Sheet feeding equipment

A technology for feeding equipment and sheets, applied in heat exchange equipment, metal processing equipment, feeding devices, etc., can solve the problems of inconvenient length adjustment, pressing error, and inaccuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

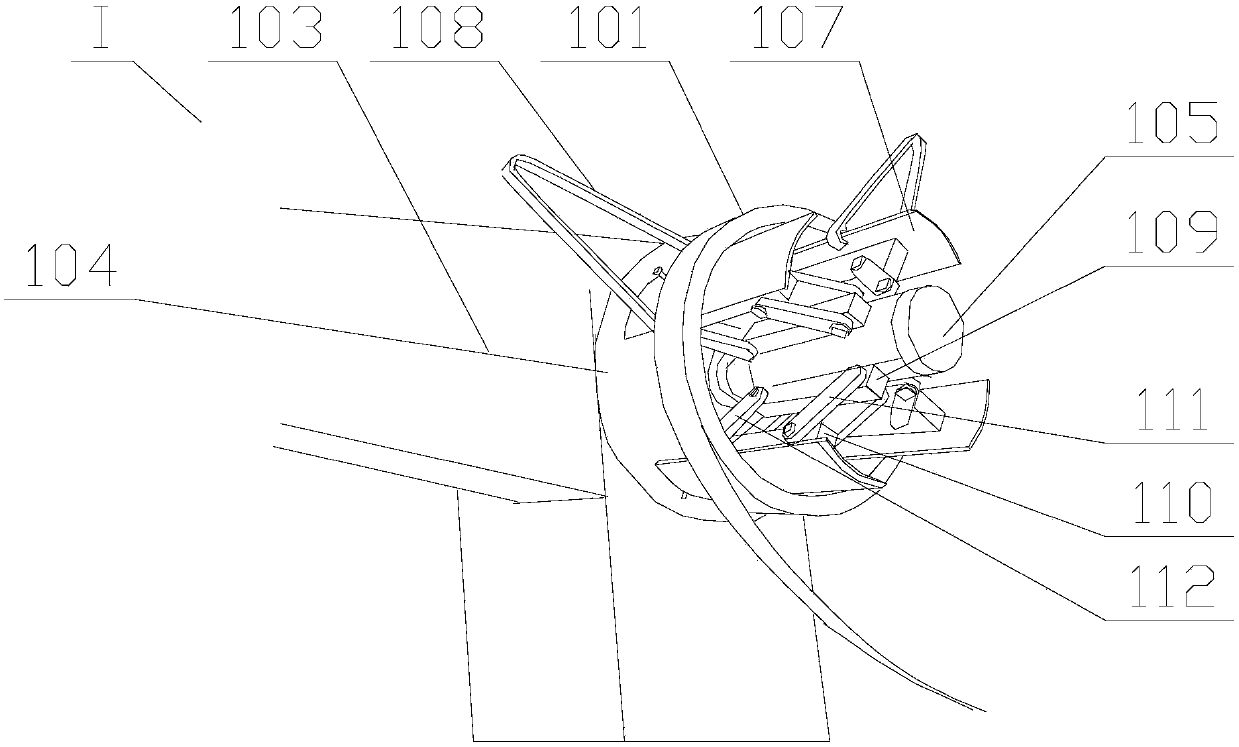

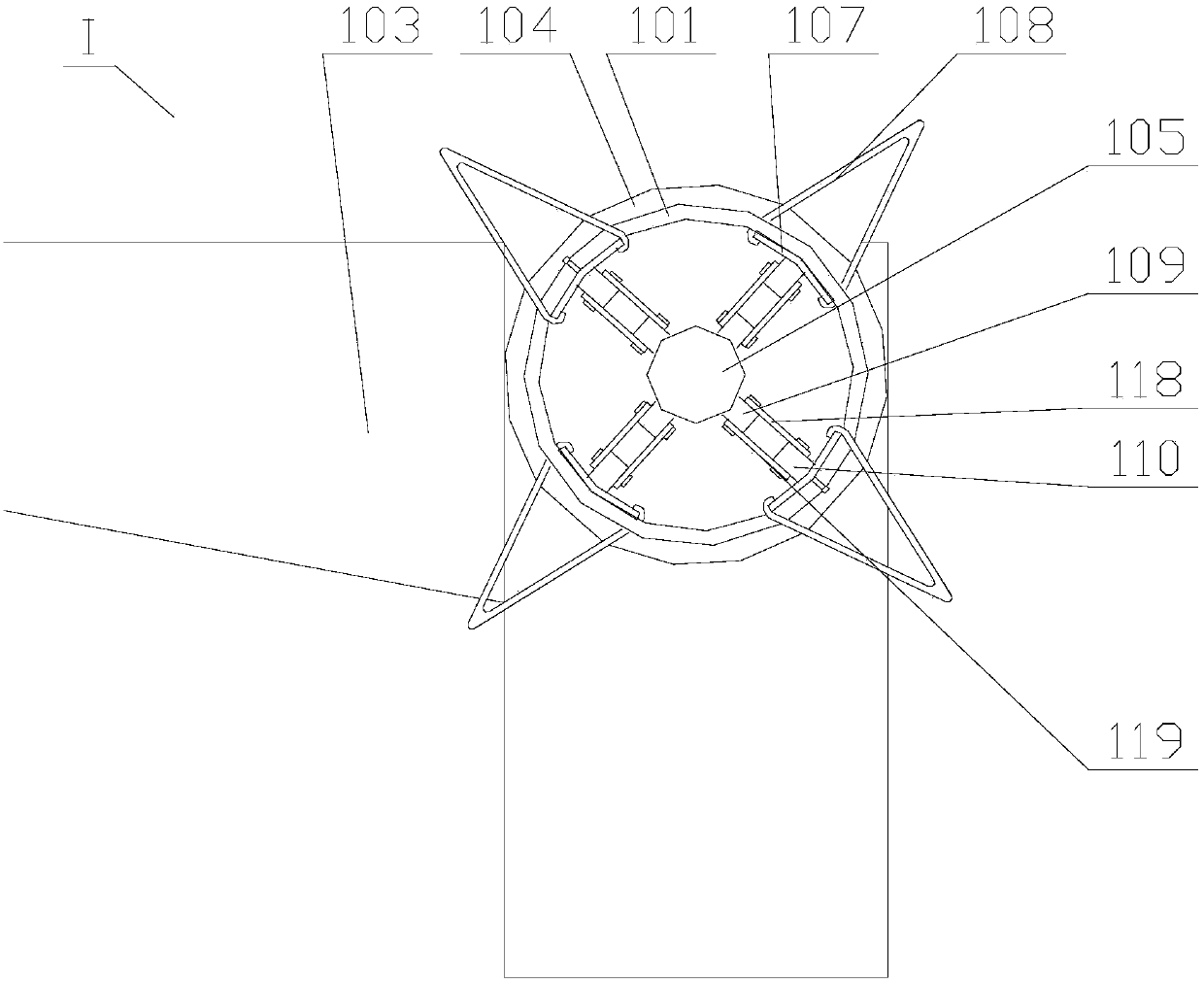

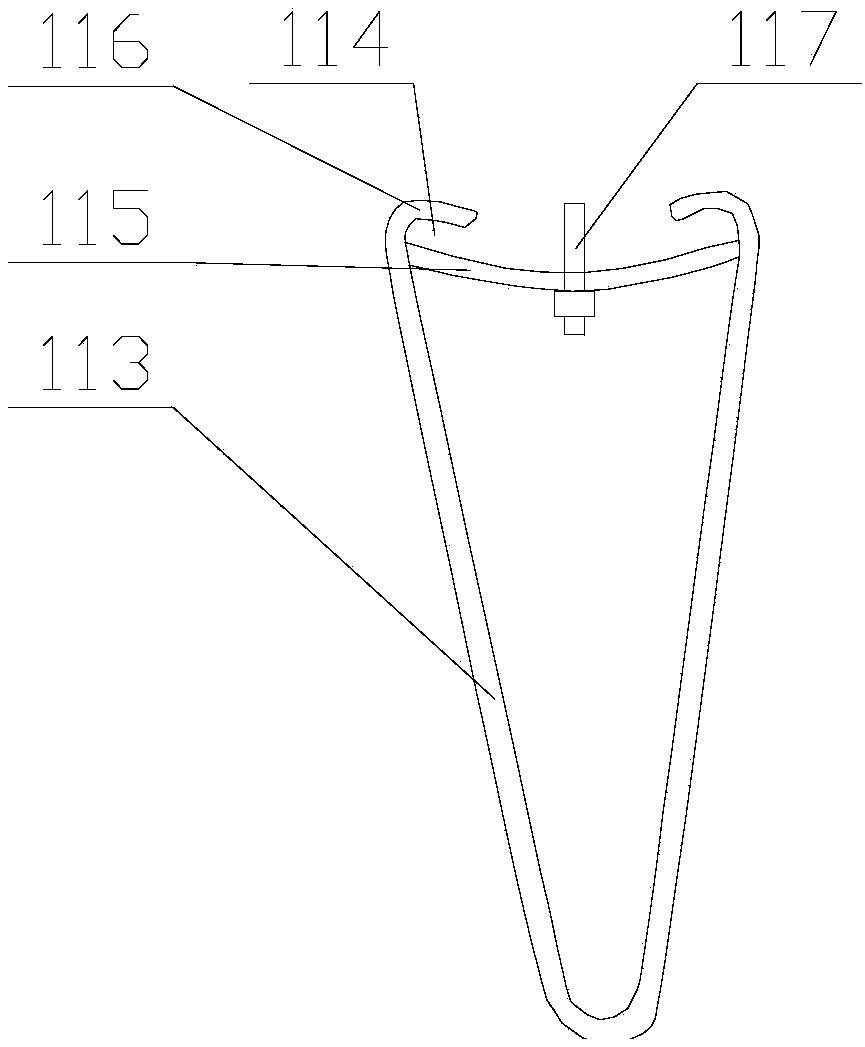

[0036] Such as Figure 1-11 A sheet feeding machine shown includes a winding mechanism I, a conveying mechanism II, and a pushing mechanism III; the winding mechanism I is used for winding the first sheet 101, and can realize winding and releasing of the first sheet 101; The feeding mechanism III pulls the first sheet 101 and the second sheet 102, so that they reach the pushing mechanism III through the conveying mechanism II, and then send them to the mold for pressing, forming metal sheets with corrugations, sealing grooves, etc. that meet the sheet manufacturing requirements; Winding mechanism 1 comprises frame 103, the disk body 104 that is fixed on the frame 103, the first rotating shaft 105 that is connected with the center of disk body 104, and connector, the first winding frame, limit frame 108; The first rotating shaft 105 is evenly distributed around the circumference of the first fixed block 109, the inside of the first winding frame is provided with a second fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com