Aluminum alloy wire

An aluminum alloy wire and aluminum alloy technology, applied in the field of aluminum alloy wire, can solve problems such as difficult application, and achieve the effects of excellent strength and bending properties, excellent electrical conductivity, electrical conductivity and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

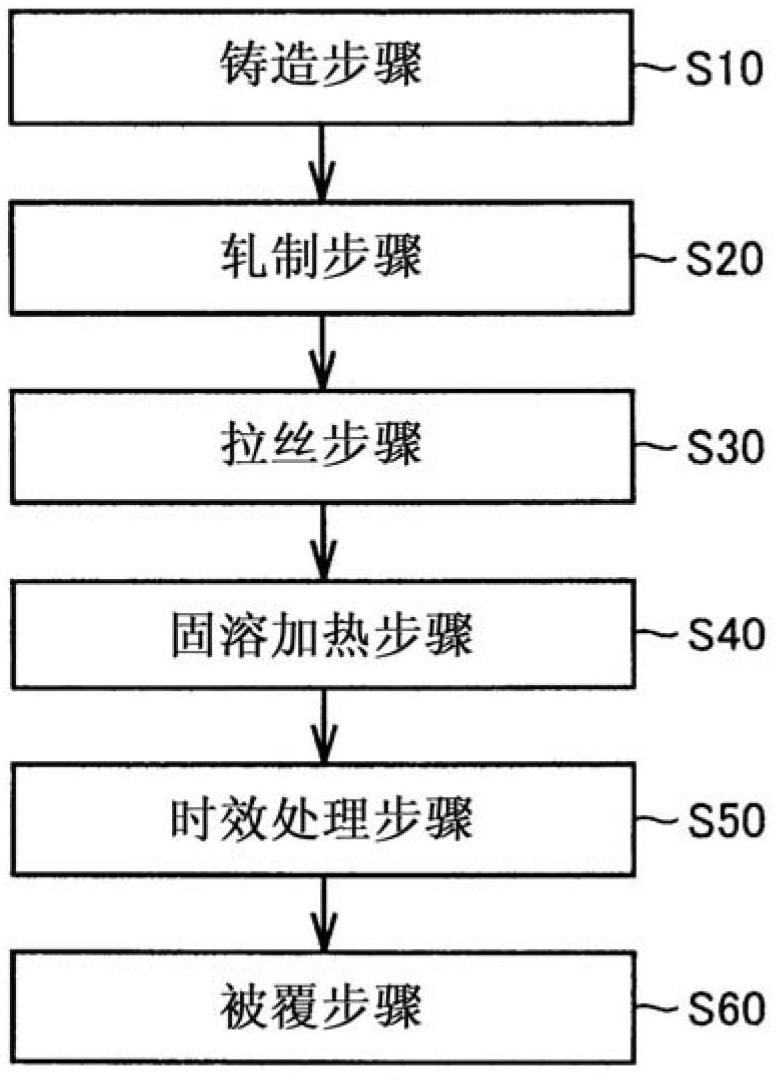

Method used

Image

Examples

no. 1 approach

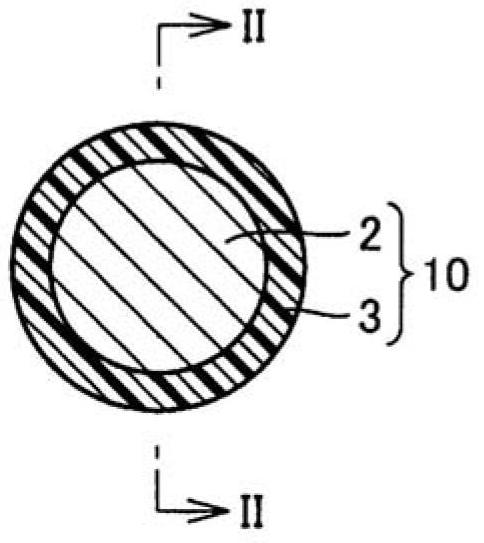

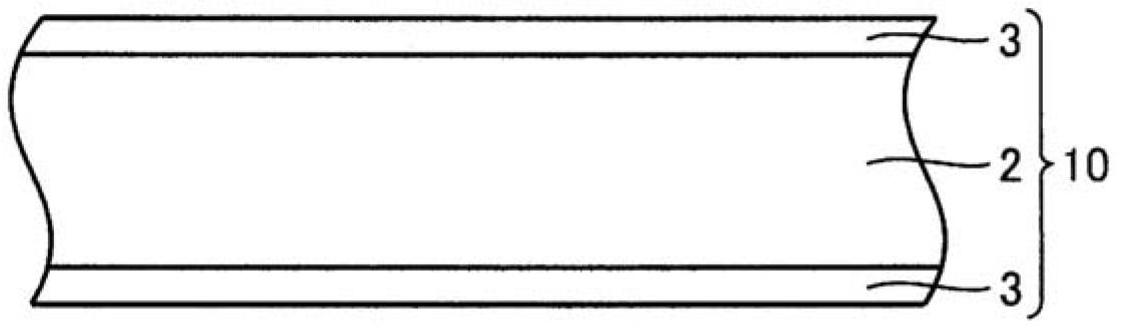

[0087] refer to figure 1 with 2 , the covered electric wire including the aluminum alloy wire of the present invention will be described.

[0088] Such as figure 1 with 2 As shown in , a covered electric wire 10 according to an embodiment of the present invention includes an aluminum alloy wire 2 (hereinafter referred to as Al alloy wire 2 ) and an insulating coating layer 3 made of an insulating material covering the outer periphery of the Al alloy wire 2 . The Al alloy wire 2 is composed of an Al—Mg—Si—Cu based alloy containing 0.1% to 1.5% of Mg, 0.03% to 2.0% of Si, and 0.05% to 0.5% of Cu. In addition, in the Al alloy wire 2, the mass ratio Mg / Si of Mg to Si satisfies 0.8≤Mg / Si≤3.5, the electrical conductivity is greater than or equal to 35%IACS and less than 58%IACS, and the tensile strength is greater than or equal to 150MPa and less than Or equal to 400MPa, and the elongation is greater than or equal to 2%. The Al alloy wire 2 of the present invention contains 0.1...

no. 2 approach )

[0097] refer to Figure 4 , the covered electric wire including the aluminum alloy wire of the present invention will be described.

[0098] Such as Figure 4 As shown in , a covered electric wire 10 according to an embodiment of the present invention includes an aluminum alloy strand 20 formed by twisting together a plurality of Al alloy wires 2 of the present invention, and formed on the outer periphery of the aluminum alloy strand 20 The insulating coating 3. In the aluminum alloy strand 20, a plurality of Al alloy wires 2 are Figure 4 The pages shown extend in a direction perpendicular to each other and are twisted together. Although the insulating coating layer 3 is provided on the outer circumference of the aluminum alloy strand 20, the insulating coating layer 3 may be as Figure 4 is formed in close contact with the outer peripheral surface of the aluminum alloy strand 20 as shown in , or may be formed with a gap formed between the outer peripheral surface and the...

no. 3 approach )

[0105] The following will refer to Figure 8 The wire harness of the present invention will be described.

[0106] refer to Figure 8 A wire harness 30 in one embodiment of the present invention includes a plurality of covered electric wires 10 of the present invention and a terminal portion 31 connected to an end portion of each covered electric wire 10 . The terminal part 31 can be formed by connecting each terminal part to the end part of each covered electric wire 10 and then fixing the plurality of terminal parts together. Alternatively, the terminal portion 31 may be formed by forming a plurality of connection portions connectable to the end portions of the corresponding covered electric wires 10 . Additionally, it is possible to use Figure 8 Multiple wire bundles 30 shown in are bundled together to form a larger wire bundle. Since the covered electric wire 10 of the present invention is excellent in bending characteristics and strength, sufficient durability can al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com