Presswork die cutting device

A printing and die-cutting technology, applied in metal processing and other directions, to achieve the effect of improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

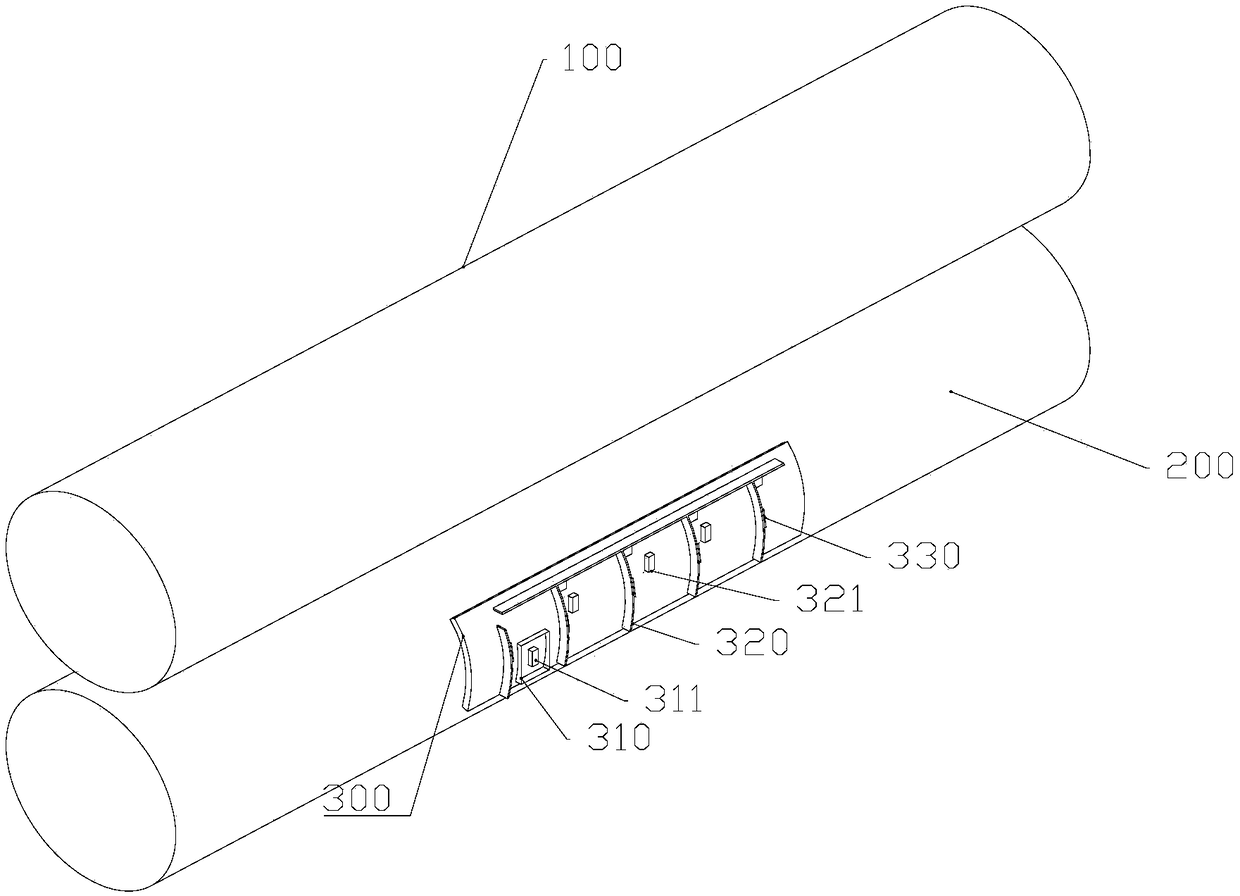

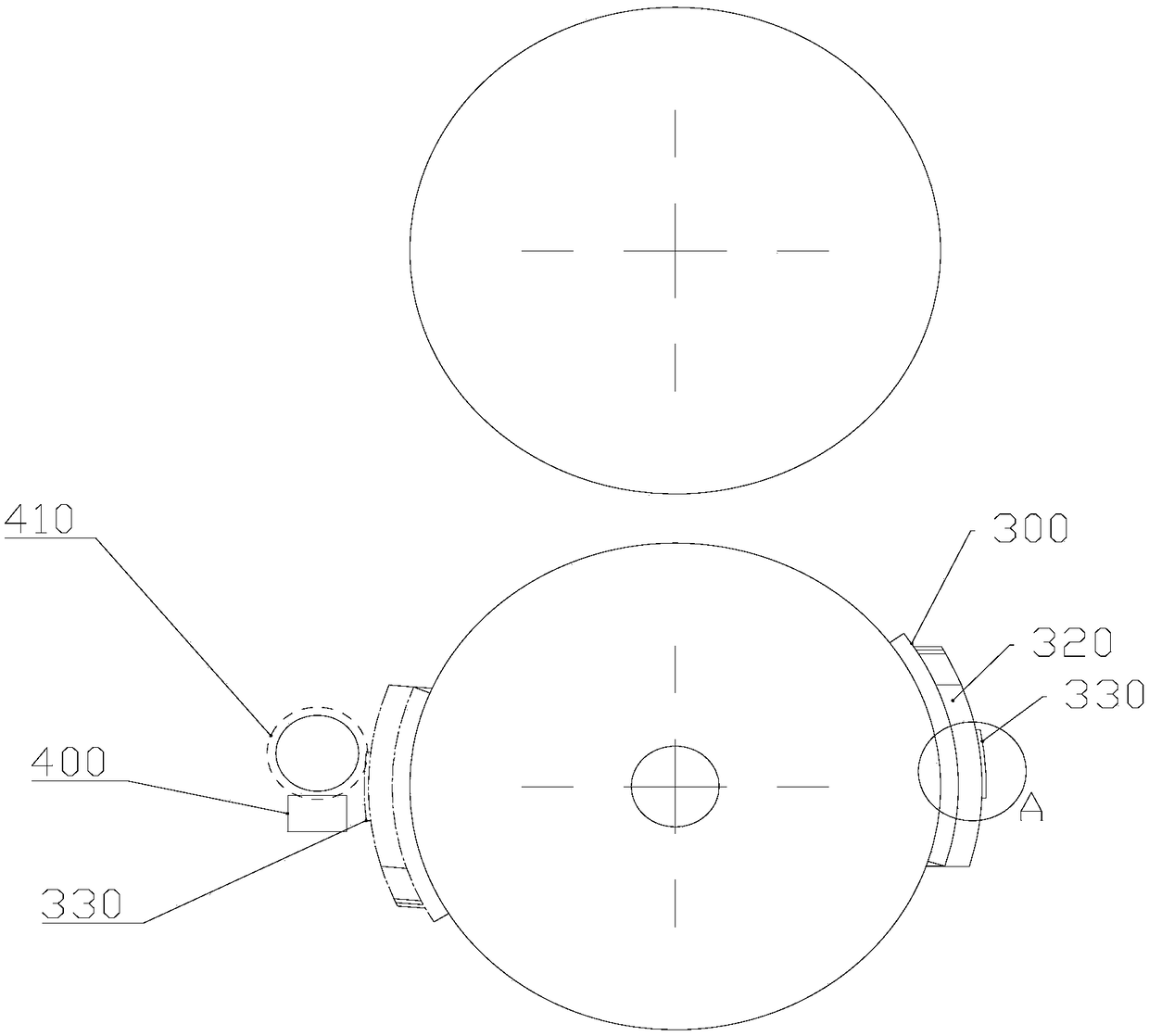

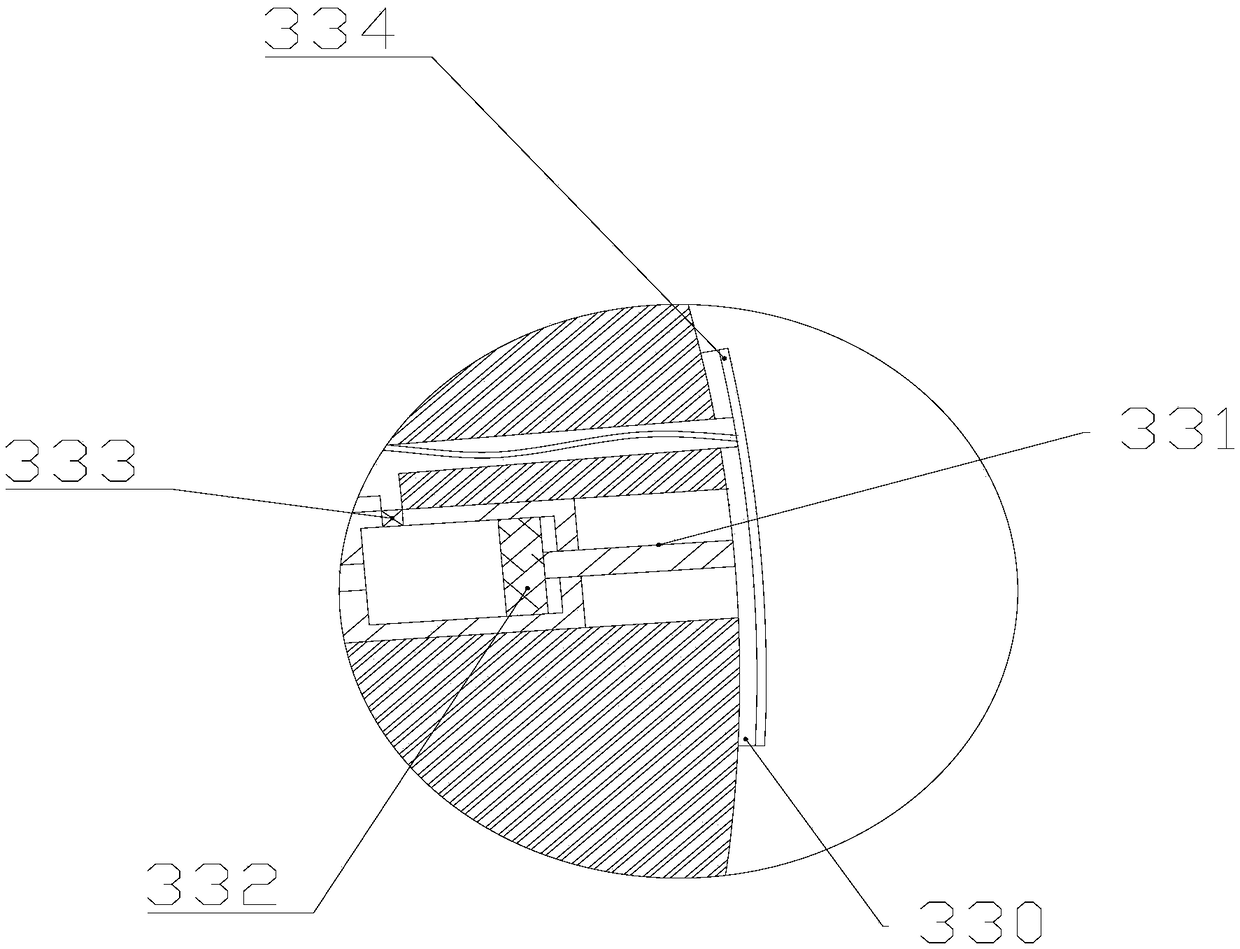

[0022] The reference signs in the drawings of the description include: pressure roller 100, cutter roller 200, die-cutting plate 300, positioning block 330, closed cutter 310, open cutter 320, closed elastic block 311, open elastic block 321 , positioning block 330, piston rod 331, piston 332, pressure relief valve 333, electrostatic adsorption block 334, powder storage box 400, powder upper roller 410, valve body 510, closed valve ball 520.

[0023] The embodiment is basically as attached figure 1 and figure 2 Shown: a printed matter die-cutting device, including a frame, a conveying mechanism for transporting printed matter, a pressure roller 100 arranged at the outlet of the conveying mechanism, a cutter roller 200 arranged below the pressure roller 100, and a feeder arranged on the cutter roller 200 The powder storage box 400 and the air pump on one side.

[0024] Such as figure 1 The cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com