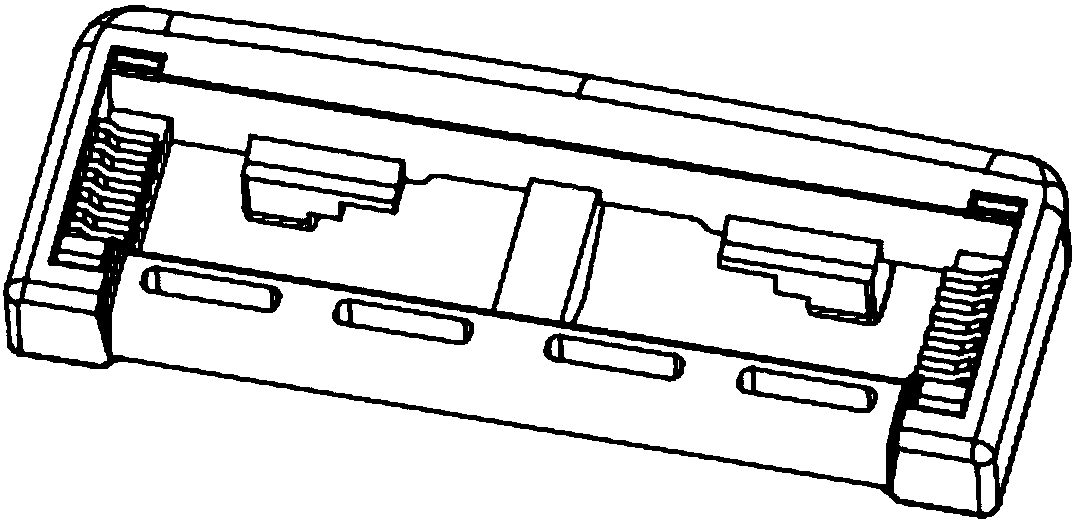

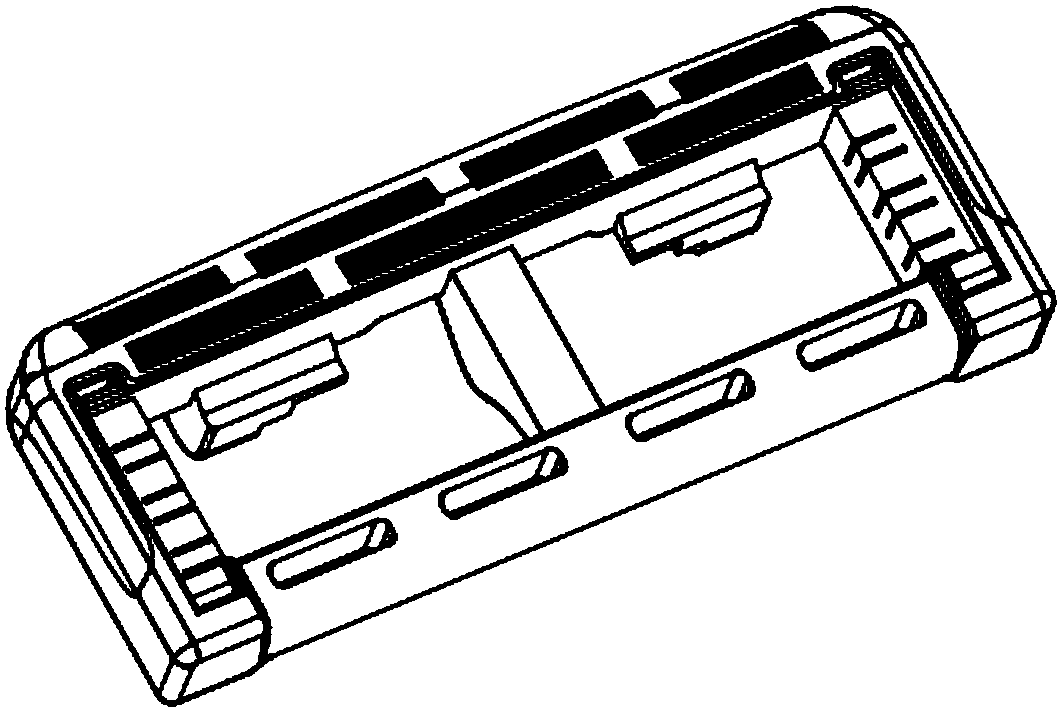

Matrix-arranged beard leaking tool bit

A matrix type, cutter head technology, used in metal processing and other directions, to ensure comfort, efficiency, and easy care.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

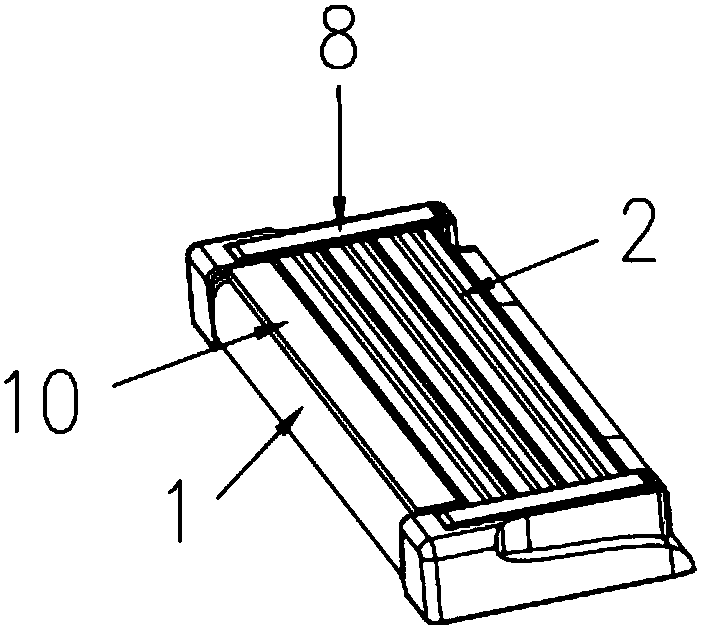

[0069] Embodiment one: if Figure 9 As shown in the figure, each set of blade assemblies 1 has only one blade, and there are 6 sets in total, and the gap between the blade assemblies 2 and the blade assemblies 2 in the figure gradually decreases from large to large.

[0070] The biggest advantage of this arrangement of blades is that it is aimed at people whose beards do not grow very fast. On the premise of ensuring the shaving efficiency, it can also ensure the irritation of the blades to the skin, thereby ensuring the comfort of shaving. When this blade is shaving, the gap between the first cut, the second cut and the third cut is relatively large, so it is easier to touch the beard on the skin when shaving, so that the thin and dense beard on the skin is in the front The excision was carried out in a few cuts, and the following four, five, and six layers of blades were used to better protect the comfort of the skin, because the gap between the blades has become smaller, an...

Embodiment 2

[0071] Embodiment two: if Figure 10 As shown in the figure, each set of blade assemblies 1 has only one blade, and there are 6 sets in total, and the gap between the blade assemblies 2 and the blade assemblies 2 in the figure gradually increases from small to large.

[0072] The gap of the blade assembly gradually increases from small to large, and the arrangement of the blades is mainly aimed at customers with fast-growing beards, and this arrangement is more suitable for them. Judging from the arrangement of the blades, the gaps between the six layers of knives become larger from small to large, and the gaps between the first three layers of blades are not large, so that the angle of the edge of the blade when shaving the face is not very large, which is better It provides customers with comfort and a more veneer effect. The gaps between the fourth, fifth, and sixth layers of knives gradually increase, so that the angle between the blade and the blade when shaving is also ...

Embodiment 3

[0073] Embodiment three and embodiment eighteen: as Figure 11 and Figure 26 As shown in the figure, each group of blade assemblies 1 has 2 blades, and there are 4 groups in total. The specific number depends on the actual situation. In the figure, the gap between the blade assemblies 2 and the blade assemblies 2 gradually becomes smaller. Its effect is the same as that of Embodiment 1.

[0074] The biggest advantage of this arrangement of blades is that it is aimed at people whose beards do not grow very fast. On the premise of ensuring the shaving efficiency, it can also ensure the irritation of the blades to the skin, thereby ensuring the comfort of shaving. When this blade is shaving, the gap between the first cut, the second cut and the third cut is relatively large, so it is easier to touch the beard on the skin when shaving, so that the thin and dense beard on the skin is in the front The excision was carried out in a few cuts, and the following four, five, and six l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com