One-way adjustable chain type conveying mechanism

A technology of conveying mechanism and adjustable chain, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems such as the distance between the two chains cannot be adjusted, the conveyor chain moves back, and the adjustment efficiency is low, so as to shorten the preparation time, prevent excessive rotation, Good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

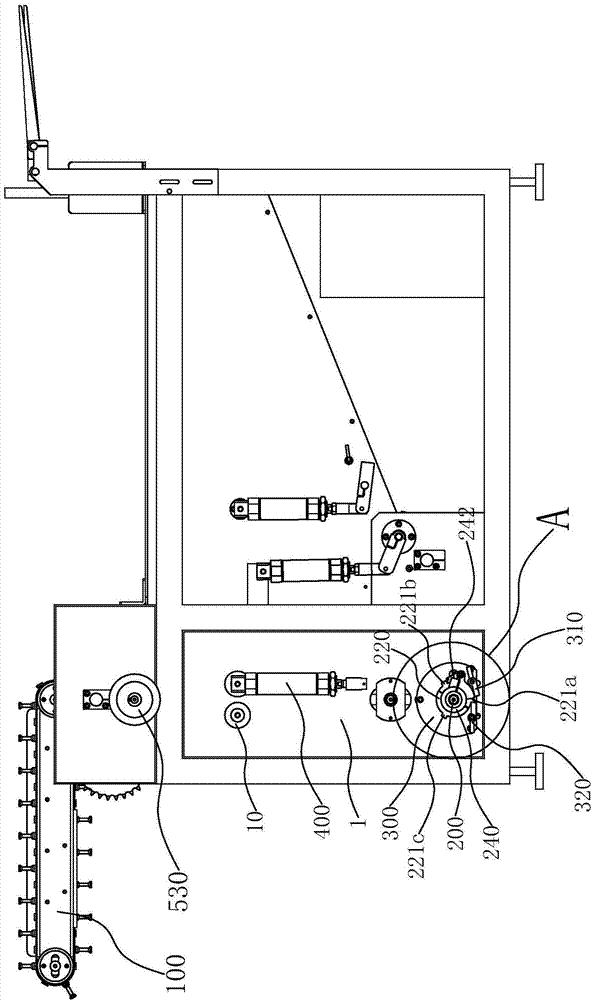

[0034] For ease of understanding, Figure 5 The arrows in indicate the direction of rotation of the transmission shaft, ratchet, and turntable, which is reverse rotation.

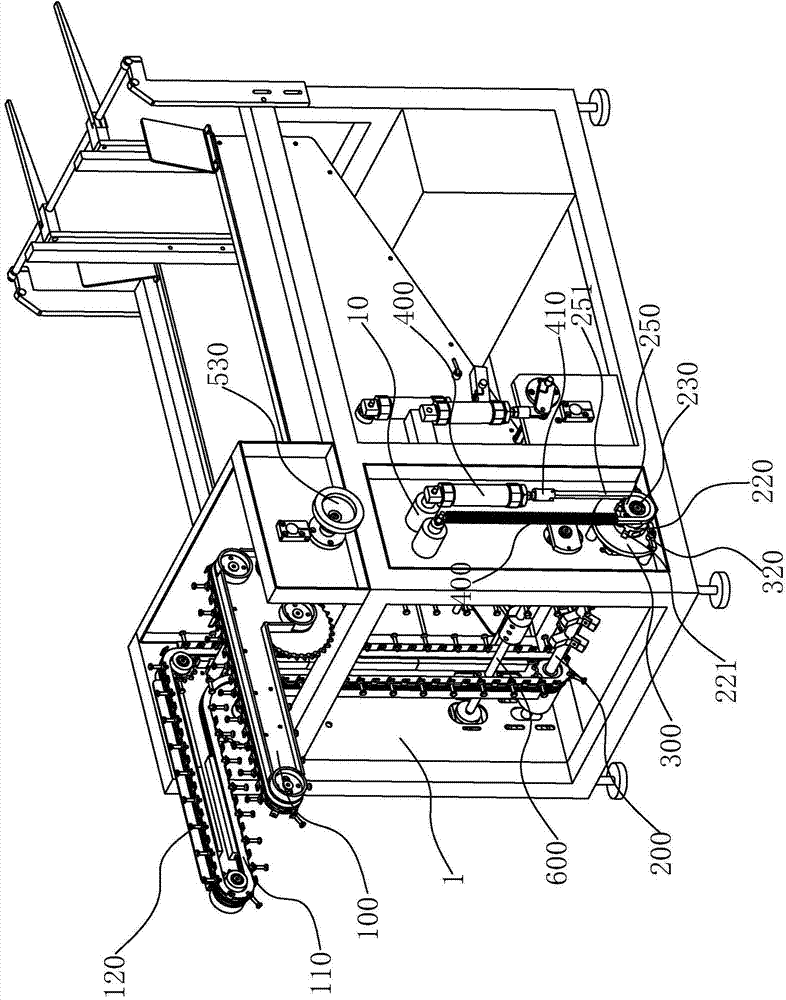

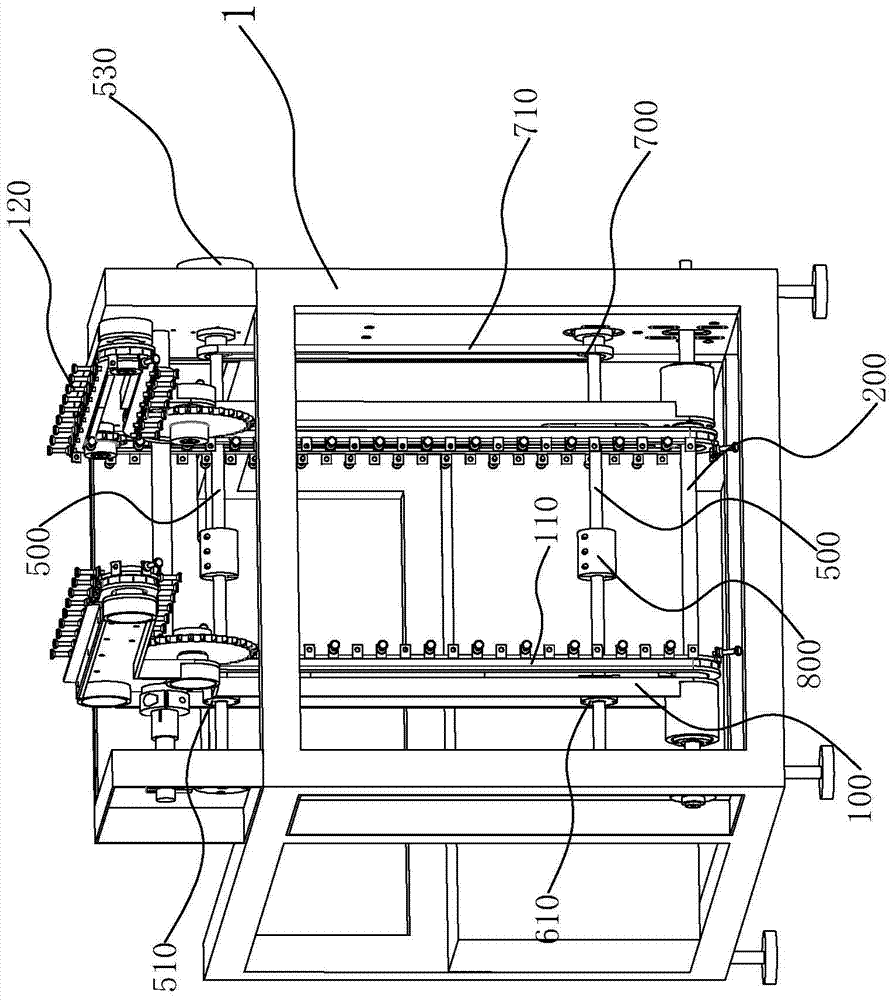

[0035] Such as Figure 1 to Figure 4 As shown, a one-way adjustable chain conveying mechanism of the present invention is installed on the frame 1, and includes two vertical and parallel chain plate frames 100 and a transmission shaft 200 passing through the two chain plate frames 100, and the two chain plate frames 100 is located in the frame, conveyor chains 110 are installed on the two chain plate frames 100 respectively, the two ends of the transmission shaft 200 are connected with the frame 1 respectively, and two ends in the frame are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com