Production line for automatically producing perforated bricks

A technology for perforated bricks and production lines, which is applied in chemical instruments and methods, cement mixing devices, pretreatment control, etc. Raw material particle gradation and other issues, to shorten the product production cycle, optimize the raw material particle gradation, and ensure the effect of size and weight tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

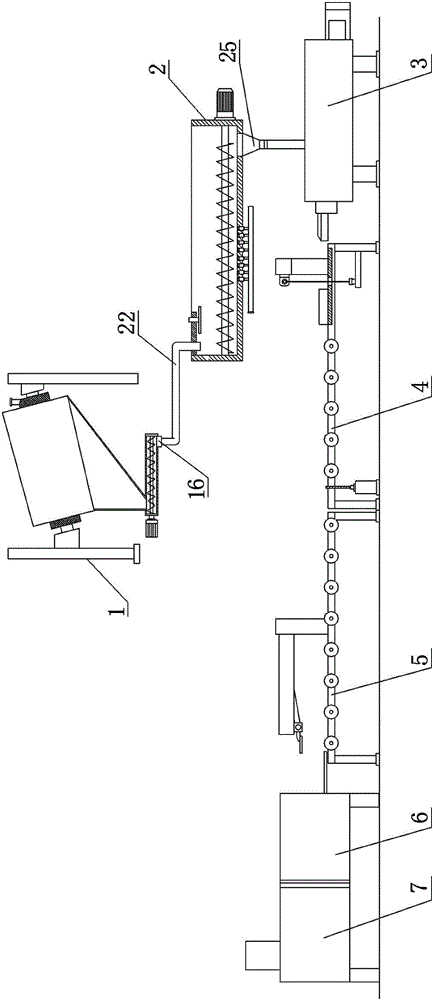

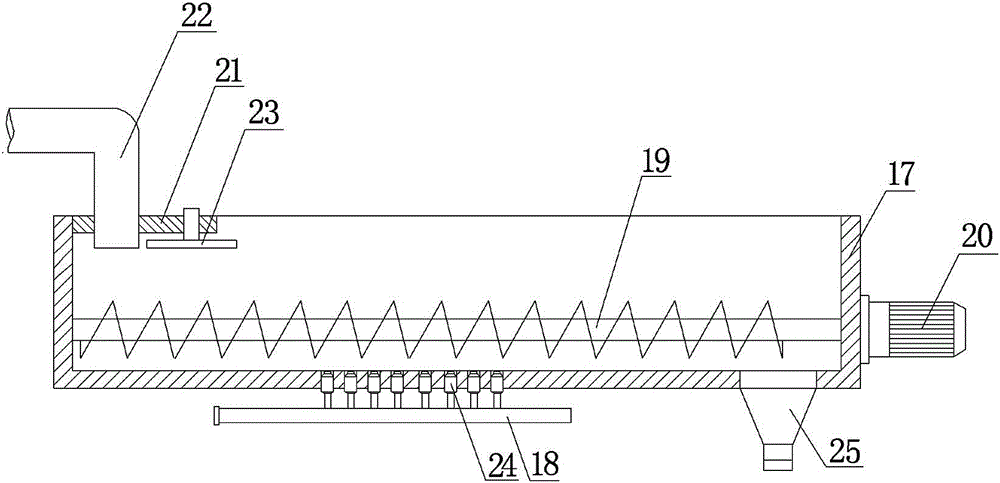

[0025] like Figure 1-7 As shown, a production line for automatic production of porous bricks, which includes a shale screening device 1, a mixer 2, a porous brick extrusion molding machine 3, a porous brick cutting machine 4, a porous brick trimming machine 5, a drying device 6 and Roasting device 7;

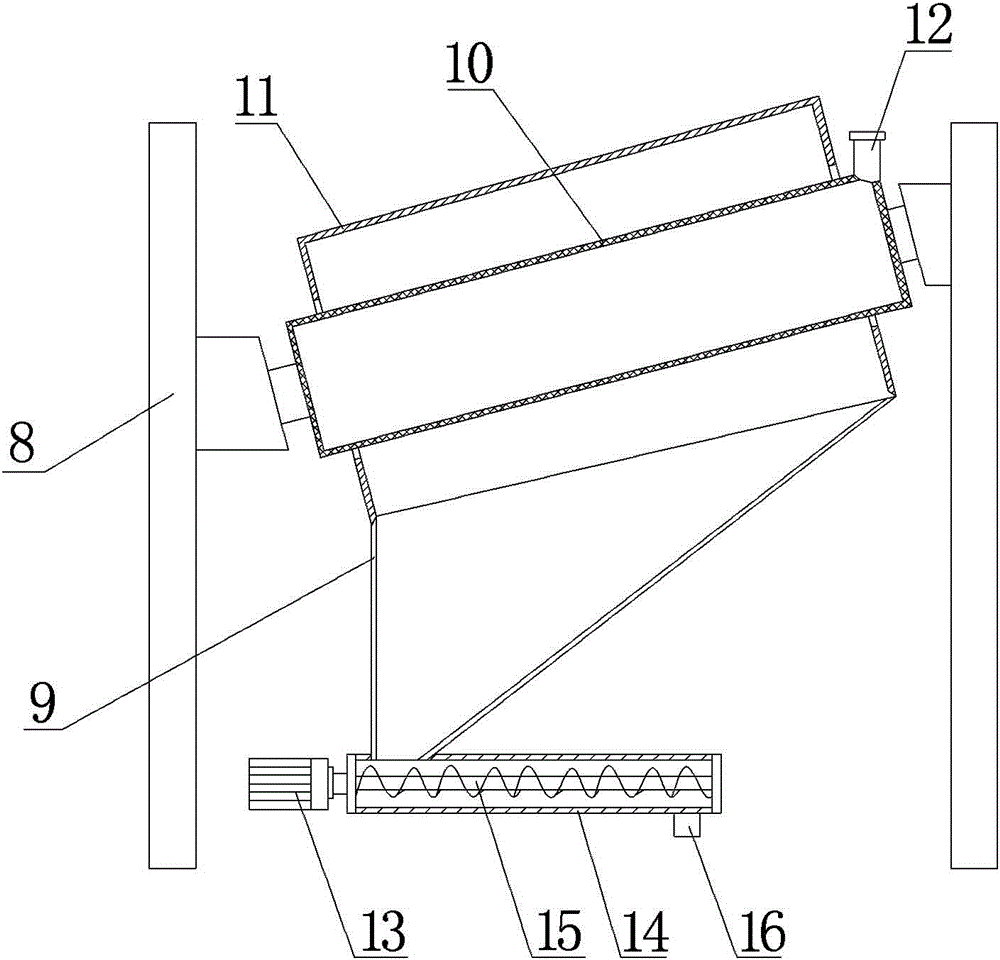

[0026] like figure 1 and figure 2 As shown, the shale screening device 1 is composed of a frame C8, an ash hopper 9, a trommel 10, a protective cover 11 and a conveying device. The trommel 10 is set at an angle with the ground and is arranged between the frame C8. The rotating shafts at both ends of the rotating shaft are installed on the frame C8. A uniform grid is provided on the cylindrical surface of the trommel 10. The grid is a square grid of 3mmx3mm. The trommel 10 is wrapped in the protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com