Metal sheet conveying device

A conveying device and metal sheet technology, which is used in the field of leveling, high-speed uncoiling of tinplate coils, and sheet conveying after shearing. Inability to accurately enter the aggregate stacking device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

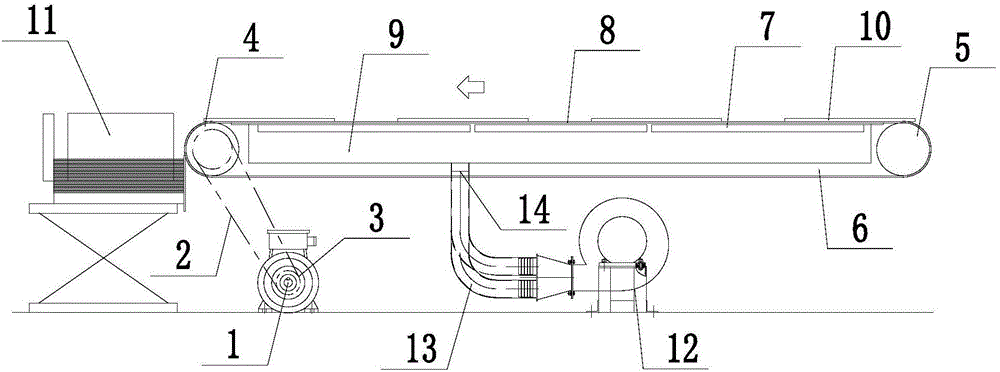

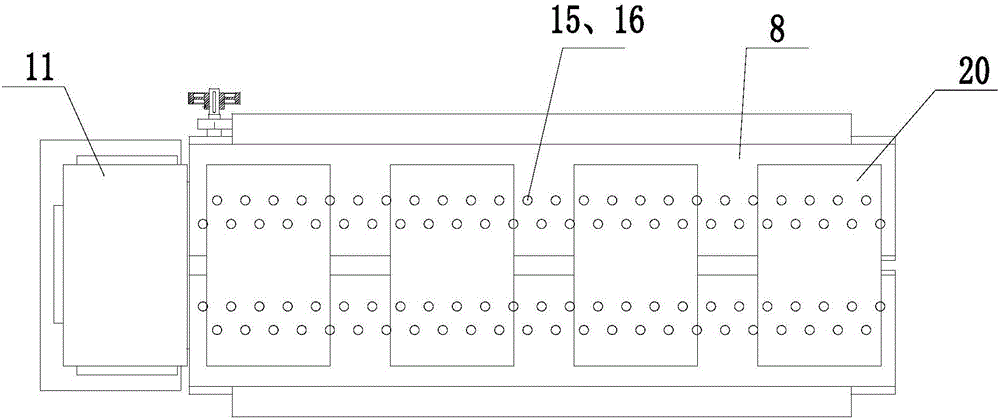

[0014] A sheet metal conveying device, which includes a motor 1, a synchronous belt 2, a synchronous pulley 3, a drive roller 4, a tension roller 5, a conveyor frame 6, a belt backing plate 7, and a conveying flat belt 8, conveying a flat belt 8 Magnet strips 10 are respectively arranged under both sides of the bottom. The conveyor frame 6 frame is provided with a closed space 9, and the closed space 9 is connected with a suction device; the suction device includes a fan 12, a connecting bellows 13 and a suction port 14, and the suction port 14 is arranged in the closed space 9 Above, the air suction port 14 is connected with the fan 12 through the connecting bellows 13 . The belt backing plate 7 covers and is arranged on the top of the closed space 9, and a plurality of first small hole belts 15 are arranged on the belt backing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com