A new energy lithium battery pack auxiliary welding device

A lithium battery pack and auxiliary welding technology, applied in auxiliary devices, auxiliary welding equipment, welding equipment, etc., can solve problems such as low work efficiency, safety problems, and easy swinging of nickel sheets, so as to facilitate removal and improve welding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

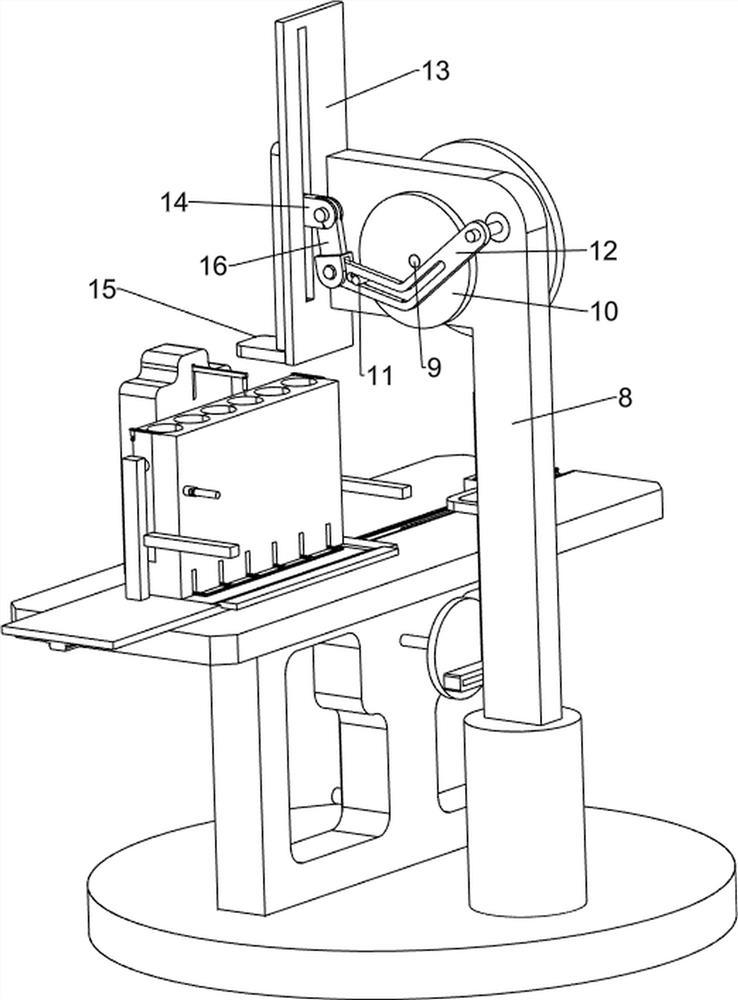

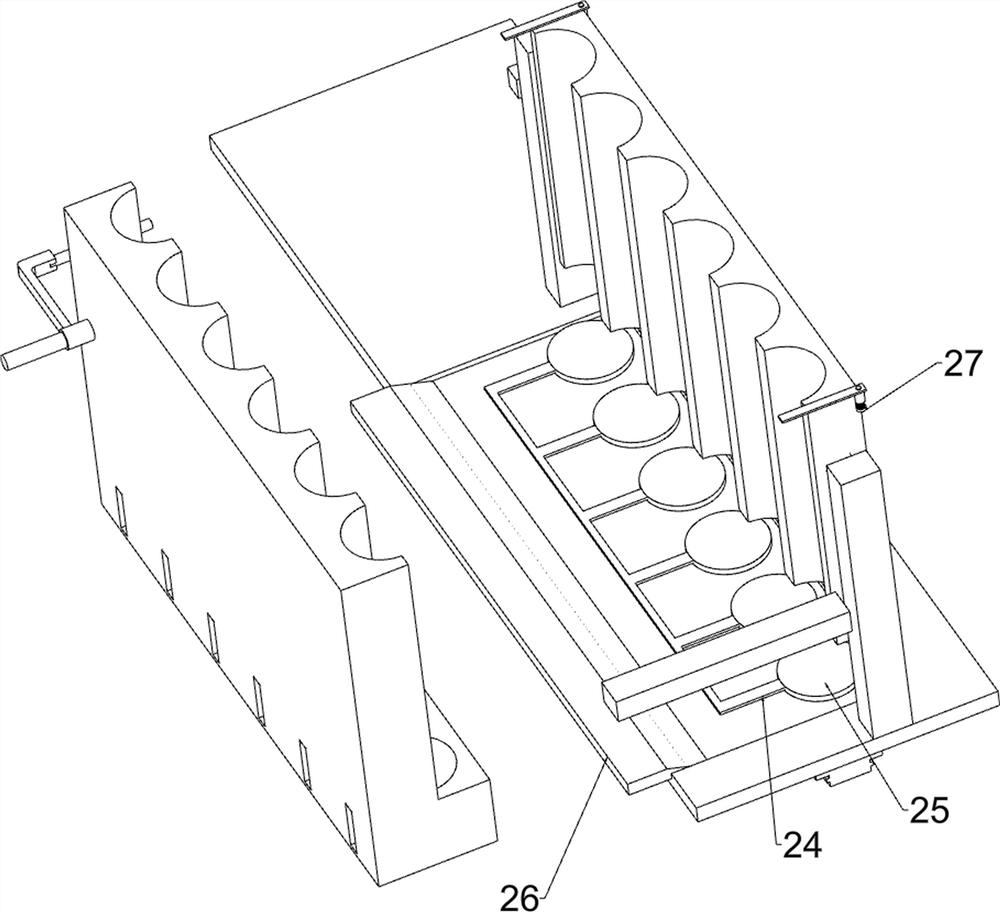

[0027] Such as figure 1 As shown, an auxiliary welding device for a new energy lithium battery pack includes a base 1, a workbench 2, a sliding plate 4, an intermittent moving device 5, a welding machine 6 and a placement device 7, and a workbench 2 is arranged in the center of the top of the base 1. There is a straight chute 3 in the center of the top of the workbench 2, and a sliding plate 4 is installed in the straight chute 3, and an intermittent moving device 5 is arranged on the side wall of the workbench 2. The intermittent moving device 5 cooperates with the sliding plate 4, and the workbench 2. A welding machine 6 is arranged in the middle of the front side of the top, and a placing device 7 is arranged on the top of the sliding plate 4, and the placing device 7 cooperates with the welding machine 6.

[0028] When needing to make a lithium battery pack, the staff places a certain amount of lithium battery negative poles upwards in the placement device 7, and then plac...

Embodiment 2

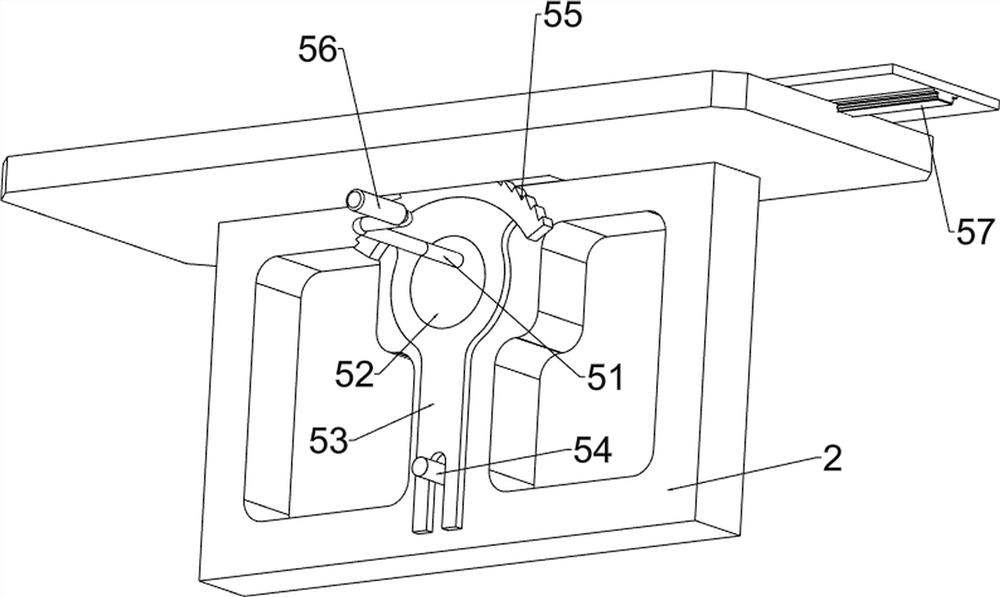

[0030] Such as figure 1 , figure 2 with image 3 As shown, the intermittent moving device 5 includes a first rotating shaft 51, a cam 52, a swing plate 53, a guide shaft 54, a toggle tooth 55, a rocking handle 56 and a damping strip 57, and the side wall of the workbench 2 is provided with the first rotating shaft in a rotational manner. 51, the first rotating shaft 51 is provided with a cam 52, and the position of the outer wall of the cam 52 is fitted with a swing plate 53 in an interference fit. The central axis and the central axis of the first rotating shaft 51 are in the same vertical plane, the square groove under the swing plate 53 is slidably matched with the guide shaft 54, the top of the swing plate 53 is provided with a toggle tooth 55, and the workbench directly above the toggle tooth 55 There is a square hole at the 2 position, a crank handle 56 is provided at the front end of the first rotating shaft 51, a damping bar 57 is provided at the bottom of the slidi...

Embodiment 3

[0034] Such as Figure 4 , Figure 5 As shown, on the basis of Embodiment 2, a new energy lithium battery pack auxiliary welding device also includes a second support frame 8, a rotating shaft 9, a first turntable 10, a first sliding shaft 11, and a folded plate 12. , chute plate 13, sliding block 14, pressing plate 15 and connecting rod 16, the position in the middle of the rear side of the top of the base 1 is provided with a second support frame 8, and the rotation type on the second support frame 8 is provided with a rotating shaft 9, and the right end of the rotating shaft 9 A first turntable 10 is provided, and the right side of the first turntable 10 is eccentrically provided with a first sliding shaft 11, and the upper part of the rear side of the right side wall of the second support frame 8 is rotatably provided with a folded plate 12, which is opened on the folded plate 12. There is a chute, the first sliding shaft 11 is slidably matched with the chute in the foldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com