Joss paper cutting travelling mechanism

A technology for cutting walking and money paper, applied in metal processing and other directions, can solve the problems of uneven paper money, high labor cost, and slow processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

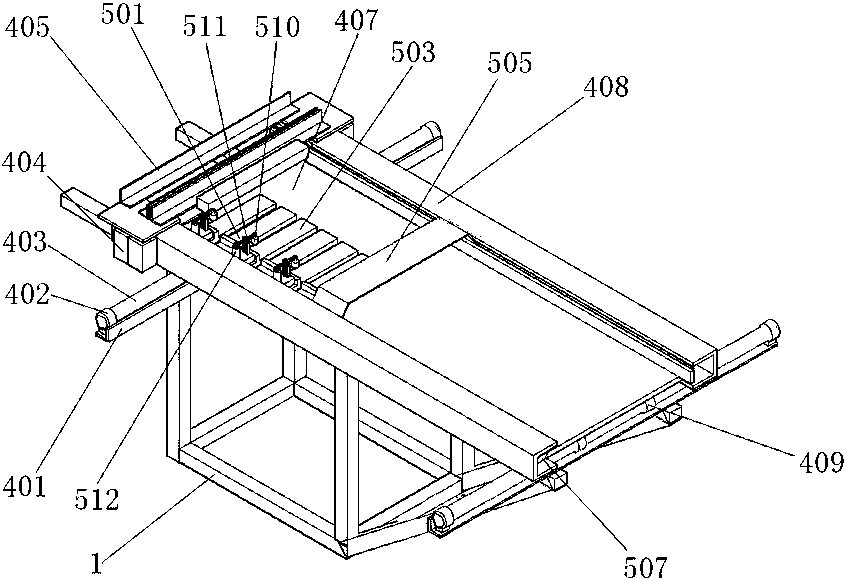

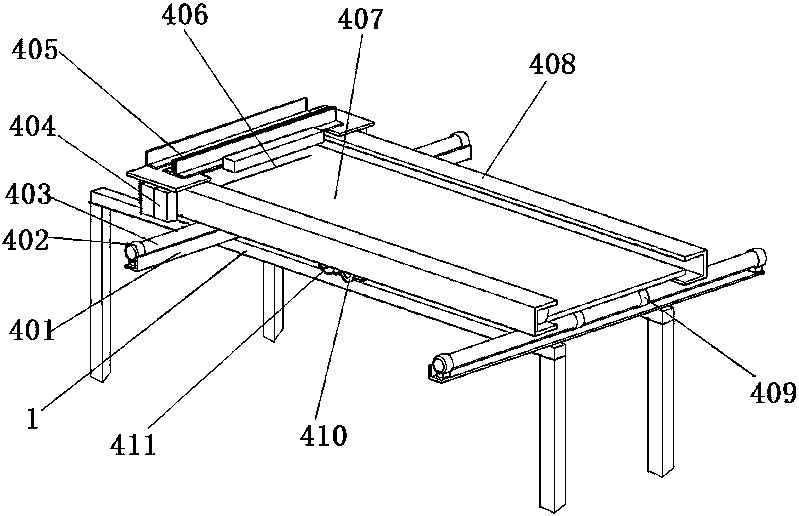

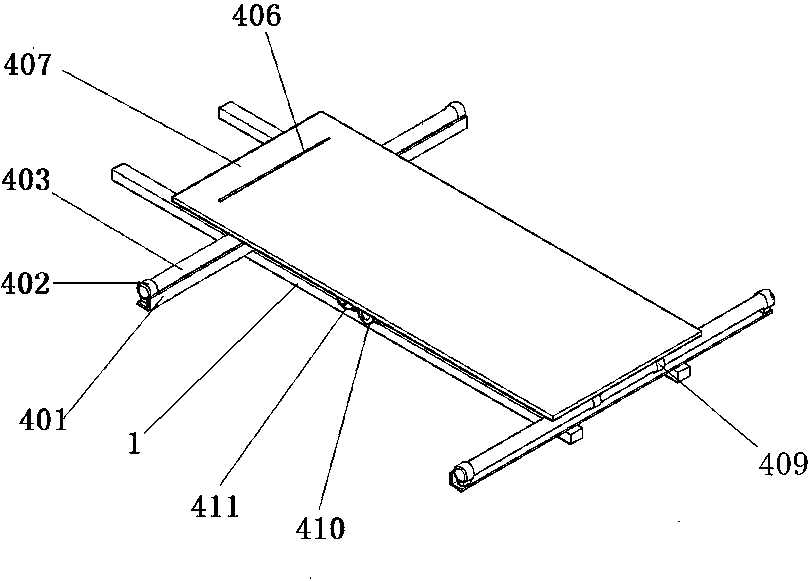

[0020] The specific implementation, structure, features and functions of the money paper cutting walking mechanism proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0021] see Figure 1 to Figure 6 , a walking mechanism for money paper cutting according to the present invention, comprising a frame, a left and right moving mechanism, and a front and rear moving mechanism, characterized in that the left and right moving mechanism consists of a base 401, a fixed sleeve A402, a slide rail A403, a contraction pump A404, and a pressing plate A405, cutting groove 406, panel 407, channel steel 408, sliding sleeve A409, screw shaft 410, motor B411, sliding sleeve B412, bearing seat A413, base 401 is installed on frame 1, and fixed sleeve A402 is installed on base 401 , the sliding rail A403 is installed in the fixed sleeve A402, the sliding sleeve A409 is installed on the sliding rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com