Inner clipper of shaver

A razor and inner knife technology, applied in the field of razors, can solve the problems that the inner surface of the inner knife and the outer knife cannot be guaranteed to be always parallel, the fit is not very tight, and the shaving effect is affected, so as to improve the beard cutting rate , good shaving effect and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

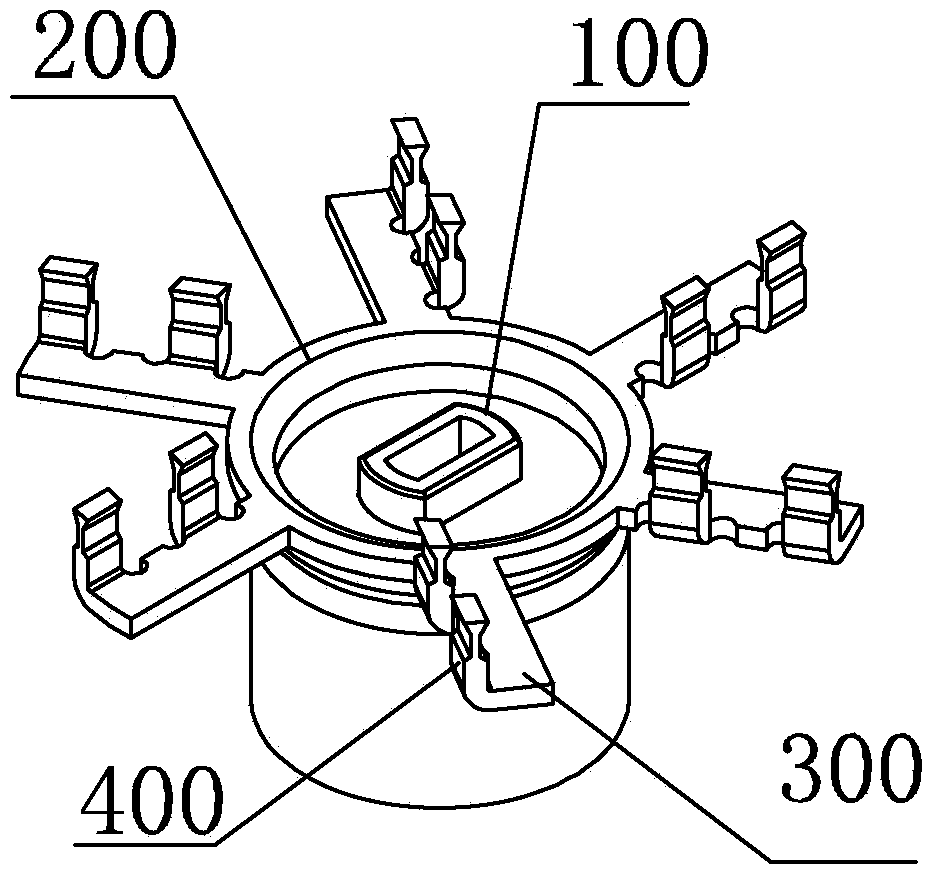

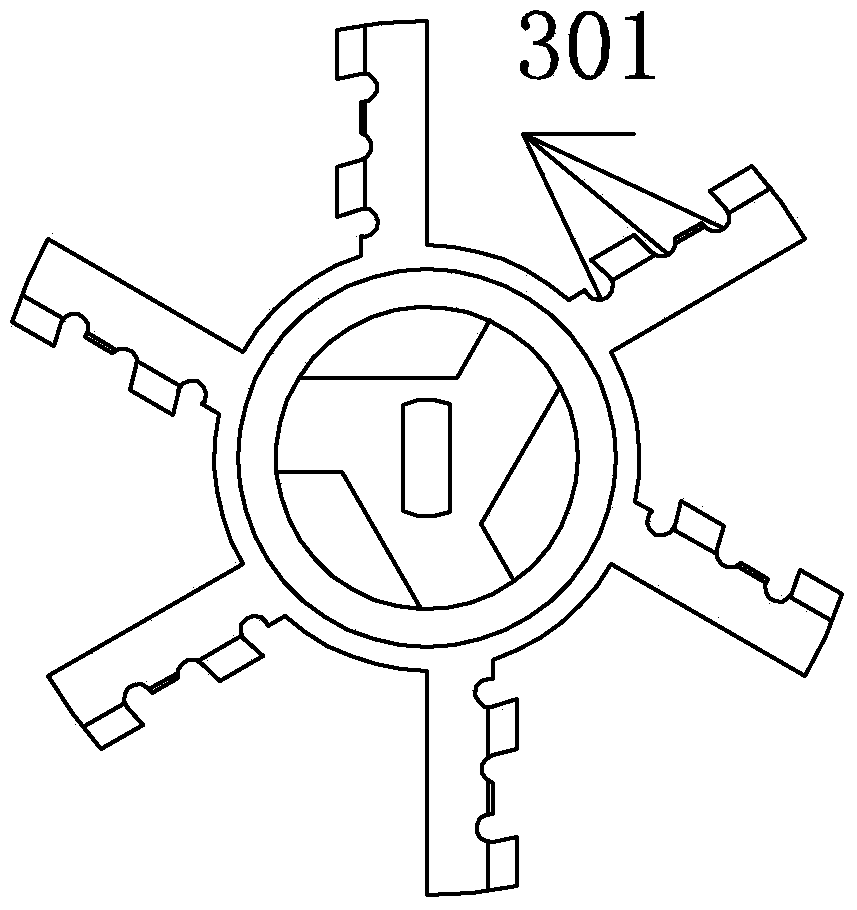

[0036] Such as figure 1 , figure 2 , Figure 5 As shown, the inner cutter of the razor in this embodiment includes a knife seat 100 and a knife body 200 connected with the knife seat 100. At least one group of radial arms 300 protrude from the outer periphery of the knife body 200, and the vertical direction of the radial arm 300 There is at least one set of knife arms 400 standing upright in the direction, and the knife arms 400 have at least one acute cutting edge 401 on them, and are radially arranged along the knife body 200 . The knife arm is arranged vertically along the radial arm, and is arranged radially along the knife body. When the inner knife and the outer knife cooperate to shave, the inner surface of the inner knife and the outer knife are more compact, and the inner surface of the inner knife and the outer knife are always parallel , to achieve a better shaving effect.

[0037] In this embodiment, multiple groups of radial arms 300 protrude from the outer p...

Embodiment 2

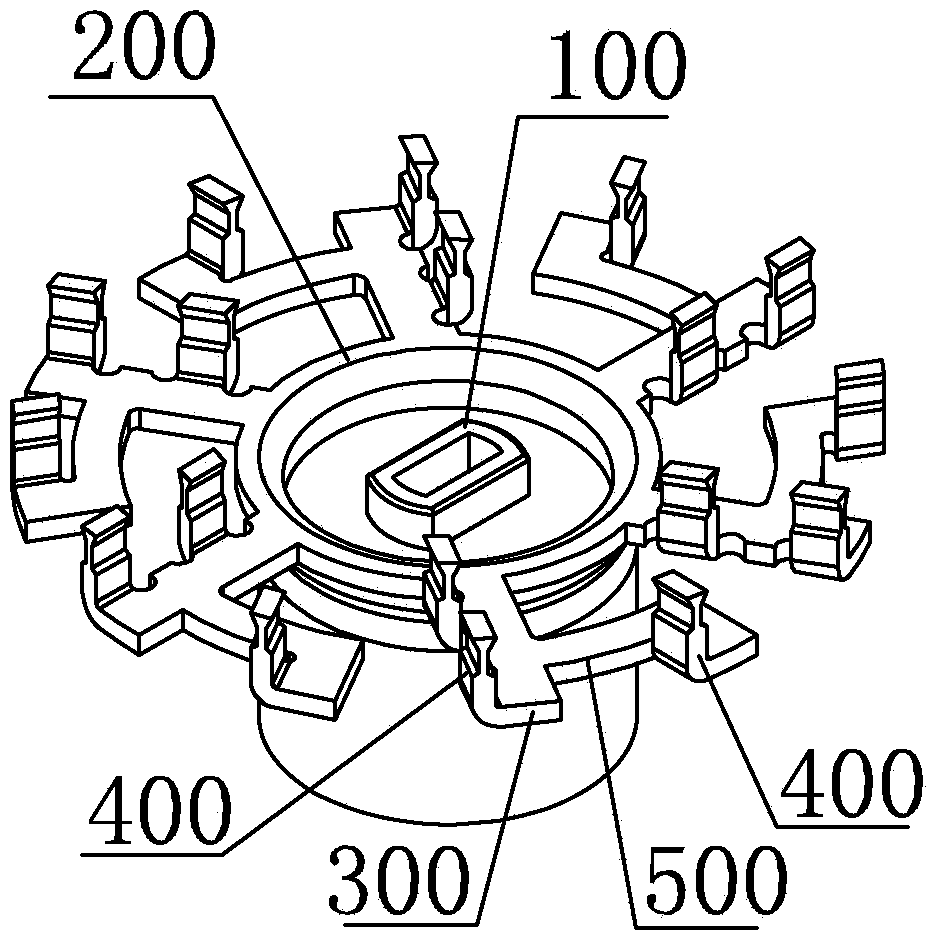

[0041] The main difference between this embodiment and Embodiment 1 is that a transverse arm is arranged on the radial arm. Such as image 3 , Figure 4 , Figure 5 As shown, the inner cutter of the razor in this embodiment includes a knife seat 100, and a knife body 200 connected to the knife seat 100. At least one group of radial arms 300 protrude from the periphery of the knife body 200, and the sides of the radial arms 300 Stretch transverse arm 500, radial arm 300 and transverse arm 500 all upright knife arm 400 in vertical direction; 500 erects the knife arm 400 in the vertical direction.

[0042] In this embodiment, multiple groups of radial arms 300 protrude from the outer periphery of the cutter body 200, and the radial arms 300 may be two groups, three groups, four groups, five groups or even more. 200, the vertical direction of each group of radial arms 300 is erected with two groups of knife arms 400, and the knife arms 400 extend vertically from the surface of...

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the structure of the acute cutting edge on the knife arm has changed. Such as Figure 6As shown, there are acute-angled cutting edges 401' on the opposite sides of the knife arm 400' along the radial direction, thereby forming a double-sided acute-angled cutting edge. A knife surface 402' is formed between the two acute-angled cutting edges 401', and the knife surface 402' faces The inner slope forms a relief groove 403', and the upper part of the knife arm 400' supporting the knife surface and the relief groove forms a knife neck 404', and the range of the acute angle β is between 20° and 45°. The advantage of the acute-angle cutting edge in this embodiment is that the cut beard can slide down from the knife relief groove formed inwardly on the knife face, so as to avoid accumulation on the knife face and affect shaving.

[0047] The knife arm in this embodiment can be applied to Embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com