Orderly harvesting and conveying device for stem leaf vegetables

A technology for conveying devices and stems and leaves, which is applied in the field of orderly harvesting conveying devices and vegetable harvesting machinery. It can solve the problems of impractical harvesting of stems and leaves vegetables, complex structure of machinery and tools, disordered and disordered leaf vegetables, etc., and achieve outstanding substantive Features, increased conveying density, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

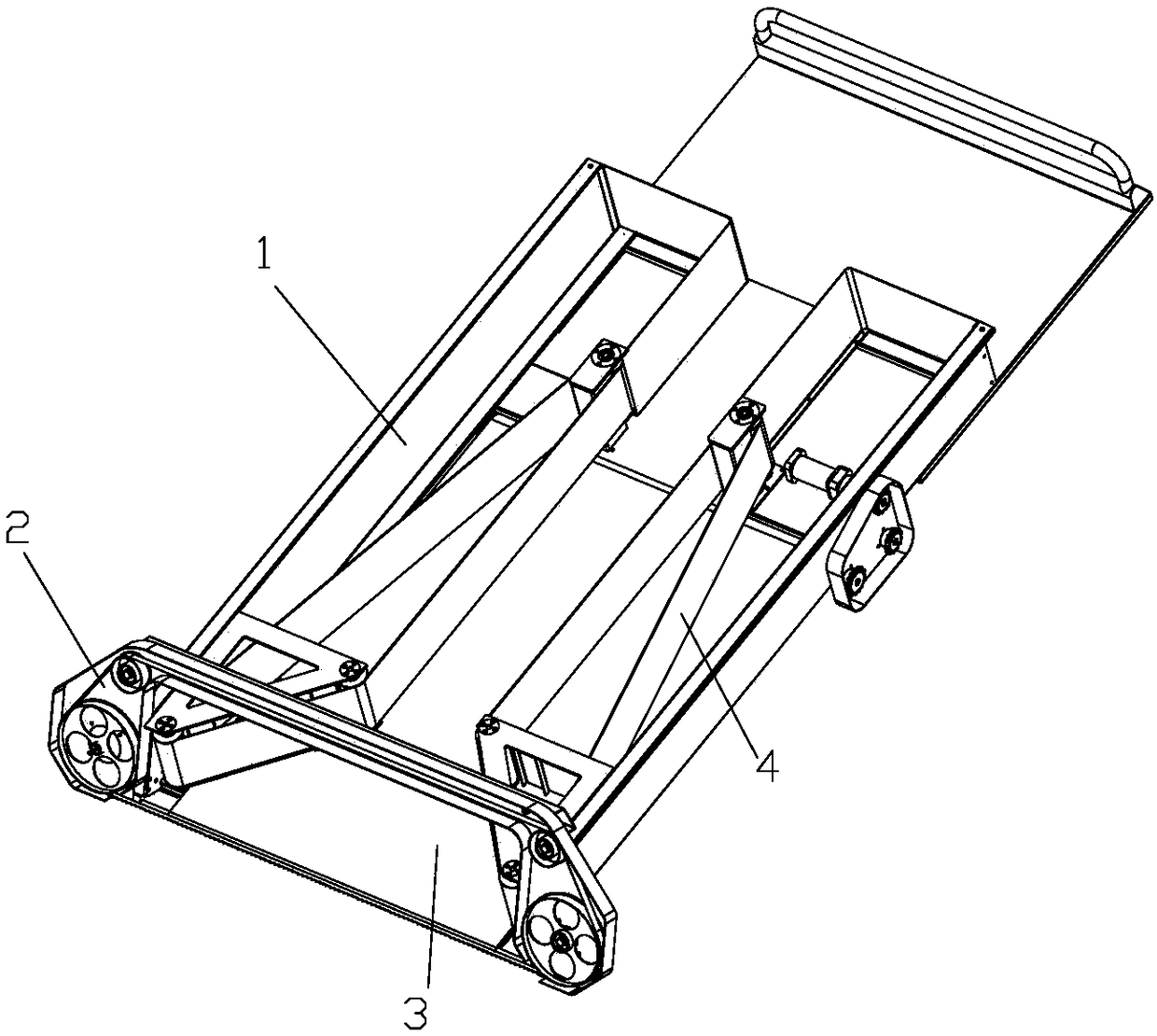

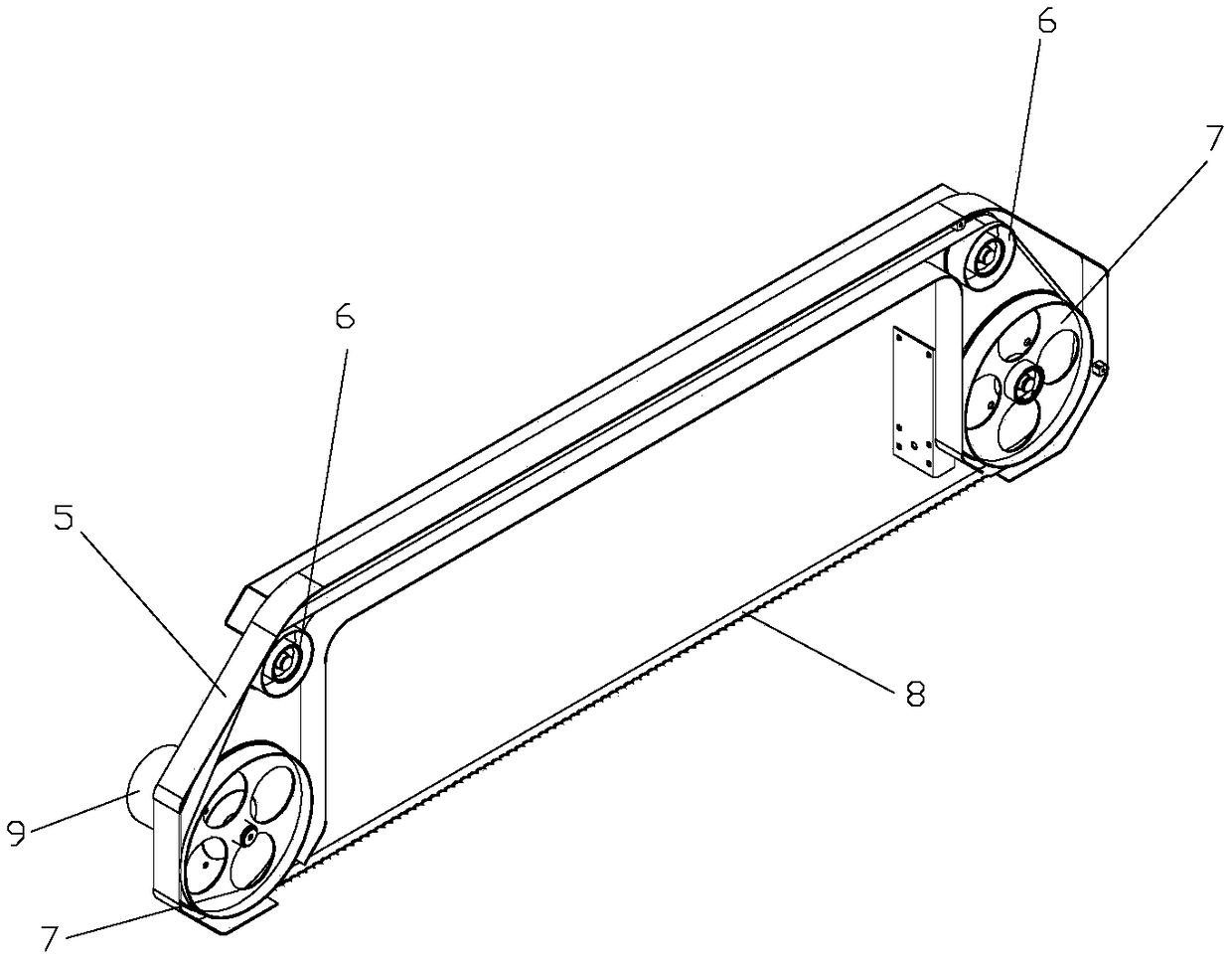

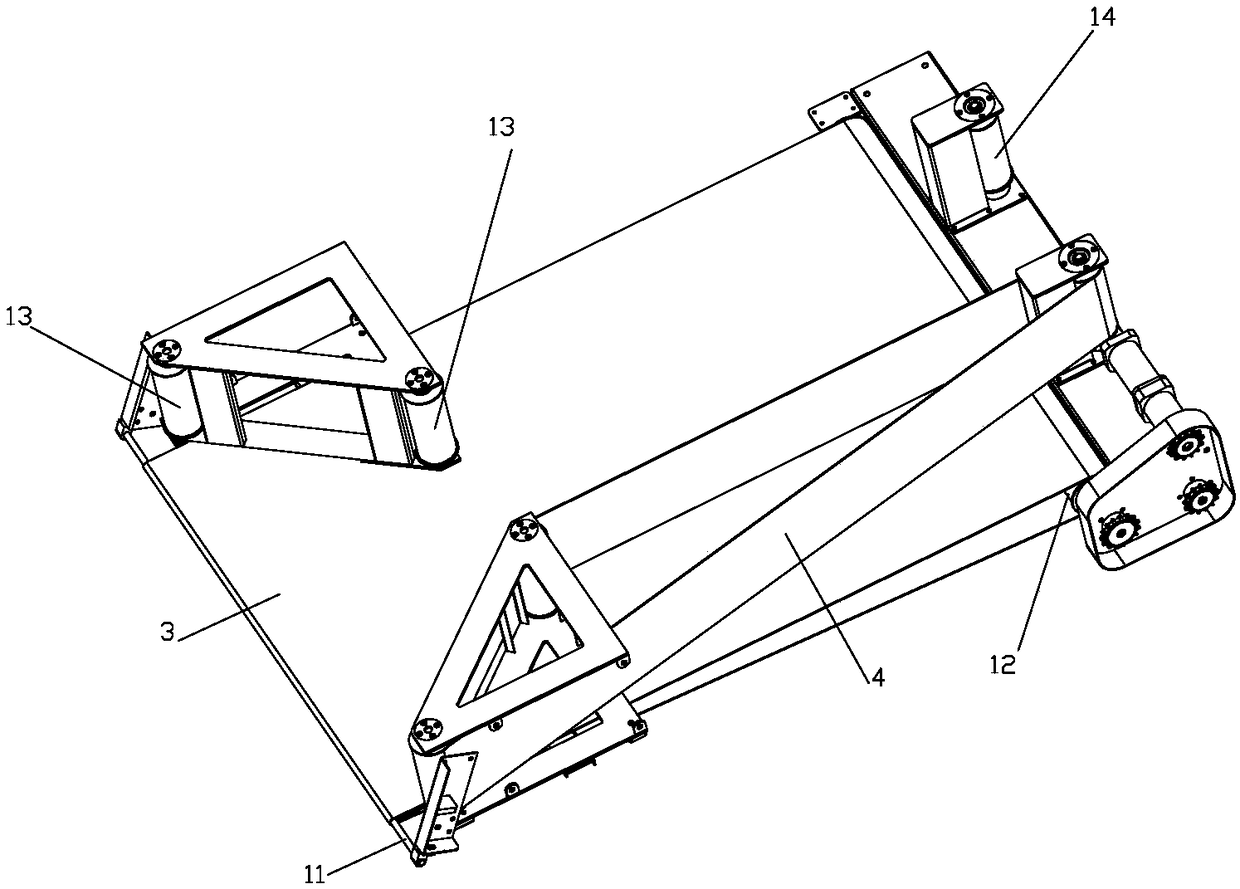

[0020] figure 1 It is a structural schematic diagram of the delivery device for ordered harvesting of stem and leaf vegetables in this embodiment. The device is mainly composed of a frame 1, a cutting device 2 installed on the frame 1 and a conveying device. The conveying device includes a rotary bottom conveyor belt 3 and a rotary side conveyor belt 4. The front end of the bottom conveyor belt 3 is located at the cutting device. After 2 and inclined to the rear and upward, the side conveyor belt 4 is arranged above the bottom conveyor belt 3, forming a Y-shaped conveying channel with a shrinking entrance with the bottom conveyor belt 3, and its entrance width is the same as that of the cutting device 2 , and run at the same linear speed as the bottom conveyor belt 3 . The ratio of the front end width to the rear end width of the shrinkage entrance formed by the side conveyor belts 4 on both sides is 3:1, and the opening angle of the shrinkage entrance is 80° 0 , the width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com