Deformable soft copper bar

A soft copper bar, deformation technology, applied in bendable conductors, bendable cables, metal/alloy conductors, etc., can solve the problems of unstable connection, bumping and friction of electrical devices, saving internal space and eliminating stress , the effect of strong overcurrent capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1. Material selection: T2 red copper is selected before production. T2 red copper is 0.1mm thick red copper foil. Put the selected red copper foil into the heating furnace and heat it to 900°C. After the temperature reaches the standard, transfer the material from the heating furnace In the thermoforming press, the red copper foil is stamped and formed according to the mold in the press to obtain a red copper sheet, and the red copper sheet is rapidly cooled by water cooling at a temperature of 10°C to harden the red copper sheet. increase strength;

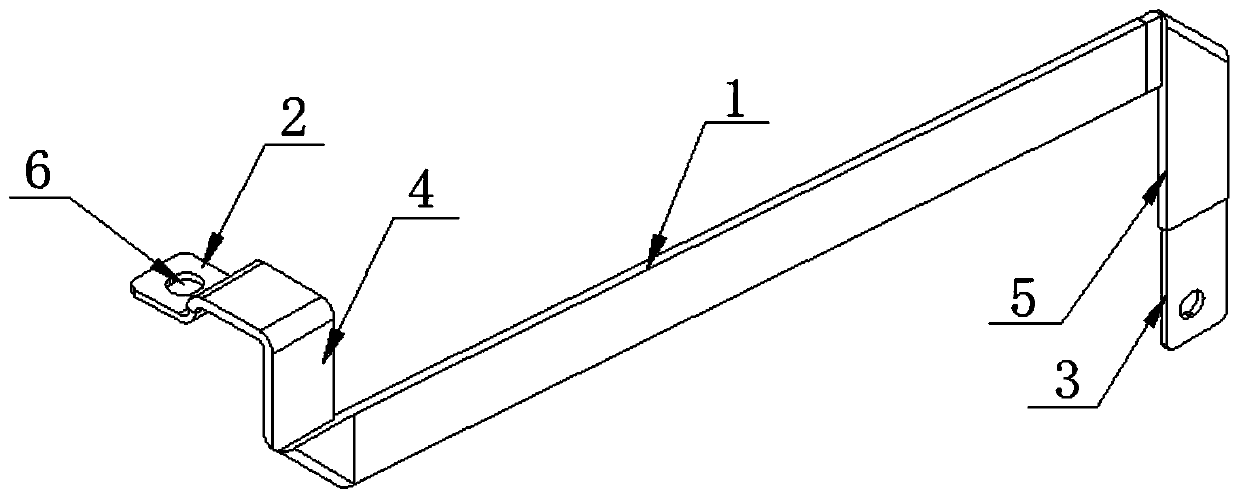

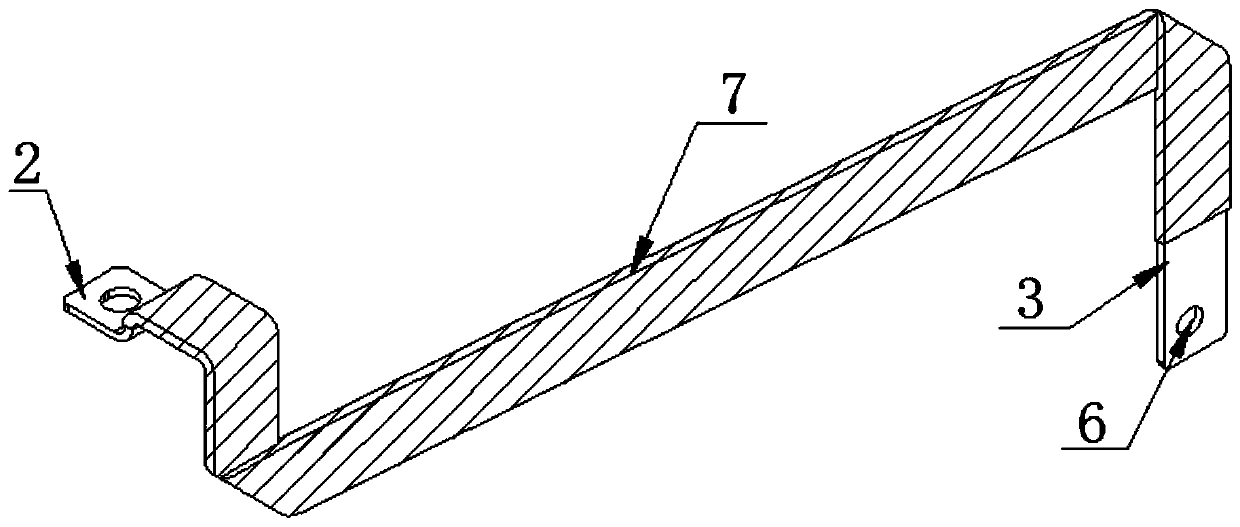

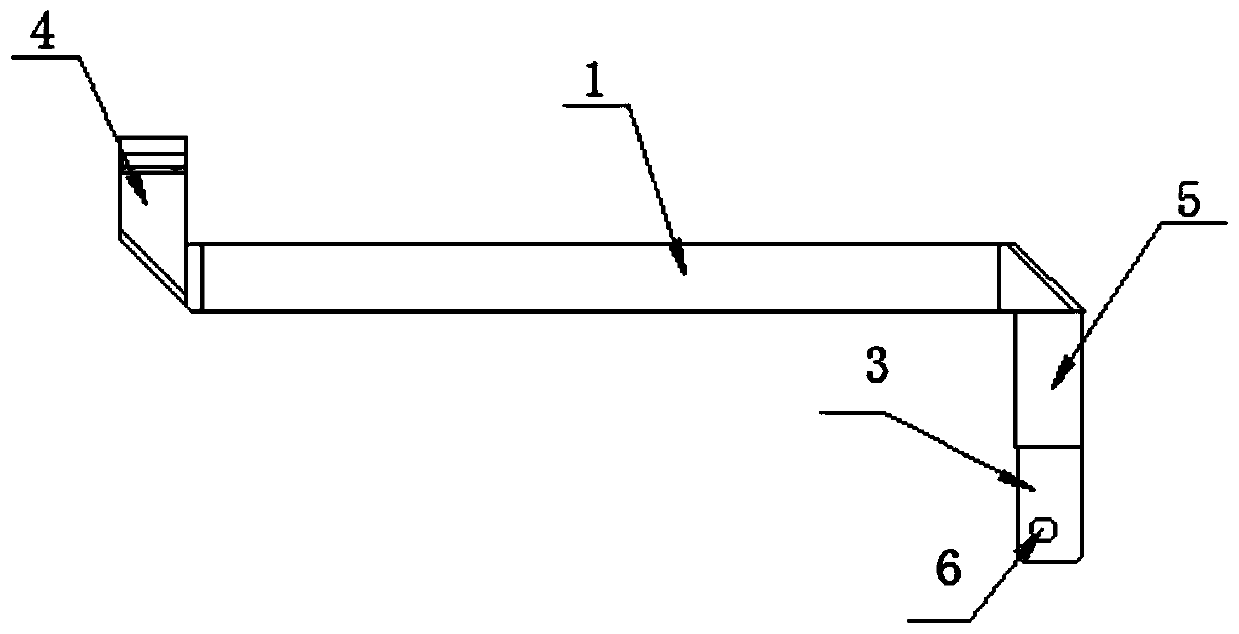

[0028] S2. Surface treatment: Use punching equipment to punch holes on both sides of the surface of the copper sheet to form two connection holes 6, namely the first connection part 2 and the second connection part 3. After the punching is completed, the copper plate Remove burrs and blunt sharp corners on the surface of the material, so that there are no sharp edges on the surface and no damage to the outer surface;

[...

Embodiment 2

[0032] S1. Material selection: T2 red copper is selected before production. T2 red copper is 0.1mm thick red copper foil. Put the selected red copper foil into the heating furnace and heat it to 950°C. After the temperature reaches the standard, transfer the material from the heating furnace In the thermoforming press, the red copper foil is stamped and formed according to the mold in the press to obtain a red copper sheet, and the red copper sheet is rapidly cooled by water cooling at a temperature of 20°C to harden the red copper sheet. increase strength;

[0033] S2. Surface treatment: Use punching equipment to punch holes on both sides of the surface of the copper sheet to form two connection holes 6, namely the first connection part 2 and the second connection part 3. After the punching is completed, the copper plate Remove burrs and blunt sharp corners on the surface of the material, so that there are no sharp edges on the surface and no damage to the outer surface;

[...

Embodiment 3

[0037] S1. Material selection: T2 red copper is selected before production. T2 red copper is 0.1mm thick red copper foil. Put the selected red copper foil into the heating furnace and heat it to 1000°C. After the temperature reaches the standard, transfer the material from the heating furnace. In the thermoforming press, the red copper foil is stamped and formed according to the mold in the press to obtain a red copper sheet, and the red copper sheet is rapidly cooled by water cooling at a temperature of 30°C to harden the red copper sheet. increase strength;

[0038] S2. Surface treatment: Use punching equipment to punch holes on both sides of the surface of the copper sheet to form two connection holes 6, namely the first connection part 2 and the second connection part 3. After the punching is completed, the copper plate Remove burrs and blunt sharp corners on the surface of the material, so that there are no sharp edges on the surface and no damage to the outer surface;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com