Width-adjustable continuous foaming production line of rigid polyurethane foam

A polyurethane rigid foam and production line technology, which is applied in the field of polyurethane rigid foam continuous foaming production line, can solve the problems of production line waste, low production capacity, and high labor intensity, and achieve the goals of reducing product cost, high production efficiency, and improving material cutting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

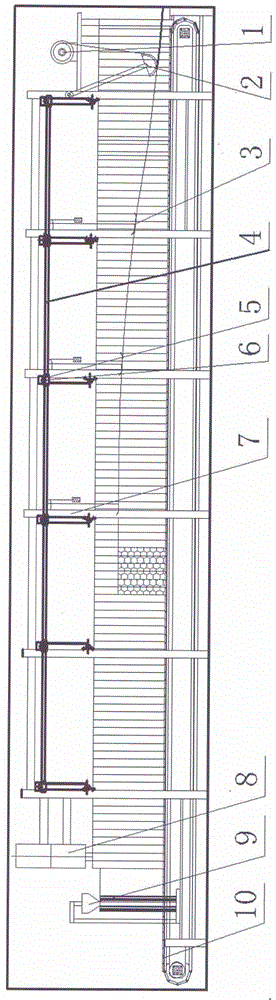

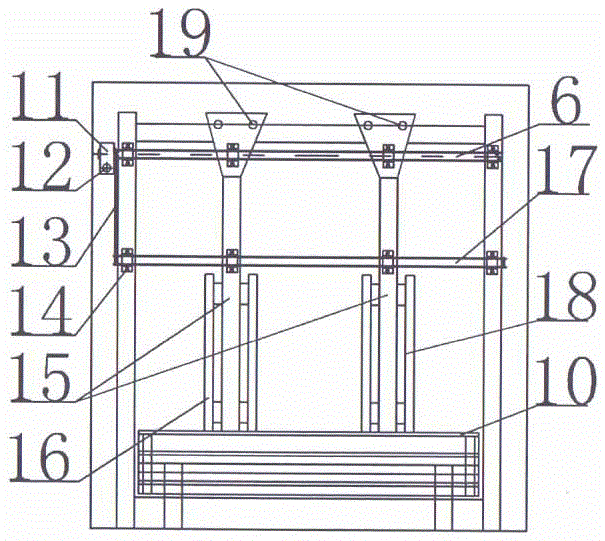

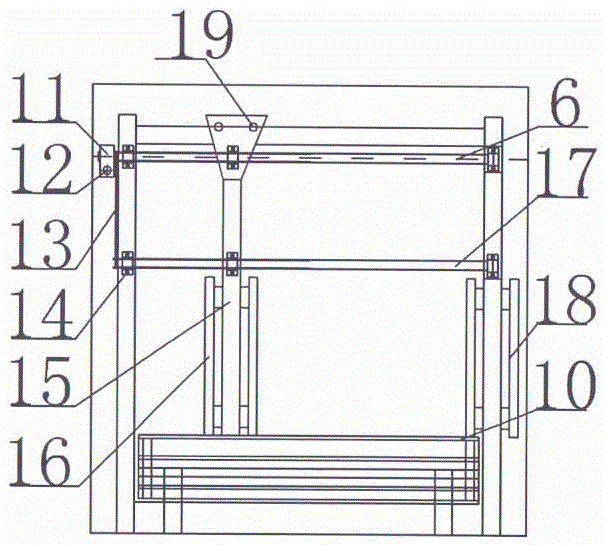

[0023] A continuous foaming production line of polyurethane hard foam with adjustable width, such as figure 2 and image 3 As shown, at least one of the crawler belts 16 and 18 on both sides of the crawler production line used in the polyurethane rigid slab foam foaming and curing molding part can move left and right, so that the width of the produced foam can be adjusted.

[0024] The width-adjustable continuous foaming line includes a production line frame 7, a crawler conveyor belt 10 at the bottom, crawler conveyor side plates 16, 18 on the left and right sides, and an electric width adjustment device. Foaming production line is fixed by framework 7 conveying crawler belt 16,18 and lower conveying crawler belt 10 below. When foaming is produced, the foam is foamed and solidified on the synchronous three-sided conveyor belt, and then sent to the cutting section.

[0025] Wherein, the electric width adjustment device part is composed of multiple groups of worm gear screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com