Feeding device of irregular workpiece automatic processing machine tool

A special-shaped workpiece, automatic processing technology, applied in the direction of metal processing, etc., can solve the problems of special-shaped workpiece rotation, special-shaped workpiece clamping, and the material cannot be pushed smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

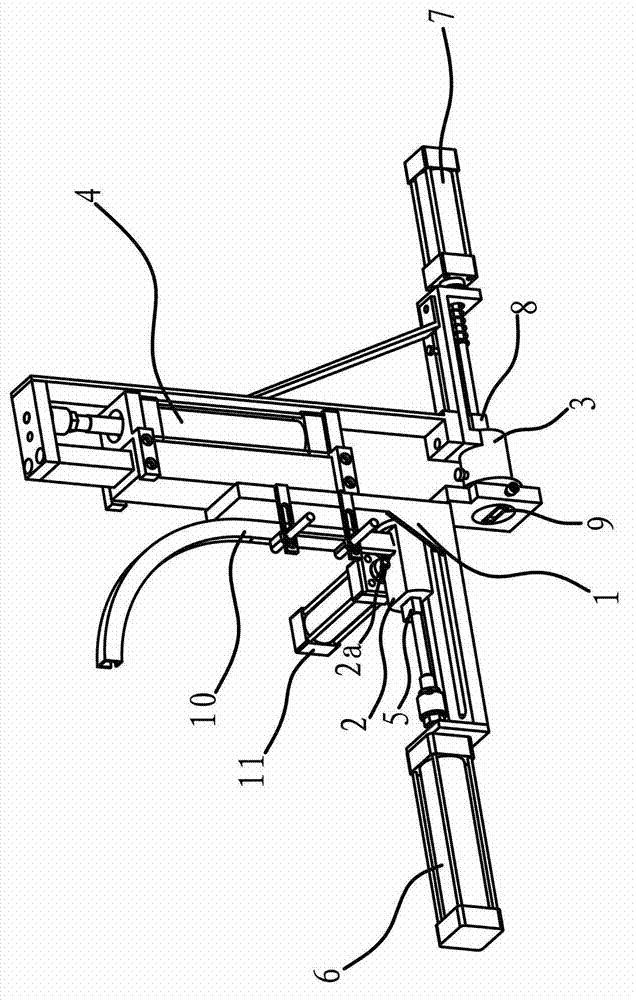

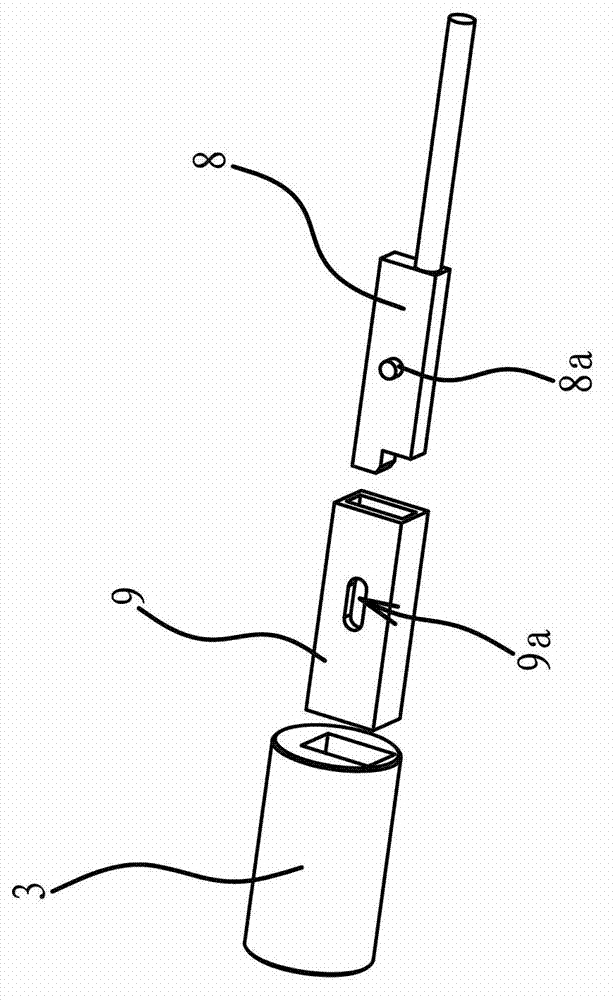

[0039] Such as Figures 1 to 4 As shown, a feeding device for an automatic processing machine tool for special-shaped workpieces includes a bracket 1 on which a cylindrical rear splicing sleeve 2 is fixed, and the rear splicing sleeve 2 has a feed port 2a positioned at its side and a The discharge opening at its end, the side wall of the rear joint material sleeve 2 has a plane parallel to the axis of the rear joint material sleeve 2, the feed port 2a is located at the plane and the opening direction of the feed port 2a is in line with the plane. It is vertically arranged, and the side wall of the rear splicing sleeve 2 is also fixedly connected with a jacking cylinder 11. On the side wall, the piston rod of the jacking cylinder 11 can press the special-shaped workpiece against the feeding port 2a. The cavity of the rear material sleeve 2 is provided with a rear push rod 5, and the support 1 is provided with a cylinder-6 that can drive the rear push rod 5 to reciprocate trans...

Embodiment 2

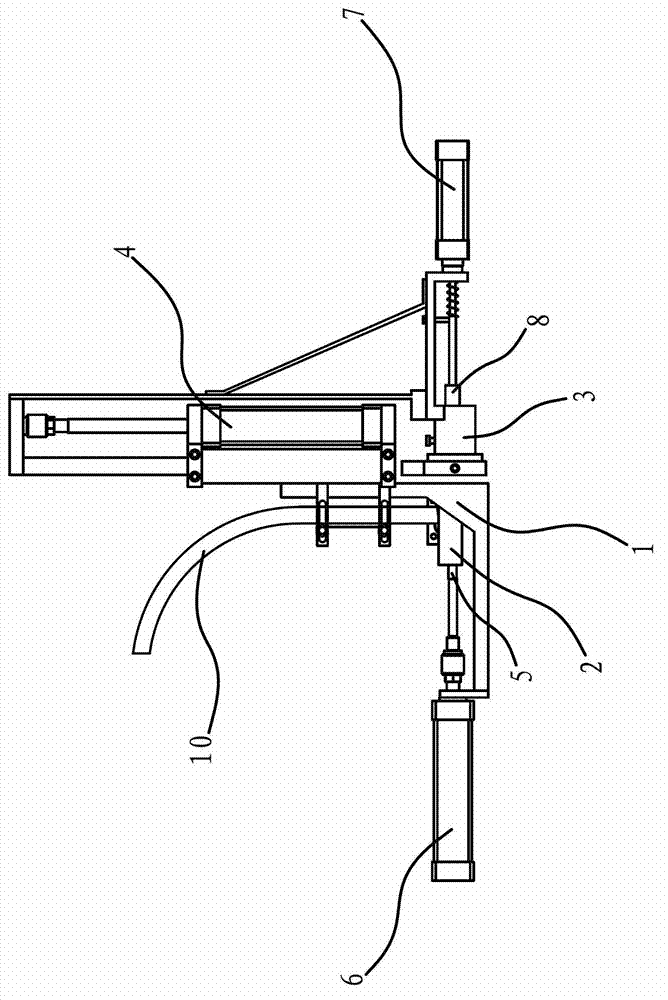

[0048] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figures 5 to 7 As shown, a feeding device for an automatic processing machine tool for special-shaped workpieces includes a bracket 1 on which a cylindrical rear splicing sleeve 2 is fixed, and the rear splicing sleeve 2 has a feed port 2a positioned at its side and a The discharge opening at its end, the side wall of the rear joint material sleeve 2 has a plane parallel to the axis of the rear joint material sleeve 2, the feed port 2a is located at the plane and the opening direction of the feed port 2a is in line with the plane. It is vertically arranged, and the side wall of the rear splicing sleeve 2 is also fixedly connected with a jacking cylinder 11. On the side wall, the piston rod of the jacking cylinder 11 can press the special-shaped workpiece against the feeding port 2a. The cavity of the rear material sleeve 2 is provided with a rear push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com