Paper bag transfer mechanism of feeding device

A technology of conveying mechanism and paper bag, applied in the field of paper bag processing, can solve problems such as unreasonable gas distribution and transmission, operation failure of paper suction components, etc., and achieve the effect of reducing interference, orderly conveying and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

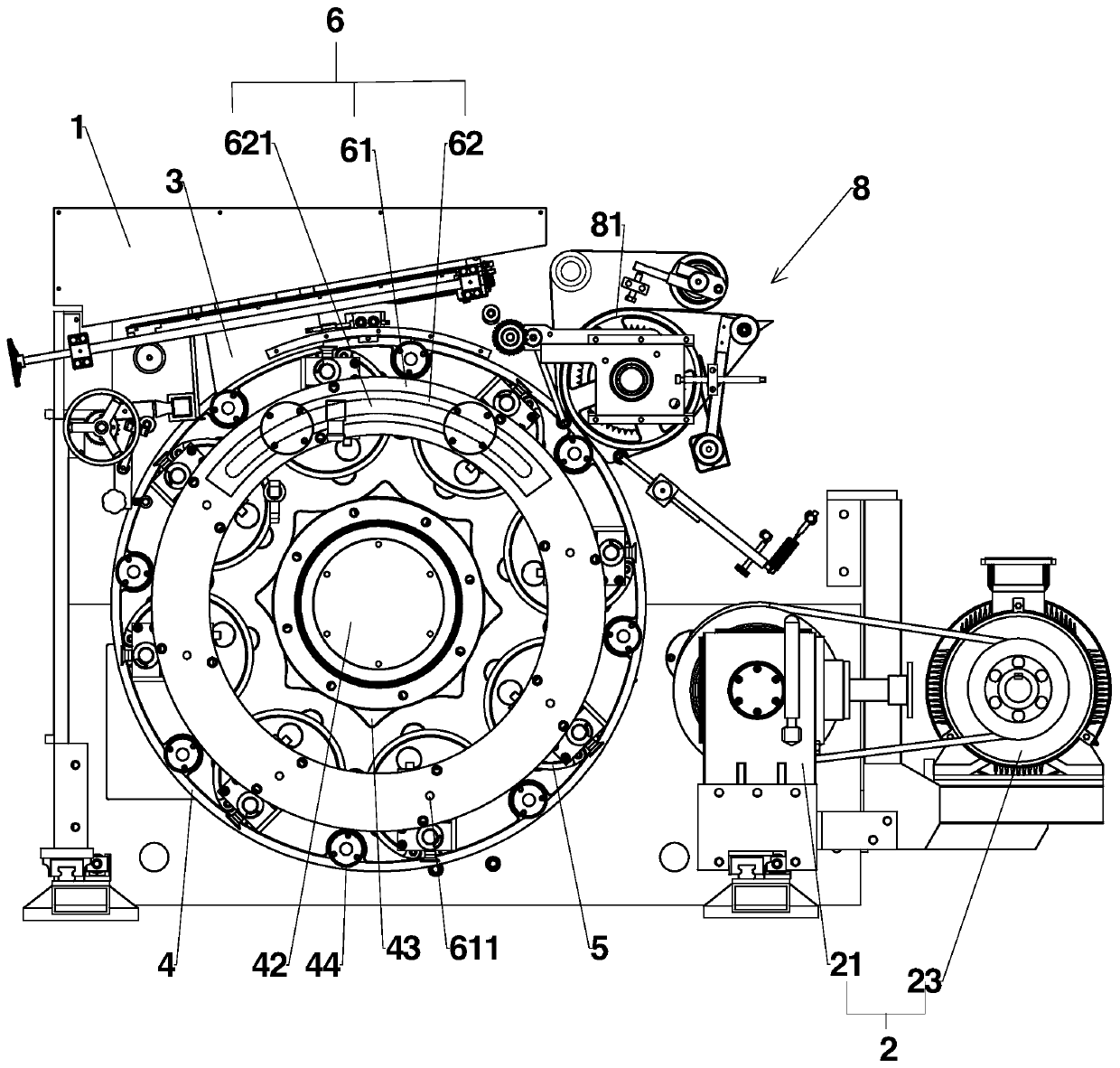

[0036] refer to figure 1 , is a paper bag automatic feeding device disclosed by the present invention, comprising a frame 1, the frame 1 is provided with a drive mechanism 2, and a turntable 4 and a paper suction assembly 5 driven by the drive mechanism 2; the frame 1 The upper side is provided with a bin 3 for placing paper bags, and the other side above the frame 1 is provided with a discharge mechanism 8 .

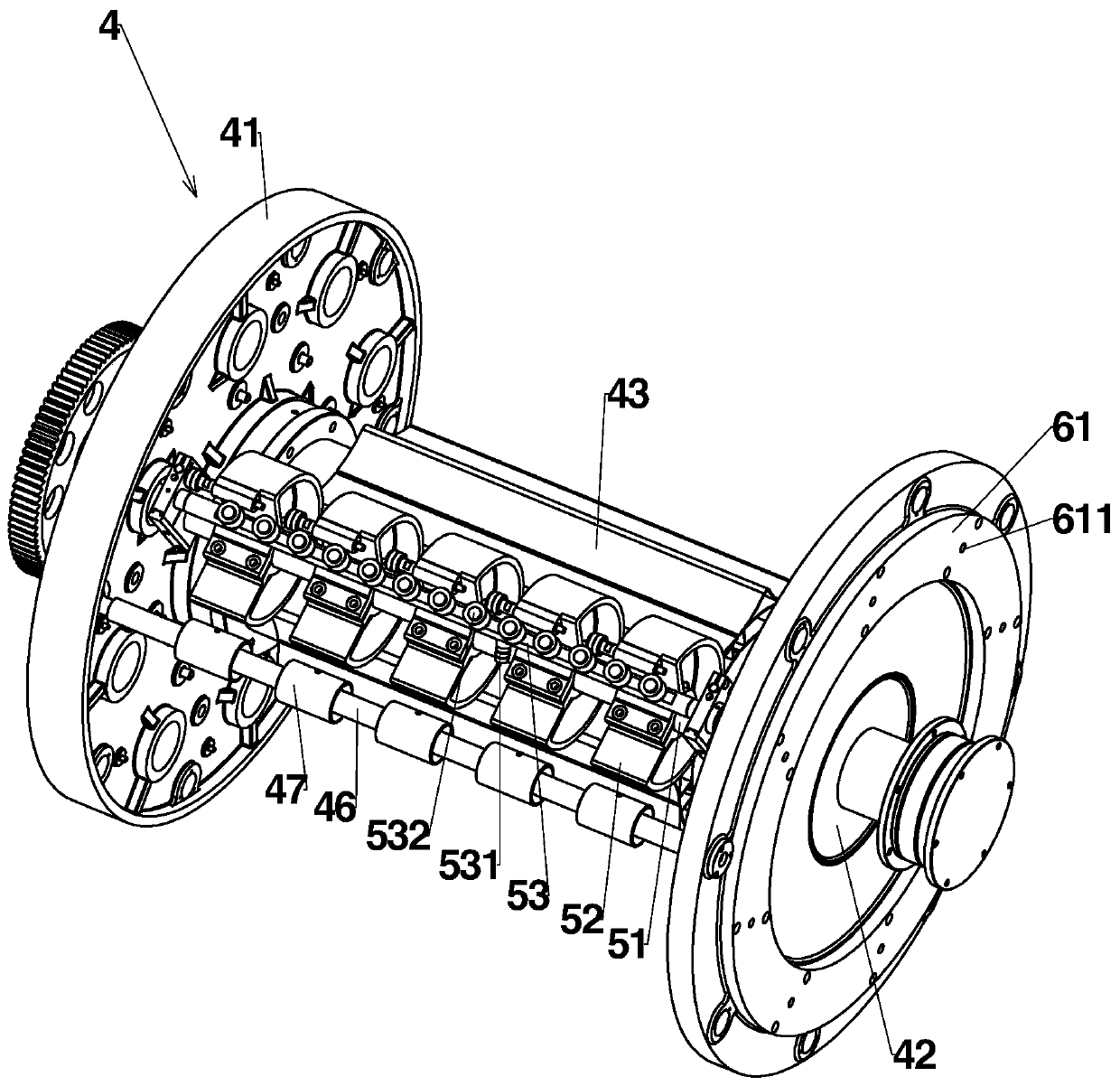

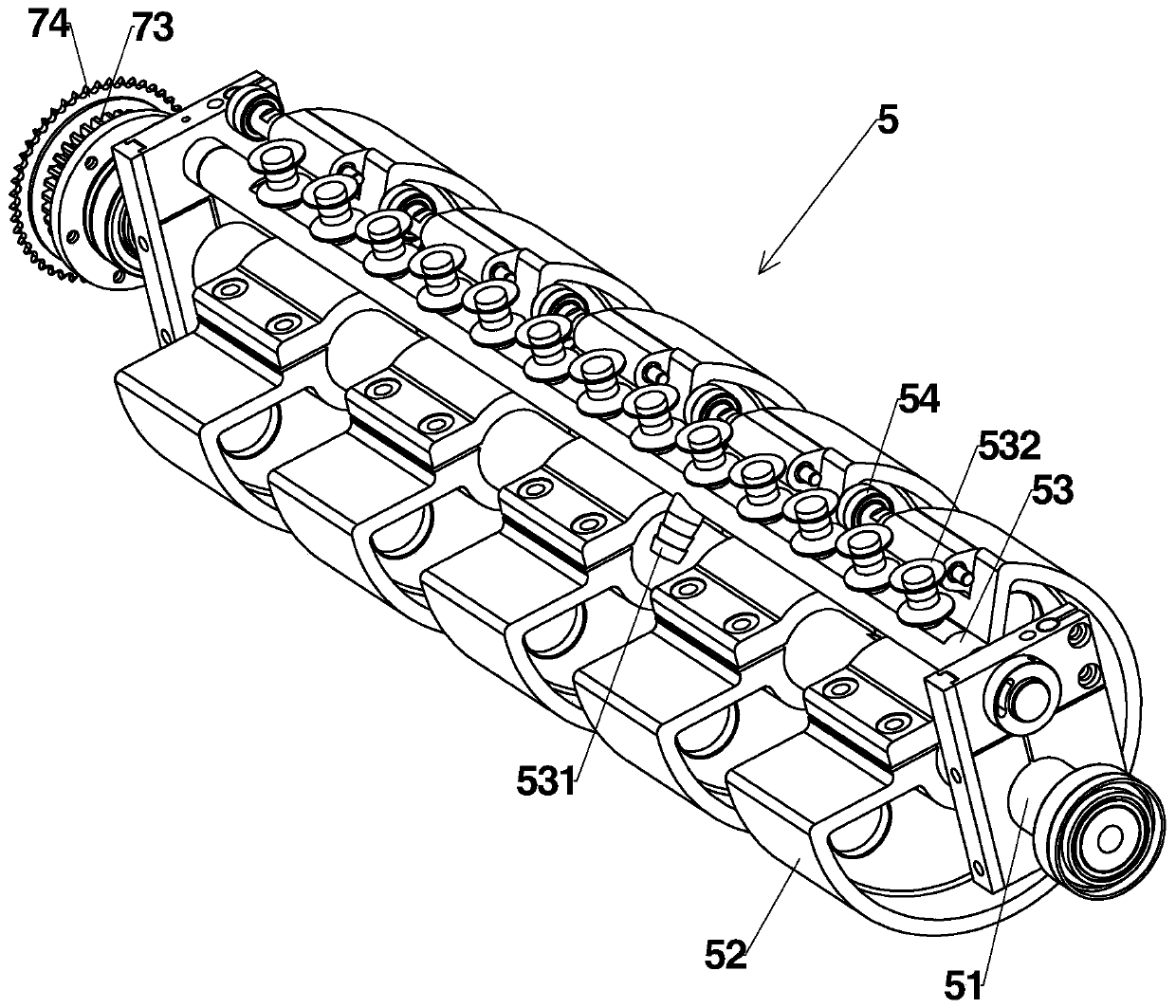

[0037] Such as figure 1 The shown paper suction assembly 5 is provided with eight groups, and the eight groups of paper suction assemblies 5 are evenly arranged around the rotation center circumference of the turntable 4, and the paper suction assembly 5 is rotatably arranged on the turntable 4; the turntable 4 is also provided with a rotatable support There are eight sets of shafts 46 and supporting shafts 46, and the supporting shafts 46 are locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com