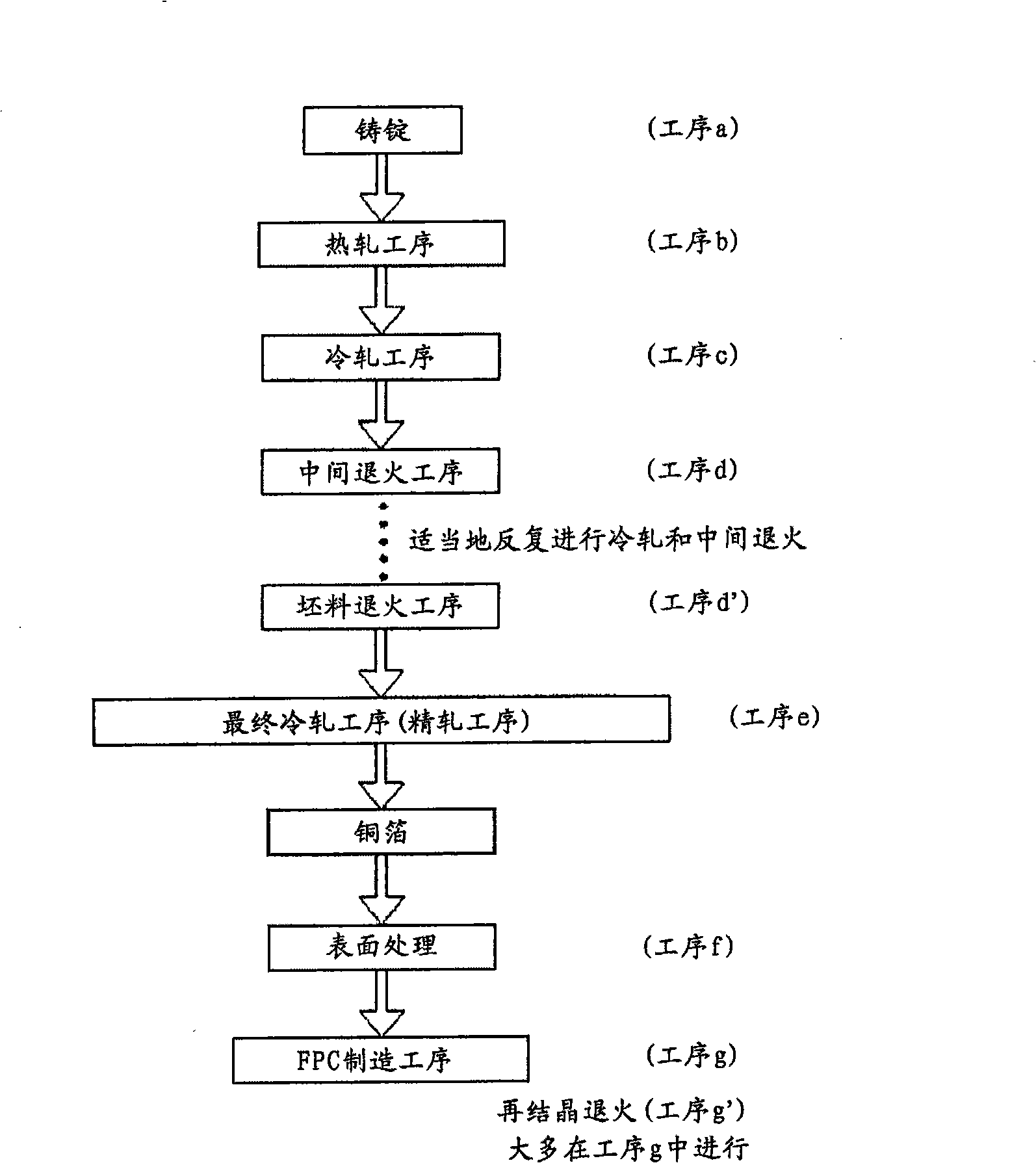

[0078] For rolled copper foil, the greater the total reduction in the final cold rolling process (for example, 90% or more), the easier room temperature softening tends to occur. If this undesired phenomenon (softening at room temperature) occurs, the deformation of the copper foil will easily occur when the copper foil is sheared or laminated with the substrate during the FPC manufacturing process, which is the main reason for the decrease in the yield.

[0079] By including Sn in Cu, room temperature softening can be suppressed (control of softening temperature or recrystallization start temperature) eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com