Continuous production device of hard blocky polyurethane foam

A block foam and production device technology, which is applied in the field of polyurethane rigid block foam continuous production devices, can solve the problems of many labor, low production capacity, poor dimensional stability of composite boards, etc., and achieves reduced product cost, high production efficiency, Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

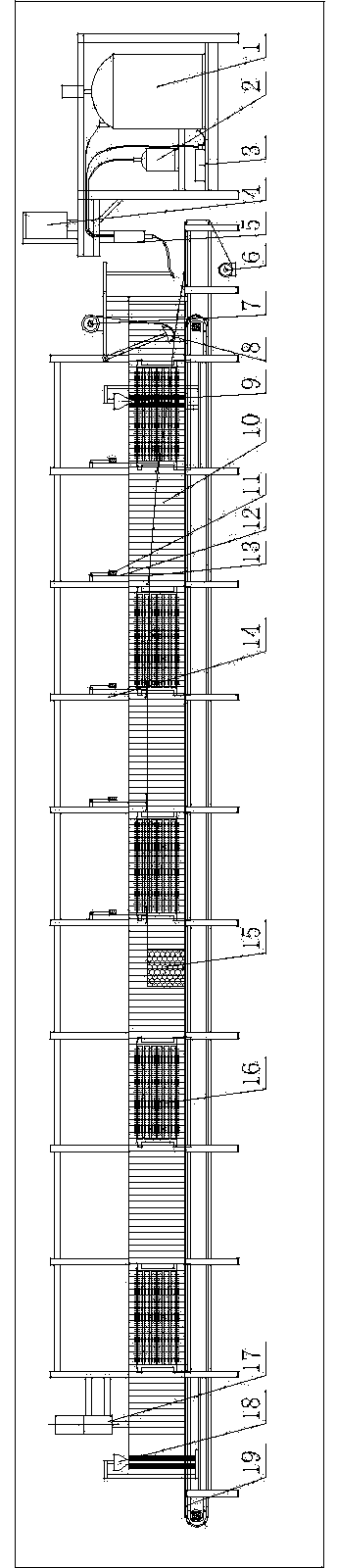

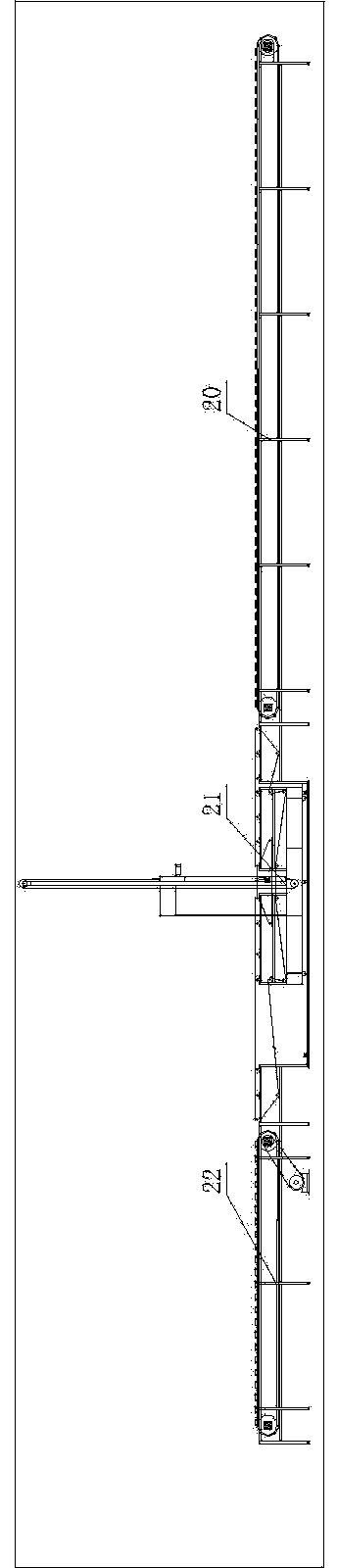

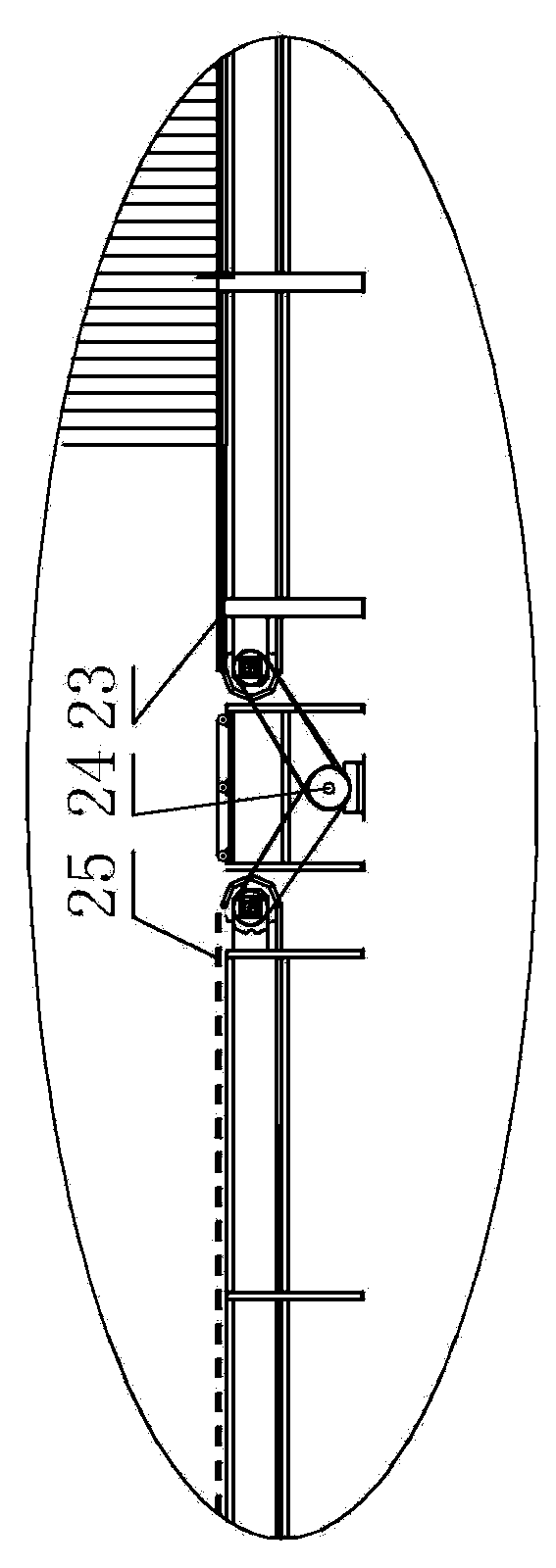

[0038] A polyurethane rigid block foam continuous production device comprises polyurethane foam pouring equipment 5, an adjustment device 8 for adjusting the leveling of the poured cloth and the force of the top paper, a continuous foaming frame 14, a drying tunnel heating device 16, The flat top device 13 for smoothing the upper surface of the foam, the paper feeding and delivery devices 9 and 17, the foam transfer devices 20 and 22, and the long foam cutting equipment 21. The continuous foaming frame is set behind the polyurethane foam pouring equipment; the continuous foaming frame includes a load-bearing cross bar, a lower conveying track for conveying continuous block foam, and a clamp track for fixing the left and right frames of the foam. During the foaming process, the lower conveying track and the left and right gripper tracks are kept in sync; a paper feeding device is installed at the front end of the continuous foaming frame; Paper mechanism; the left and right pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com