Light-scent dried flowers and preparation method thereof

A flower and fragrance technology, applied in the directions of botanical equipment and methods, separation methods, chemical instruments and methods, etc., can solve the problems such as the use limitation of light fragrance flowers, short shelf life, elimination of light fragrance flowers, etc. Large cell permeability, good antibacterial and bactericidal properties, and the effect of eliminating unpleasant odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

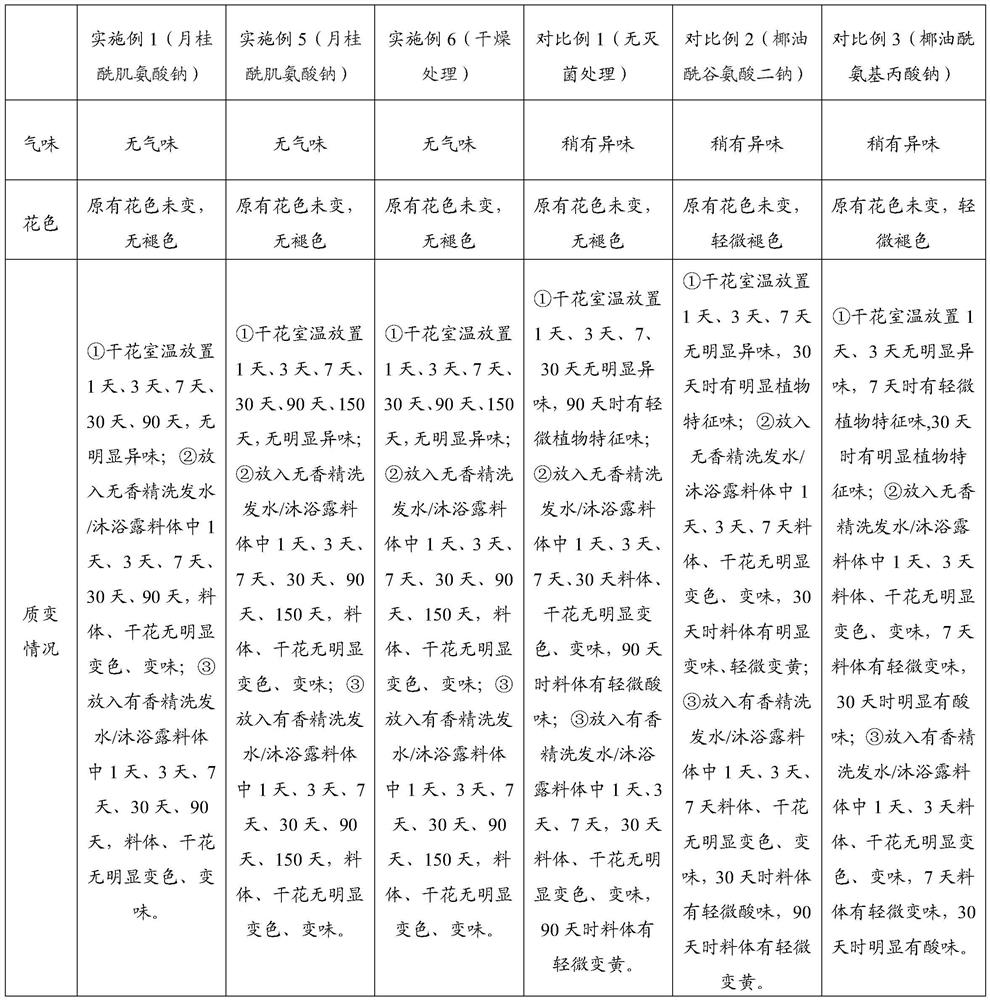

Examples

Embodiment 1

[0032] Sterilization treatment: cut the purple forget-me-not flower branch to the required size, soak the cut purple forget-me-not flower branch in 0.5% sodium chloride aqueous solution for 6 hours, take it out and wash it with deionized water three times, and then Dried to obtain salt treated flowers. Then soak the salt-treated fresh flowers in 65% ethanol aqueous solution for 6 hours, take them out and wash them three times with deionized water, and then filter and dry to obtain the sterilized fresh flowers.

[0033] Surfactant treatment: Soak the sterilized flowers in 10% sodium lauroyl sarcosinate aqueous solution, taking the liquid surface completely submerged in the sterilized flowers as the benchmark, take it out and wash it with deionized water for three hours after 36 hours. Over and over, get table-active processing flowers.

[0034] Drying treatment: place the surface-activated fresh flowers in an oven to dry for 4 hours at a temperature of 38° C. to obtain dried f...

Embodiment 2

[0036] Sterilization treatment: cut the purple forget-me-not flower branch to the required size, soak the cut purple forget-me-not flower branch in 1.5% sodium chloride aqueous solution for 2 hours, take it out and wash it three times with deionized water, and then Dried to obtain salt treated flowers. Then soak the salt-treated fresh flowers in 85% ethanol aqueous solution for 2 hours, take them out and wash them three times with deionized water, and then filter and dry to obtain the sterilized fresh flowers.

[0037] Surfactant treatment: Soak the sterilized flowers in 30% sodium lauroyl sarcosinate aqueous solution, take the liquid surface completely submerged in the sterilized flowers as the benchmark, take it out and wash it with deionized water for three hours after 12 hours. Over and over, get table-active processing flowers.

[0038] Drying treatment: place the surface-activated fresh flowers in an oven and dry them at a temperature of 58° C. for 2 hours to obtain dri...

Embodiment 3

[0040] Sterilization treatment: cut the purple forget-me-not flower branch to the required size, soak the cut purple forget-me-not flower branch in 0.8% sodium chloride aqueous solution for 5 hours, take it out and wash it three times with deionized water, and then Dried to obtain salt treated flowers. The salt-treated fresh flowers are soaked in 70% ethanol aqueous solution for 5 hours, taken out, washed three times with deionized water, and then filtered to obtain the sterilized fresh flowers.

[0041] Surfactant treatment: Soak the sterilized flowers in 15% sodium lauroyl sarcosinate aqueous solution, take the liquid surface completely submerged in the sterilized flowers as the benchmark, take it out and wash it with deionized water for three hours after 28 hours. Over and over, get table-active processing flowers.

[0042] Drying treatment: place the surface-activated fresh flowers in an oven at a temperature of 45° C. to dry for 3.5 hours to obtain dried flowers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com