Knitting method of spandex rib fabric with matched thick and thin drop needles

A spandex and fabric technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of anti-spandex yarn, etc., and achieve the effect of smooth cloth surface, clear cloth surface texture and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

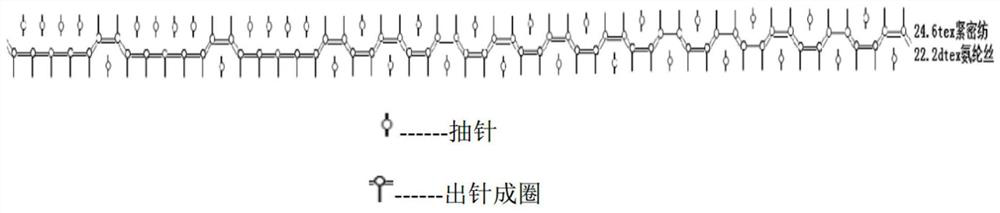

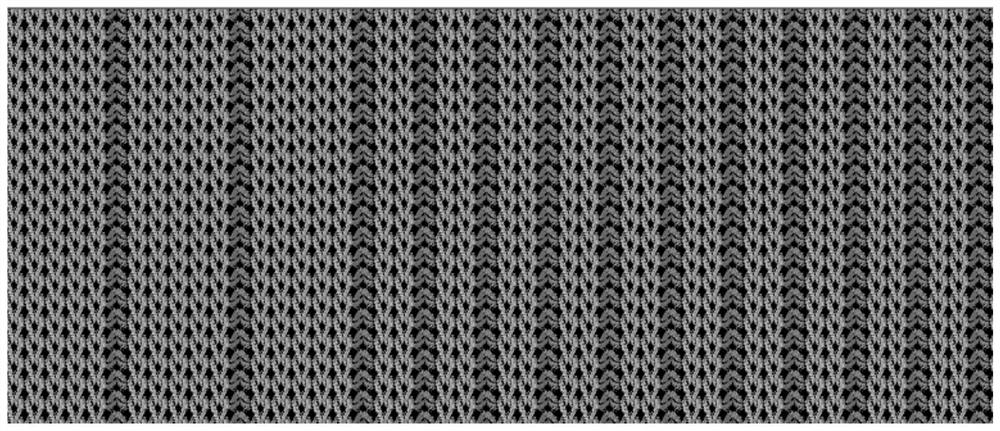

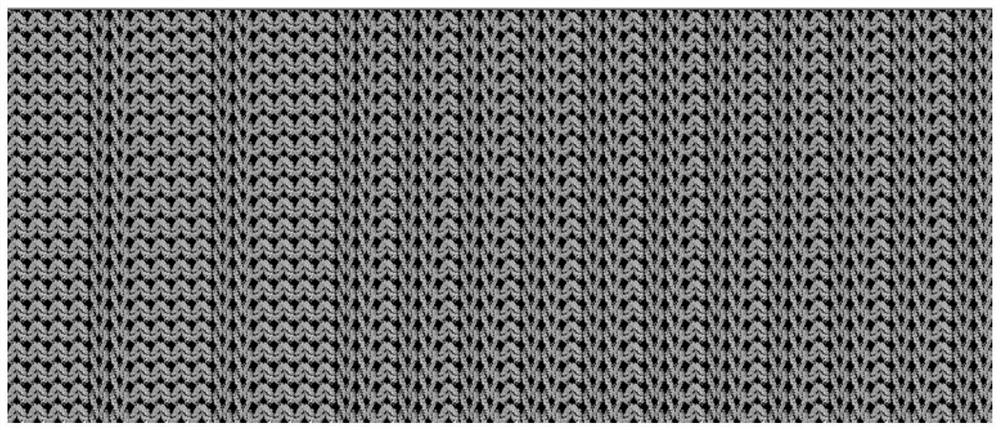

[0017] In this embodiment, the selected yarn count is 24.6tex compact spinning and 22.2dtex spandex yarn, and the equipment uses 18G double-sided knitting large circular knitting machine. organizational structure such as figure 1 said, stands for drawing a needle, It means that the needles form a circle, and a total of 48 needles (including needle withdrawal) is a cycle. 24.6tex compact spinning and 22.2dtex spandex yarns participate in weaving at the same time. Use 3 groups of 4 drawing needles and 2 drawing needles to form a circle, 10 groups of 1 drawing needle and 2 drawing needles to form a circle, which is the combination of 48 drawing needles and drawing needles for upper needles, and the lower needles are 3 needles corresponding to upper needles. A group of 5 needles is drawn into a circle and 1 needle is withdrawn, and a group of 10 is 2 needles formed into a circle and 1 needle is withdrawn. The weaving method of spandex yarn is that both the upper needle and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com