Aluminum tube double-moving extruding machine gasket recycling device and aluminum tube double-moving extruding machine

A recovery device and extrusion machine technology, applied in the field of aluminum tube extrusion, can solve the problems of heavy workload, lower efficiency of aluminum tubes, and long recycling cycle, etc., and achieve the effects of compact structure, improved production efficiency, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

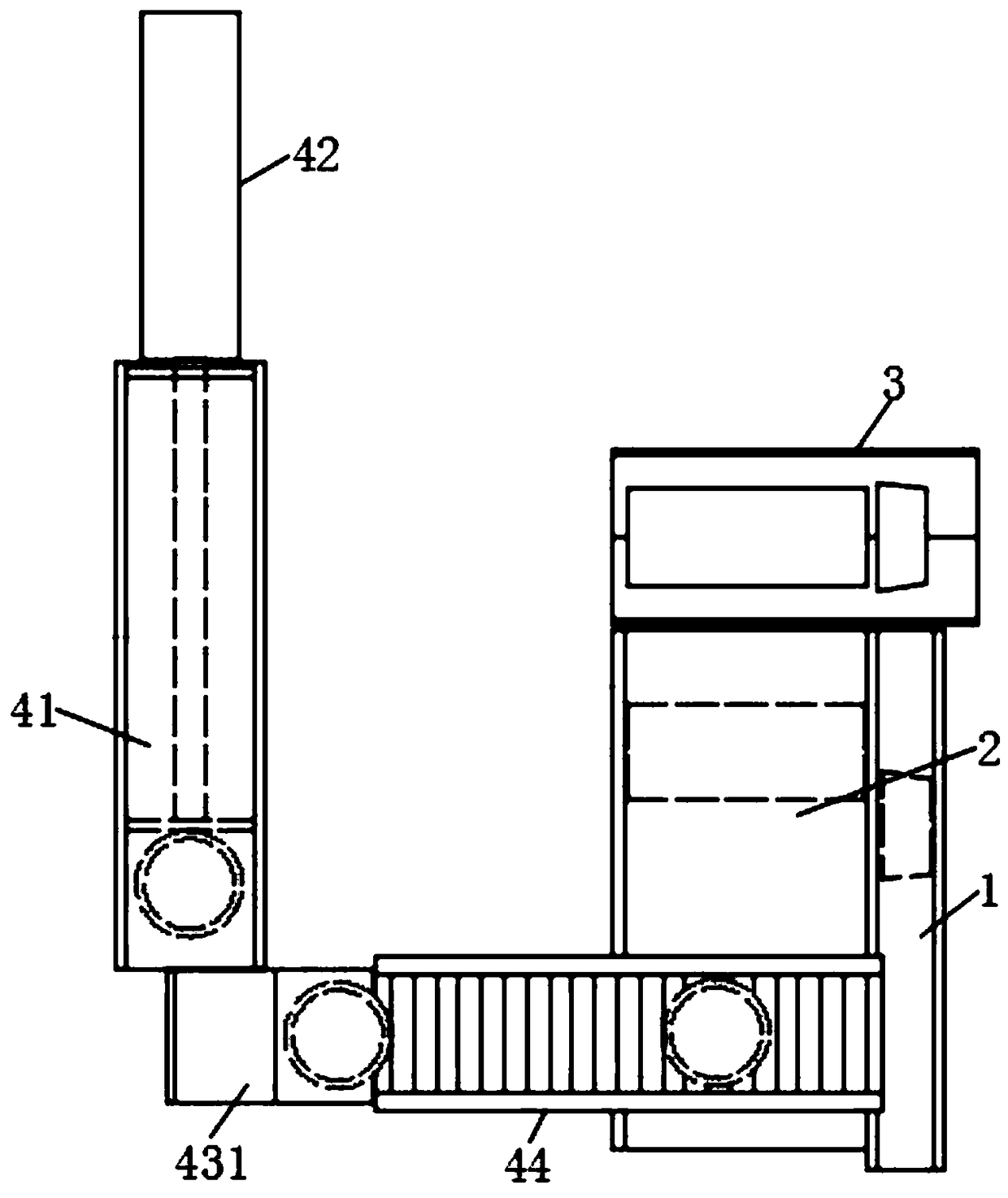

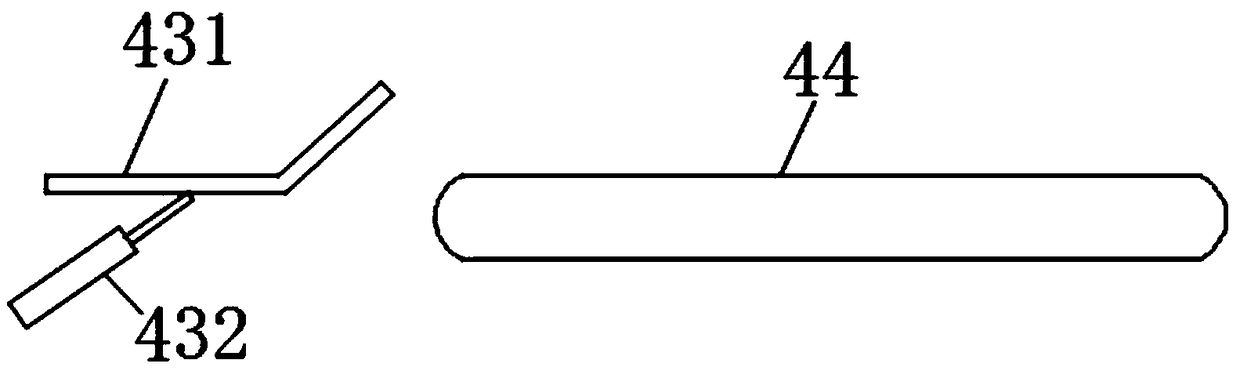

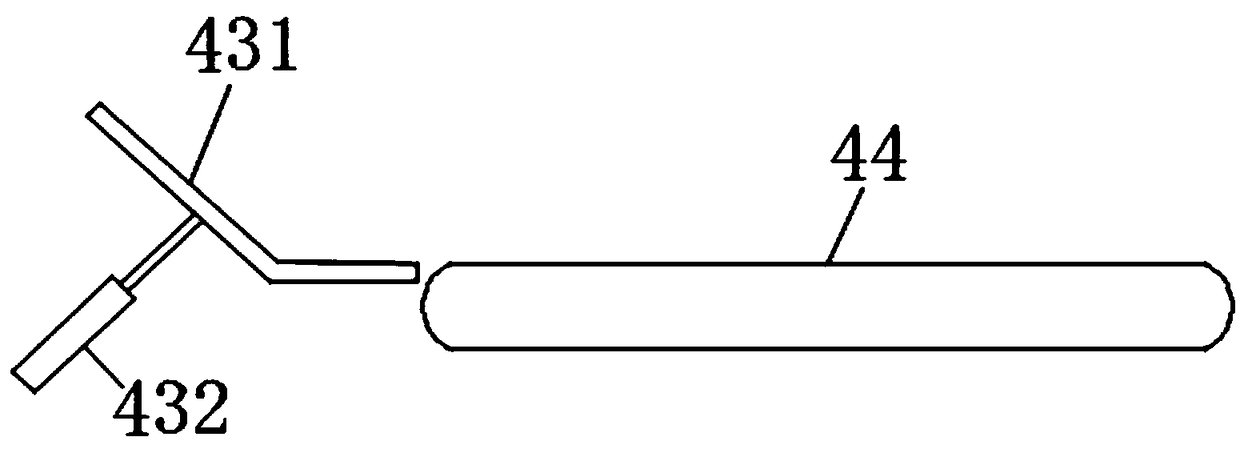

[0042] Example one: such as figure 1 As shown, this embodiment provides a gasket recovery channel 1, an aluminum rod transportation channel 2, an ingot supply slot 3, and a gasket connection recovery mechanism 4;

[0043] The two ends of the above-mentioned gasket recovery channel 1 and the aluminum rod conveying channel 2 are respective feeding ends and discharging ends;

[0044] The above-mentioned spindle supply slot 3 is a strip-shaped slot body with open ends and upper part, which is arranged horizontally and connected with a manipulator, which can drive the above-mentioned spindle supply slot 3 to move up and down;

[0045] In the initial state, the above-mentioned ingot supply groove 3 falls on the ground, and the discharge ends of the above-mentioned gasket recovery channel 1 and the aluminum rod conveying passage 2 respectively extend to the upper end of one side of the above-mentioned ingot supply groove 3, and are connected to the above-mentioned ingot supply groove 3 Conn...

Embodiment 2

[0055] Embodiment two: such as Figure 4 , 5 As shown in 6, this embodiment provides an aluminum tube double-action extruder, which includes an aluminum tube extrusion die 51, an extrusion barrel 52, a double-action extrusion rod 53, and the gasket recovery device in the first embodiment. The aluminum tube extrusion die 51 is vertically arranged, and the middle part has an aluminum tube extrusion hole passing through it horizontally. The extrusion cylinder 52 is horizontally and spaced at one end of the aluminum tube extrusion die 51, and the middle part is provided with horizontally passing through it. And the extrusion channel corresponding to the aluminum tube extrusion hole, the dual-action extruder can drive the extrusion cylinder 52 to move horizontally to abut or move away from the aluminum tube extrusion die 51, the dual-action extrusion rod 53 The extrusion channels are matched and arranged at intervals at one end of the extrusion channel away from the aluminum tube ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com