Assembling system for wood right-angle clamping plate of polyurethane insulation box

An assembly system and insulation box technology, applied in chucks, metal processing equipment, manipulators, etc., can solve the problems of low pass rate of wooden right-angle plywood connection strength and assembly accuracy, high labor intensity, low efficiency, etc., and achieve improvement The effect of high labor intensity, high feeding efficiency and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

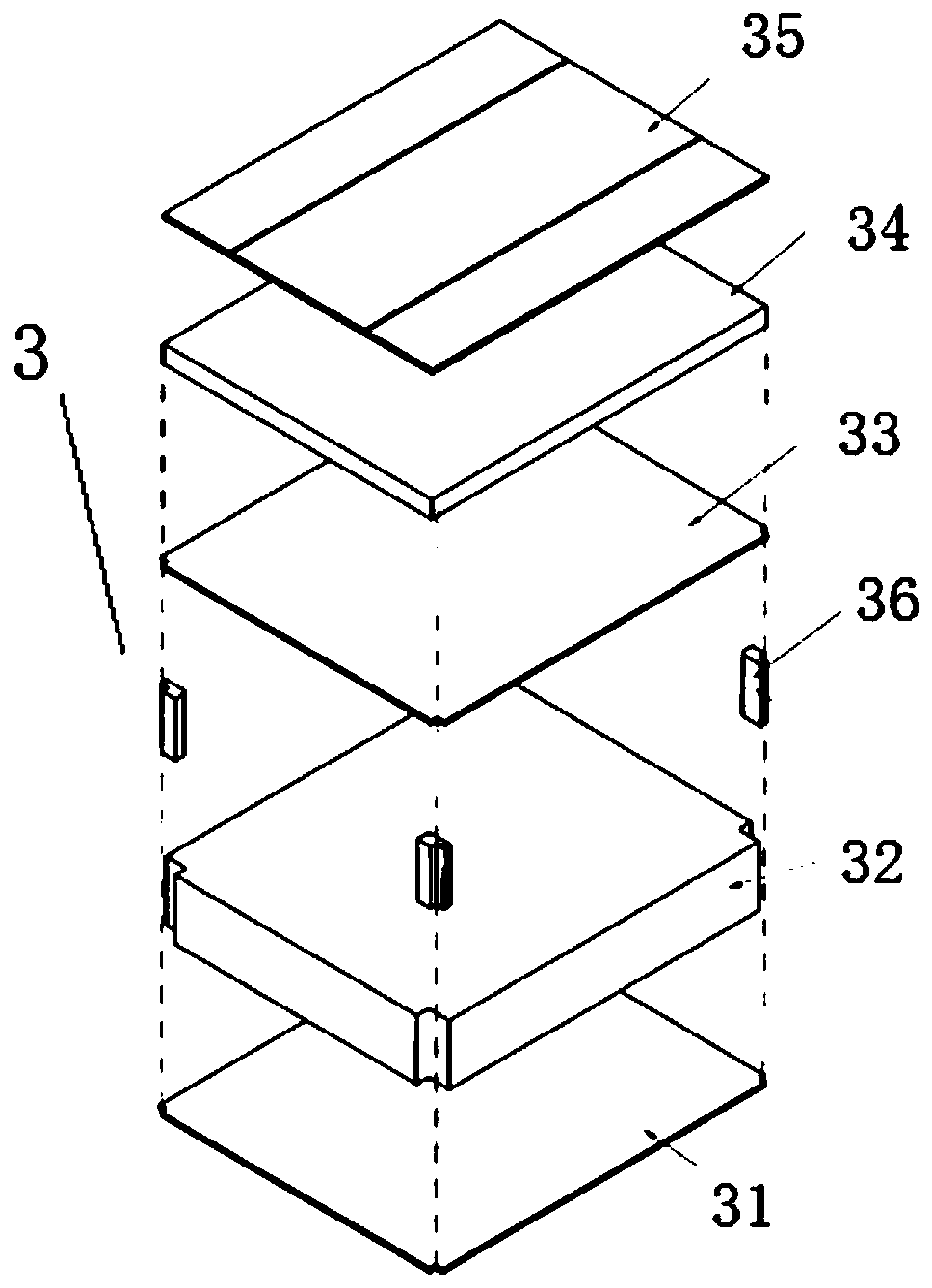

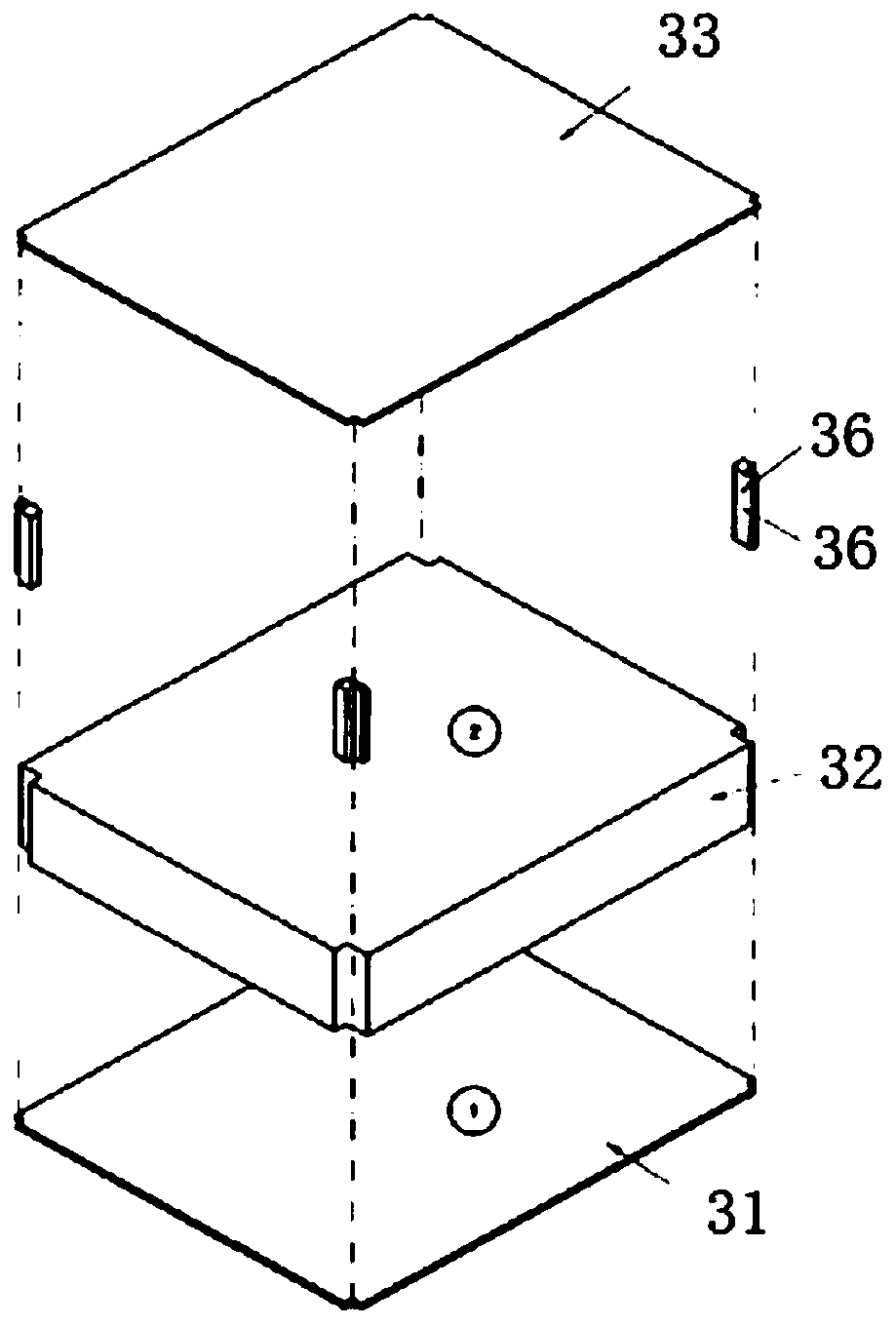

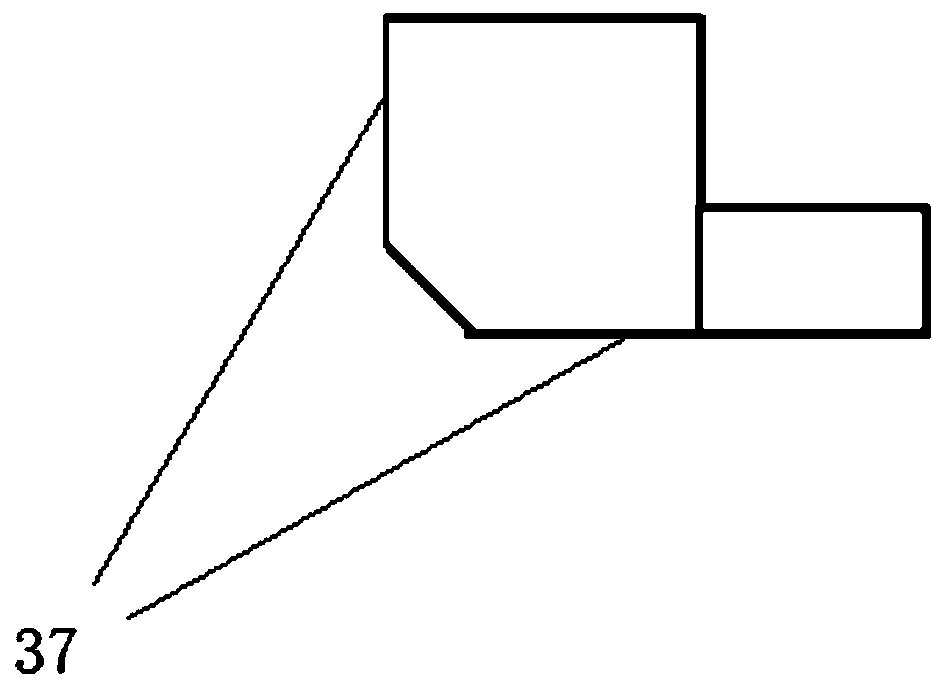

[0069] Insulation boxes 3 in the form of L03, L03+, etc., which include K1, and box-type structures such as K2 and K5, wherein, see figure 1 As shown, the K1 box structure includes the bottom part composed of No. 1 board 31 (made of plywood) and No. 2 board 32 (made of polyurethane board), and the upper part compounded on the top of No. 2 board 32, respectively. No. 3 board 33 (plywood), No. 4 board 34 (polyurethane board material) and No. 5 board 35 (plywood), and the four corners of No. 2 board 32 are provided with right-angle grooves, and correspondingly assembled on the right-angle grooves There is a right-angle splint 36 (the outside of the splint also has grooves), and the K2 and K5 box structures refer to figure 2 As shown, compared with the K1 box structure, the upper part omits the No. 4 plate 34 and the No. 5 plate 35, and the rest are the same. The structure of every wooden right-angle splint 36 is referring to image 3 As shown, its four surfaces (including two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com