Warp tension adjusting mechanism for weaving functional polyester fabric

A warp tension adjustment and functional technology, applied in looms, textiles, papermaking, textiles, etc., can solve the problems of increased device complexity and low tension adjustment efficiency, and achieve improved tension adjustment efficiency, increased adjustable range, The orderly effect of warp delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

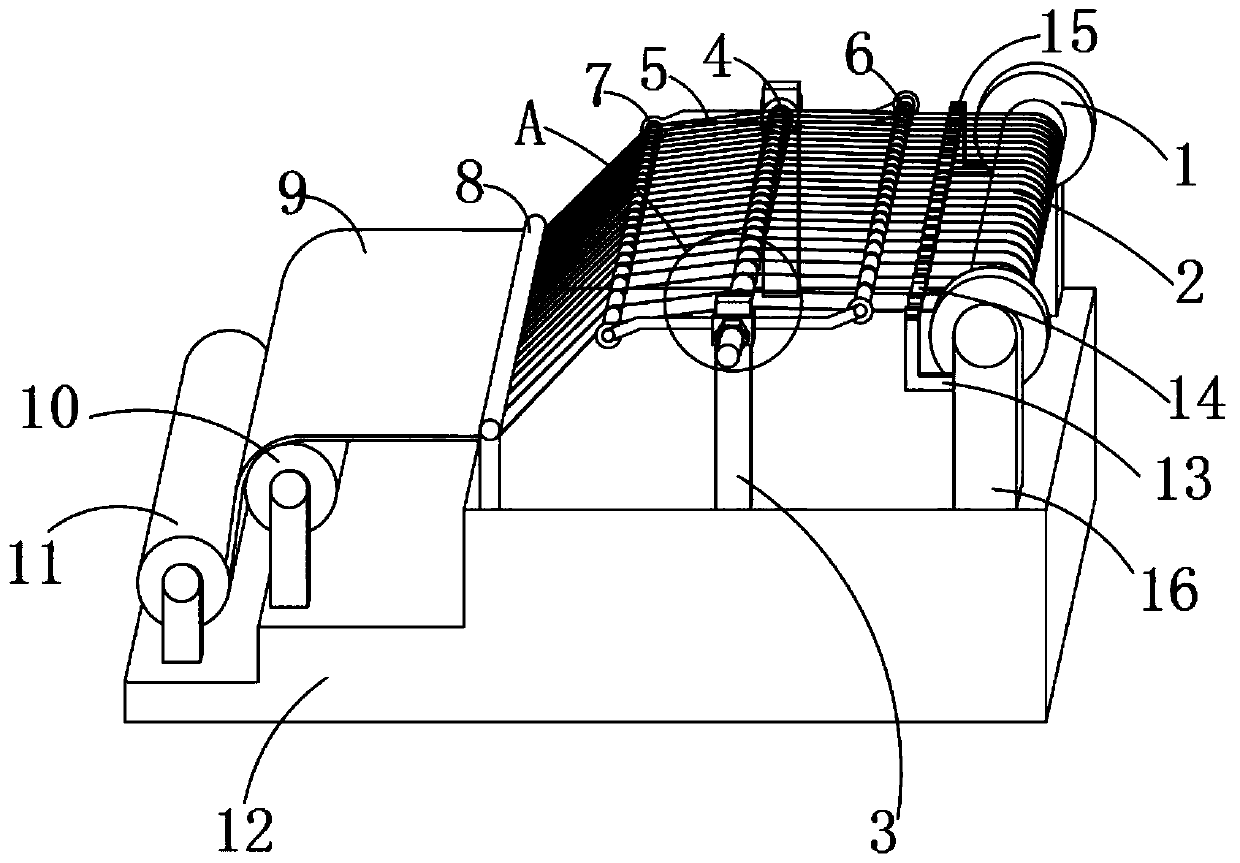

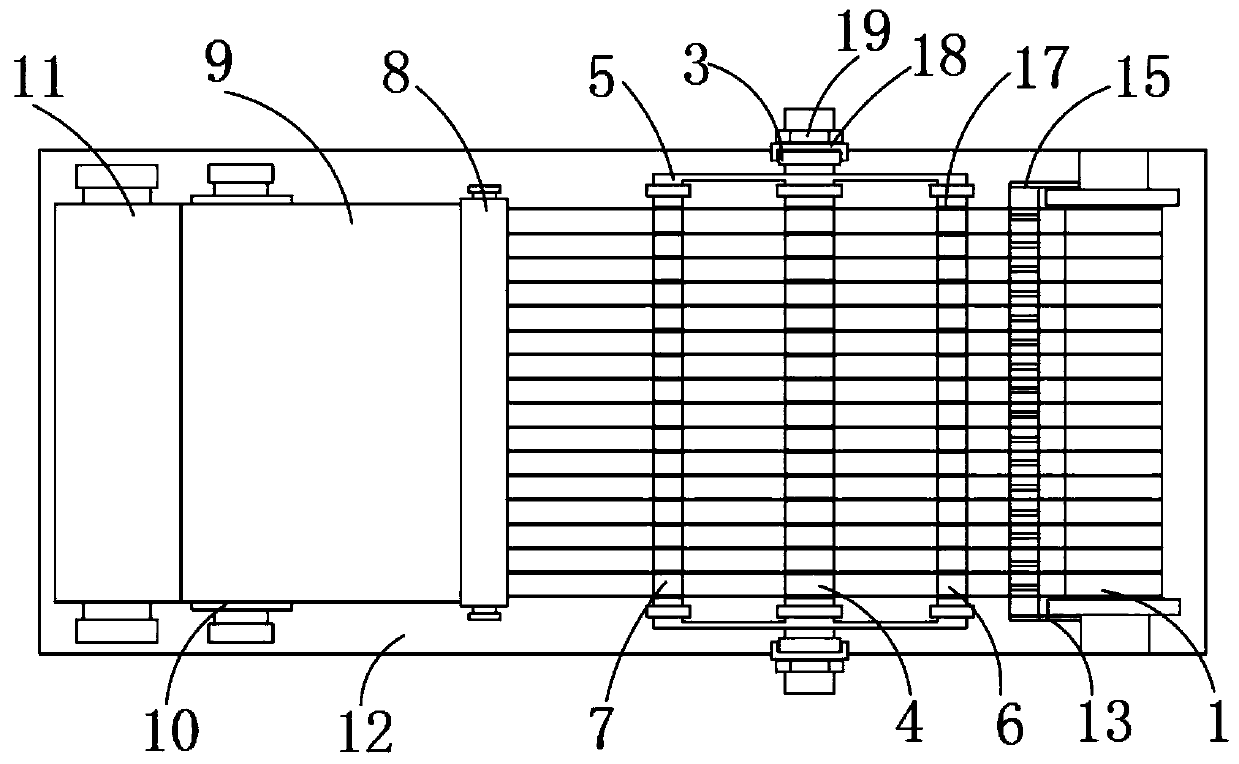

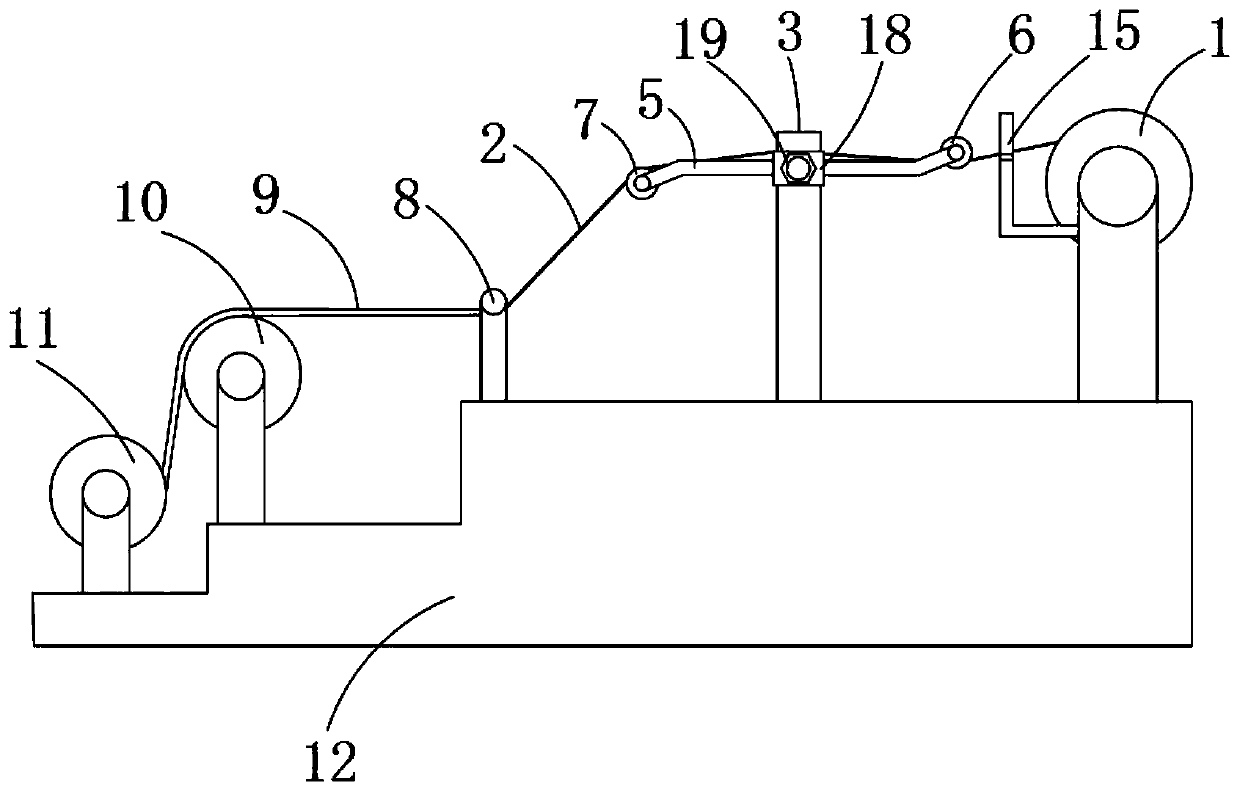

[0024] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a warp tension adjustment mechanism for weaving functional polyester fabrics, including a fixed base 12, a number of fixed plates 16 are welded to the top of the fixed base 12, and the tops of the two fixed plates 16 pass through the rotating shaft The yarn collection roller 1 is rotatably connected, the outer end surface of the yarn collection roller 1 is wound with warp yarn 2, and the top of the fixed base 12 is welded with two support frames 3, and the tops of the two support frames 3 are embedded with a rotating rod 4, and the rotating rod 4 The two ends of both ends are equipped with clamping plate 18, in order to facilitate the connection of clamping plate 18 and rotating rod 4, the middle part of clamping plate 18 is provided with a circular hole, rotating rod 4 is embedded in the clamping plate 18 through the circular hole, rotating rod 4 The two ends are threadedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com