Multi-stage screening limit feeding device and method

A feeding device and position-limiting technology, which is applied in the field of multi-stage screening limit-feeding devices, can solve the problems of inability to separate potatoes, inability to position them separately, inability to differentiate treatment of seed potatoes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

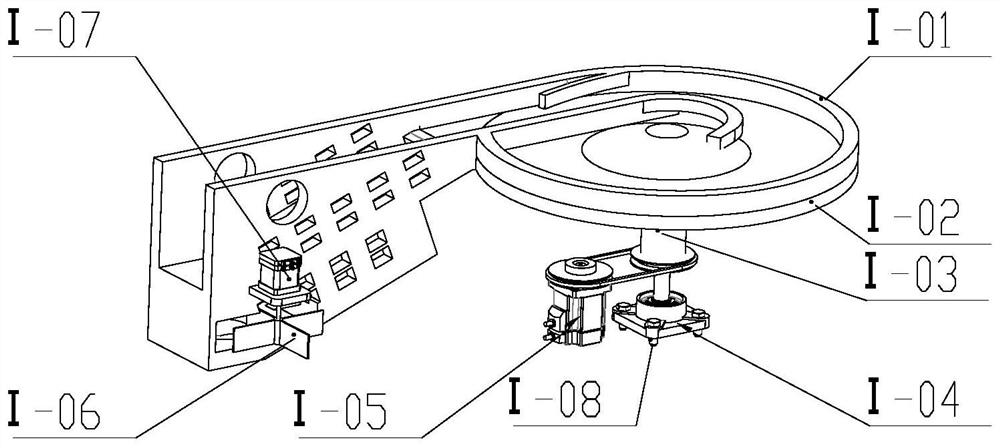

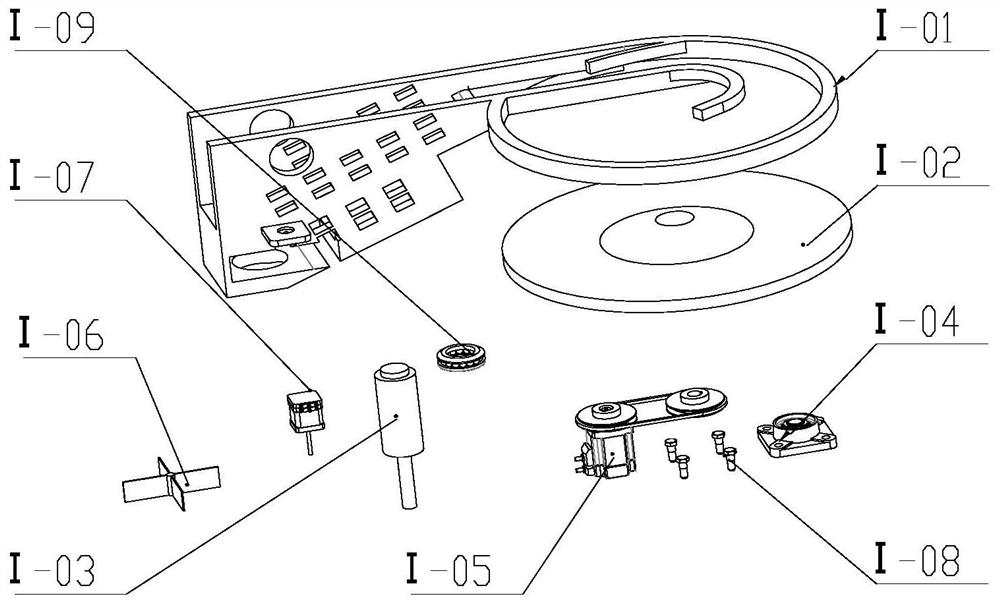

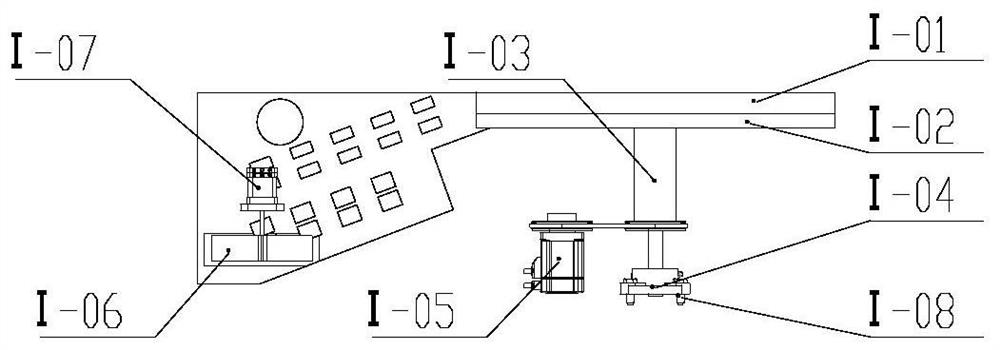

[0058] Attached below Figure 1-Figure 17 The present invention is described in detail, specifically, the structure is as follows:

[0059] This embodiment provides a multi-stage screening limit feeding device, such as Figure 1-Figure 5 As shown, it includes the limit track I-01, the bearing plate I-02, the driving device, and the limit mechanism. The bearing plate I-02 is installed under the head end of the limit track I-01. 02 connected; the limit mechanism is fixed on the side of the drop opening at the end of the limit track I-01.

[0060] Specifically, the limiting track I-01 includes an outer baffle I-0101, an inner baffle I-0102, a first sorting track I-0105, a second sorting track I-0106, a first ramp I- 0111, the second ramp Ⅰ-0110, such as Figure 4 and Figure 8 As shown, the outer baffle I-0101 includes a first arc portion and a first straight line that are integrally connected, and the inner baffle I-0102 includes a second arc portion and a second straight li...

Embodiment 2

[0077] This embodiment provides a multi-stage screening limit feeding device for sorting potatoes, specifically, such as Figure 18-Figure 22As shown, the potatoes enter the multi-stage screening limit feeding device described in Example 1, and the structure of driving the transmission shaft I-03 to rotate through the power device to drive the rotation of the carrier plate I-02 provides friction to the potatoes. Any one of the two ends of the long axis of the potato, so according to the translation theorem of force:

[0078] The force acting on the rigid body can be equivalently moved from the original point of action to any point in the rigid body in parallel. At the same time, a force couple is added, and the force couple is the moment of the original force to the new point of action. Get the force and force couple M=l×f1 whose size is the same as f1, and make the potato rotate. Among them, I is the distance from the friction point to the center of gravity of the potato. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com