Low-stubble push-over type stevia rebaudiana harvesting and drying mechanism

A technology of stevia and low stubble, which is applied in the field of low stubble push-down type stevia shaving mechanism, can solve the problems of unfavorable stevia harvesting and use, poor use effect, complex structure and the like, and achieves reduction of harvesting cost, simple structure and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

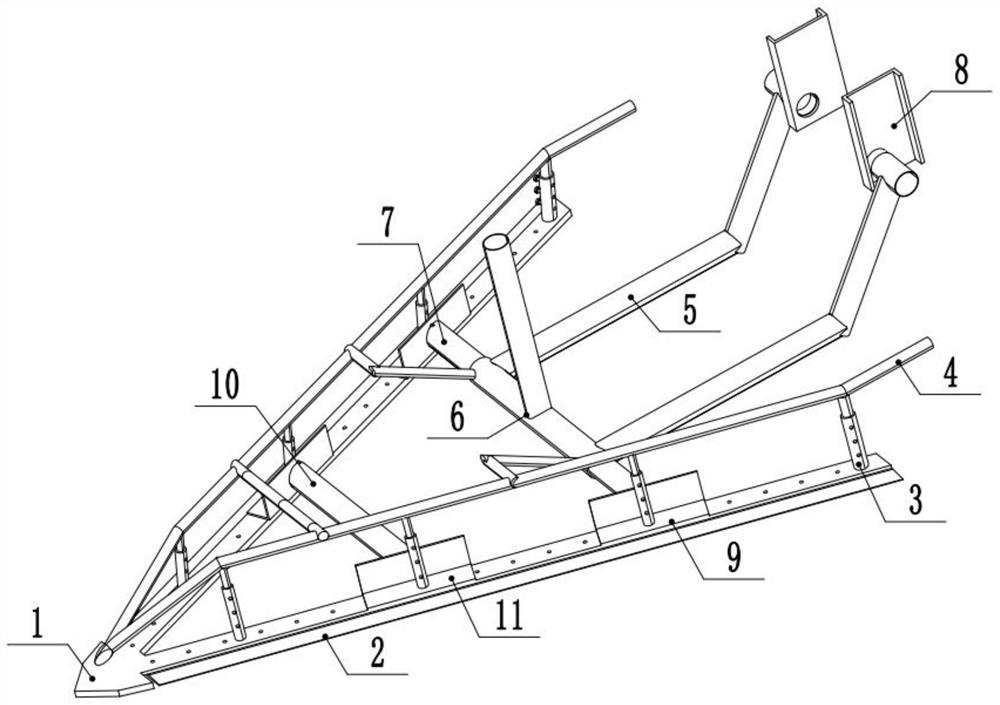

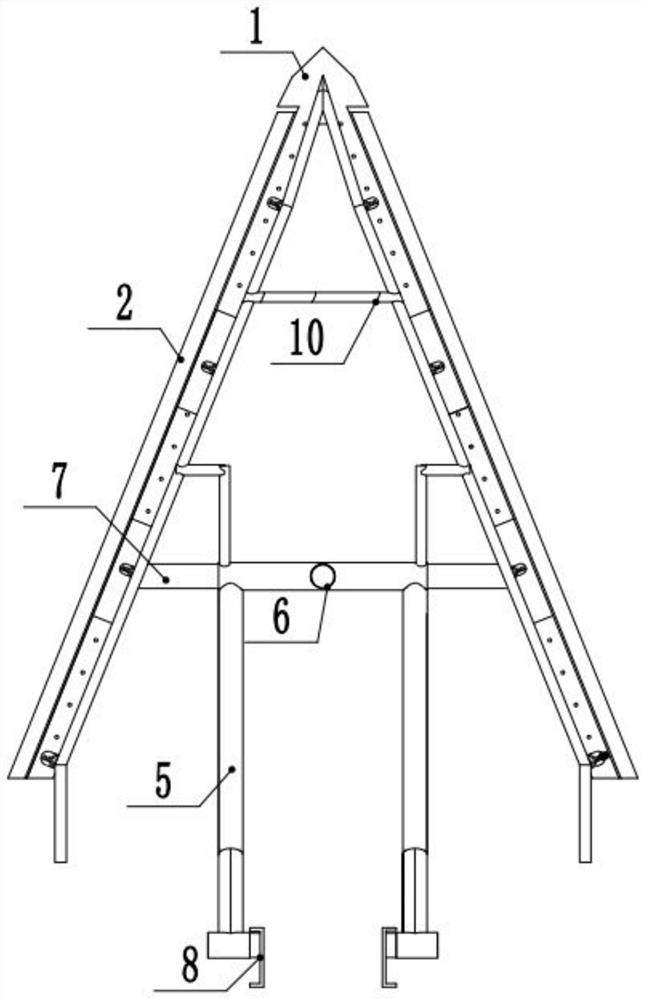

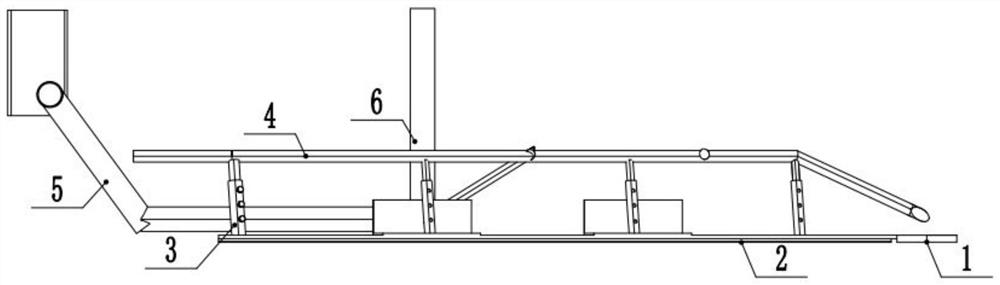

[0020] see Figure 1-3 , a low-stubble push-down type stevia mowing and drying mechanism, including a triangular base 1, a cutter 2 is fixed on the outer surface of the triangular base 1 on both sides through adjusting bolts, and the angle of the cutter 2 can be adjusted through the adjusting bolts. The adjustment range is 40-50 degrees to adapt to different widths. The cutter 2 and the triangular base 1 are on the same horizontal plane. The front cutter 2 is on the inside and the rear cutter 2 is on the outside. The purpose is to ensure harvesting When the stevia rebaudiana is tilted inward, the front part does not fall down, and the cutter 2 at the rear part makes the stevia rebaudiana turn outward, which is beneficial to harvesting and drying.

[0021] Moreover, the upper surface of the triangular base 1 is fixedly welded with a plurality of fixed cylinders 3, and the fixed cylinder 3 is fixedly connected with a fixed frame 4 by adjusting bolts. Adjustment, the quantity of...

Embodiment 2

[0024] see Figure 1-3 , a low-stubble push-down type stevia mowing and drying mechanism, including a triangular base 1, a cutter 2 is fixed on the outer surface of the triangular base 1 on both sides through adjusting bolts, and the angle of the cutter 2 can be adjusted through the adjusting bolts. The adjustment range is 40-50 degrees to adapt to different widths. The cutter 2 and the triangular base 1 are on the same horizontal plane. The front cutter 2 is on the inside and the rear cutter 2 is on the outside. The purpose is to ensure harvesting When the stevia rebaudiana is tilted inward, the front part does not fall down, and the cutter 2 at the rear part makes the stevia rebaudiana turn outward, which is beneficial to harvesting and drying.

[0025] Moreover, the upper surface of the triangular base 1 is fixedly welded with a plurality of fixed cylinders 3, and the fixed cylinder 3 is fixedly connected with a fixed frame 4 by adjusting bolts. Adjustment, the quantity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com