Patents

Literature

39results about How to "Improve cutting rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

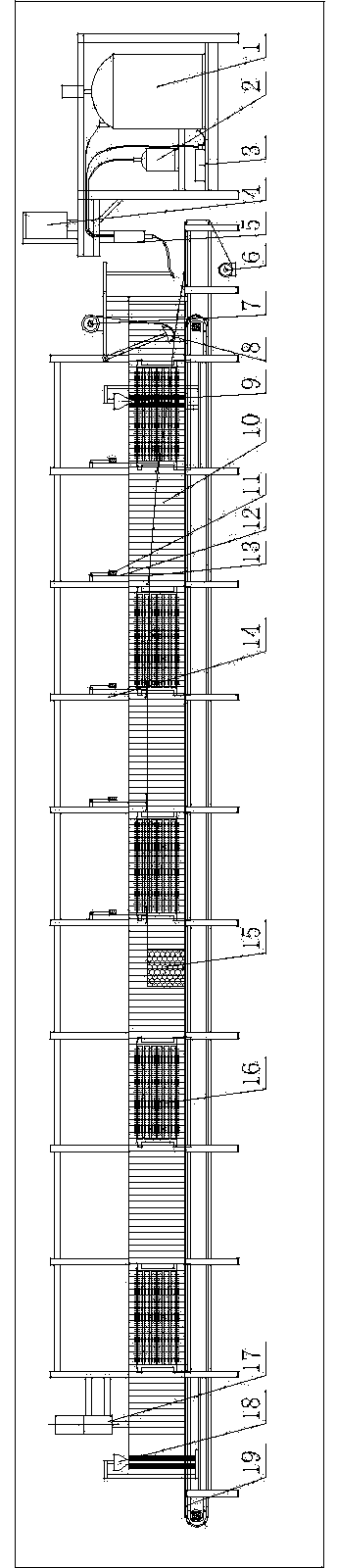

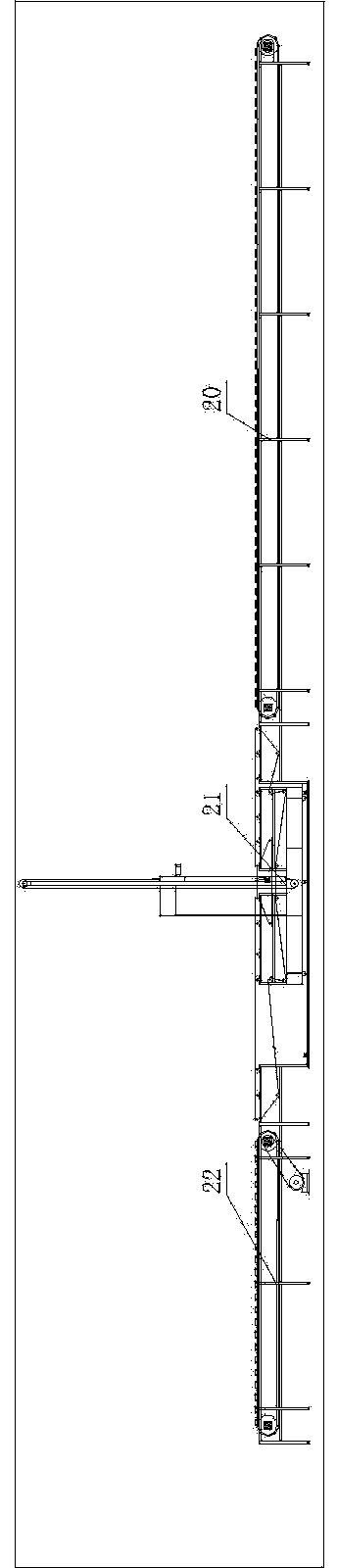

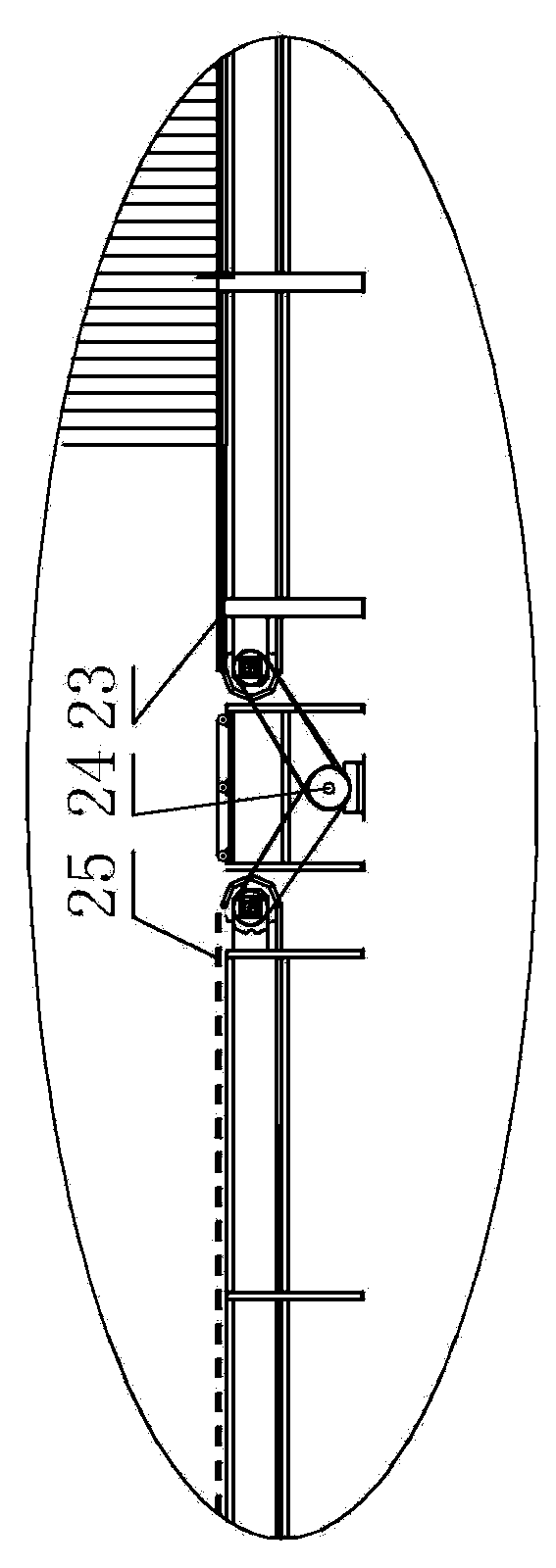

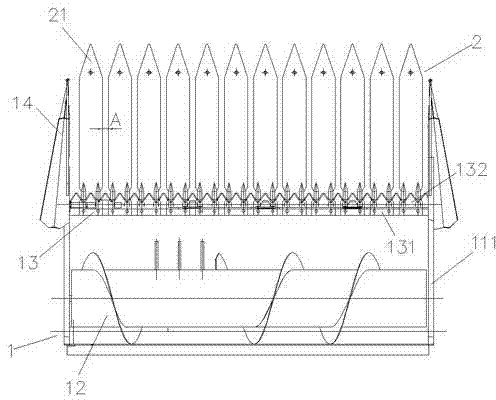

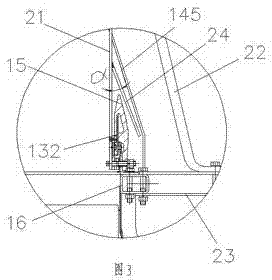

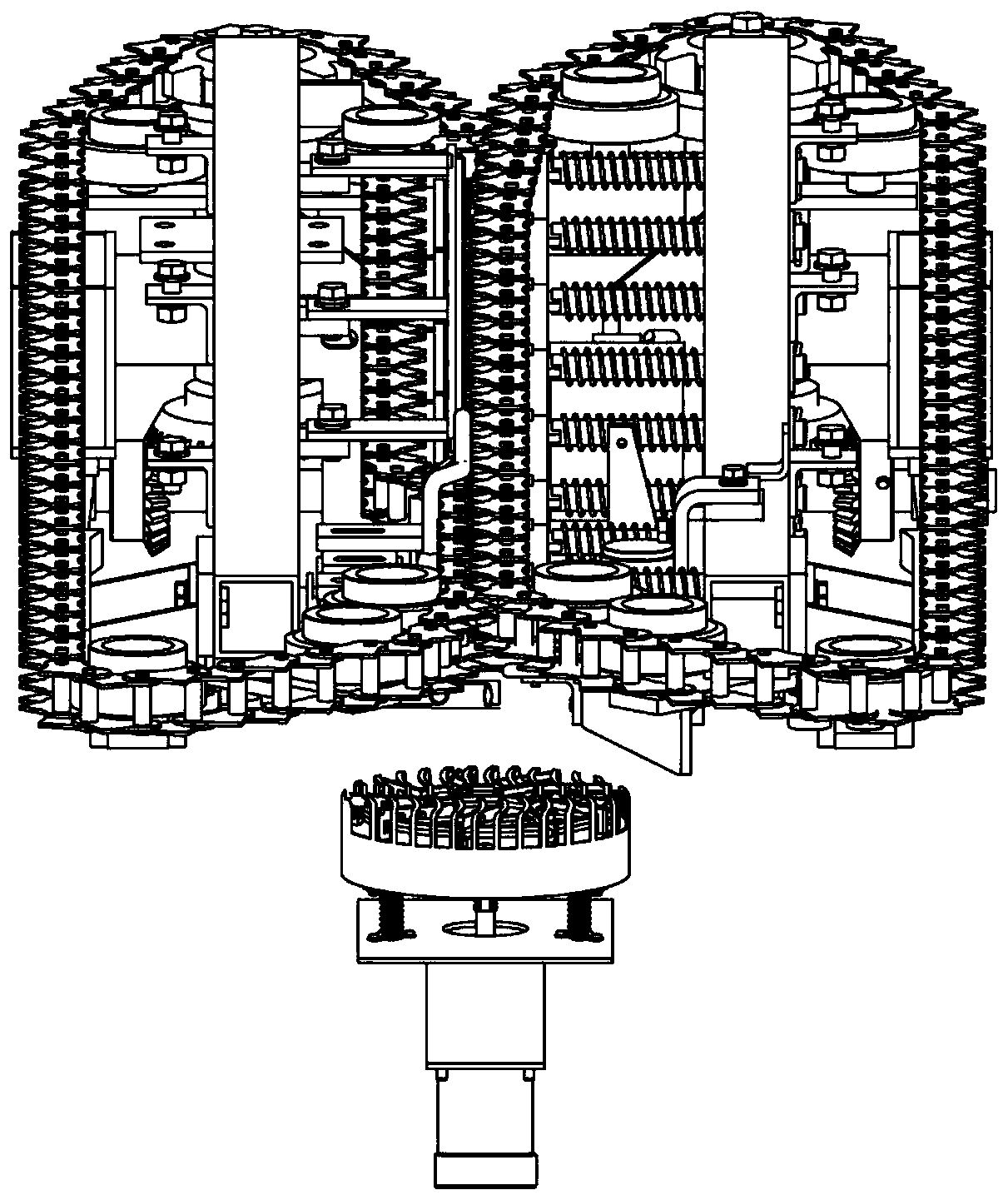

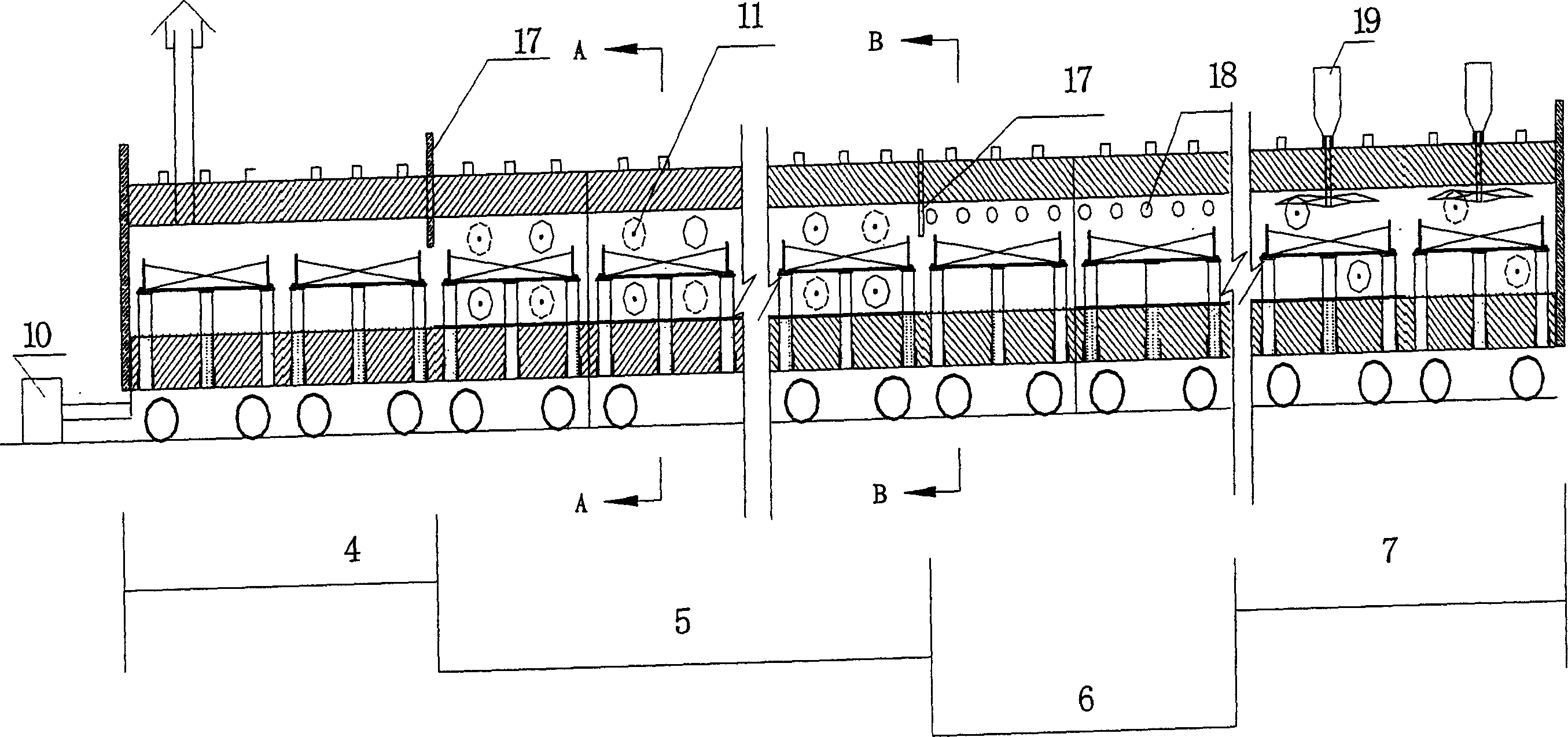

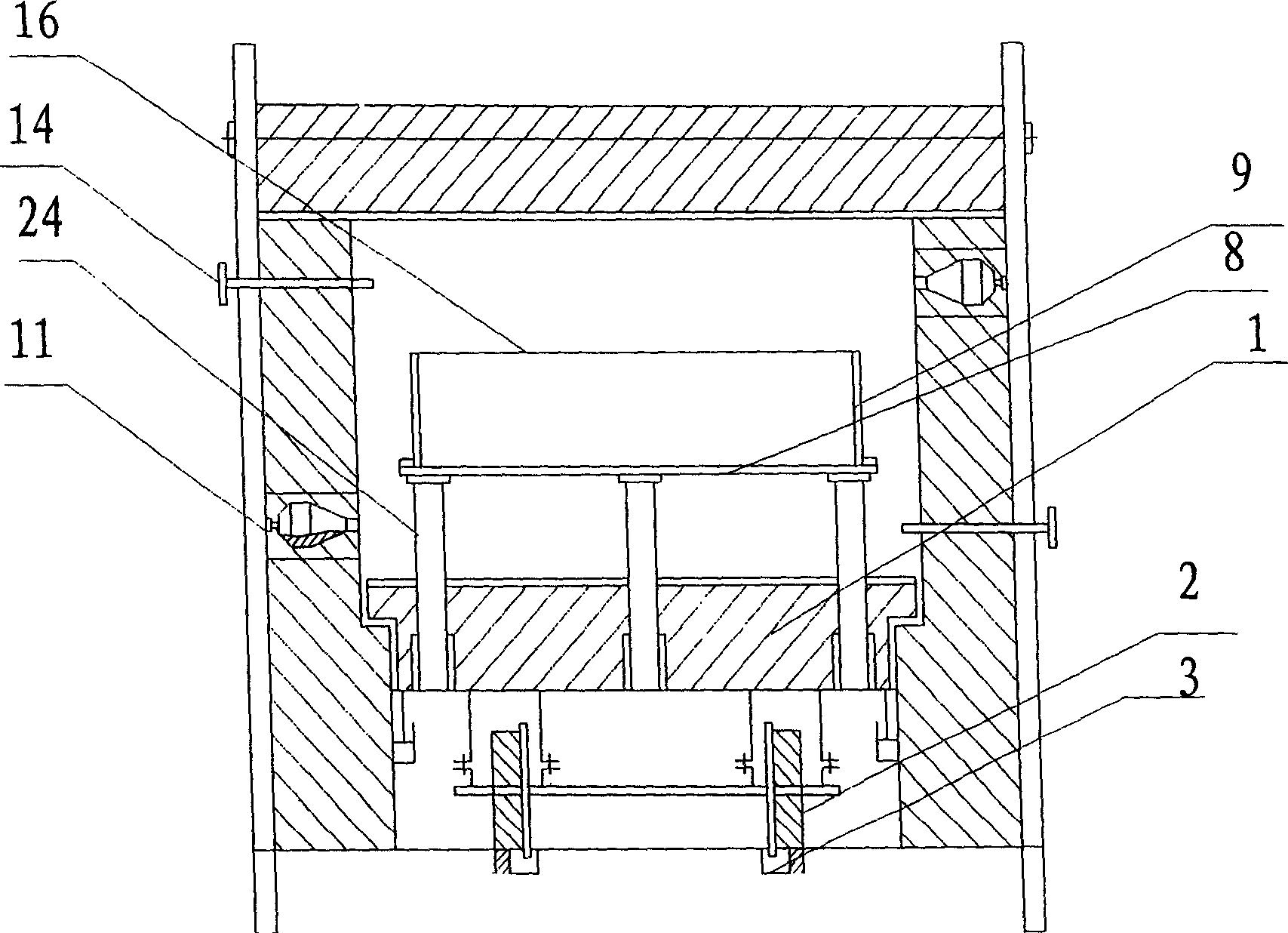

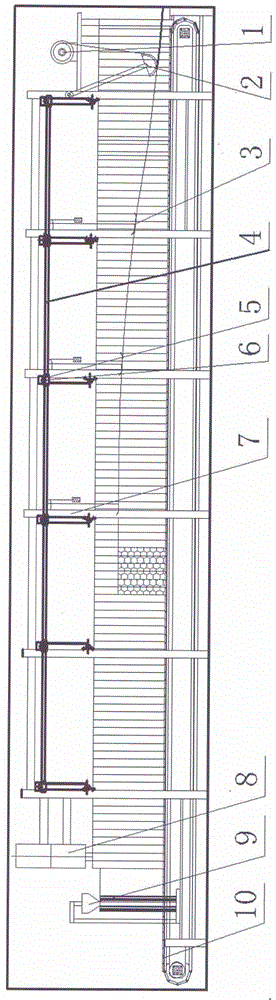

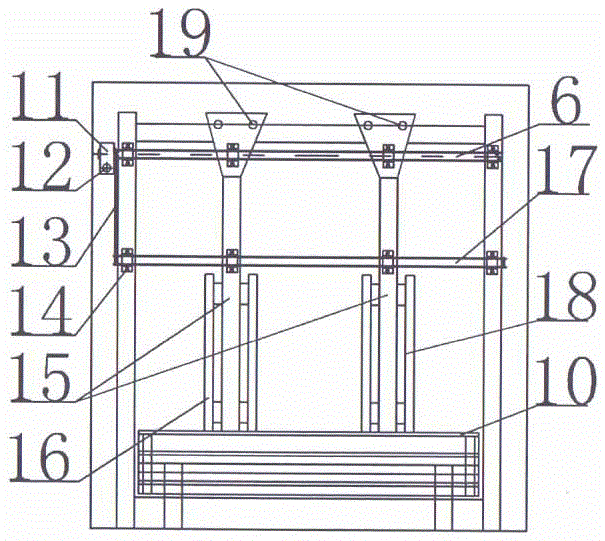

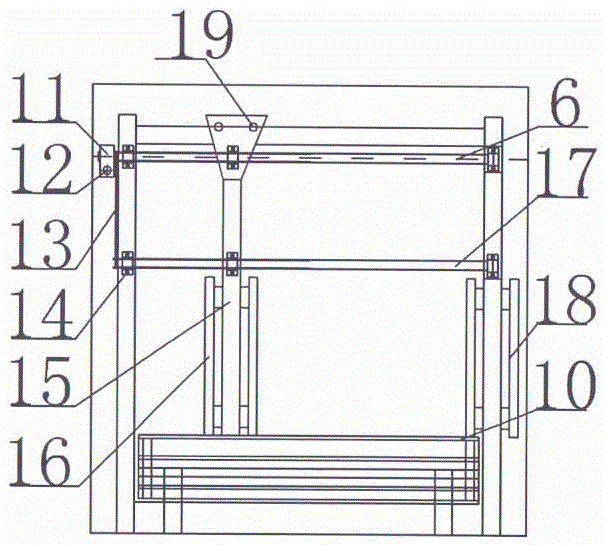

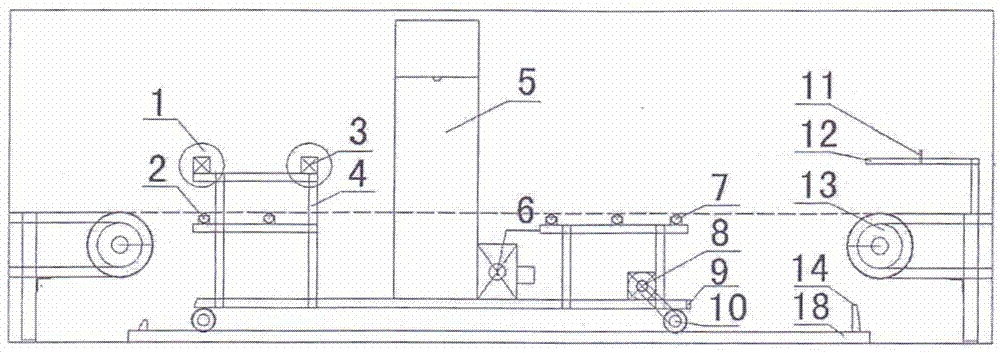

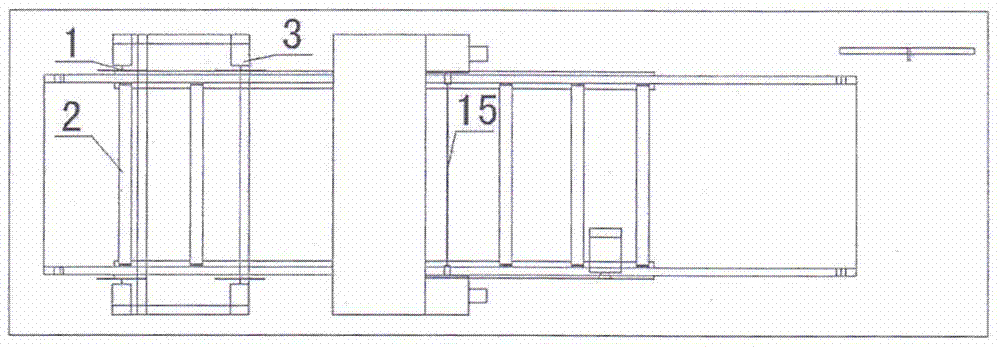

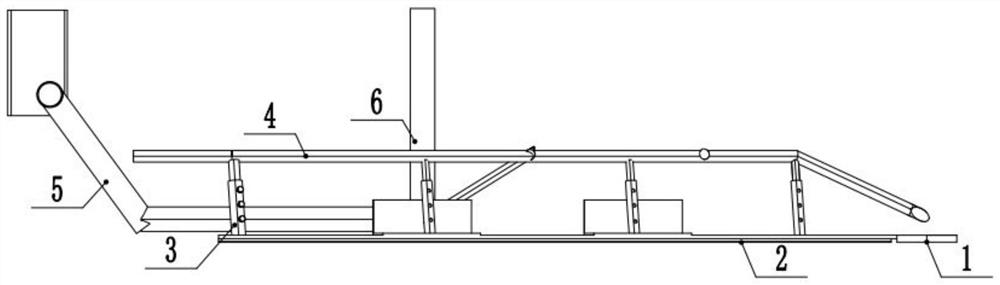

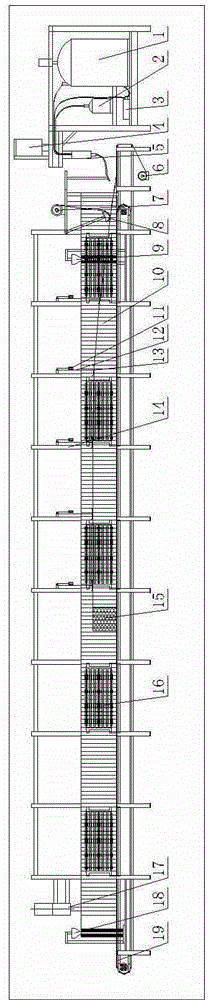

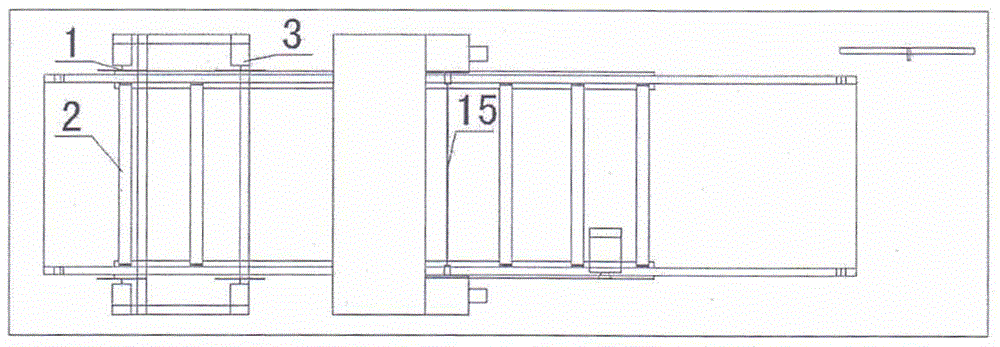

Continuous production device of hard blocky polyurethane foam

The invention discloses a continuous production device of hard blocky polyurethane foam. A continuous foaming rack is arranged at the rear part of a polyurethane foaming pouring device, and comprises a cross rod used for bearing load, a lower delivery track used for conveying continuous blocky foam and a clamp track used for fixing a left frame and a right frame of foam for formation; during the foaming process, the lower delivery track and the left-and-right clamp track are kept synchronous; a paper releasing device is arranged at the front end of the continuous foaming rack, and is divided into a paper releasing mechanism for lower-layer paper, a paper releasing mechanism for upper-layer paper, and a left-and-right plastic film paper releasing mechanism; a left-and-right paper collecting mechanism is arranged at the rear end of the continuous foaming rack, and is synchronous with the clamp track. The continuous production device realizes the continuous production of a factory, is stable in quality, low in cost and high in production efficiency, and can realize large-scale production; besides, a top pressing device is arranged in a production line, the upper surface of produced hard foam is relatively flat, the material cutting ratio is high, and the product cost is reduced.

Owner:JIANGSU LVYUAN NEW MATERIALS

Process for producing shikimic acid

InactiveCN101024609AReduce labor intensityReduce usageCarboxylic compound separation/purificationPlant ingredientsAcetic acidOrganic solvent

The invention supplies a shikimic acid producing method that includes the following steps: adding water into raw material chinese anise, taking recycling for 6-8 hours at 50-80 degree centigrade, concentrating to skikimic acid extractive raw material; mixing and whisking raw material and silica gel according to 1:1, leaching by ethyl acetate, testing and collecting eluate, concentrating and filtering to gain shikimic primary crystallization, taking recrystallization by using the same method. The invention sharply simplifies distilling process, improves working efficiency, decreases producing cost, and could shikimic acid of 90-95% purity.

Owner:NANJING AGRICULTURAL UNIVERSITY

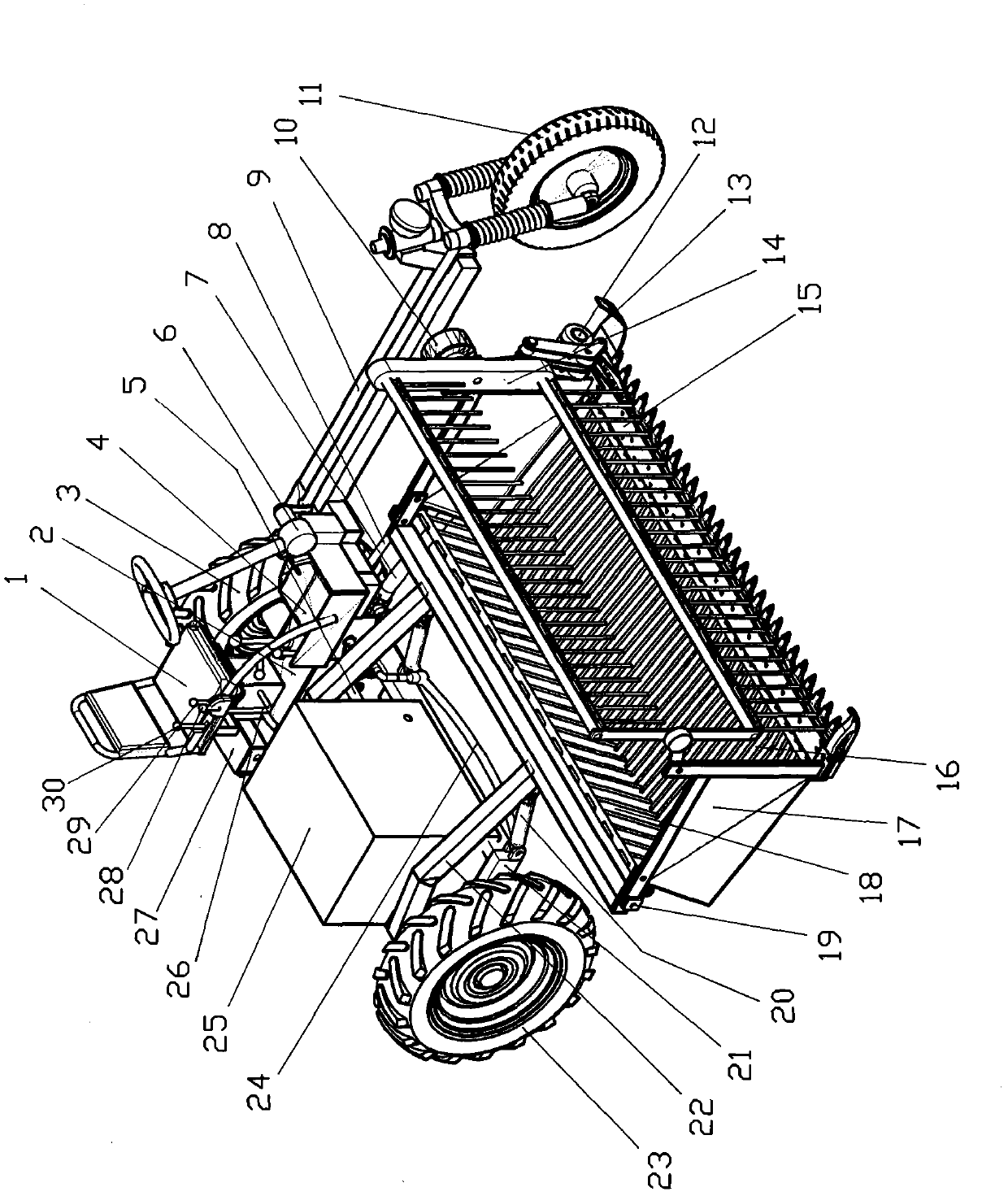

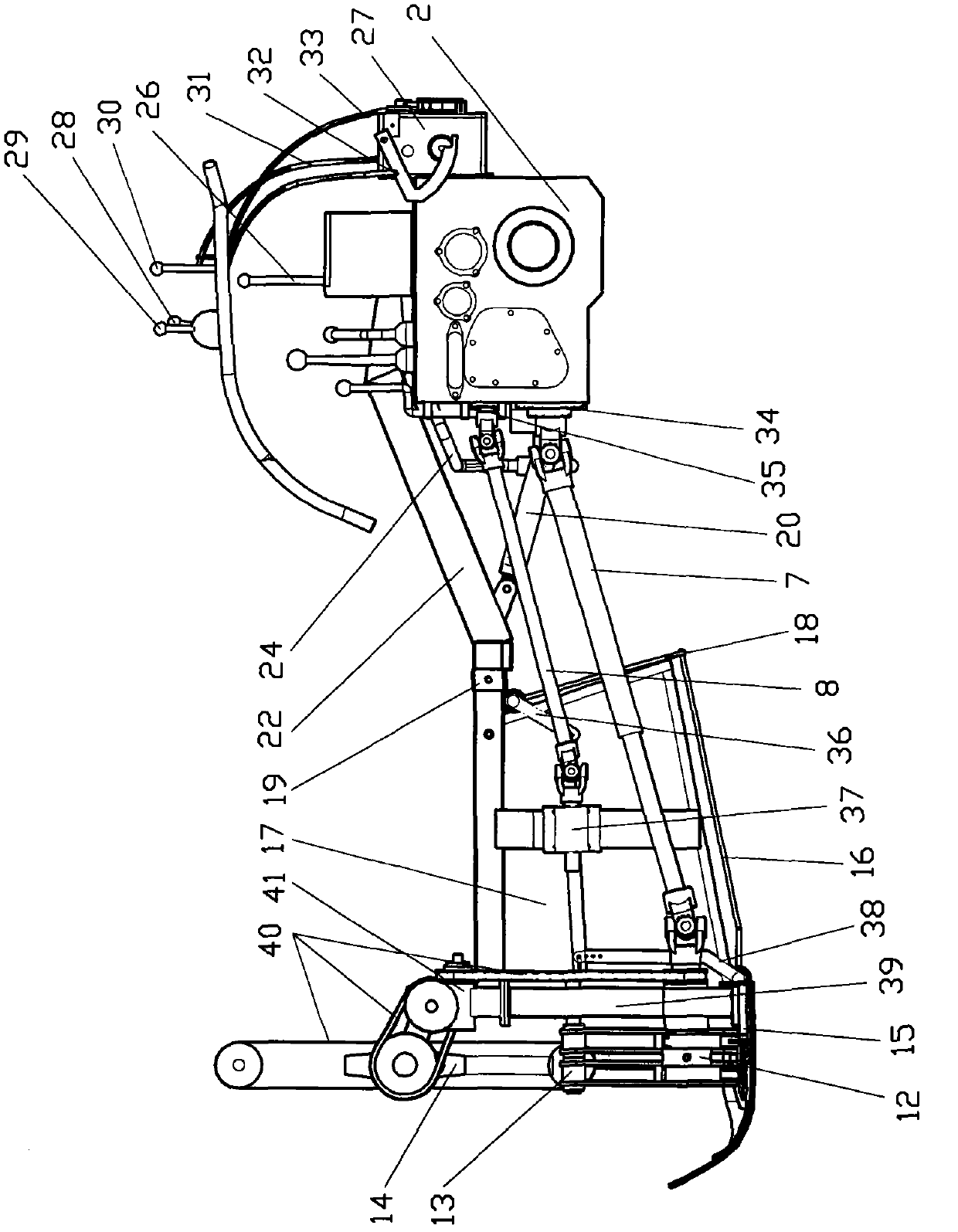

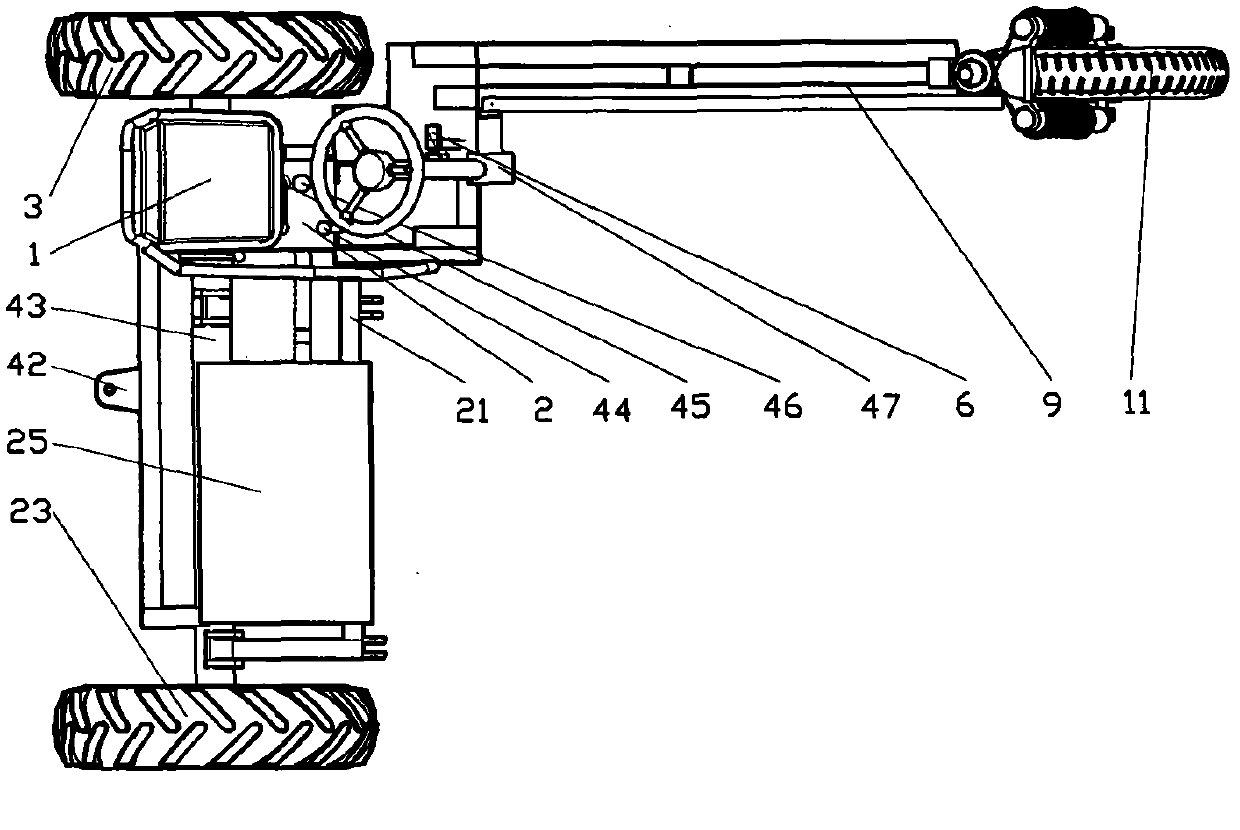

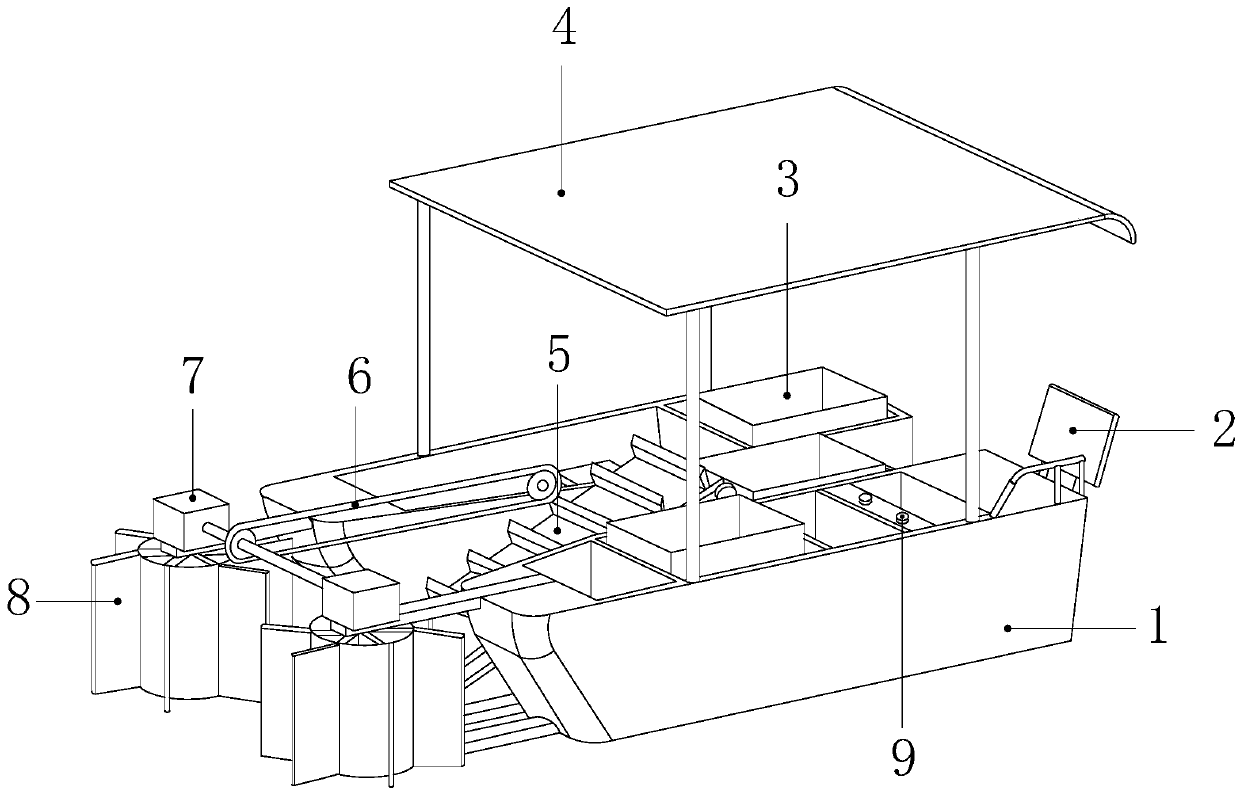

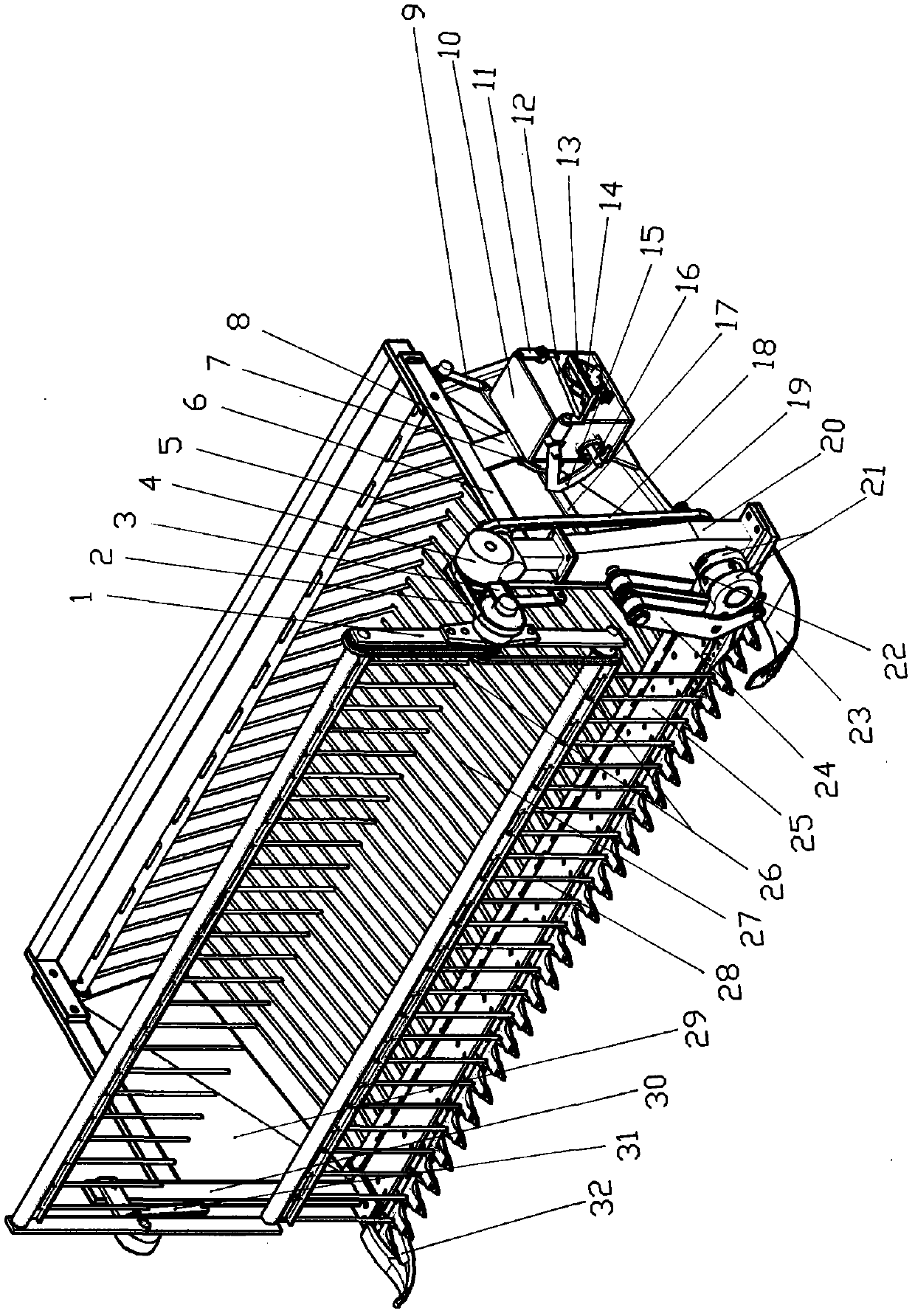

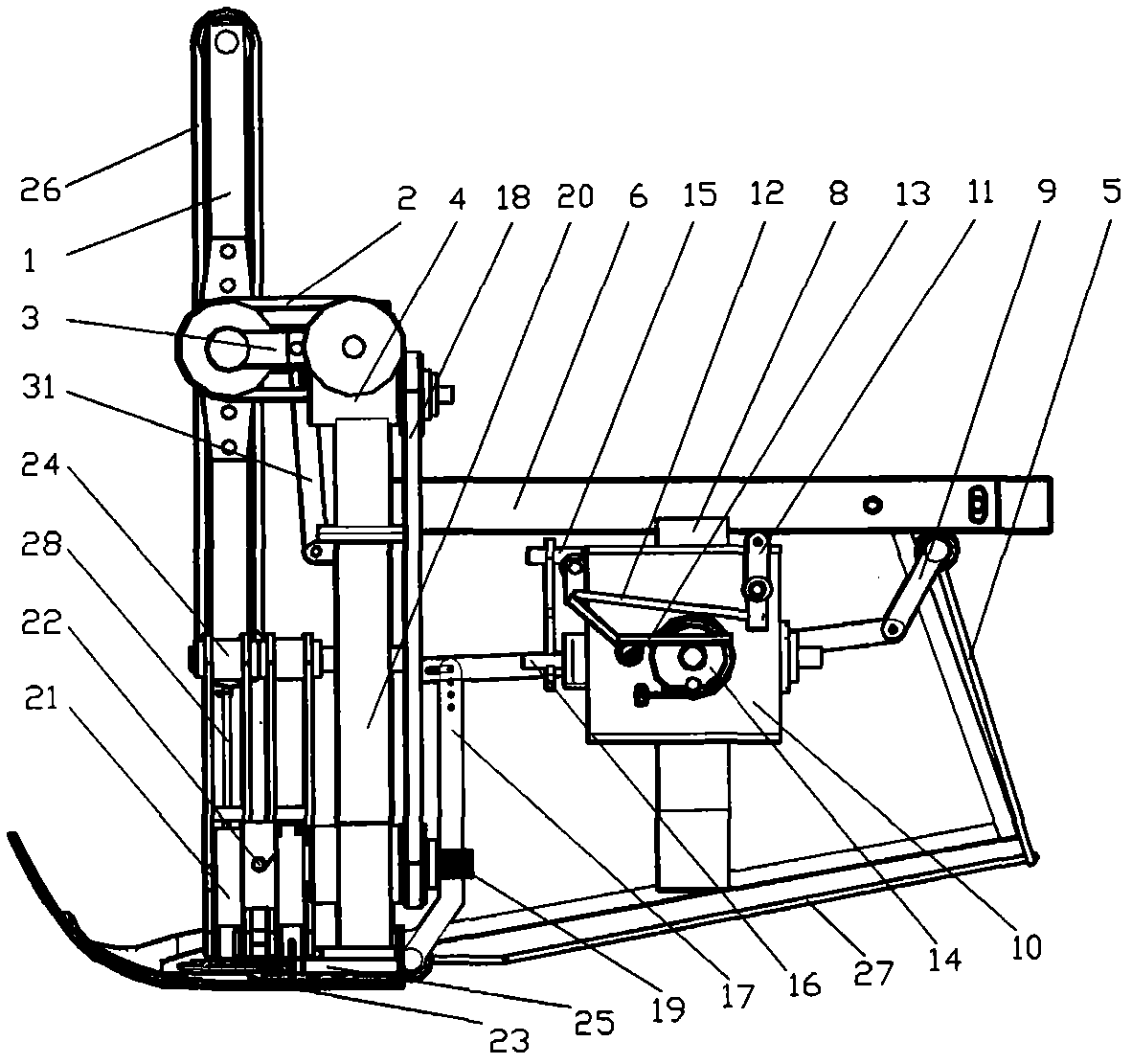

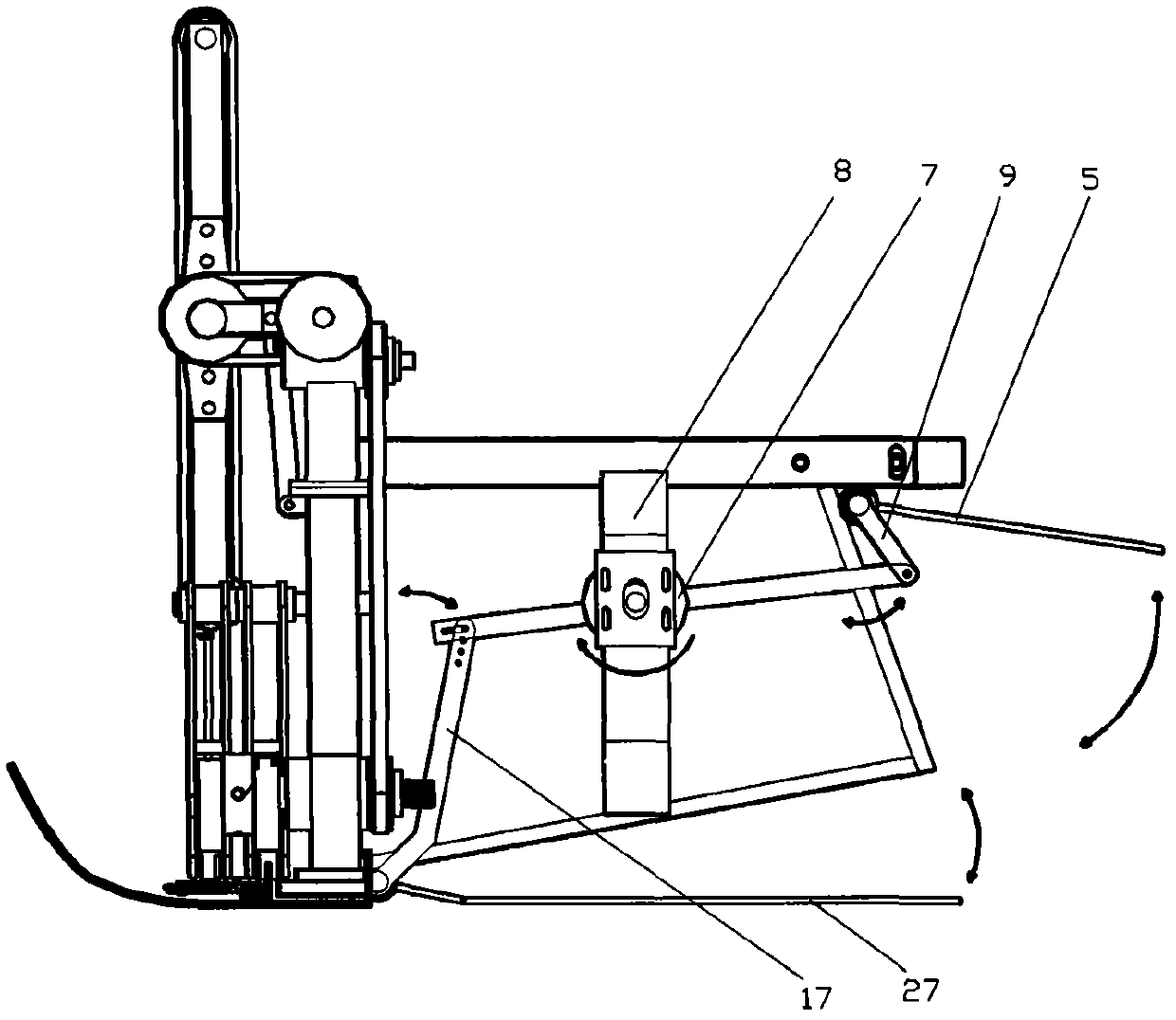

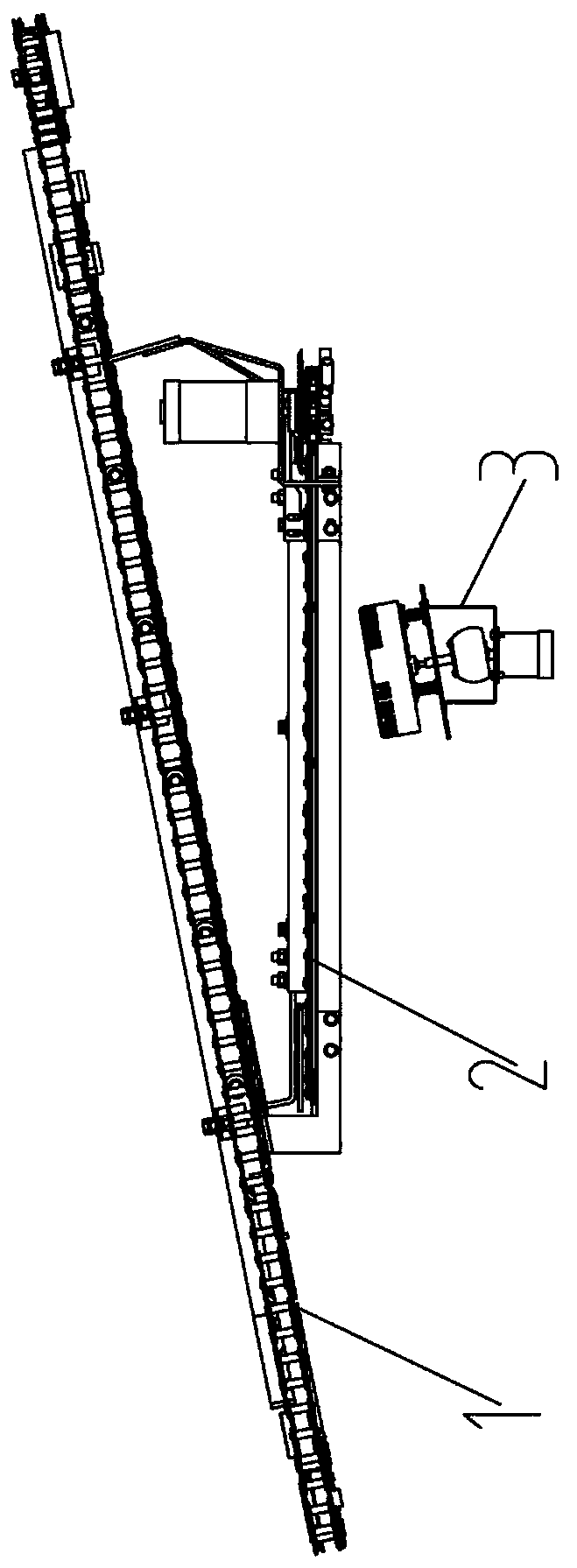

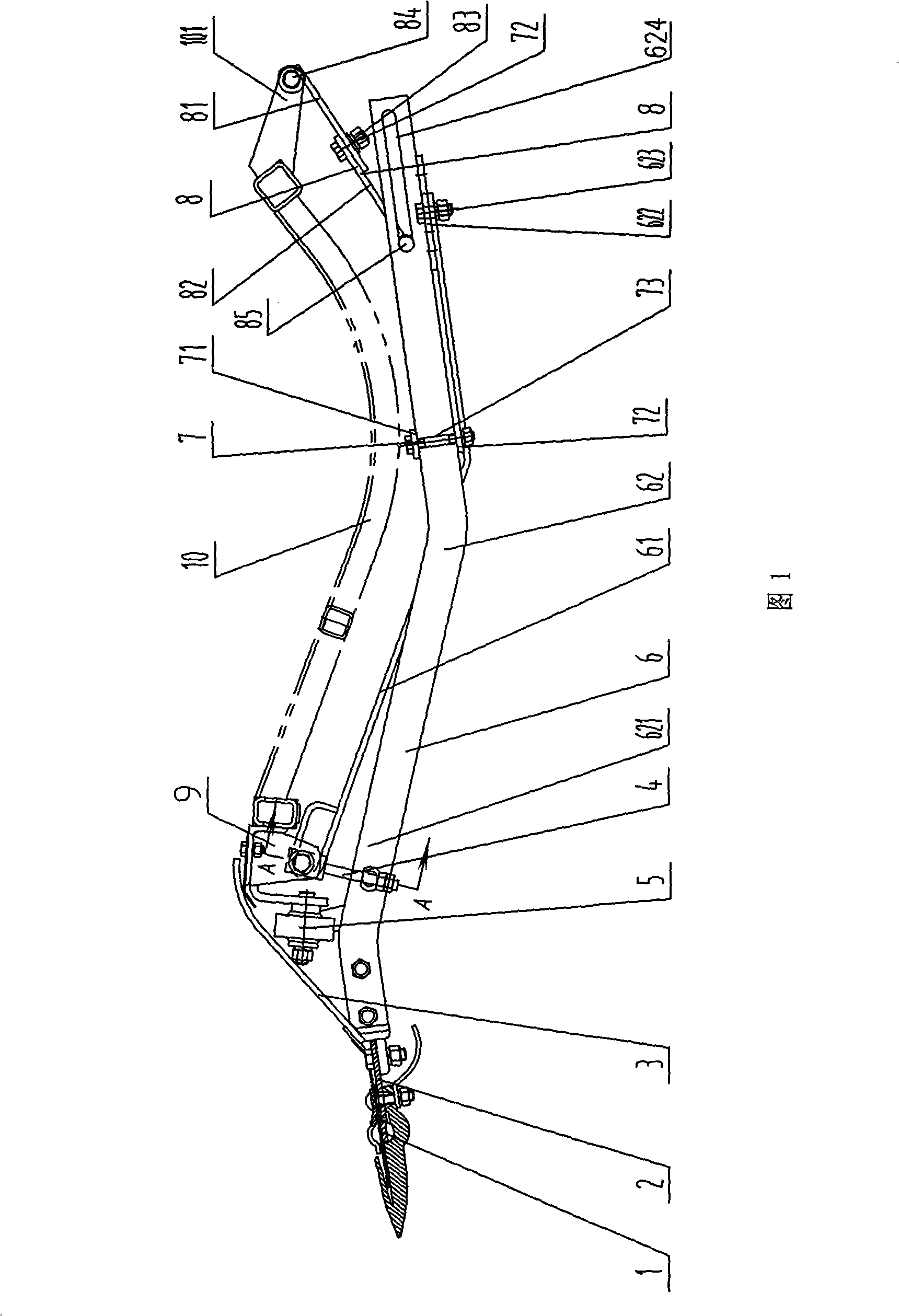

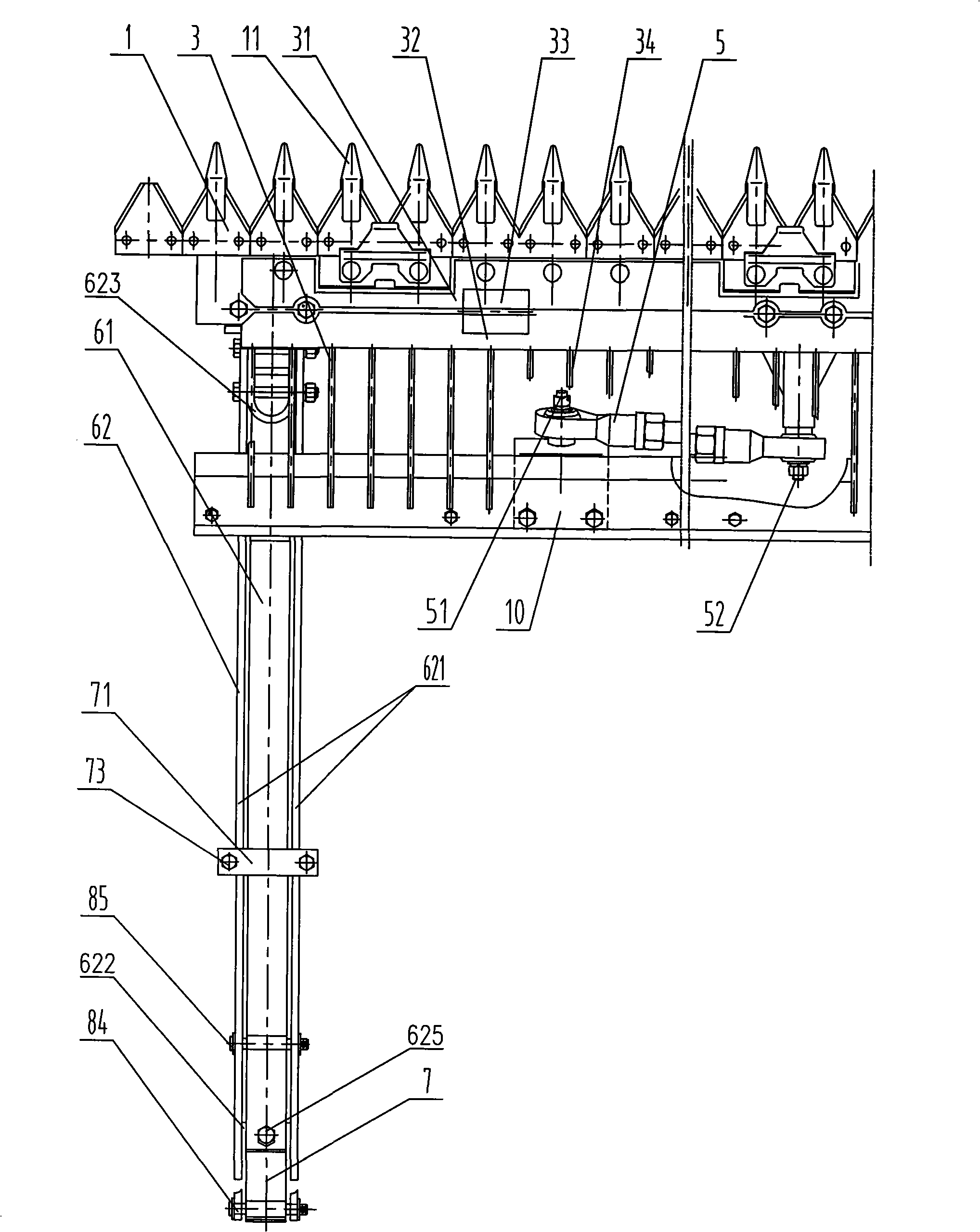

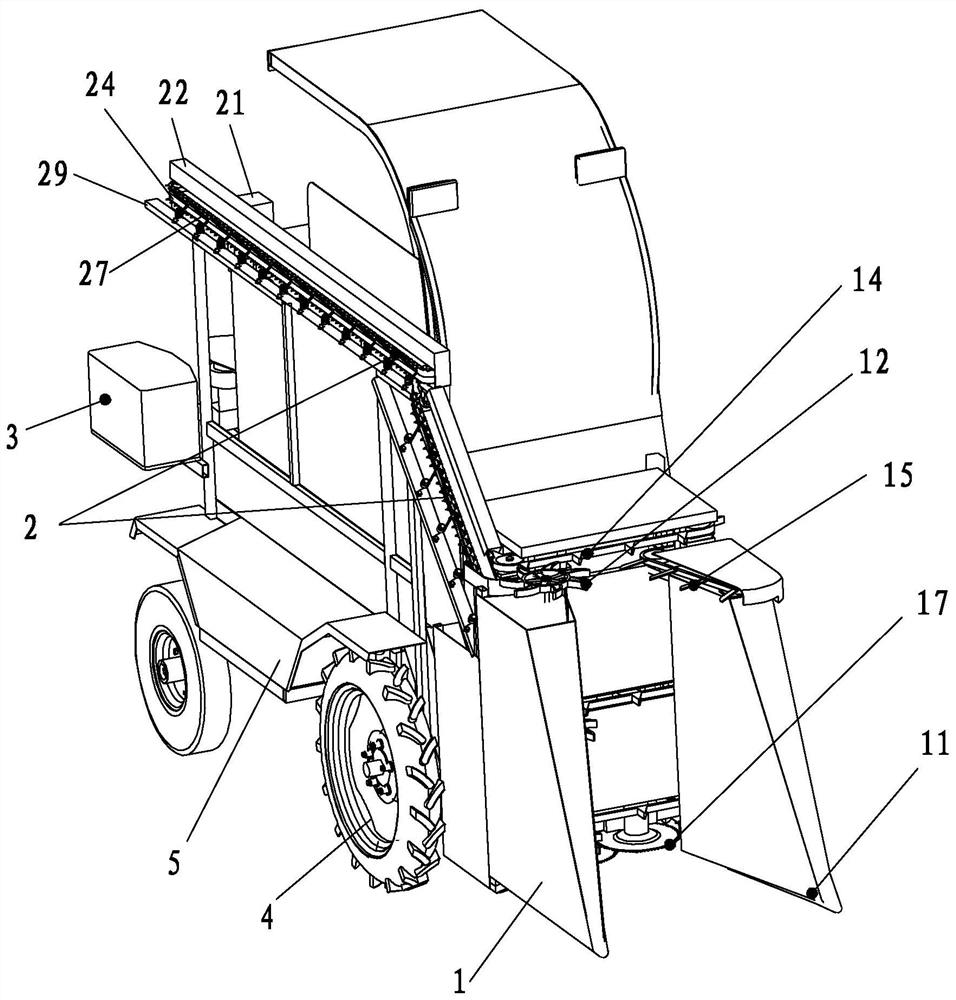

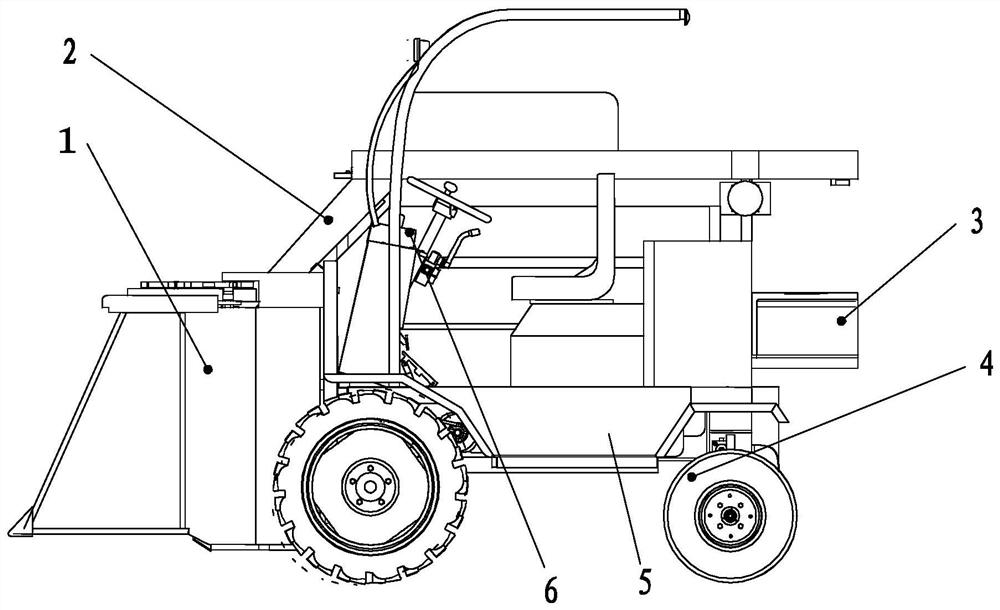

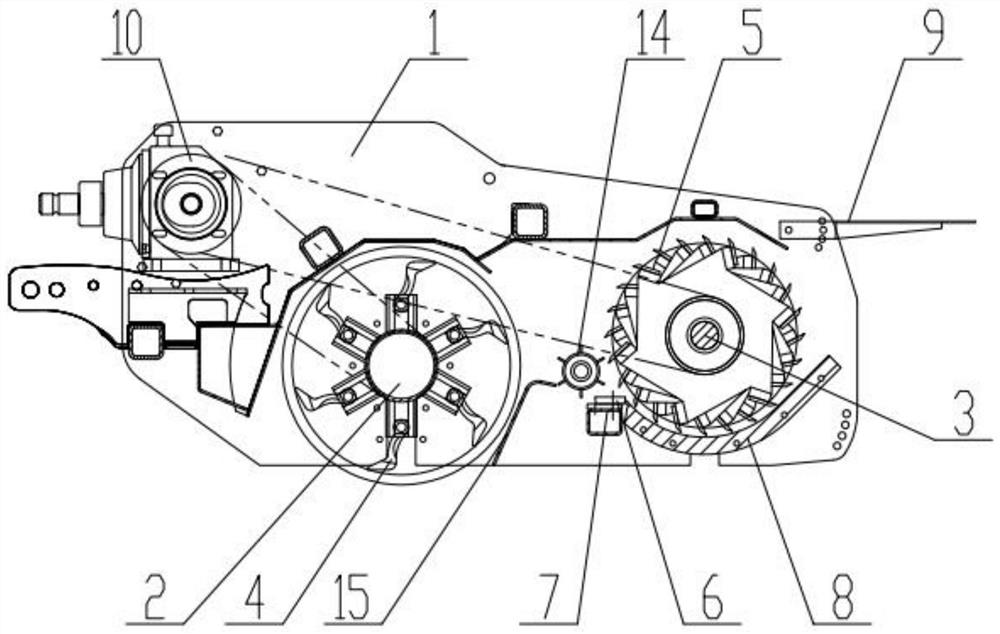

Self-propelled gather-free combined grass harvester

The invention discloses a self-propelled gather-free combined grass harvester, which comprises a double moving-knife cutter, a reel device, a grass collecting box, a hydraulic lifting mechanism, an intermittent paving gearbox device, a paving device and a side three-wheel motor vehicle. With the adoption of the self-propelled gather-free combined grass harvester disclosed by the utility model based on a principle of cutting grasses by interacted double knives, the grass cutting speed is improved; cut grass can directly gathered into the grass collecting box under the action of the reel device, so that the quality and yield of the grass are improved; the grass is collected by the grass collecting box, so that the damage of tines of a hayrake on the surface vegetation of a grassland is prevented, the grassland resource can be greatly protected and utilized, the the degree of grinding of excess vehicle wheels on the grassland is relieved, and the weight of a machine is reduced; the self-propelled gather-free combined grass harvester is a three-in-one machine type, so that excess mechanisms and components caused by auxiliary units are reduced; the self-propelled gather-free combined grass harvester is an is an easily-operated, easily-maintained, efficient and conveniently-popularized grassland farming machine, and greatly stands out the characteristics of energy conservation and environmental friendliness.

Owner:刘启和

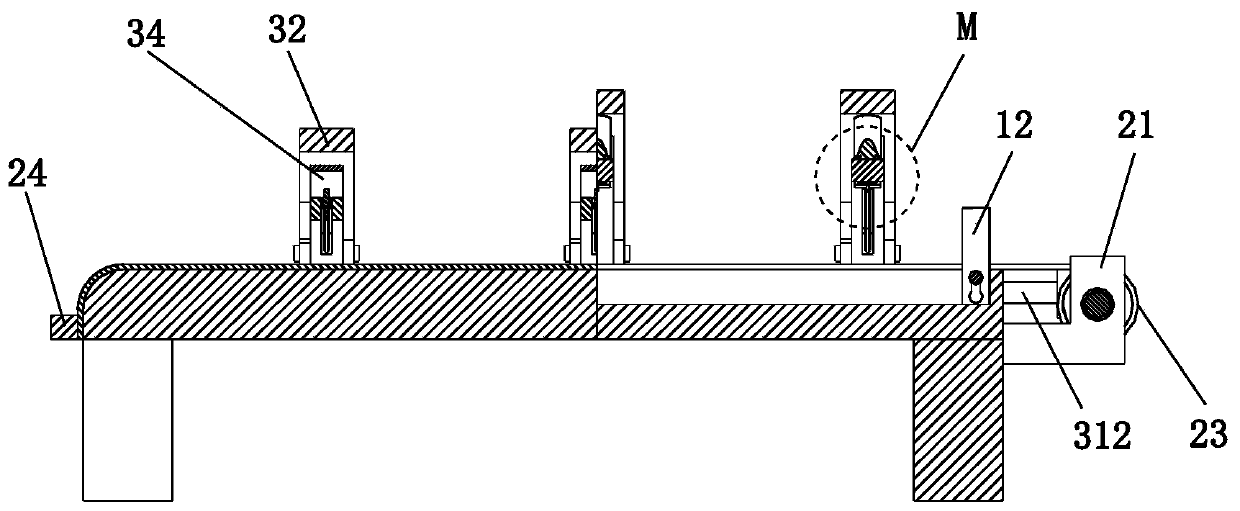

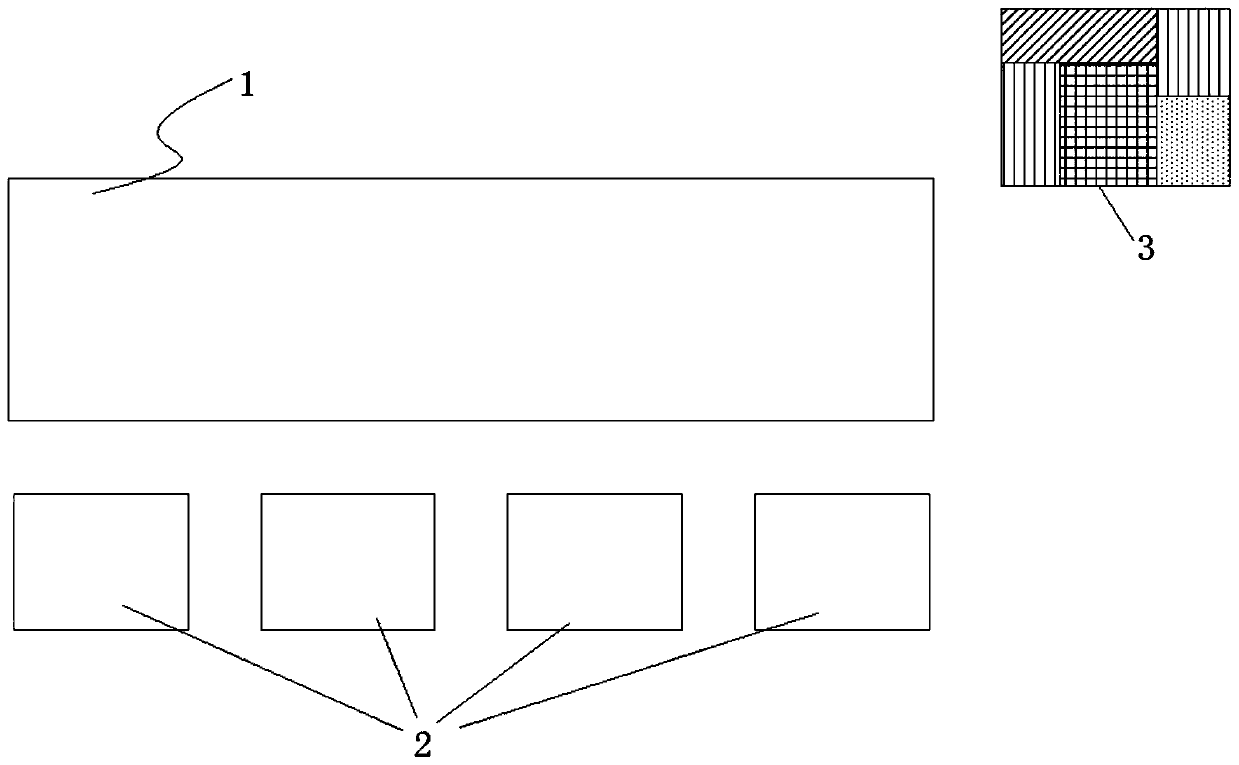

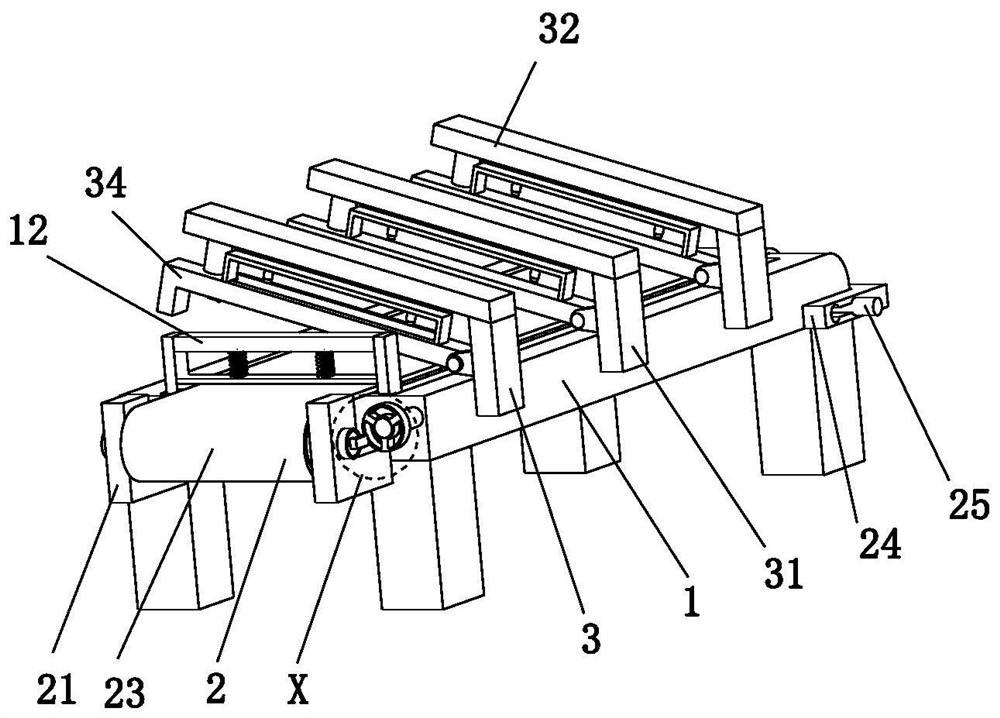

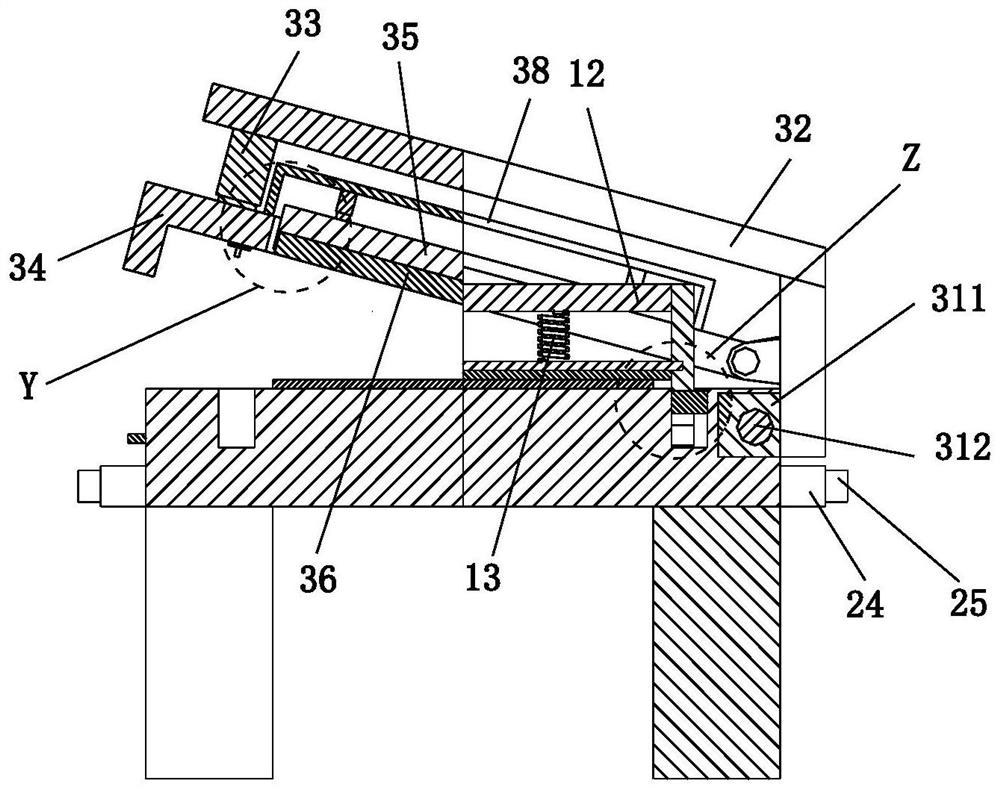

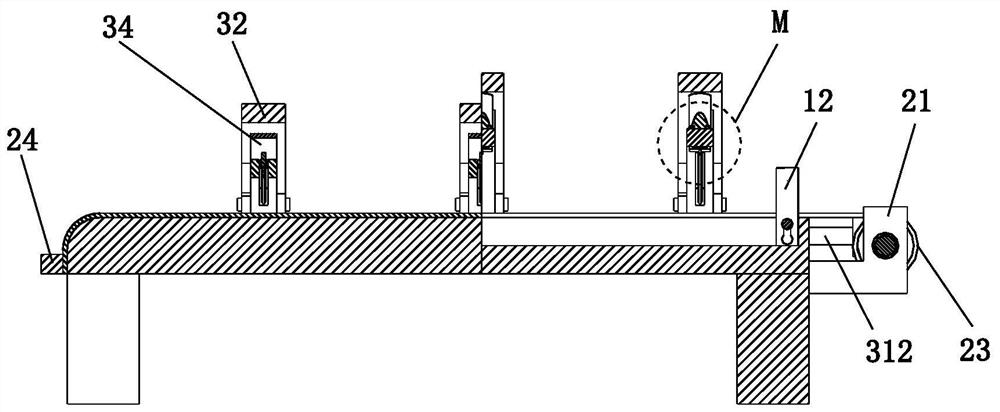

Plastic film cutting device and cutting processing method

ActiveCN111203930AImprove the stabilityImprove cutting accuracyMetal working apparatusPlastic filmMaterials science

The invention relates to a plastic film cutting device. The plastic film cutting device comprises a working table, a clamping device and cutting devices, wherein the clamping device is arranged on theworking table; and the cutting devices are equidistantly arranged on the upper end surface of the working table from left to right. According to the plastic film cutting device and a cutting processing method, a plastic film is cut by adopting the design concept of multiple clamping, so that the stability of the entire plastic film is improved, the entire plastic film is in a non-relaxed state, and furthermore, the precision and efficiency of plastic film cutting are improved; and meanwhile, a pre-cutting structure and a cutting structure are combined for cutting the plastic film so as to improve the quality of plastic film cutting.

Owner:江门市蓬江区东洋机械有限公司

Algae automatic clearing equipment for hydroelectric power generation

ActiveCN109706903ATo achieve the purpose of automatic cleaningReduce nitrogen and phosphorus contentWater cleaningWater contaminantsEngineeringAlgae

The invention provides algae automatic clearing equipment for hydroelectric power generation, and relates to the field of water surface pollutant clearing equipment. The problems that clearing equipment is wound by algae, and growth of the algae cannot be treated radically are solved. The algae automatic clearing equipment for hydroelectric power generation comprises a clearing mechanism, a powerwheel set, a supporting rotary shaft, a water release rotating wheel and a control button; through mutual cooperation of a rotating shaft and a brushing mechanism, the inner wall of a supporting frameis rubbed by a brush continuously to achieve the purpose of automatic cleaning of the supporting frame; through mutual cooperation of the rotating shaft and a slaked lime containing groove, slaked lime powder can be thrown out of a powder discharging channel from a cavity, the slaked lime powder enters to react with nitrogen and phosphorus in the water, the content of the nitrogen and phosphorusin the water is lowered, and mass propagation of the algae can be treated radically; and then through cooperation of the rotating shaft and a cutting mechanism, algae plants are cut into the minimizedsize, and thus the situation that the algae plants are too long and then wind the clearing equipment, and consequently the working efficiency of the equipment is low is prevented.

Owner:洁云环保技术(苏州)有限公司

Pasture cutting line collecting machine

The invention discloses an environment-friendly holding-free pasture cutting collecting device of pasture cutting machinery, particularly relates to a pasture cutting line collecting machine, and belongs to the field of pastoral machinery. The pasture cutting line collecting machine comprises a double-motive-power cutting device, a seedling pulling device, a pasture collecting box, an intermittent placing gearbox device and a placing device. The pasture cutting line collecting machine has the advantages that the interactive double-motive-power pasture cutting principle is adopted, the pasture cutting speed is accelerated, the cut pasture enters the pasture collecting box to be collected under the effect of the seedling pulling device, the pasture quality and the cutting thoroughness are improved, the pasture collecting box is adopted for collecting the pasture, the damage to the pasture field ground surface vegetation and the surface layer pasture roots caused by holding teeth of the existing pasture holding machine is changed, the grassland resources can be preferably protected and utilized, the pasture cutting line collecting machine belongs to a high-efficiency pastoral machine tool capable of being conveniently popularized, and the characteristics of energy saving and environment protection are obviously realized.

Owner:刘启和

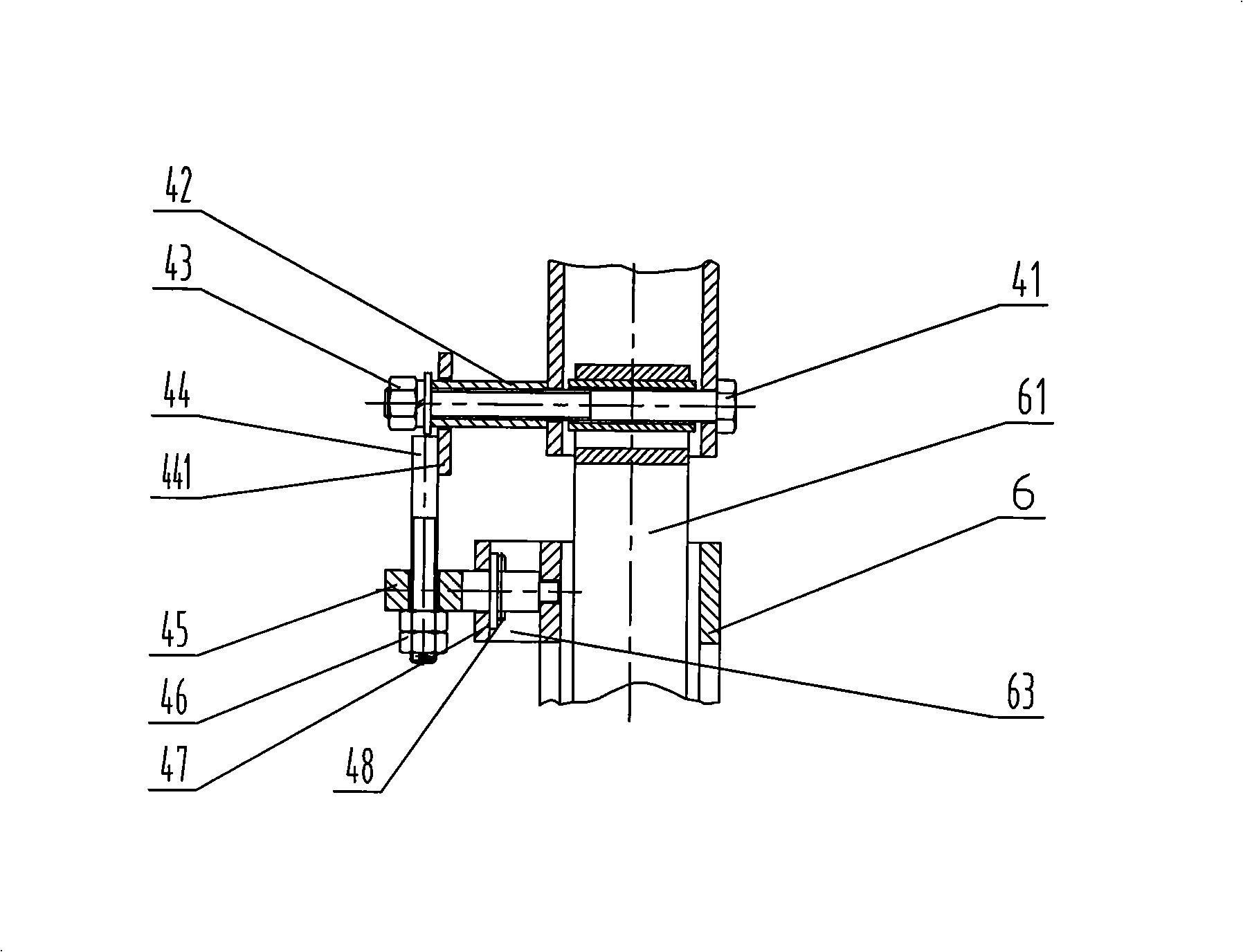

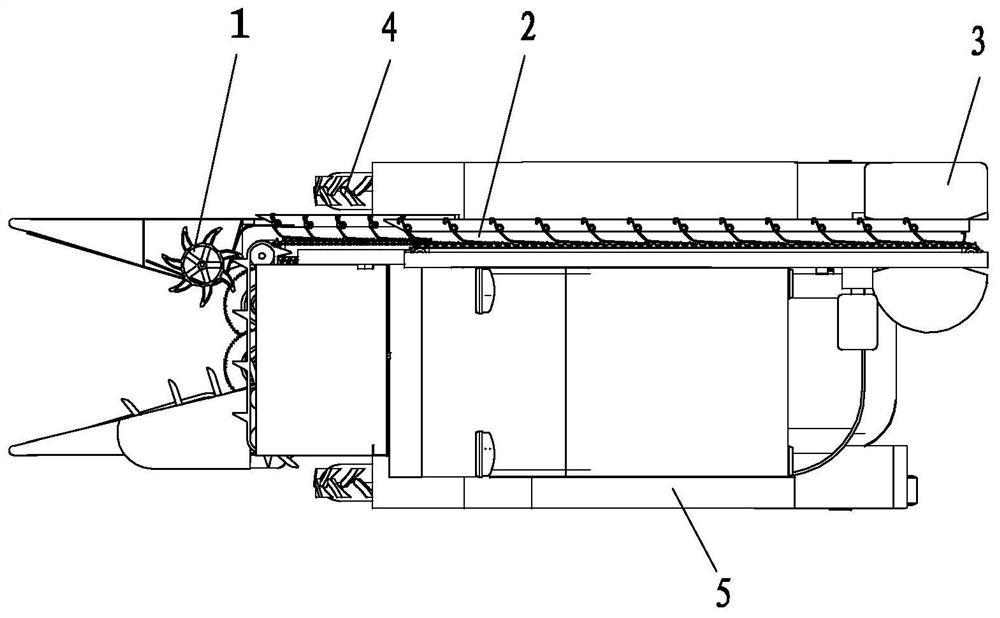

Header device of corn kernels harvester

The invention discloses a header device of corn kernels harvesters. The header device comprises a header combination and a header suspension mechanism. The header combination comprises a header body, a header auger, a combination of moving cutters and a divider. The divider includes a standing rod, a side rod, an oblique strut, a set square and a base rod. The header suspension mechanism is arranged in front of the combination of the moving cutters and comprises a plurality of side-by-side corn dividing-line plates with equal intervals, a plurality of supporting beams and a connecting bracket. One ends of the supporting beams are fixed on the lower parts of the front ends of the corn dividing-line plates and the other ends of the supporting beams are fixed on the lower front of the connecting bracket. The lower end of the corn dividing-line plate is fixed on an edge protecting device and the upper end of the connecting bracket is fixed on the lower front beam of the header body. The header device has the advantages of being simple in structure, low in manufacturing cost and convenient to produce. The divider can prevent stalks of maize which are harvested from falling to unharvested regions. The corn dividing-line plates can guarantee the stalks of maize of different spacing to be guided and divided by guide sharp angles, so that the harvesting rate of maize crops is improved.

Owner:JIANGSU WORLD AGRI MACHINERY

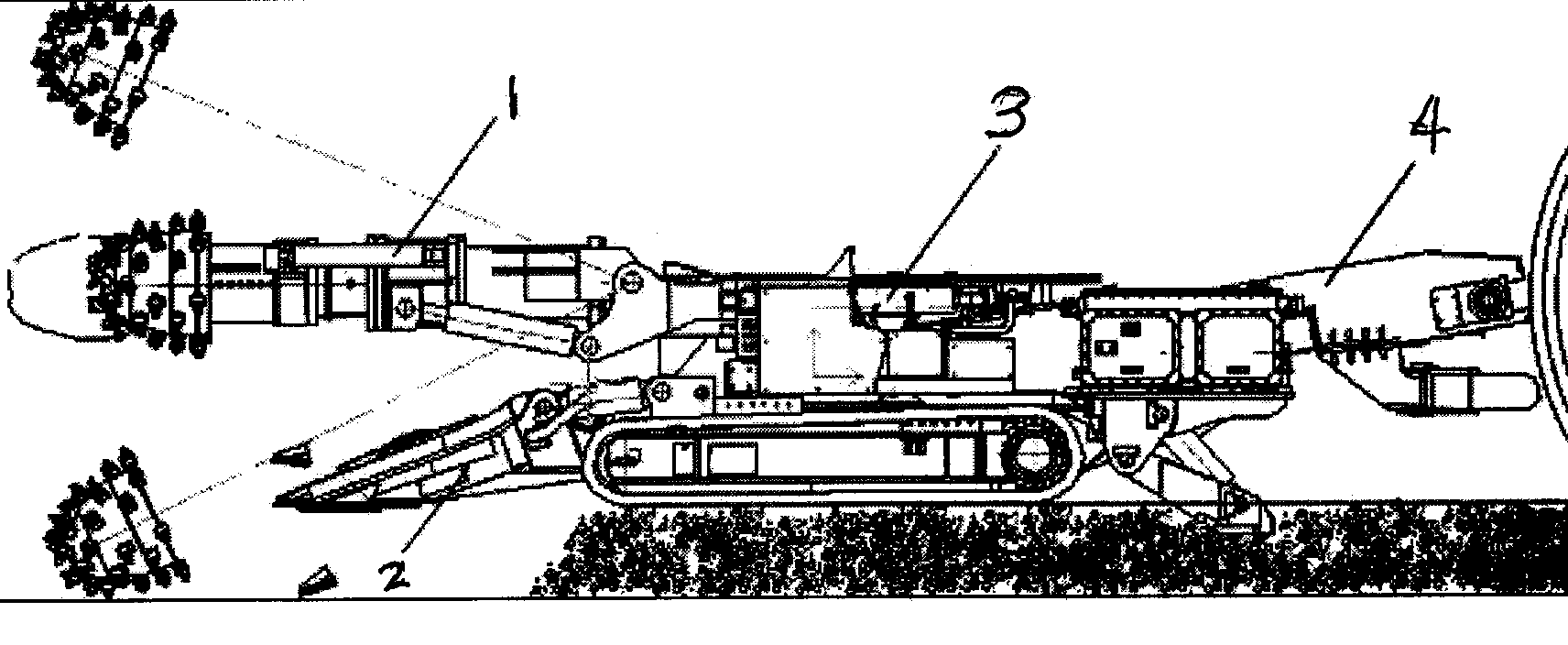

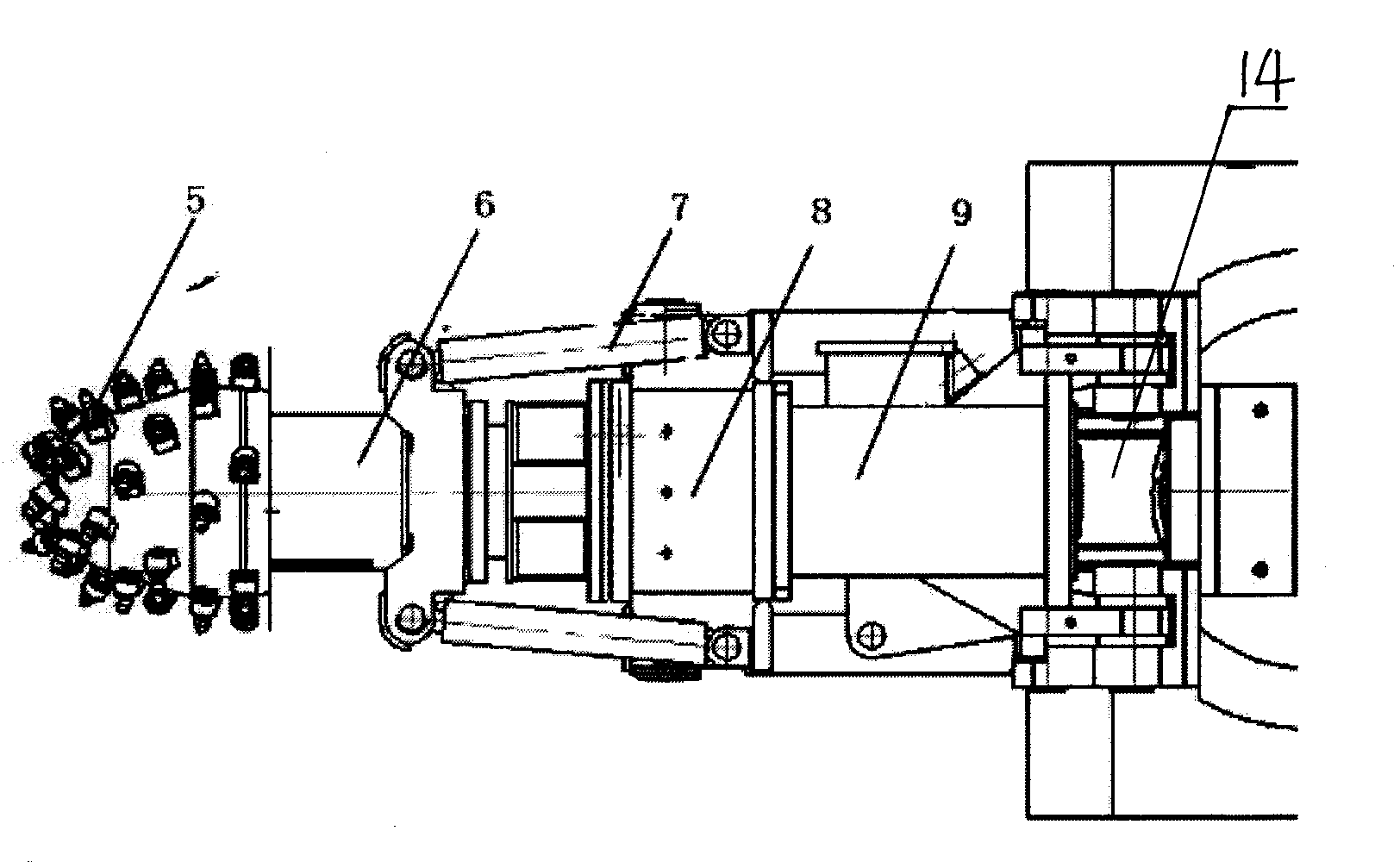

Tunneling machine

The invention relates to a tunneling machine, which is characterized in that a cutting head and a cutting speed reducer form hinge connections on both ends of a stretching bush though high strength bolts, a cutting motor forms a hinge connection behind the cutting speed reducer, a cutting portion is connected with a body frame through a connection pin, a stretching cylinder drives the cutting head to move forward along the stretching bush, a shovel plate and a first conveyor are connected with a shovel plate stretching frame through pins, the shovel plate stretching frame slides along a sliding box on the body frame, and a second conveyor connection frame forms a hinge connection on a first conveyor rear groove through a high strength bolt. The tunneling machine has the following advantages that: stretching degree and dinting depth of the cutting portion of the tunneling machine are increased to improve cutting rate so as to achieve stretching of the shovel plate portion; by matching with the increase of the stretching degree of cutting portion, shipment is increased, such that the first conveyor and the second conveyor can synchronously perform stretching movements along with the shovel plate so as to significantly improve the unloading condition of the first conveyor.

Owner:LIAONING GENERAL MINING MACHINERY EQUIP MFG

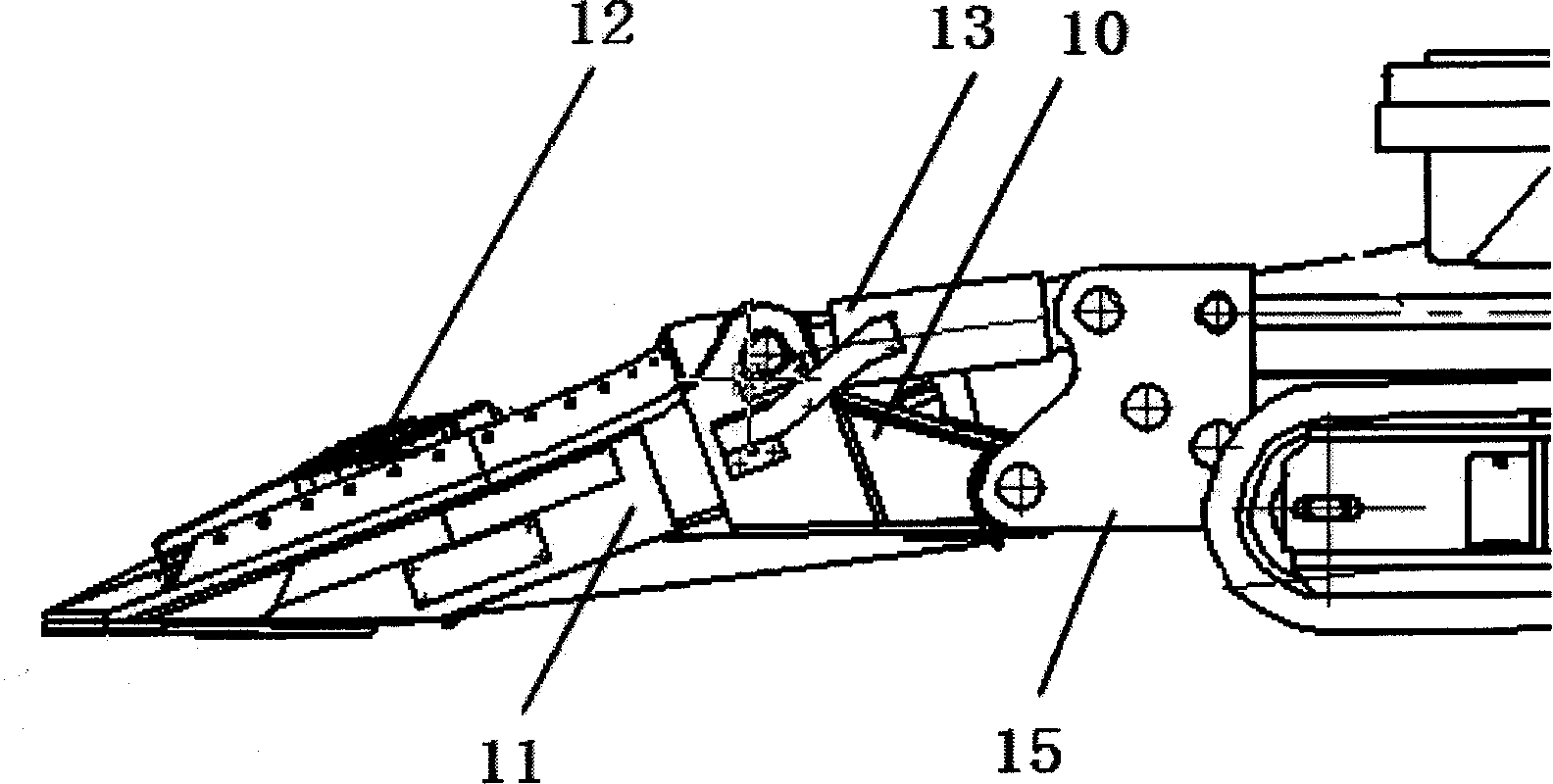

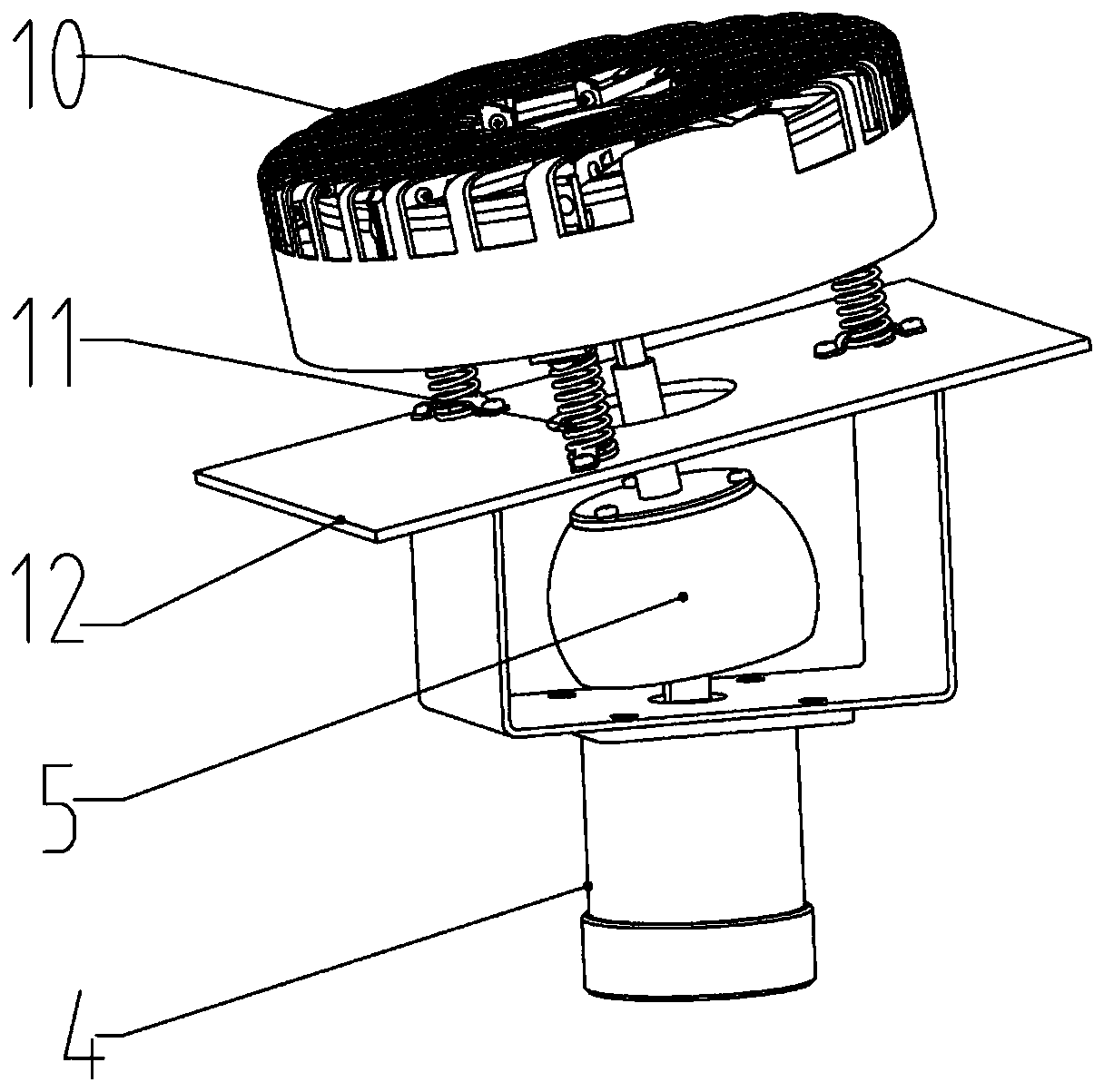

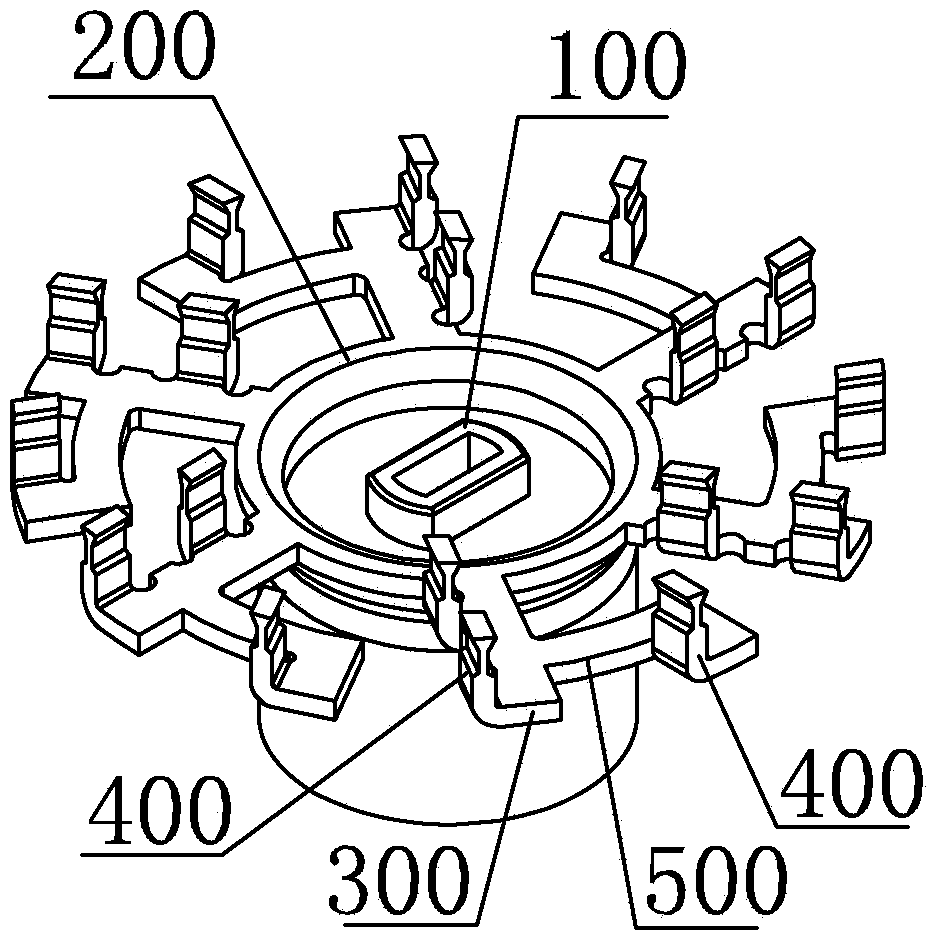

Floating root cutting device for garlic combined harvesting

PendingCN111406496AImprove cutting efficiencyIngenious installationDigger harvestersAgricultural engineeringStructural engineering

The invention relates to a floating root cutting device for garlic combined harvesting in the technical field of agricultural machinery. A floating root cutting main body component comprises a protective net cover which is obliquely arranged in the direction opposite to the garlic conveying direction; a plurality of floating springs are installed on an installation frame, and the floating springssupport and are connected to a connecting frame on the lower side of the protective net cover; a cutter head close to the top wall of the protective net cover and a cutter head base assembly for supporting and fixing the cutter head are arranged in the protective net cover, and a rotary driving component for driving the cutter head base assembly and the cutter head to rotate at a high speed is installed on the installation frame; the top wall of the protective net cover is arranged to be of a net-shaped structure densely provided with a plurality of top grid holes, and the center of the top ofthe protective net cover is arranged to be of a vertically-through round hole structure so as to position garlics; the center of the top of the protective net cover directly faces the center of an alignment chain, and the top grid holes penetrate through the top wall of the protective net cover and the upper portion of the side walls of the protective net cover from front to back. Therefore, thecutting indexes such as the root system cutting rate, the cutting efficiency and the effective cutting force can be remarkably improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

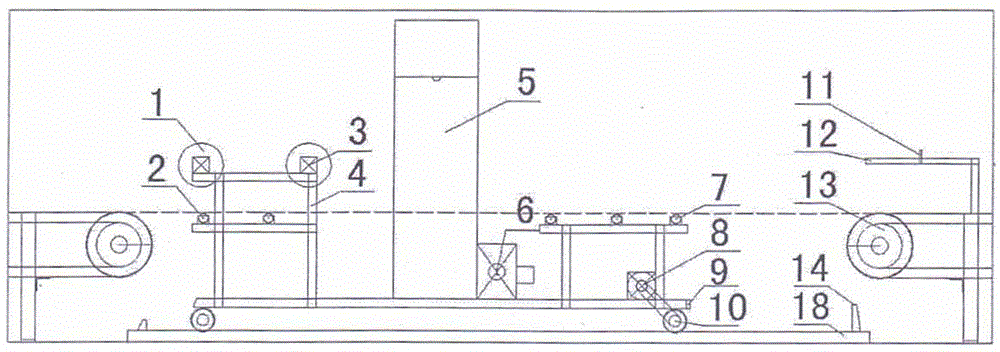

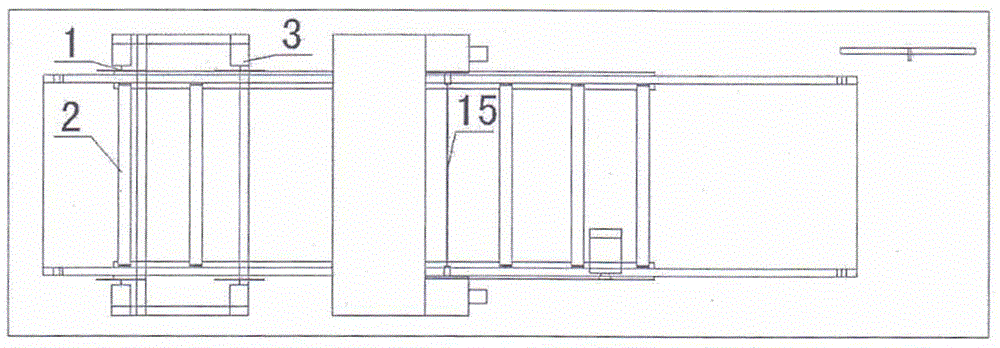

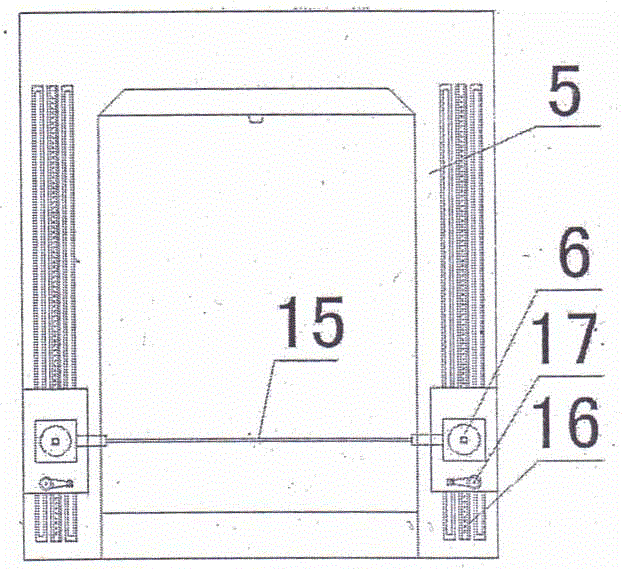

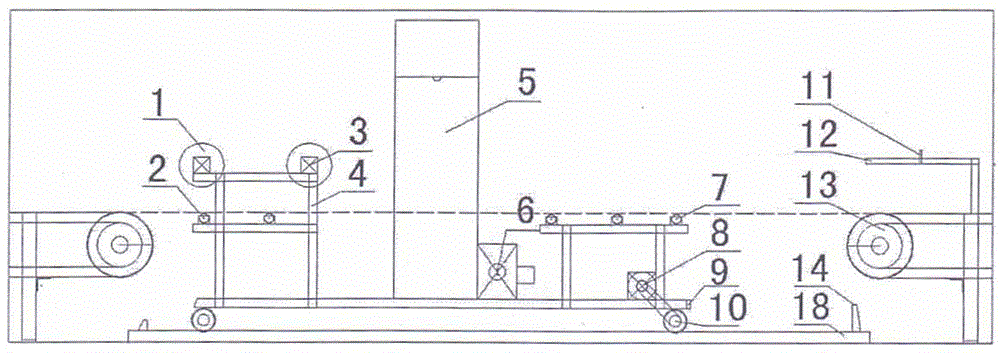

Automatic foam cutting device for continuous production line and method for automatically cutting foam

ActiveCN105479506AFully automatedRealize fully automatic operationMetal working apparatusProduction lineWaste product

The invention discloses an automatic foam cutting device for a continuous production line and a method for automatically cutting foam. The automatic foam cutting device comprises a base moving on a guide rail, wherein a clamp protection device is mounted on the base and is used for guiding, limiting, clamping and righting foam transmitted by a front segment of production line; a cutting device is arranged on the base and behind the clamp protection device and is used for cutting the cured and formed foam produced by the continuous production line into segments; a travel switch is arranged on the base and is matched with a baffle plate on the guide rail; a rapid conveying belt is arranged behind the base, and an induction device is arranged above the rapid conveying belt am dos is used for controlling the opening of the cutting device and adjusting the cutting length of foam. According to the automatic foam cutting device, the continuously produced foam is cut and separated according to the fixed length, the production efficiency and the cutting precision are improved, the output percentage is increased, and waste products are reduced.

Owner:南通觅睡方家居科技有限公司

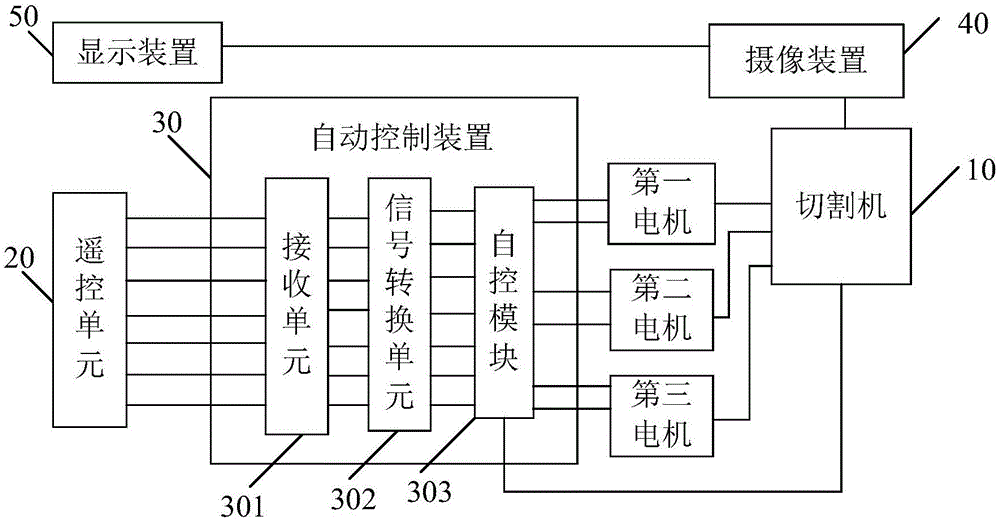

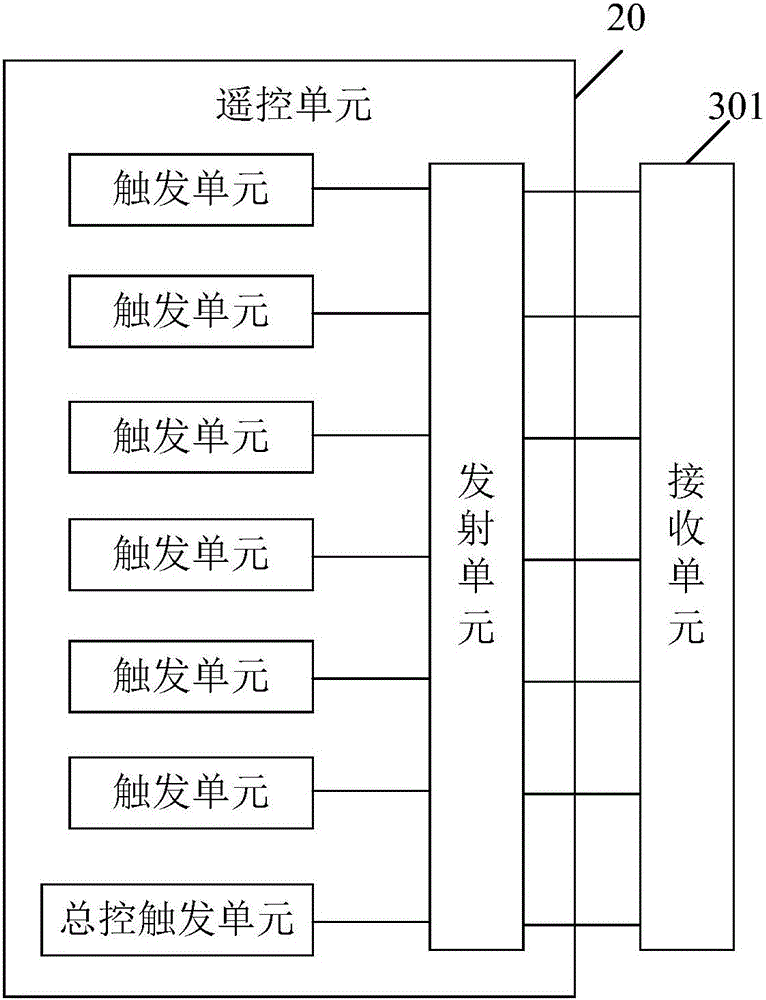

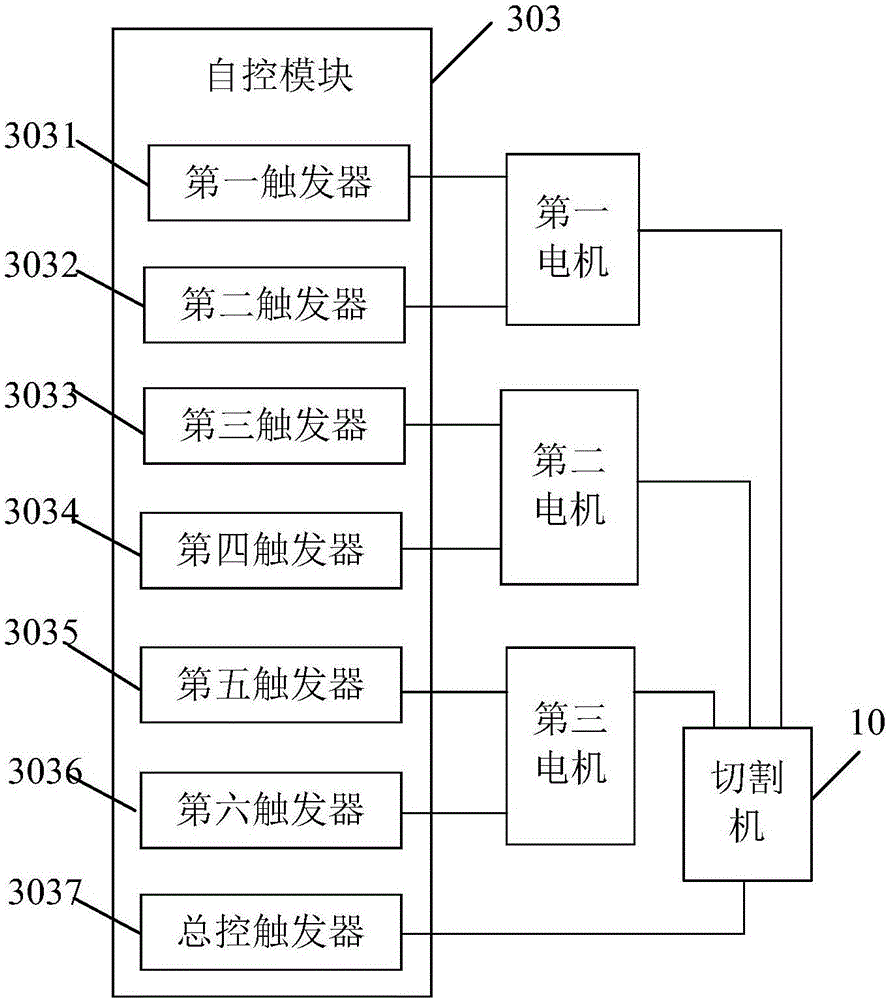

Automatic cutting system for casting riser

InactiveCN106623872ARealize automatic adjustment functionReduce labor intensityAuto regulationAutomatic control

The invention discloses an automatic cutting system for a casting riser. The automatic cutting system comprises a cutting machine and a first motor, a second motor, a third motor, a remote control unit and an automatic control device which are connected with the cutting machine; the automatic control device comprises a receiving unit, a signal conversion unit and an automatic control module which are sequentially connected, and the automatic control module comprises a first contactor, a second contactor, a third contactor, a fourth contactor, a fifth contactor and a sixth contactor. According to the automatic cutting system for the casting riser, the function of automatically adjusting a cutting arm is achieved by arranging the remote control unit and the automatic control device, remote operation control is achieved by operating the remote control unit and adjusting the position relation between the cutting machine and the casting riser, then the purposes of reducing the labor intensity of site operation personnel and increasing the cutting rate and the coincidence rate of equipment cutting are achieved, and meanwhile personnel health and safety are guaranteed.

Owner:KOCEL STEEL

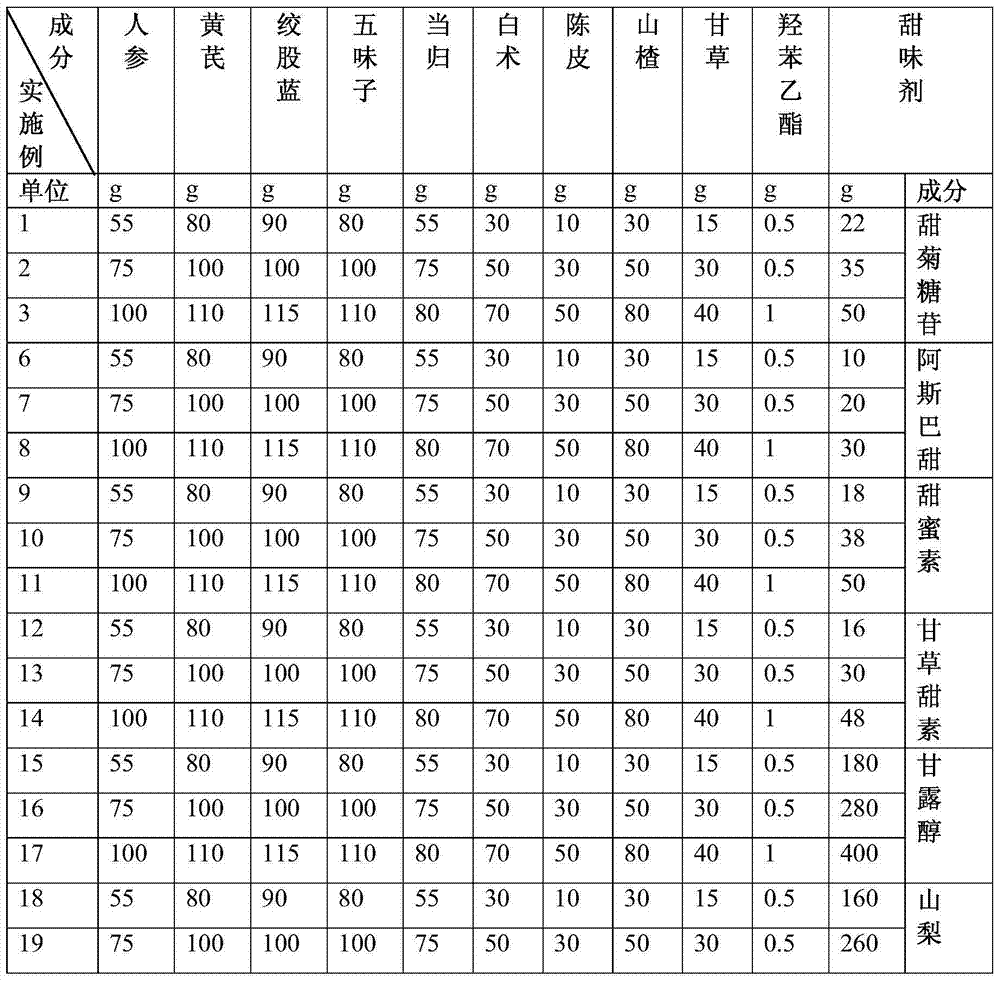

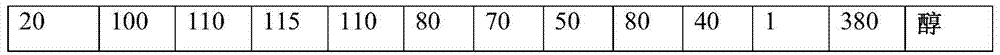

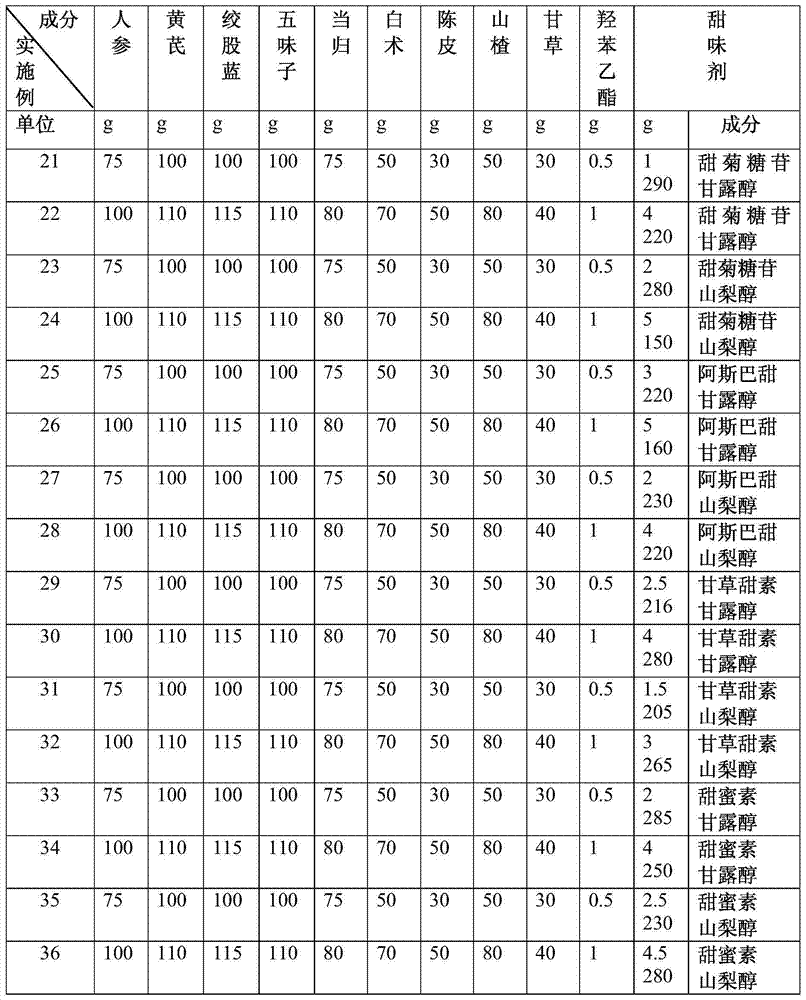

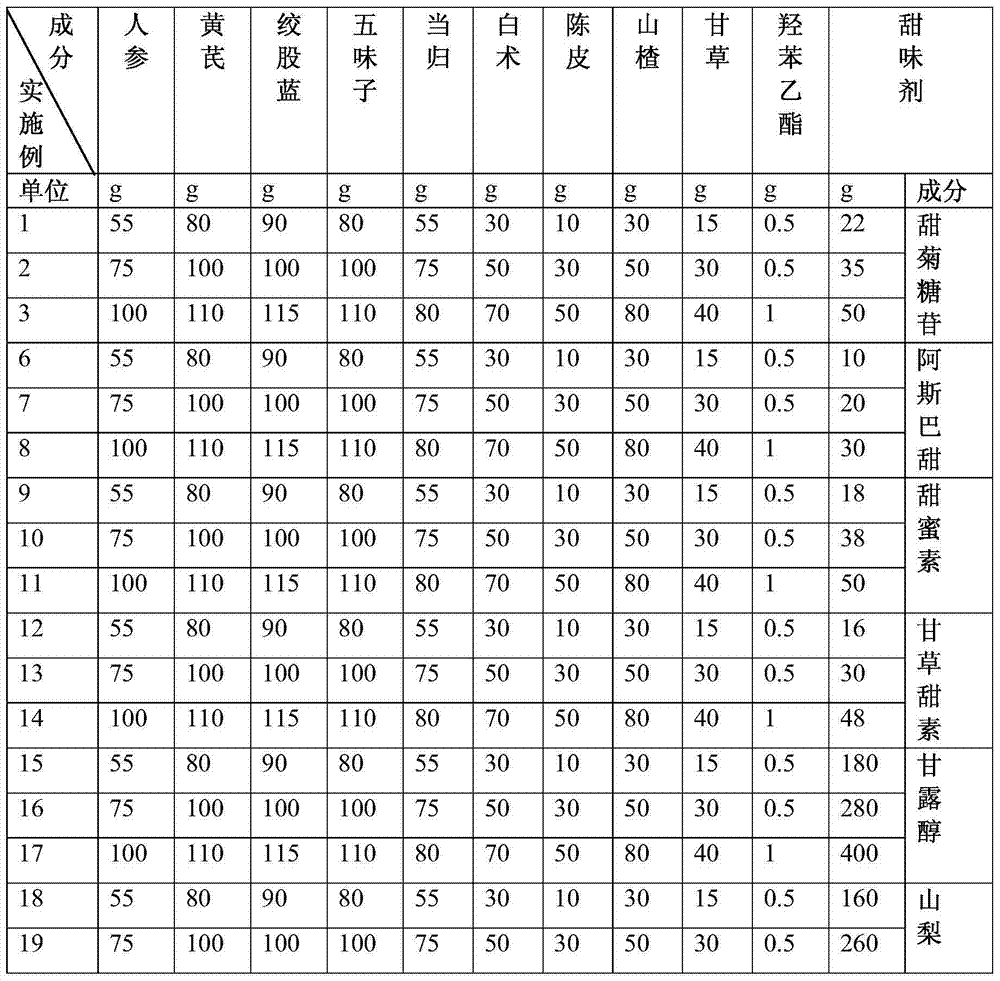

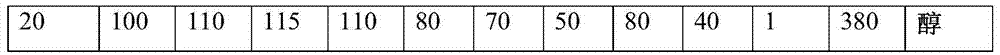

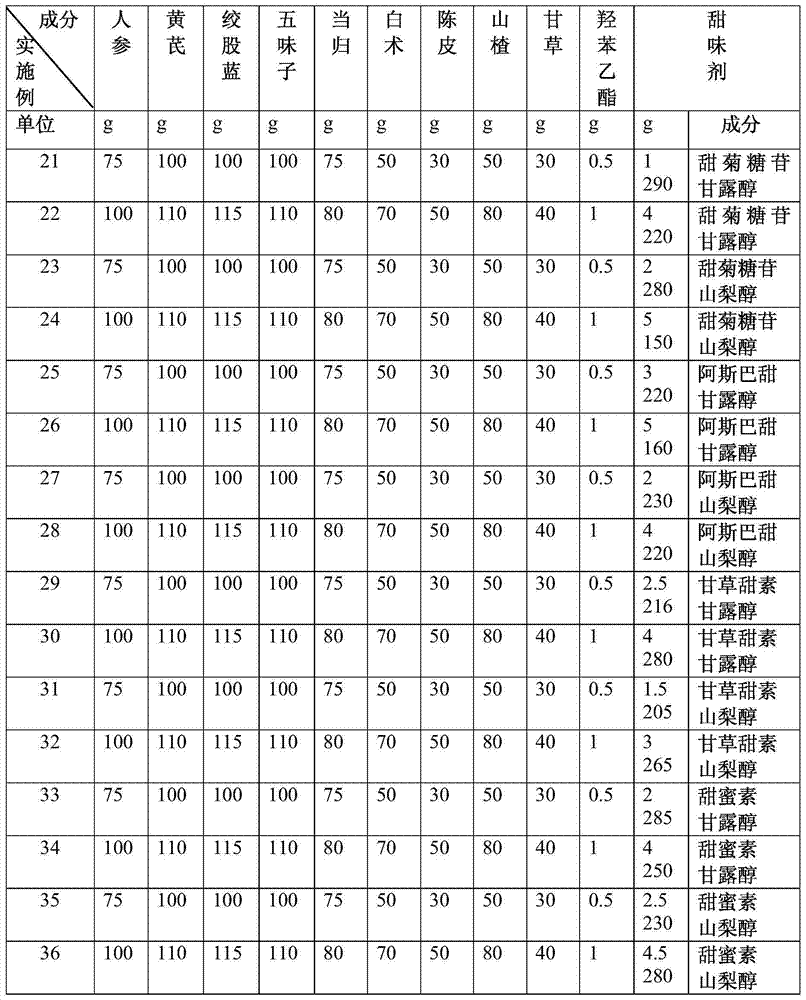

Sugar-free nine-ingredient blood-replenishing oral liquid and preparation method thereof

ActiveCN103494934ADoes not affect the tasteGreat tastePharmaceutical delivery mechanismPharmaceutical non-active ingredientsSucroseAdditive ingredient

The invention relates to the technical field of traditional Chinese medicine preparations, in particular to sugar-free nine-ingredient blood-replenishing oral liquid and a preparation method thereof. The sugar-free nine-ingredient blood-replenishing oral liquid is characterized by being prepared from Chinese herbal medicinal ingredients of ginseng, astragalus, gynostemma pentaphyllum, schisandra chinensis, angelica sinensis, rhizoma atractylodis, tangerine peels, hawthorn and liquorice and minor ingredients of ethylparaben and a sweetening agent. The sweetening agent replaces a sugar ingredient of original nine-ingredient blood-replenishing oral liquid, so that sugar-avoiding patients suffering from hypertension, obesity, diabetes, heart diseases and the like can administrate the oral liquid as well. By the sugar-free nine-ingredient blood-replenishing oral liquid, hematopoiesis of human bodies is enhanced by means of improving endocrine and metabolism of human bodies so as to tonify qi-blood and comprehensively treat anemia, and the sugar-free nine-ingredient blood-replenishing oral liquid has functions of replenishing qi and enriching the blood, and strengthening the spleen and benefiting the stomach. In conclusion, the sugar-free nine-ingredient blood-replenishing oral liquid is safe and non-toxic; sucrose is replaced by the low-calorie sweetening agent, so that bitterness of traditional Chinese medicine is improved, and the oral liquid tastes good to allow the patients to accept easily.

Owner:GUANGXI YINGKANG PHARMA

Soybean flexible cutting knife device

The invention discloses a flexible soybean cutting knife device which comprises a movable cutter bar assembly, a flexible guard bar, grid mechanisms, a drag link mechanism, a horizontal adjusting rod, spring plate mechanisms, an elastic regulating mechanism and a draw plate mechanism. The movable cutter bar assembly is flatly placed in a guard on the flexible guard bar; a plurality of grid mechanisms are arranged at the back side of the flexible guard bar, the front ends of a plurality of collateral spring plate mechanisms are vertically connected with the flexible guard bar respectively. The front part of each spring plate mechanism is connected with a knife beam seat fixed on a header by the corresponding drag link mechanism; the end of each spring plate mechanism is movably connected with a header body by the draw plate mechanism and a connecting plate, and the elastic regulating mechanism is arranged at the mid-back part of each spring plate mechanism. The flexible soybean cutting knife device can respectively adjust different inclination angles of each spring plate mechanism, which can cause the flexible guard bar together with the cutting knife to form certain deflection according to different ridge heights, and float up and down close to ground. By adopting the flexible cutting knife device to harvest soybeans, the height of cut plant stubbles is only 5cm, and the harvest rate of soybeans is improved.

Owner:JIANGSU WORLD AGRI MACHINERY

Fuel gas tunnel kiln in use for producing foam glass

InactiveCN1600710AGuaranteed continuous productionOvercome the disadvantage of high costGlass furnace apparatusGlass shaping apparatusTunnel kilnCombustor

The invention sections are in turn: preheating section, foaming section and quick cooling section, the characteristic is that a stabilizing section is behind the quick cooling section, length of each section is defined according to foam glass heating curve, kiln car driving structure is used, foaming section includes uniform distributed burner interlacing high and low; quick cooling section incluse cooling flue pipe fit inside of kiln wall and kiln top; stabilizing section indudes uniform distributed burner interlacing high and low on two sides of kiln wall, distribution density is reduced to 1 / 2-1 / 3 of the burner in foaming section, gas fuel is used by the burner as heating energy source, and automatic gas controlling system is used by the invention.

Owner:BEIJING UNIV OF TECH

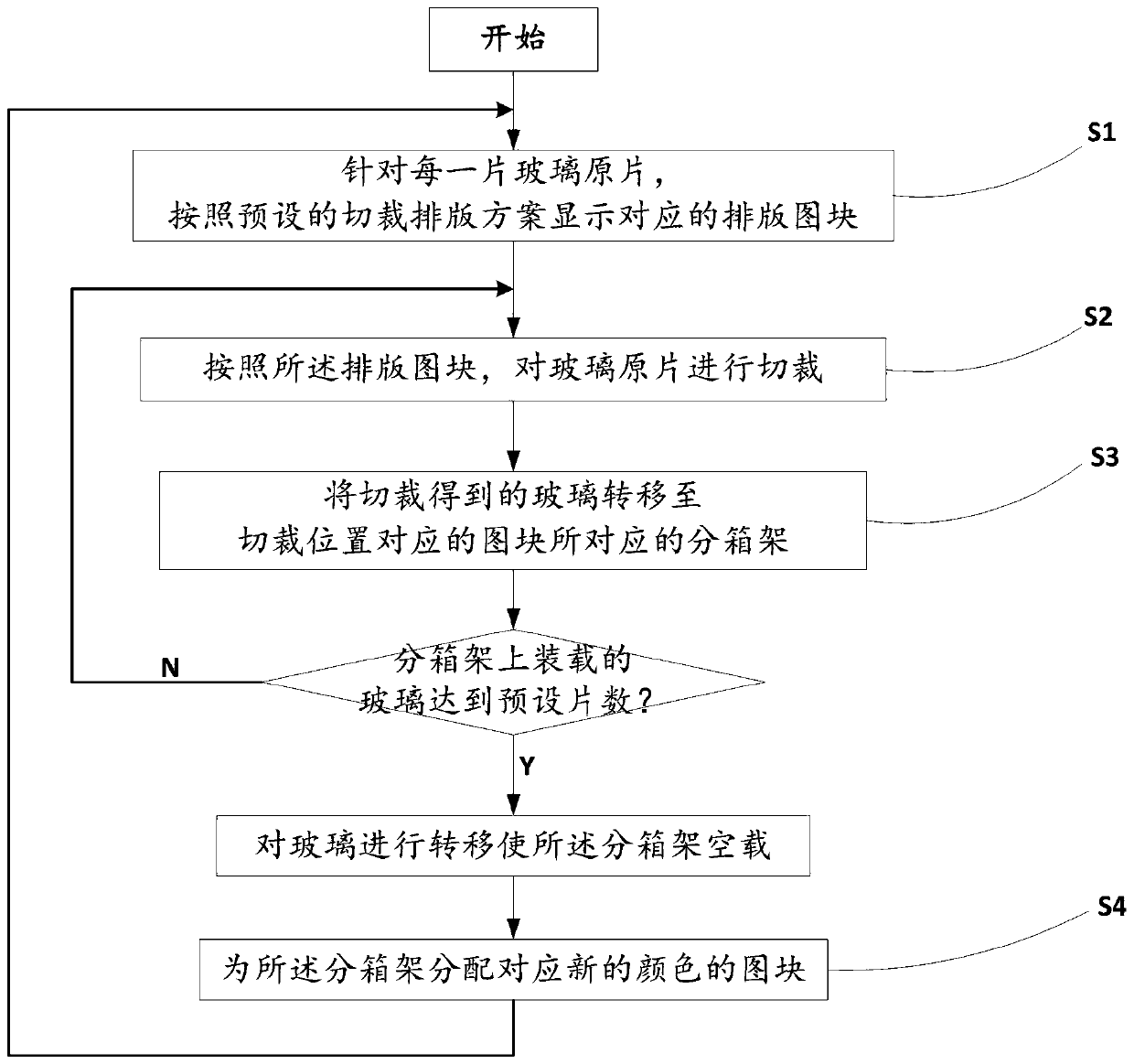

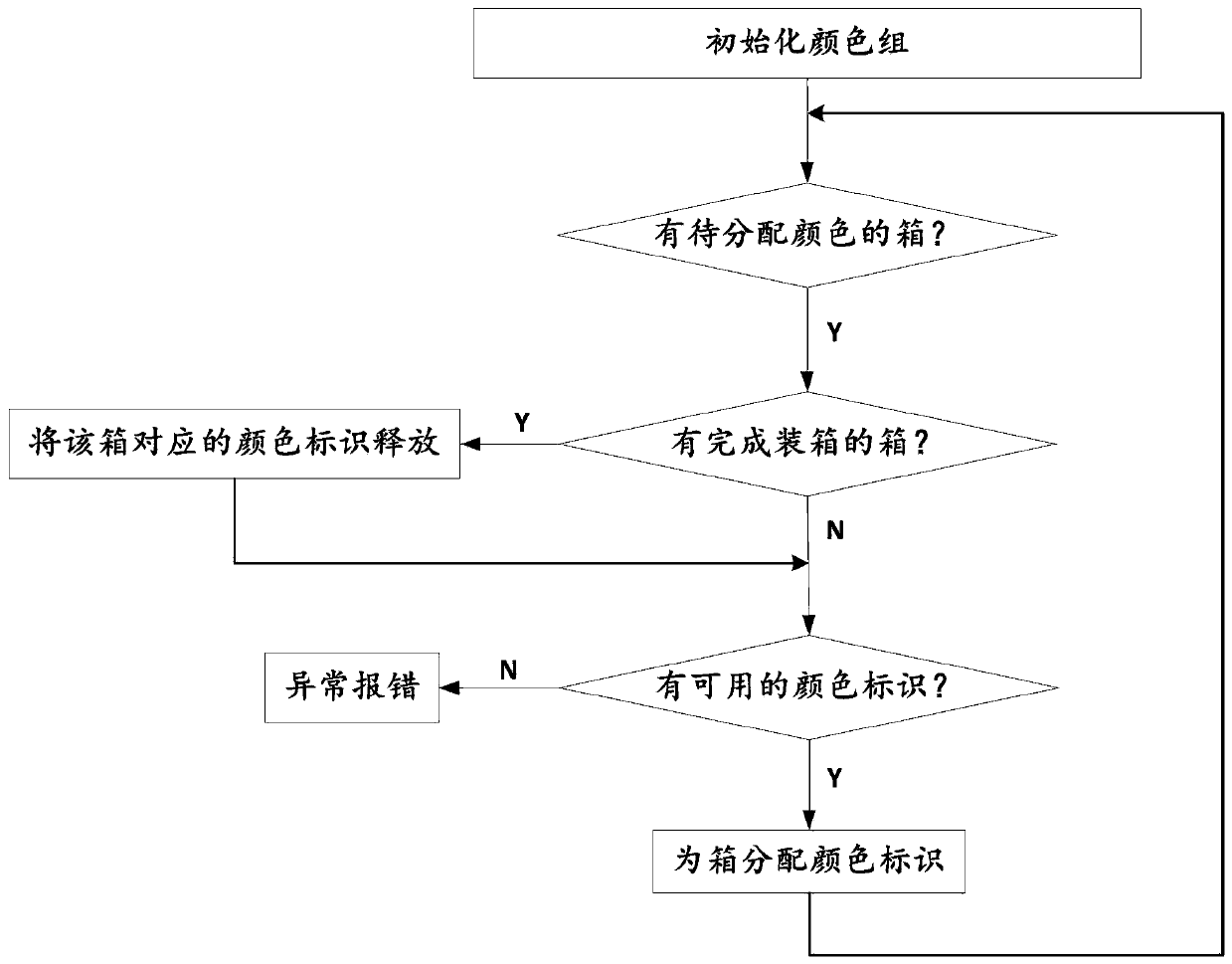

Glass cutting, boxing and shelf unloading system and boxing and shelf unloading method

ActiveCN111039019AFacilitate identification of sub-boxesImprove work efficiencyCharge manipulationGlass severing apparatusCutting glassDisplay device

The invention discloses a glass cutting, boxing and shelf unloading system and a boxing and shelf unloading method. The system comprises a cutting workbench for cutting glass, a plurality of boxing shelves, a display device and a controller; each boxing shelf is used for loading glass in the same box; to-be-cut raw glass sheets are arranged on the cutting workbench; the controller controls the display device to display layout blocks corresponding to preset cutting layout schemes; the display device displays the same or different layout blocks corresponding to different raw glass sheets; the layout blocks displayed on the display device correspond to one or more boxing shelves; the blocks, corresponding to the same boxing shelf, of the layout blocks have the same color; the blocks, corresponding to different boxing shelves, of the layout blocks have different colors; and the raw glass sheets are cut according to the corresponding layout blocks; and the cut glass is transferred to the corresponding boxing shelves according to the corresponding blocks. According to the system and method of the invention, colors are used as identifiers to distinguish boxing-based glass layout optimal patterns, and therefore, operation efficiency and sheet discharging accuracy are improved.

Owner:吴江南玻华东工程玻璃有限公司 +1

Ramulus mori shoot harvester

PendingCN114190181ARealize mechanical integrationSmooth entryCuttersCutting implementsAgricultural engineeringDrive motor

The invention relates to a mulberry twig reaper which comprises a cutting and gathering device, a conveying device, a collecting mechanism, a walking mechanism, a vehicle body and a control mechanism, the cutting and gathering device comprises a cutting device, a conveying and gathering device, a rack and a front baffle, and the conveying device comprises a driving motor, a supporting frame and a conveying assembly. The conveying assembly comprises a double-side sharp tooth chain, a chain support, a pressing strip installation plate and a plurality of spring pressing strips, an inlet of a conveying channel of the conveying device communicates with an outlet of a material guide plate of the cutting and gathering device, and the collecting mechanism is installed at the outlet of the conveying channel of the conveying device. The mulberry twig reaper can mechanically realize cutting, gathering, long-distance conveying and collecting work of mulberry twigs, the cutting and gathering device is provided with a longitudinal conveying chain, feeding is smoother, and the gathering and conveying effect is good; the conveying device adopts a conveying mode that sharp tooth chains on the two sides are matched with spring pressing strips, the clamping and conveying effects on the mulberry twigs are good, and the conveying device is suitable for long-distance mulberry twig conveying.

Owner:广西金元祥智慧农业科技有限公司

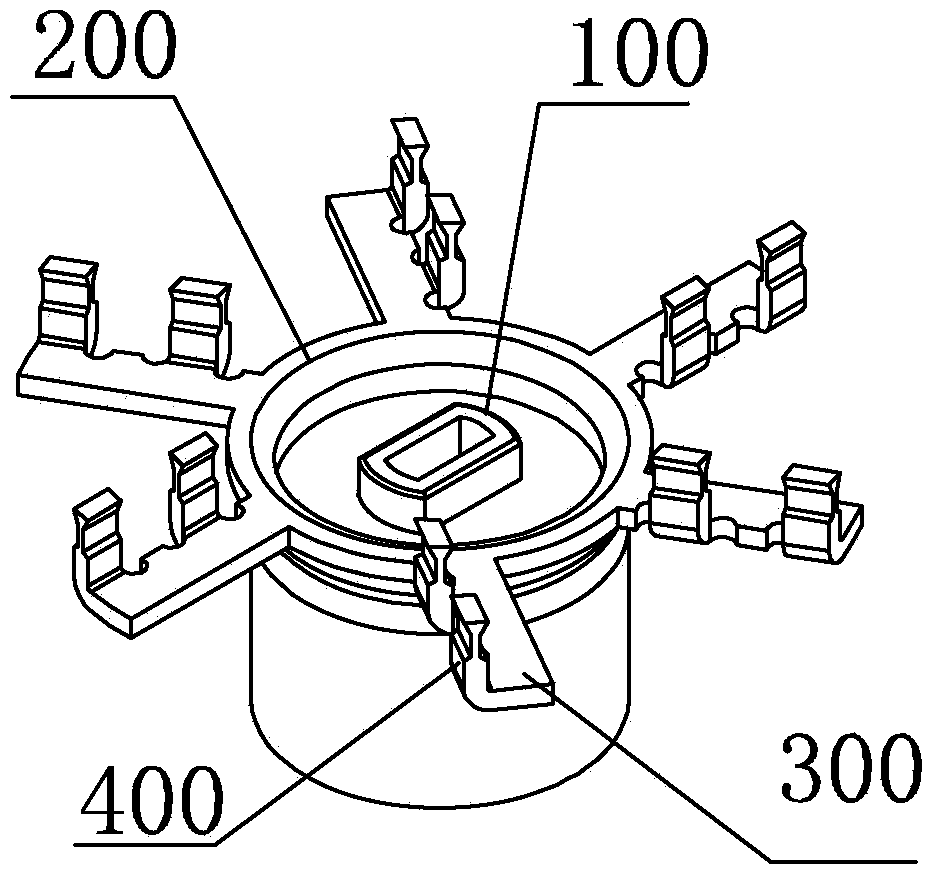

Inner clipper of shaver

InactiveCN103692458AImprove beard cutting rateGood shaveMetal working apparatusEngineeringRazor Blade

Owner:SUPERMAN GROUP

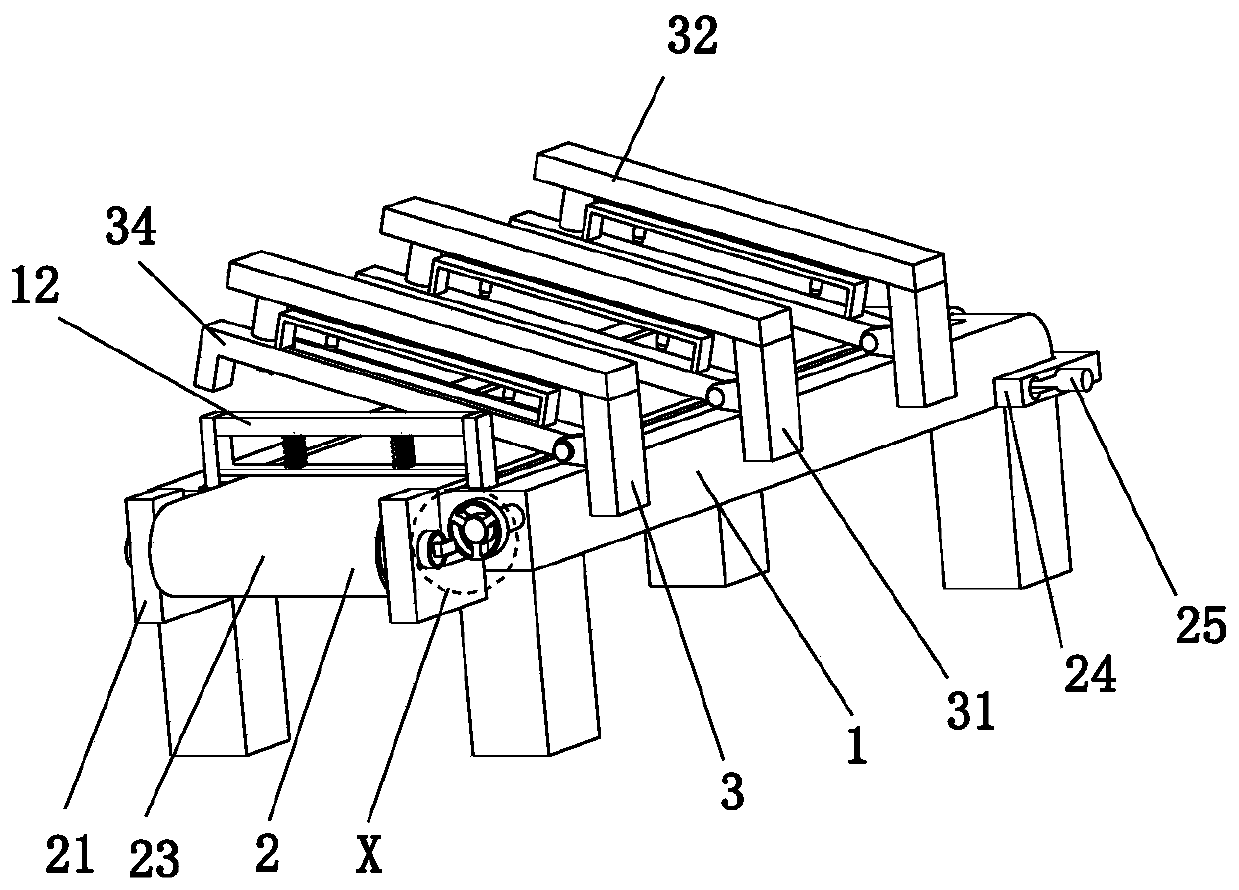

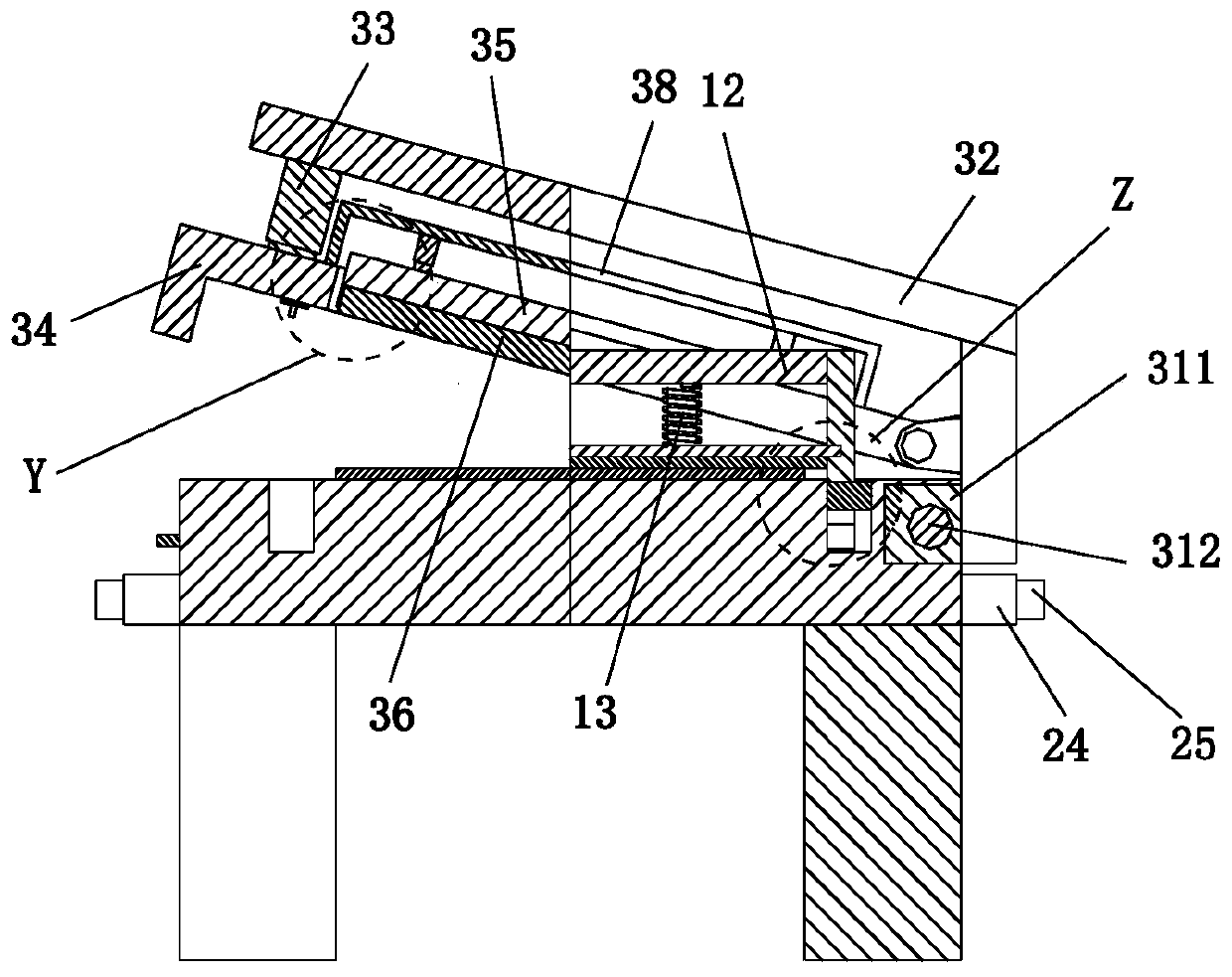

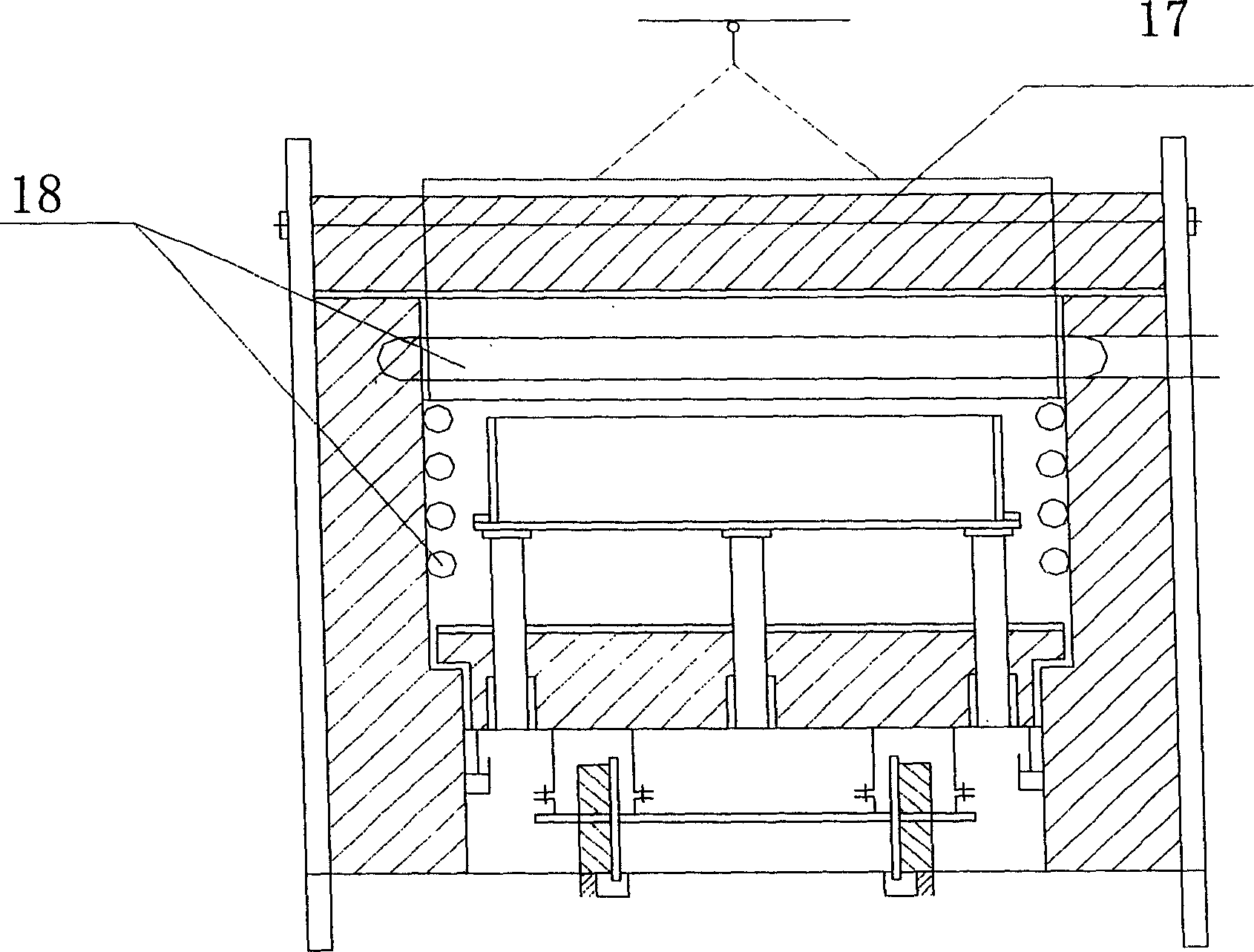

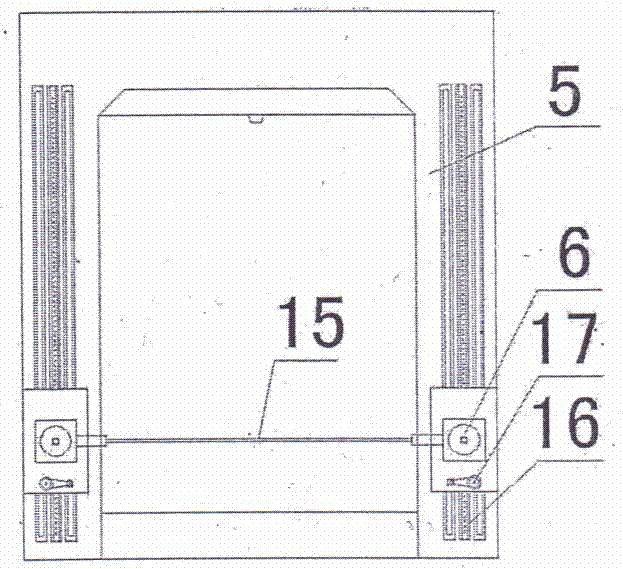

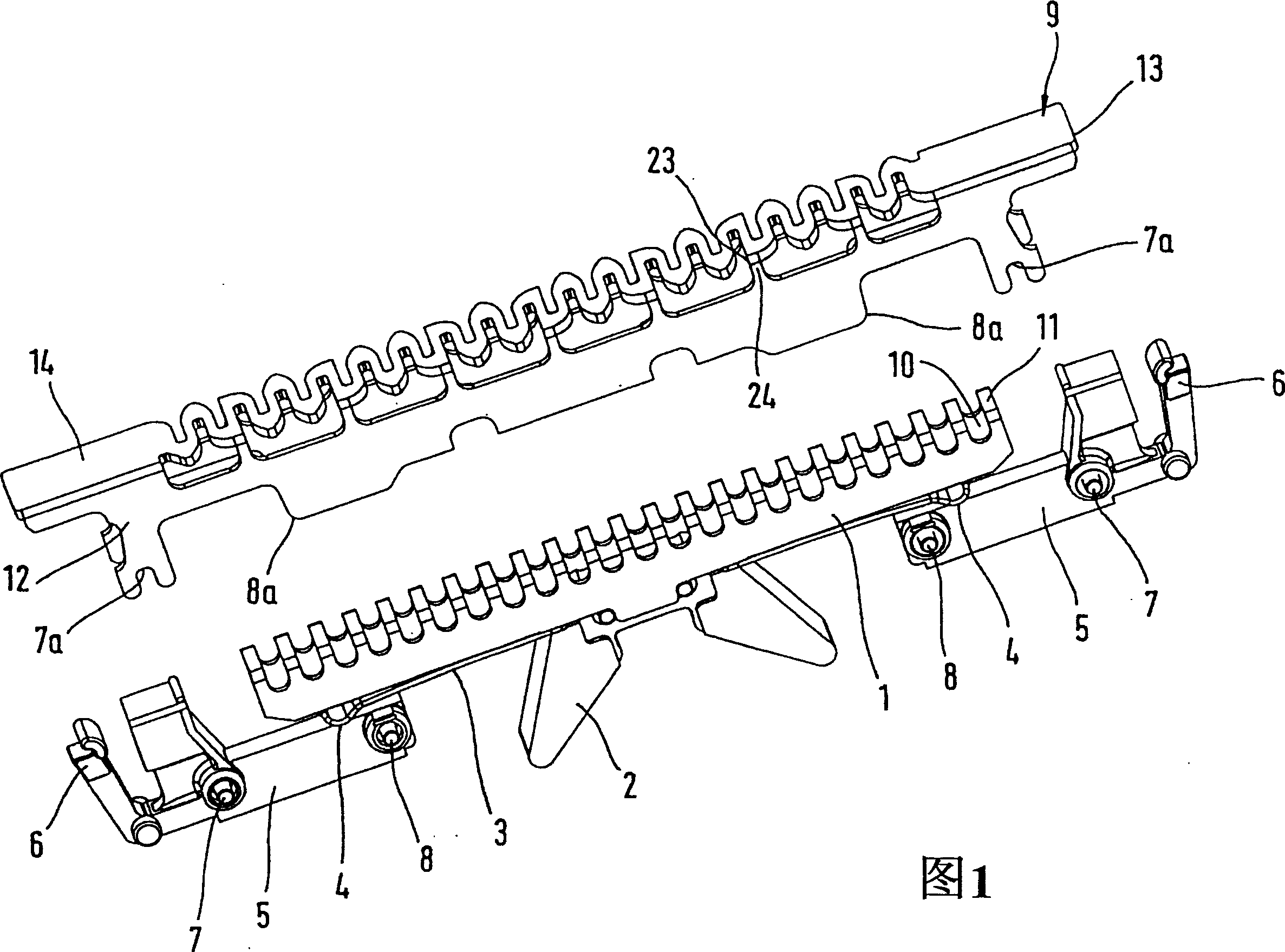

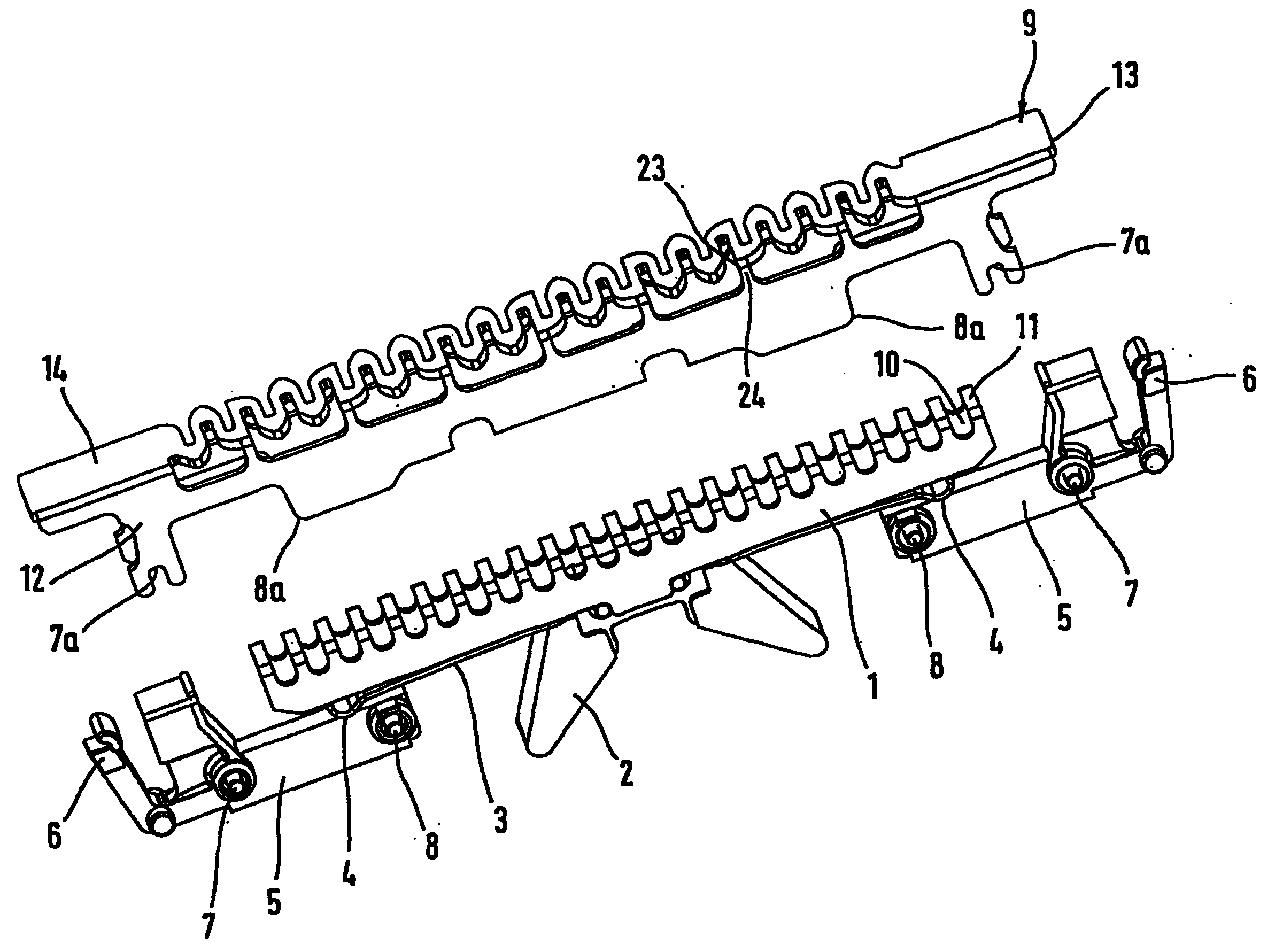

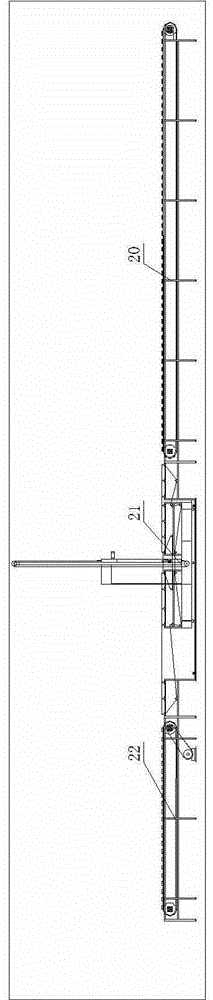

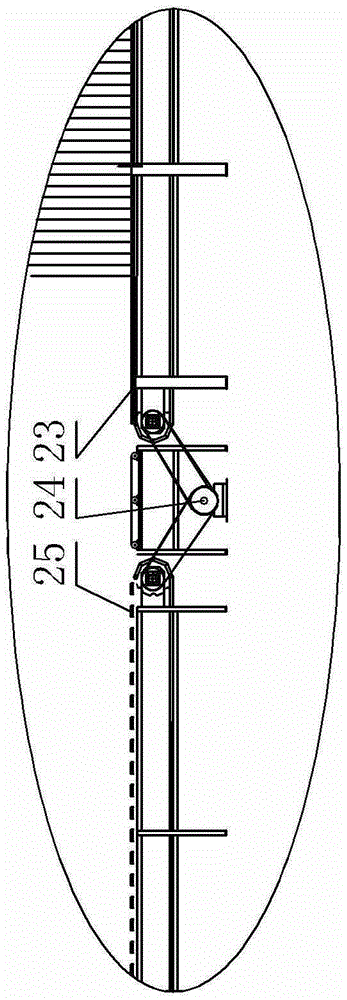

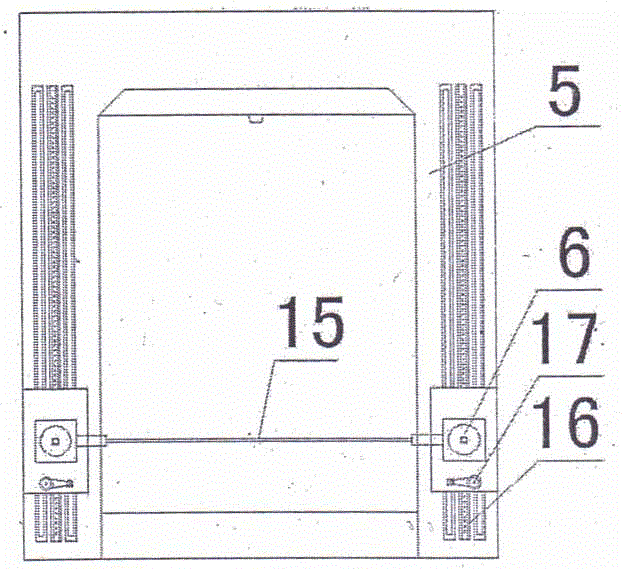

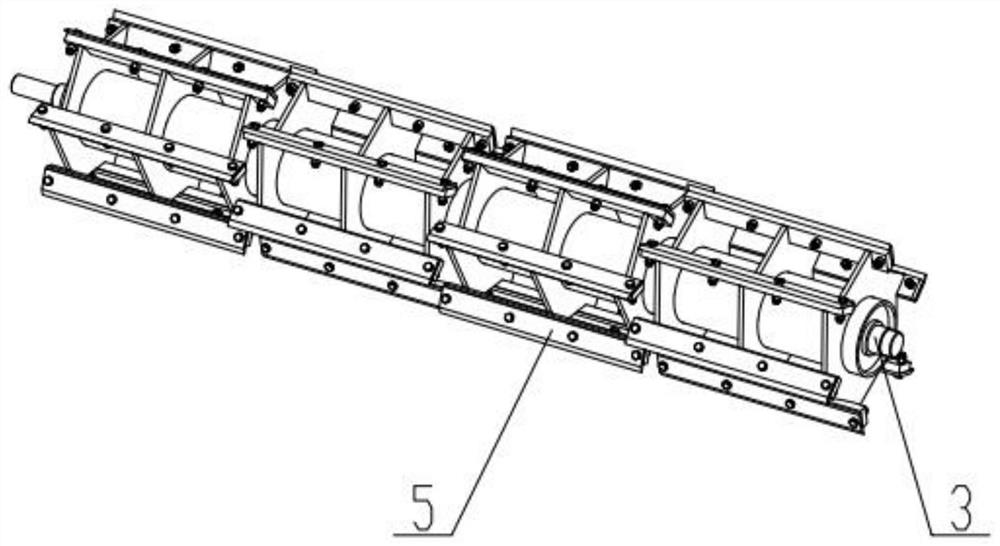

Width-adjustable continuous foaming production line of rigid polyurethane foam

The invention discloses a width-adjustable continuous foaming production line of rigid polyurethane foam. The width-adjustable continuous foaming production line comprises a bottom crawler-type transmitting belt, a left crawler-type transmitting side plate and a right crawler-type transmitting side plate. The bottom crawler-type transmitting belt, the left crawler-type transmitting side plate and the right crawler-type transmitting side plate are fixedly connected with a production line frame; and an electric width adjusting device is connected with the left crawler-type transmitting side plate and the right crawler-type transmitting side plate and adjusts movement of at least one of the left crawler-type transmitting side plate and the right crawler-type transmitting side plate. By means of the width-adjustable continuous foaming production line, continuous production of a factory is achieved, quality is stable, cost is low, the production efficiency is high, and mass production can be achieved; and in addition, the width of the production line can be adjusted, the material cutting rate of a product is increased, the product cost is reduced, and the foam has a wider application range accordingly.

Owner:JIANGSU LVYUAN NEW MATERIALS

Automatic foam cutting device for continuous production line and method for automatic foam cutting

ActiveCN105479506BFully automatedRealize fully automatic operationMetal working apparatusProduction lineWaste product

Owner:NAN TONG MI SHUI FANG SHUI MIAN CHAN YE KE JI YOU XIAN GONG SI

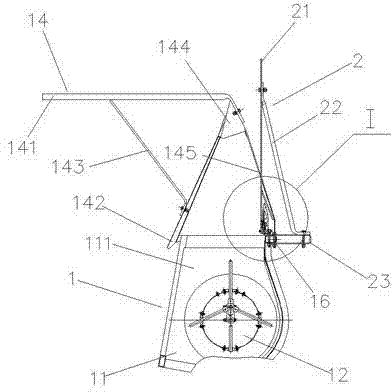

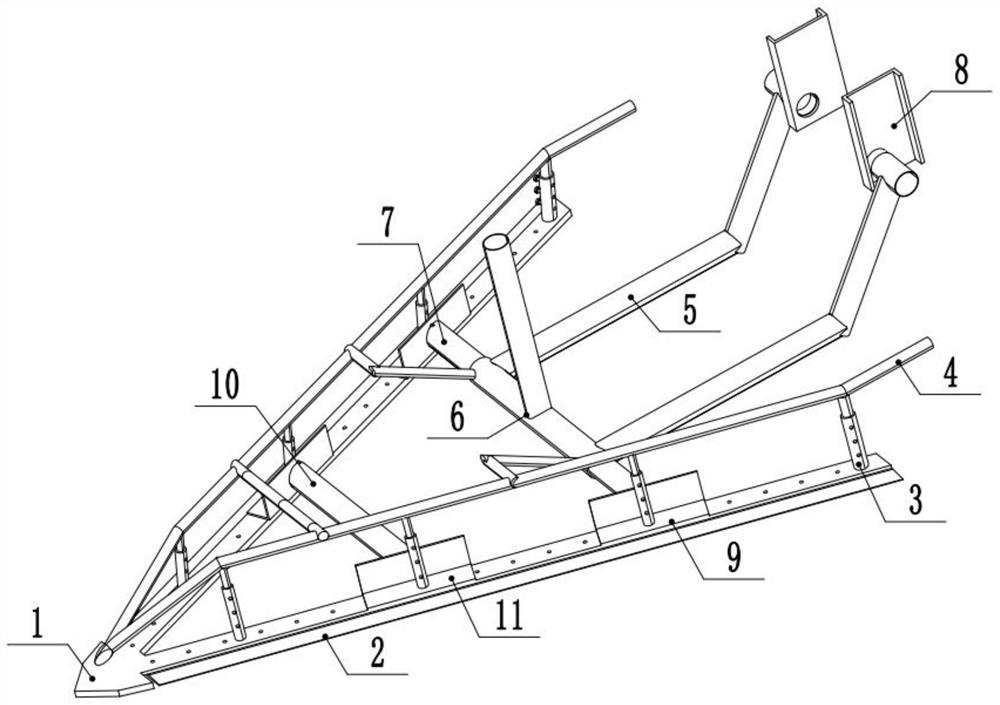

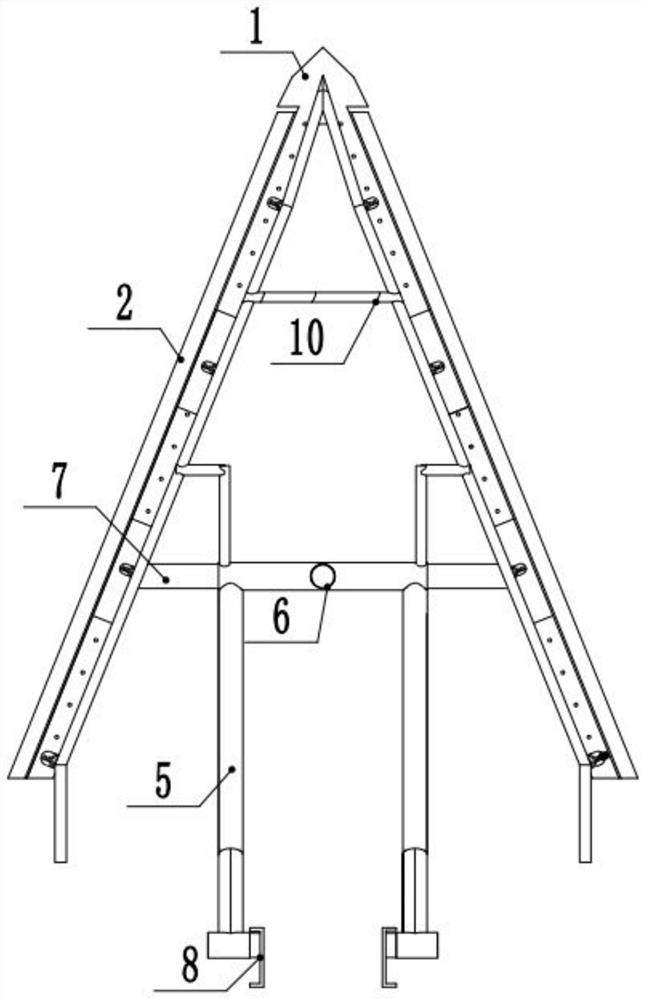

Low-stubble push-over type stevia rebaudiana harvesting and drying mechanism

The invention relates to the field of stevia rebaudiana harvesting and drying mechanisms and discloses a low-stubble push-over type stevia rebaudiana harvesting and drying mechanism. The mechanism comprises a triangular base, cutters are fixedly mounted on the surfaces of the two sides of the outer edge of the triangular base through adjusting bolts, and the cutters and the triangular base are located on the same horizontal plane. Multiple fixed cylinders are fixedly welded to the upper surface of the triangular base, fixed frames are fixedly connected in the fixed cylinders through adjustingbolts, the number of the fixed frames is two, the front ends of the two fixed frames are welded, and the two fixed frames are supported through a connecting rod. The mechanism is simple in structure,low in cost, low in stubble cutting, high in thorough cutting rate, good in using effect and capable of effectively reducing labor intensity, improving labor efficiency and reducing harvesting losses;and the mechanism is economical, practical, high in efficiency, low in stubble cutting and high in thorough cutting rate, the stevia rebaudiana harvesting cost is greatly reduced, and the mechanism is suitable for large-scale mechanized stevia rebaudiana harvesting.

Owner:HEBEI AGRICULTURAL UNIV.

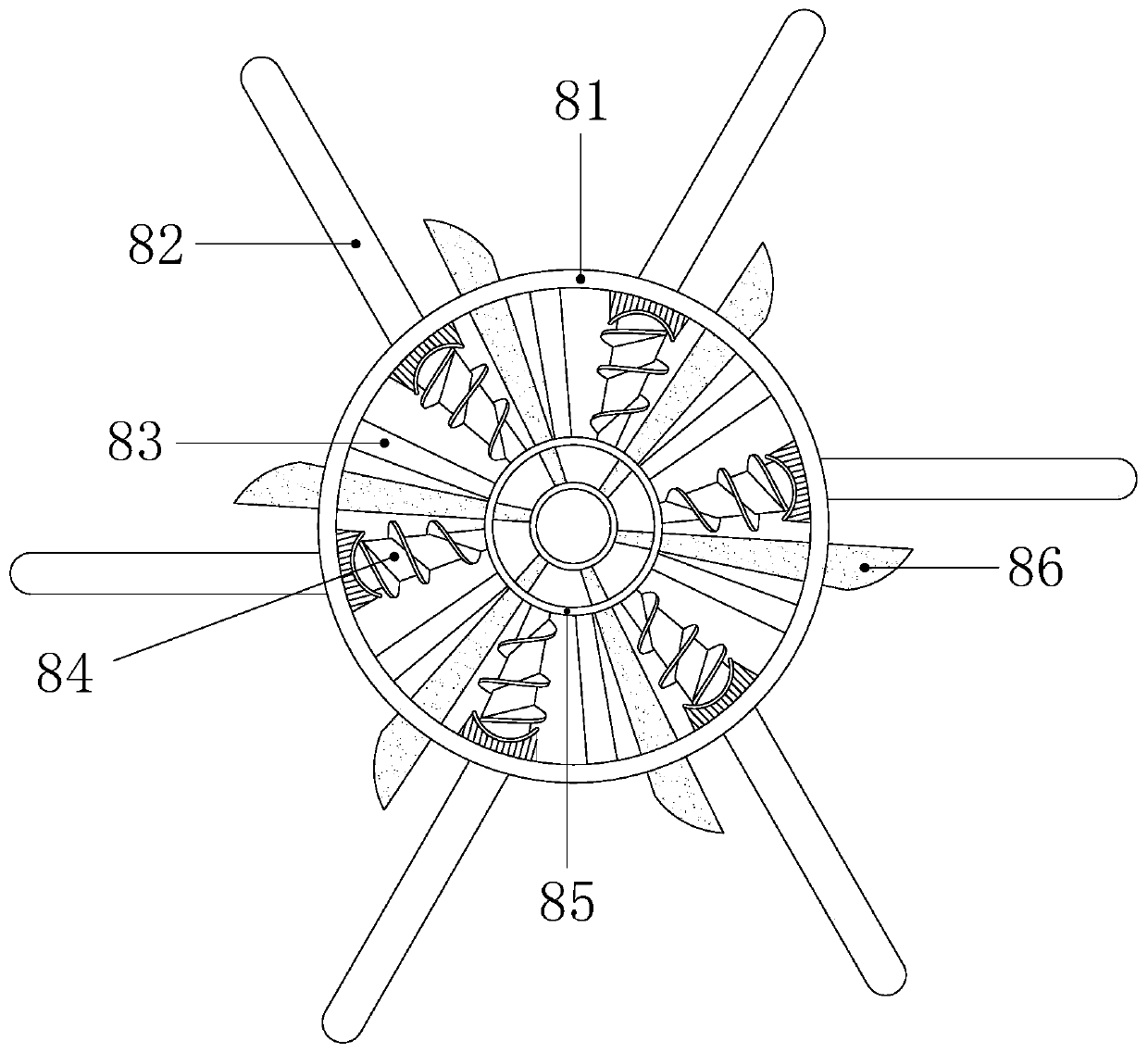

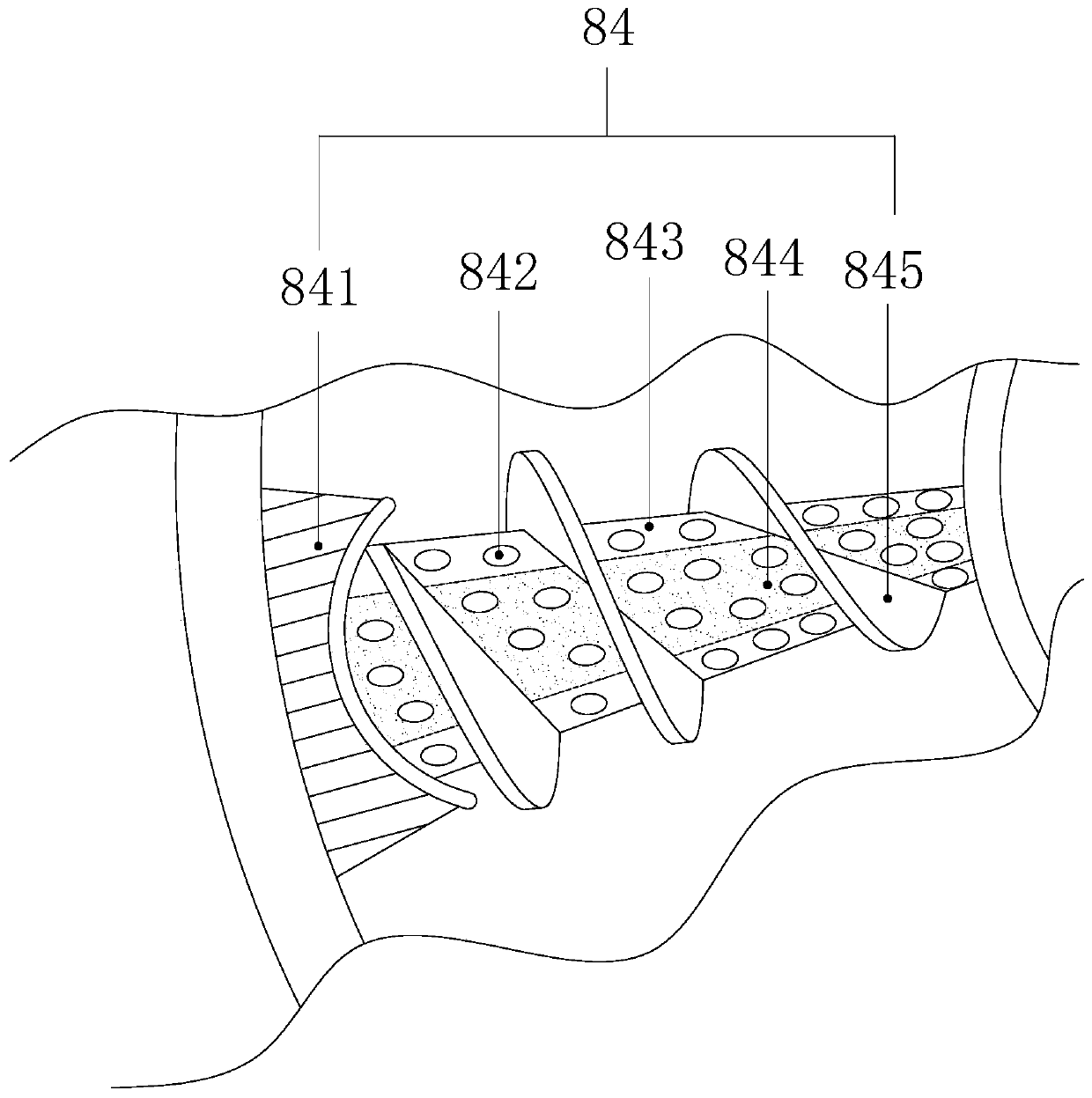

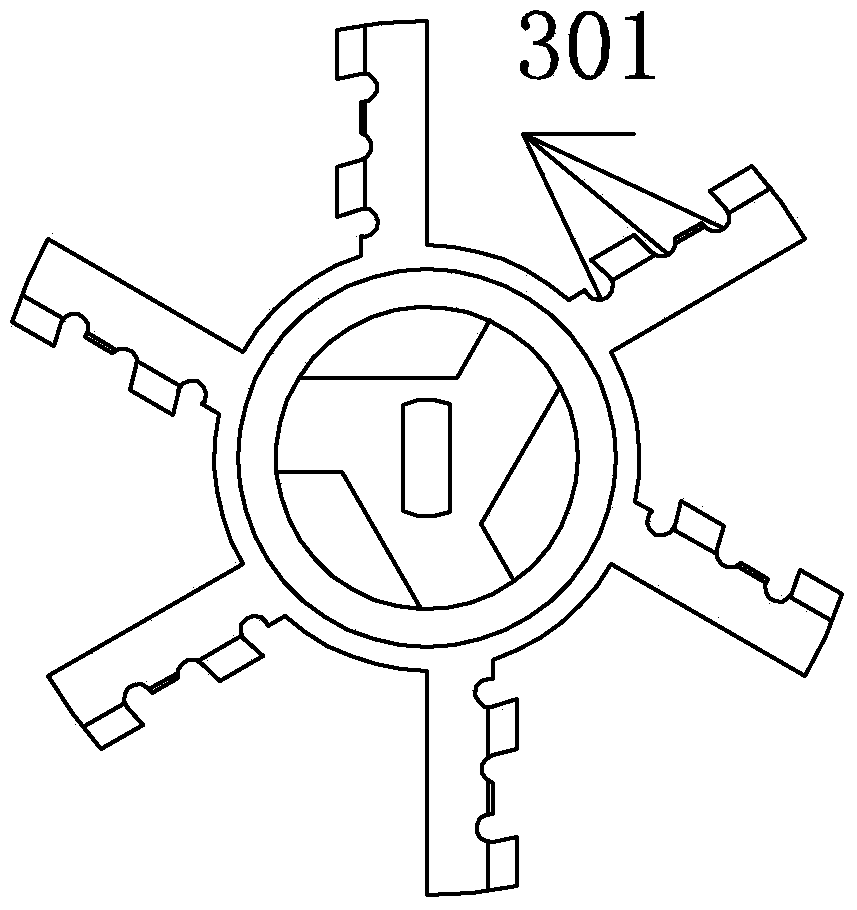

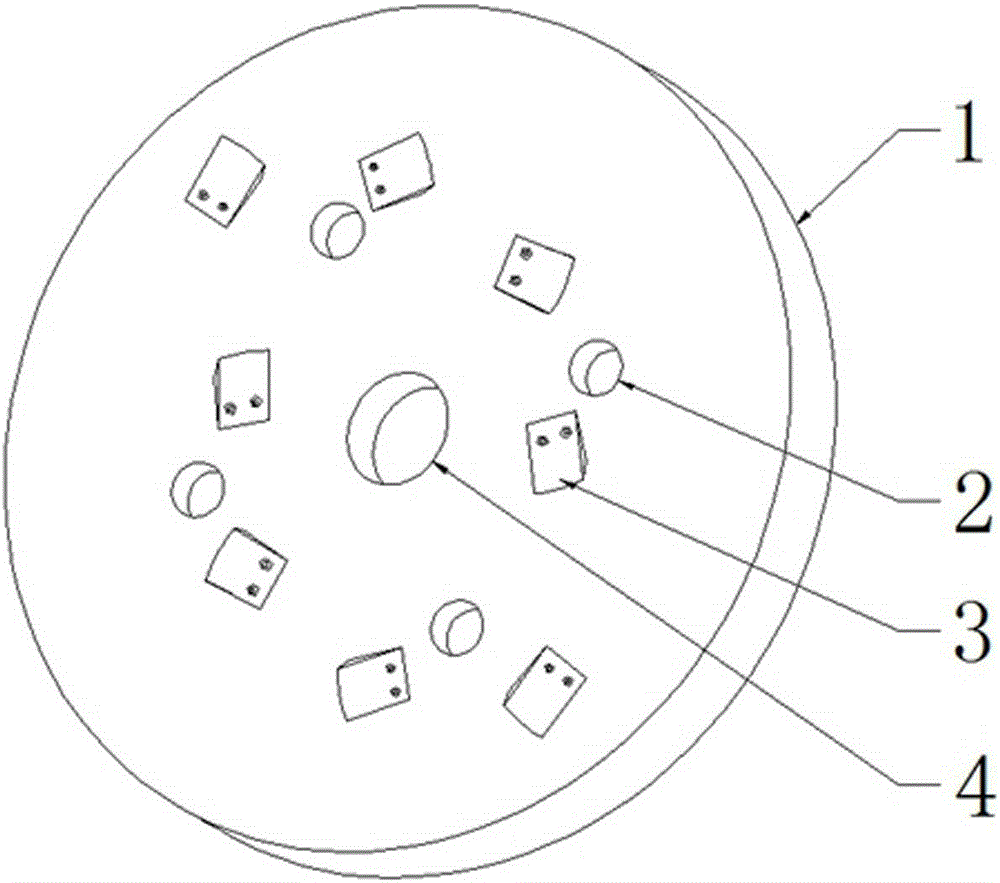

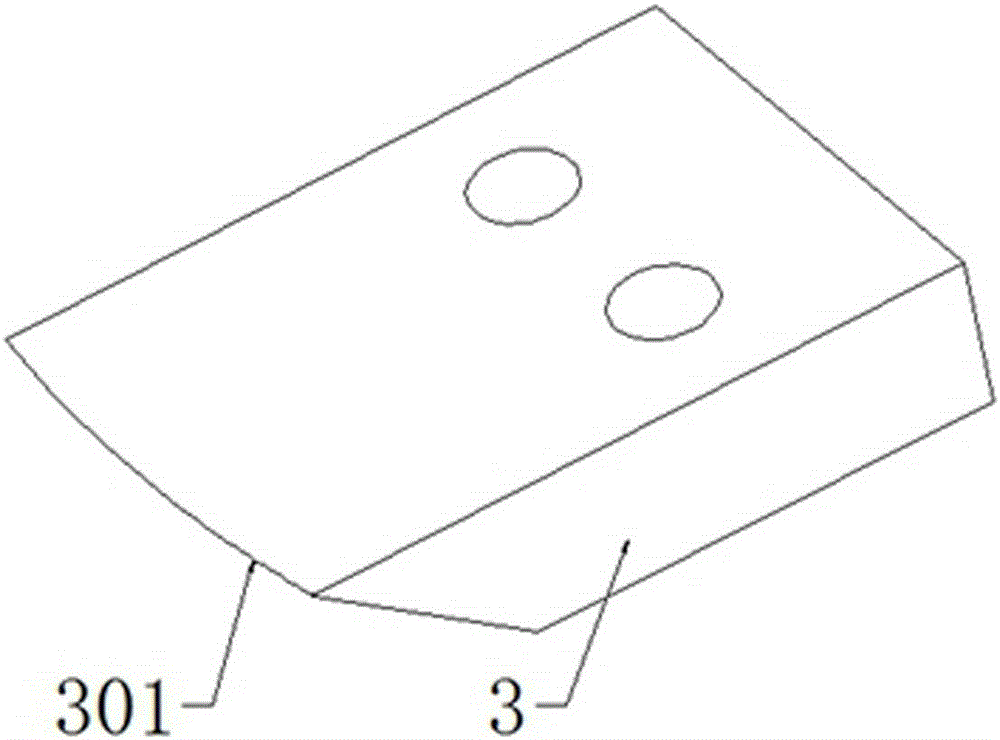

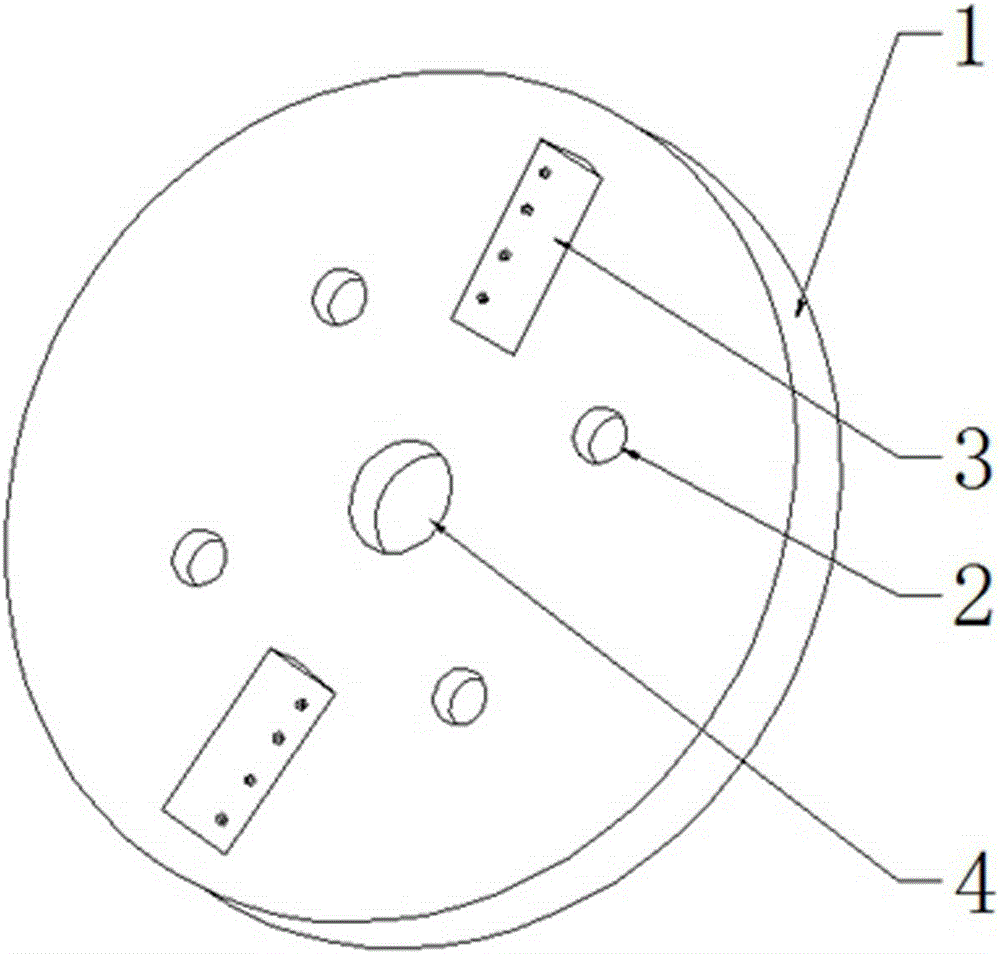

Cutting mechanism of disc cutter

The invention discloses a cutting mechanism of cutting equipment, and specifically relates to a cutting mechanism of a disc cutter. The cutting mechanism comprises a cutter head equipped with moving cutters on the surface, an axis hole in the center of the cutter head, and through holes uniformly distributed on the periphery of the axis hole. The cutter head is equipped with at least two rings of moving cutters with the center of the axis hole as the circular center, at least two moving cutters are arranged on each ring, and the moving cutters on each ring are uniformly distributed on the circumference of the cutter head. The moving cutters on two adjacent rings are not in the same radial direction of the cutter head, and the outer sides of the blades of the moving cutters on the inner ring and the inner sides of the blades of the moving cutters on the outer ring are on the same circumference. The blades of the moving cutters are curve blades with equal sliding-cutting angle. The sliding-cutting angle is 37-45 DEG C. The wedge angle of the moving cutters is 30-40 DEG C. According to the invention, continuous cutting is realized, and the cutting efficiency is improved. The resistance moment borne by the moving cutters during cutting is smooth, the power consumption and vibration are reduced, and the stability is high. The moving cutters are not easily wound with crop straws in the cutting process, the operation quality is improved, and the wear rate of the moving cutters is low.

Owner:XISHUI QUNXING BREEDING FARMERS SPECIALIZED COOP

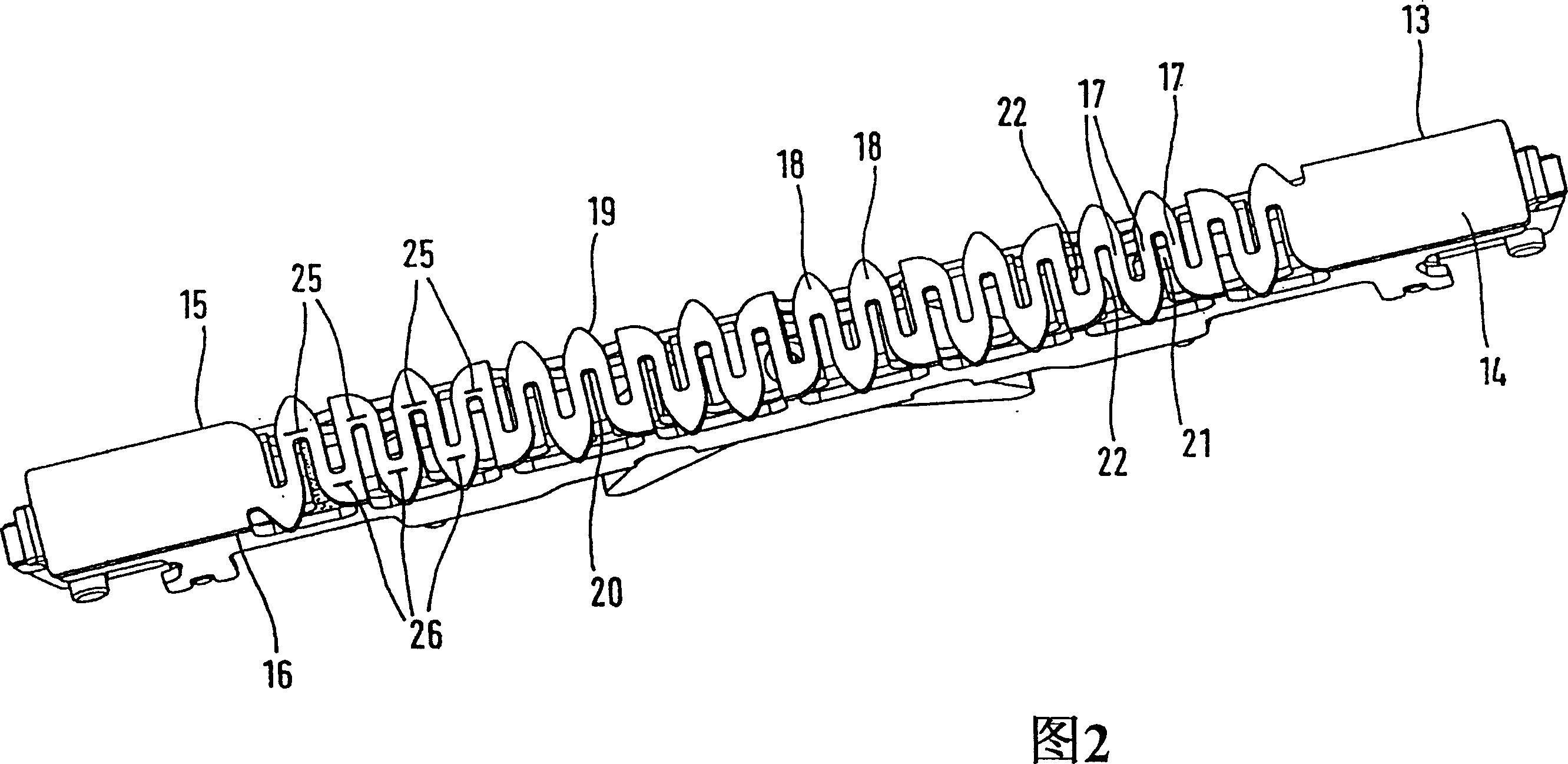

Shearing head for hair clippers

The invention is directed to a shaving head for a hair cutting apparatus, with at least one outer cutter and at least one undercutter associated therewith and having cutting edges, said cutters being movable relative to one another by a drive mechanism, with the outer cutter having an engagement surface comprised of bars and slots, which slots are open at least towards one of two lateral boundary lines of the engagement surface, said boundary lines defining the width of the engagement surface, wherein the bars are shaped in a meandering, sinusoidal or serpentine configuration extending to and fro between the two opposite lateral boundary lines of the engagement surface.

Owner:BRAUN AG

A kind of plastic film cutting device and cutting processing method

ActiveCN111203930BImprove the stabilityImprove cutting accuracyMetal working apparatusPlastic filmWorkbench

The invention relates to a plastic film cutting device, comprising a workbench, a clamping device and a cutting device. The clamping device is installed on the workbench, and a cutting device is installed equidistantly from left to right on the upper end of the workbench. Device, a plastic film cutting device and a cutting processing method provided by the present invention adopt the design concept of multiple clamping to cut the plastic film, improve the overall stability of the plastic film and make the plastic film as a whole in a non-relaxed state, Furthermore, the precision and efficiency of plastic film cutting are improved, and at the same time, the combination of pre-cutting and cutting structures is used to cut the plastic film, so as to improve the quality of plastic film cutting.

Owner:江门市蓬江区东洋机械有限公司

A production process for improving the tear strength of nappa shoe upper leather

ActiveCN105624343BHigh tear strengthImprove practicalityTanning treatmentLeather impregnationAfter treatmentHigh volume manufacturing

Owner:XINGYE LEATHER TECH CO LTD

A sugar-free Jiuwei Buxue Oral Liquid and its preparation method

ActiveCN103494934BDoes not affect the tasteGreat tastePharmaceutical delivery mechanismPharmaceutical non-active ingredientsSucroseAdditive ingredient

Owner:GUANGXI YINGKANG PHARMA

Process for producing shikimic acid

InactiveCN101024609BReduce labor intensityReduce usageCarboxylic compound separation/purificationPlant ingredientsAcetic acidOrganic solvent

Owner:NANJING AGRICULTURAL UNIVERSITY

Continuous Production Plant of Polyurethane Rigid Slab Foam

ActiveCN103963206BRealize continuous productionQuality improvementProduction linePulp and paper industry

The invention discloses a continuous production device of hard blocky polyurethane foam. A continuous foaming rack is arranged at the rear part of a polyurethane foaming pouring device, and comprises a cross rod used for bearing load, a lower delivery track used for conveying continuous blocky foam and a clamp track used for fixing a left frame and a right frame of foam for formation; during the foaming process, the lower delivery track and the left-and-right clamp track are kept synchronous; a paper releasing device is arranged at the front end of the continuous foaming rack, and is divided into a paper releasing mechanism for lower-layer paper, a paper releasing mechanism for upper-layer paper, and a left-and-right plastic film paper releasing mechanism; a left-and-right paper collecting mechanism is arranged at the rear end of the continuous foaming rack, and is synchronous with the clamp track. The continuous production device realizes the continuous production of a factory, is stable in quality, low in cost and high in production efficiency, and can realize large-scale production; besides, a top pressing device is arranged in a production line, the upper surface of produced hard foam is relatively flat, the material cutting ratio is high, and the product cost is reduced.

Owner:JIANGSU LVYUAN NEW MATERIALS

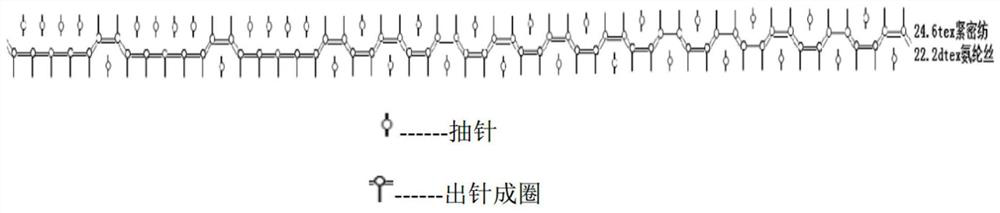

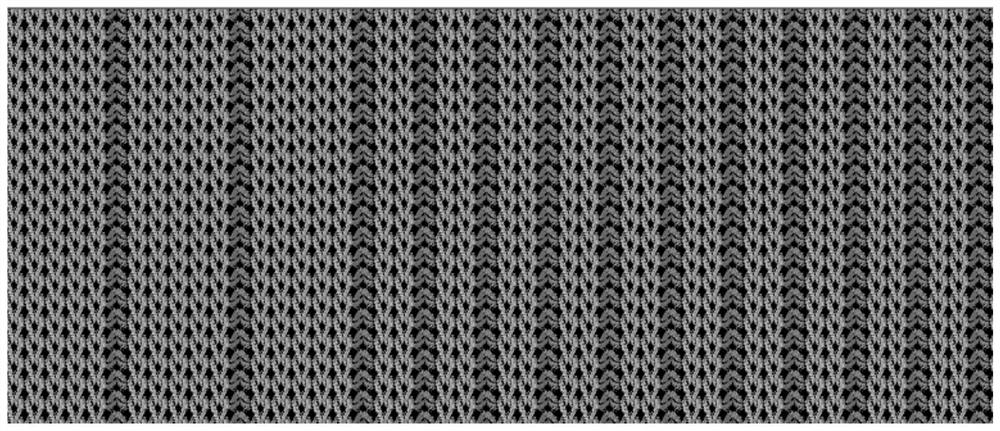

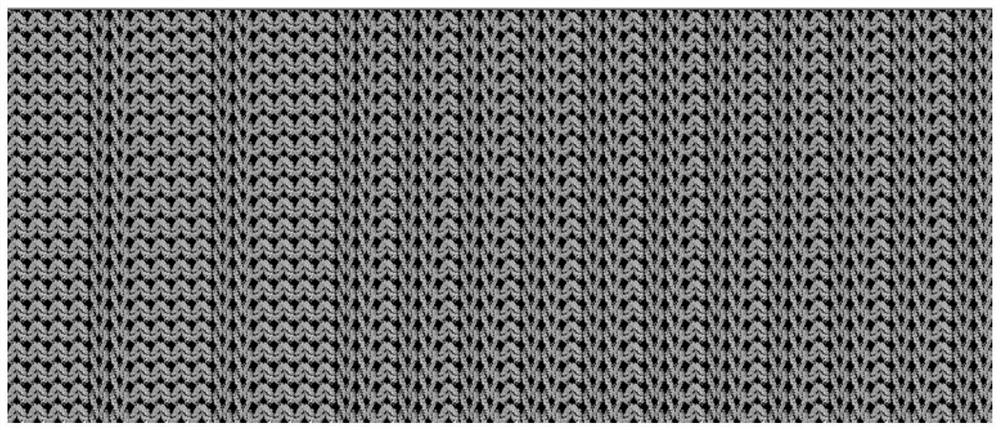

Knitting method of spandex rib fabric with matched thick and thin drop needles

ActiveCN113151960ASolve the problem of poor stretch recoveryFeel plumpWeft knittingTextile/flexible product manufactureYarnStructural engineering

The invention belongs to the technical field of knitting. The invention provides a knitting method of a spandex rib fabric with matched thick and thin drop needles, aiming at solving the problem that the fabric surface of the drop needle spandex rib fabric is easy to leak spandex defects. The spandex rib fabric is knitted by a double-faced circular knitting machine; drop needle combinations are transversely arranged; a rib stitch structure performs needle withdrawing on upper and lower needles; 48 upper needles and 48 lower needles form a knitting cycle; the upper needles include three sets of drop needles and needle withdrawing loops, wherein each of the three sets comprises four drop needles and two needle withdrawing loops, or the upper needles include ten sets of drop needles and needle withdrawing loops, wherein each of the ten sets comprises one drop needle and two needle withdrawing loops; the lower needles include three sets of drop needles and needle withdrawing loops corresponding to the upper needles, wherein each of the three sets comprises one drop needle and five needle withdrawing loops, or the lower needles include ten sets of drop needles and needle withdrawing loops corresponding to the upper needles, wherein each of the ten sets comprises one drop needle and two needle withdrawing loops; the triangle arrangement is a full-knitting looping triangle, and the knitting mode of the spandex yarn is that both the upper needles and the lower needles participate in knitting. According to the weaving method, the spandex yarn is added, and the upper needles and the lower needles participate in weaving at the same time, so that the problems that the traditional drop needle fabric is poor in stretching recovery and the fabric surface has the spandex yarn repelling effect are solved, and the four-side stretch standard is achieved.

Owner:青岛颐和针织有限公司 +1

Continuous production line automatic foam cutting method capable of improving production efficiency and cutting precision

ActiveCN106313148AFully automatedRealize fully automatic operationMetal working apparatusProduction lineFixed length

The invention discloses a continuous production line automatic foam cutting method capable of improving the production efficiency and the cutting precision. A base capable of moving on a guide rail is included. A clamping and protecting device is mounted on the base and used for guiding, limiting, clamping and righting foam conveyed from a previous production line. A cutting device is arranged at the position, behind the clamping and protecting device, on the base and used for cutting the cured and molded foam produced through a continuous production line into segments. A travel switch is arranged on the base and cooperates with a baffle on the guide rail. A fast conveying belt is arranged behind the base. An induction device is arranged above the fast conveying belt and used for controlling starting of the cutting device and adjusting the length of cutting the foam. The foam produced continuously can be cut and separated according to the fixed length, the production efficiency and the cutting precision can be improved, the percentage of outturn can be increased, and waste can be reduced.

Owner:南通新艺材料科技有限公司

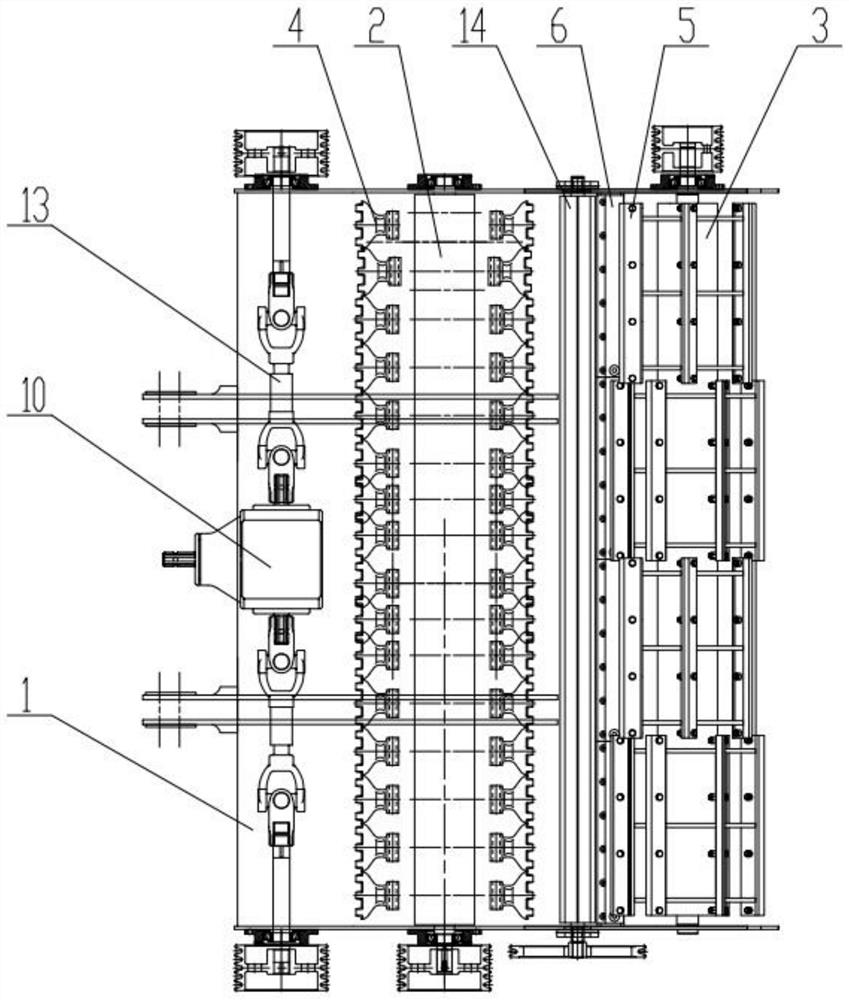

Double-shaft straw cutting and returning machine

PendingCN112492977AImprove cutting rateEffectively cut offCrop conditionersMowersAgricultural engineeringMechanical engineering

The invention relates to the field of agricultural machinery, in particular to a double-shaft straw cutting and returning machine which can effectively achieve cutting and returning treatment on cornstraw and can cut up a whole plant and cut the whole plant into sections. The double-shaft straw cutting and returning machine comprises a machine frame, the machine frame is provided with a front main shaft and a rear main shaft which are parallel to each other, the front main shaft is provided with a rough cutting device in the circumferential direction, the rear main shaft is provided with a fine cutting device in the circumferential direction, and the rotation direction of the front main shaft is opposite to that of the rear main shaft. The front main shaft is provided with the rough cutting device used for chopping whole or long straw, the rear main shaft is provided with the fine cutting device used for cutting the straw into sections, the front main shaft and the rear main shaft rotate in the opposite directions, the rough cutting device can throw the cut straw sections backwards, and the fine cutting device can cut the straw into the sections more easily.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com