Large plate support replacing system

A plate and large-scale technology, applied in the field of large-scale plate changing system, can solve the problems of low efficiency, labor cost, insecurity, inaccurate positioning, etc., and achieve the effect of compact structure, high degree of automation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

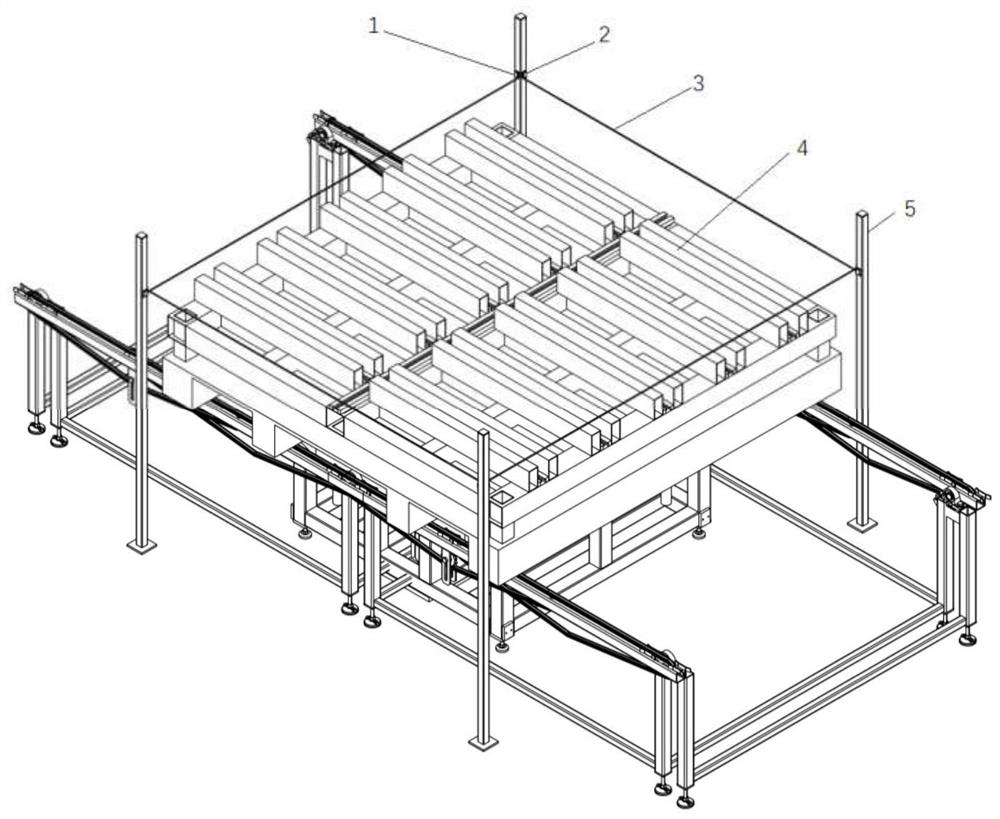

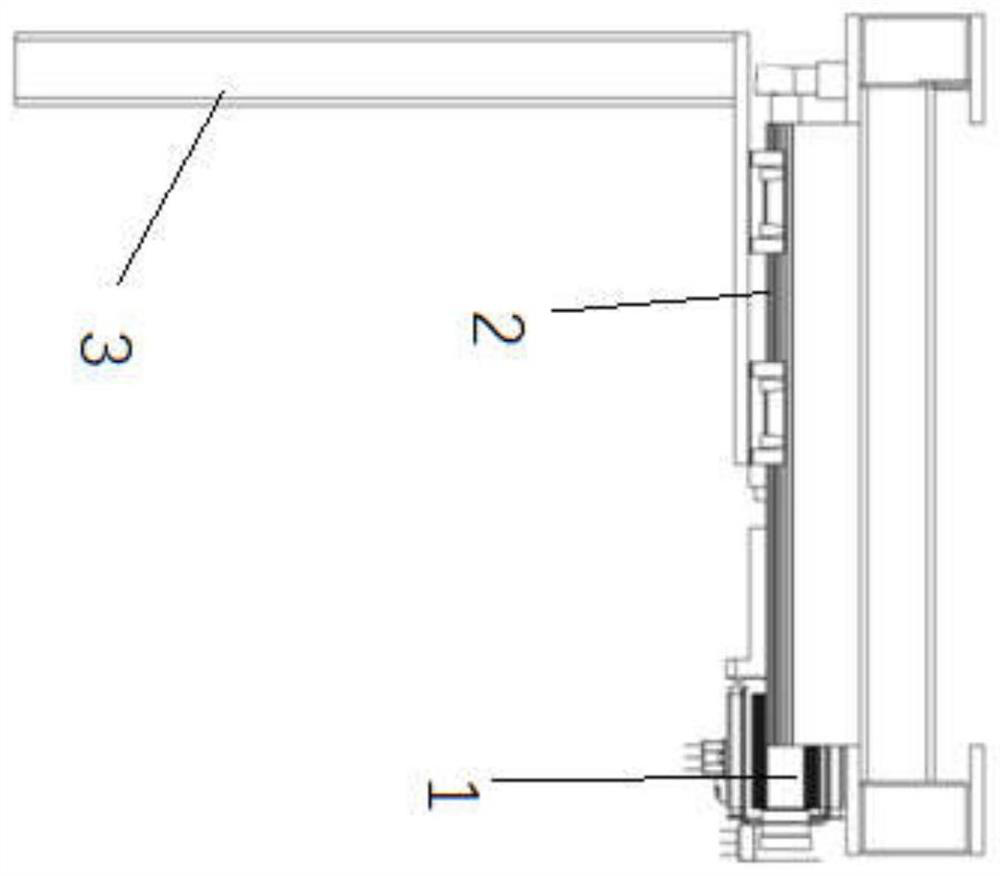

[0076] As mentioned in the background, ordinary mechanisms are prone to problems such as inaccurate positioning, low product compatibility, and unstable work when changing pallets. This application establishes an assembly line system covering a weighing platform, an automatic centering mechanism, a lifting and rotating mechanism, an adsorption separation device, a lifting device and a paper pumping device.

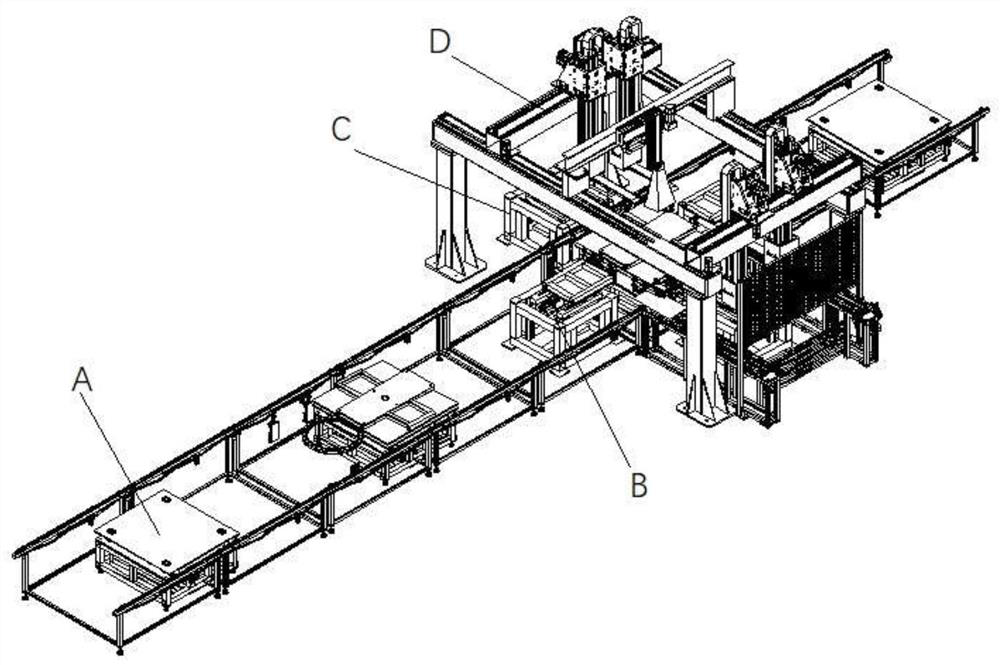

[0077] In order to overcome the low safety of traditional manual pallet change and the low compatibility and unstable structure of ordinary automatic feeding devices, the present invention provides a large-scale plate pallet change system, such as figure 1 As shown in the figure, it includes: the weighing platform A, which is used to weigh the plates; the automatic centering mechanism B, which is used to center the weighed plates; the lifting and rotating mechanism C, which is used to align The plate is lifted and rotated, and a bearing platform is provided on it for carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com