Conveying and emptying method and device for bar-shaped materials

A technology of emptying device and conveying direction, applied in the field of tobacco machinery, can solve problems such as bending, falling rods, messy rods, etc., and achieve the effect of good transmission effect, less damage to materials, and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

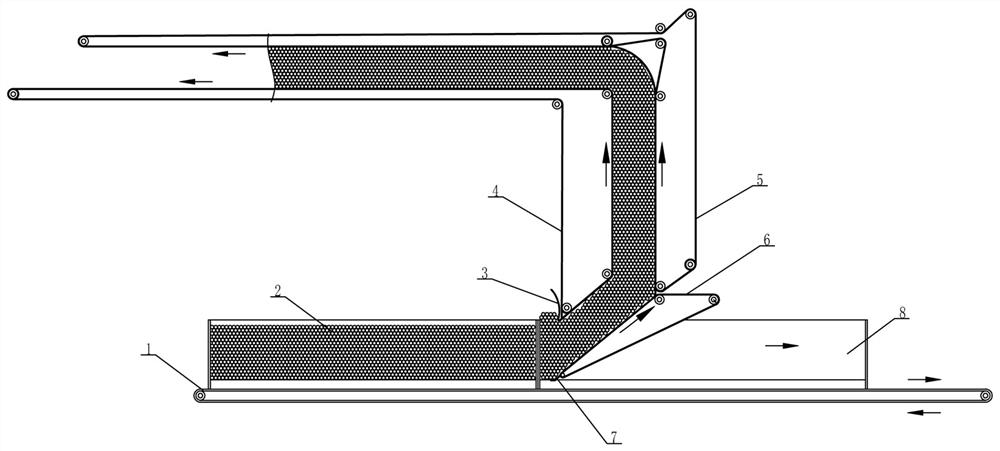

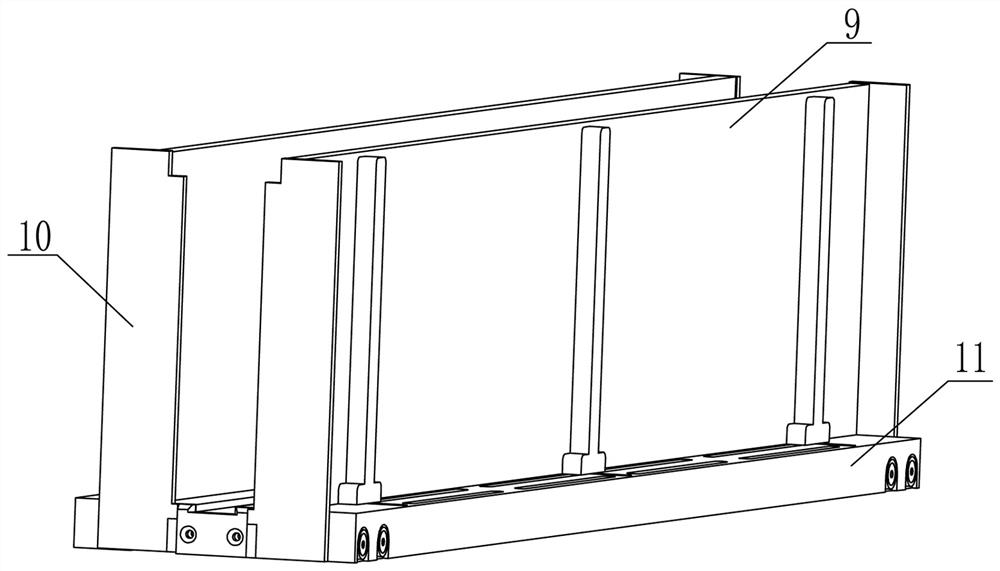

[0027] This embodiment provides a method and device for conveying and emptying rod-shaped materials, such as figure 1 , figure 2 As shown, it includes a plurality of containers 8 for carrying rod-shaped materials 2, a container conveying mechanism 1 for horizontally conveying the containers 8, and a retrieving mechanism 6 that lifts up from the bottom of the containers 8 and conveys the rod-shaped materials 2 obliquely outward , and a rod-shaped material conveying mechanism that conveys the rod-shaped material 2 in a clamping manner and is connected with the conveying surface of the reclaiming mechanism 6 .

[0028] Specifically, the rod-shaped material conveying mechanism includes a rod-shaped material left conveying mechanism 4 and a rod-shaped material right conveying mechanism 5 . The bottom of the rod-shaped material left conveying mechanism 4 is provided with an inclined surface matched with the oblique conveying surface of the reclaiming mechanism 6 .

[0029] The ro...

Embodiment 2

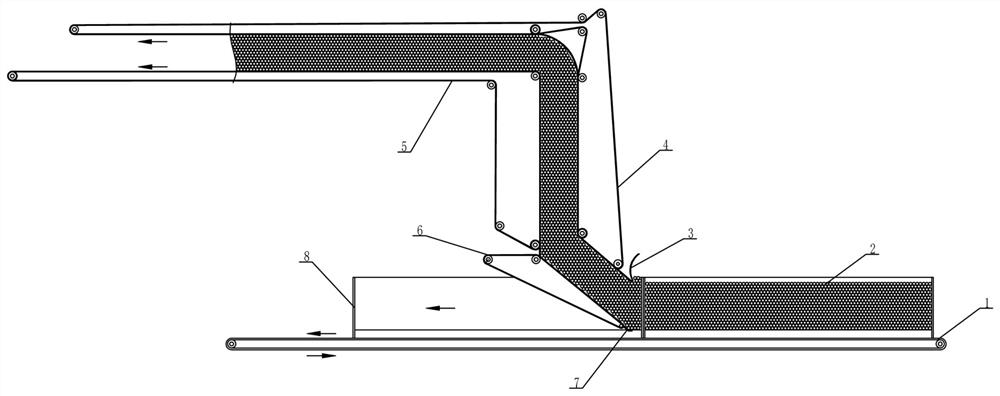

[0044] This embodiment provides a method and device for conveying and emptying rod-shaped materials, such as image 3 As shown, the specific structure is roughly the same as that in Embodiment 1, except that in this embodiment, the conveying direction of the horizontal conveying section is the same as that of the container conveying mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com