A material-pressing guide mechanism for garment cutting equipment

A technology of guiding mechanism and equipment, applied in the field of garment machinery, can solve the problems of irregular cutting by laser cutting machine, inaccurate blanking of fabrics, and non-compliance of fabrics with specifications, so as to reduce equipment maintenance costs, facilitate cutting, and avoid mutual influence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

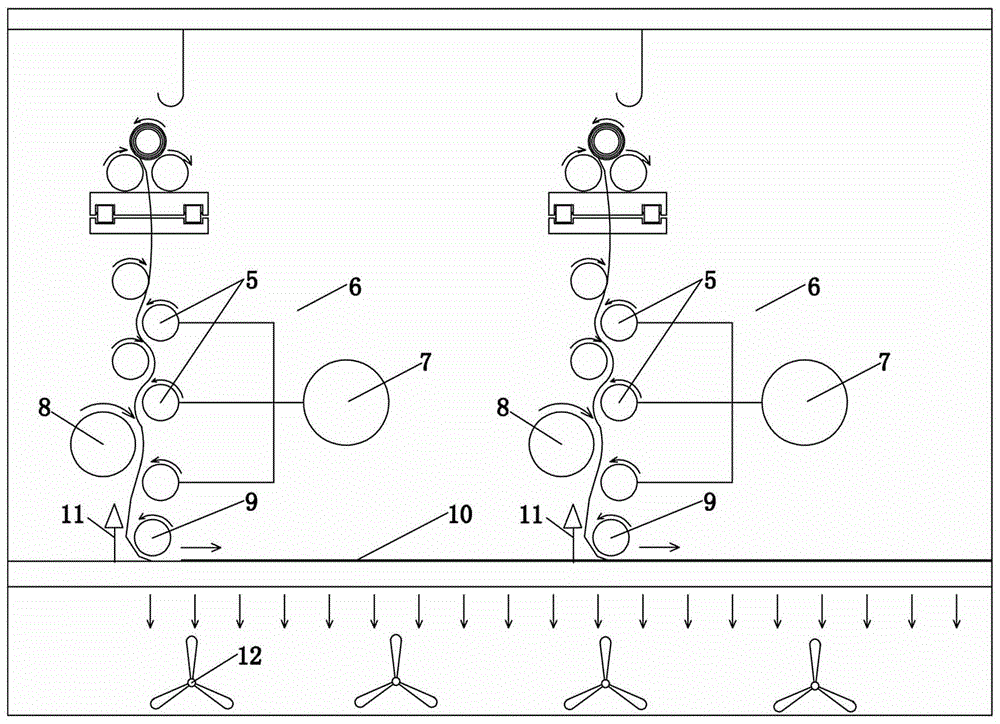

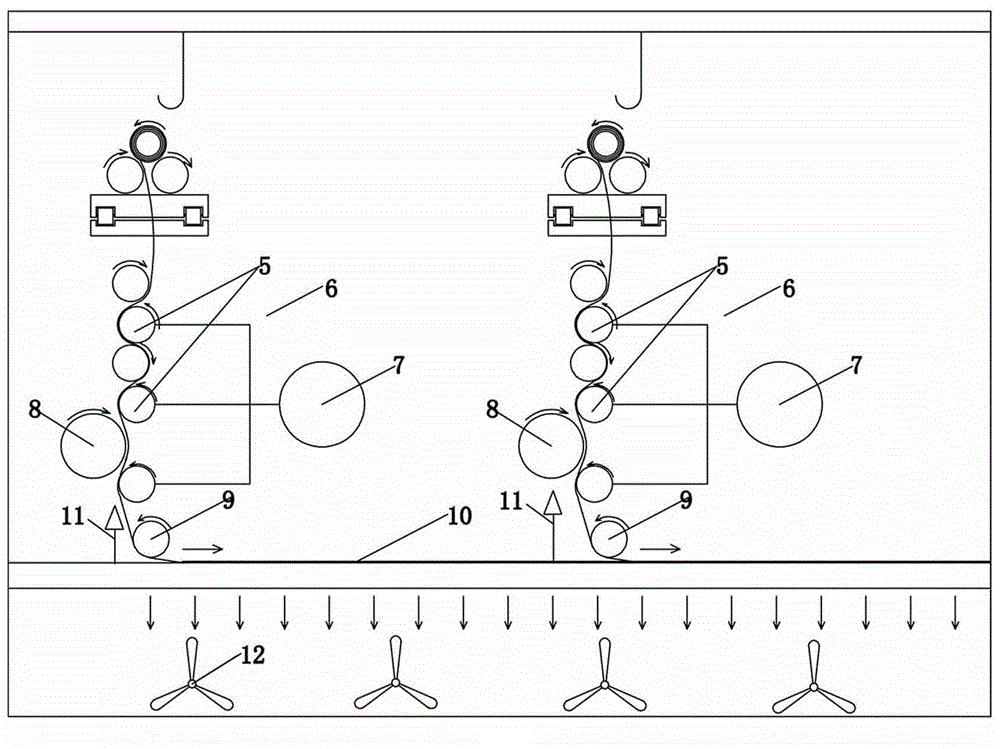

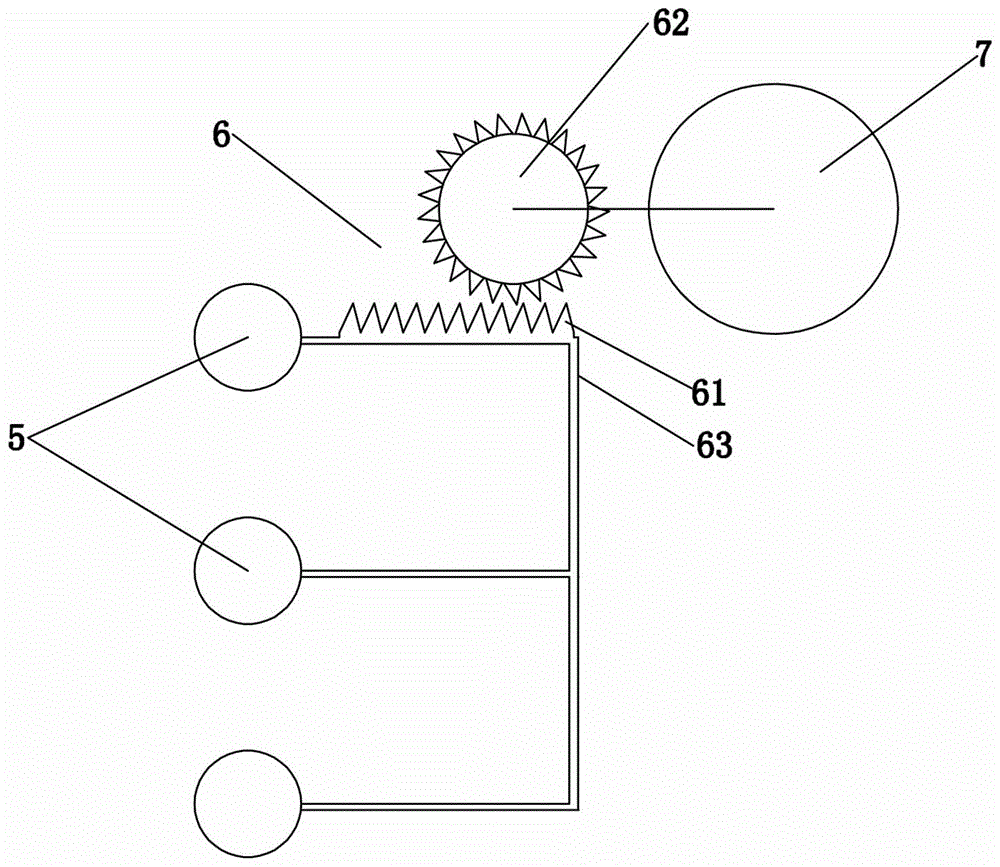

[0021] Example 1, such as Figure 1 to Figure 5 As shown, a garment cutting device includes a plurality of pressing guide mechanisms, one pressing guide mechanism represents a station, and the pressing guide mechanism includes an opening roller 8, a guide roller 9, a mesh chain 10, and three parallel And the tension roller 5 that is arranged horizontally and the drive assembly 6 that drives the tension roller 5 to move laterally so that the tension roller 5 and the opening roller 8 are vertically staggered, and the opening roller 8 and the adjacent tension roller The rollers 5 are parallel to each other and rotate in opposite directions, and the guide roller 9 is arranged below the opening roller 8 and above the web chain 10 .

[0022] As a more specific technical solution of the present invention.

[0023] The opening roll 8 includes a plurality of equal-diameter arc-shaped sheets 81 and a roll shaft 82, and the arc-shaped sheets 81 are attached to the outer surface of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com