Bowl noodle loose bag automatic bag feeding machine

A chartering machine, automatic technology, applied in packaging, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient operation and low work efficiency, and achieve the effect of easy adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

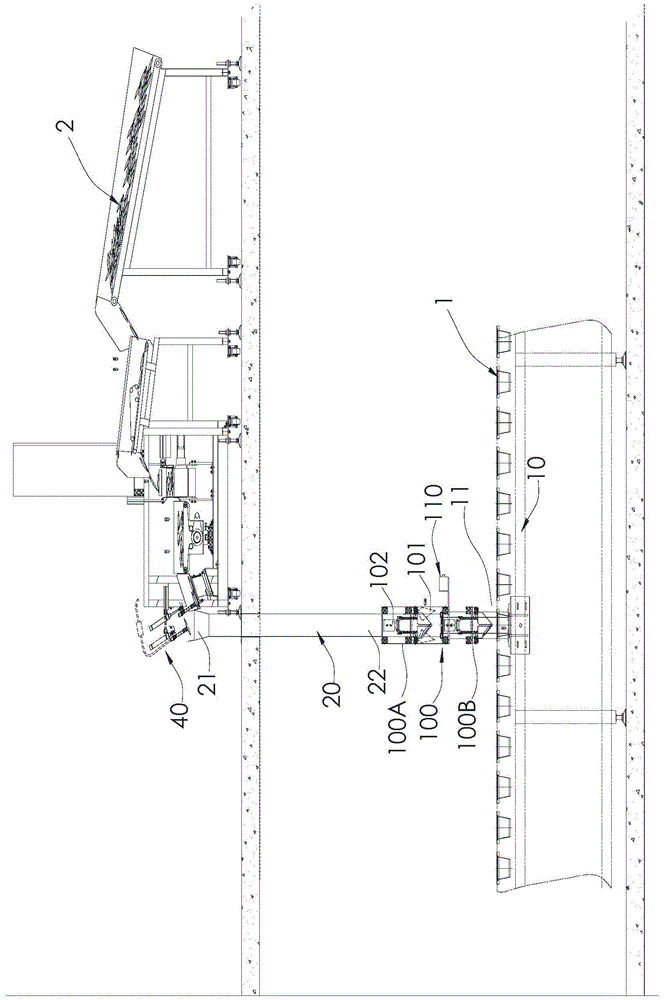

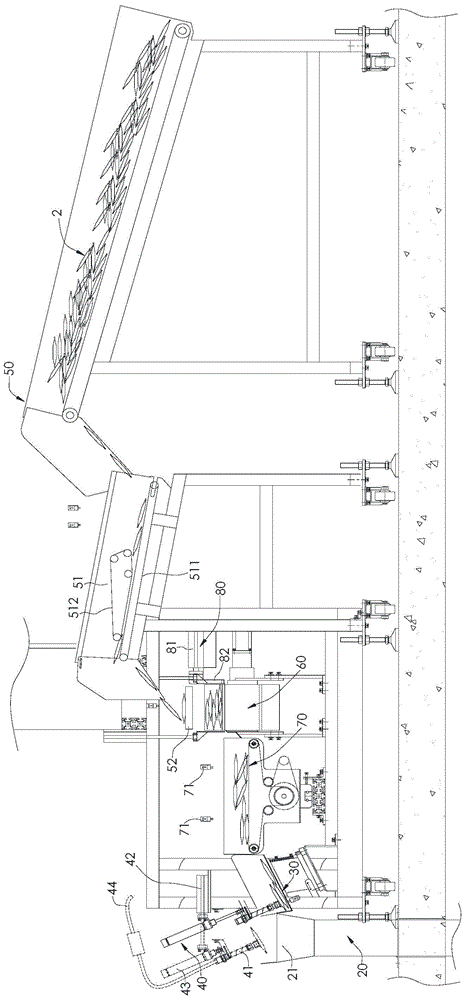

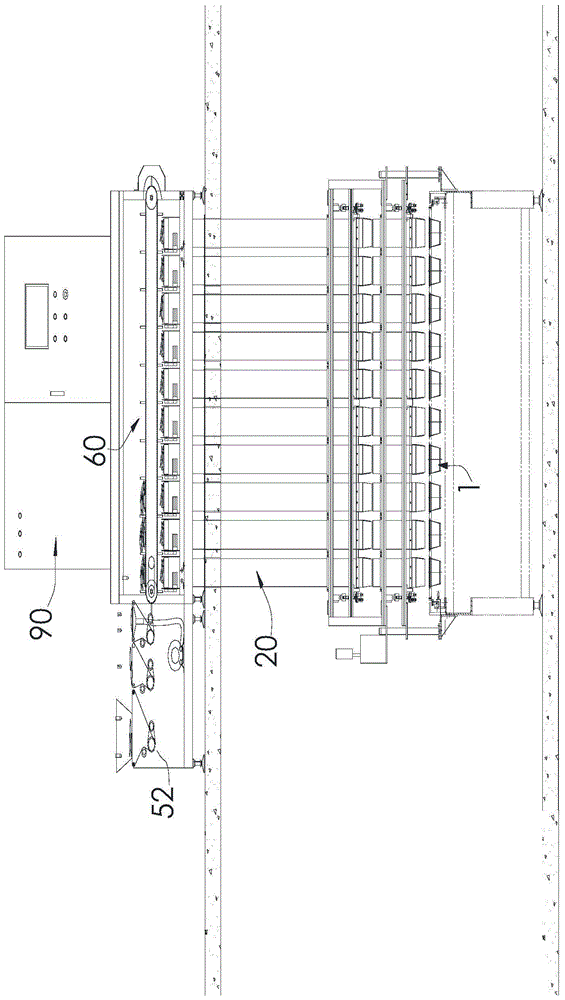

[0033] Such as Figure 1 to Figure 6 As shown, the bowl noodle loose bag automatic bag throwing machine of the present invention comprises a first conveying mechanism 10, a material pipe 20, a vibrating chute 30, a vacuum adsorption mechanism 40, a second conveying mechanism 50, a third conveying mechanism 60, a fourth conveying mechanism Mechanism 70 and pushing mechanism 80. The first conveying mechanism 10 is used for conveying the packing box 1. When conveying, the opening of the packing box 1 is upwards. The first conveying mechanism 10 is provided with a bag throwing station 11, and the bag throwing station 11 is located above the movement track of the packing box 1; The material tube 20 extends along the height direction, and the lower nozzle 22 of the material tube 20 is located above the bag delivery station 11; the vibration chute 30 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com