Patents

Literature

43results about How to "Reduce Harvest Loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

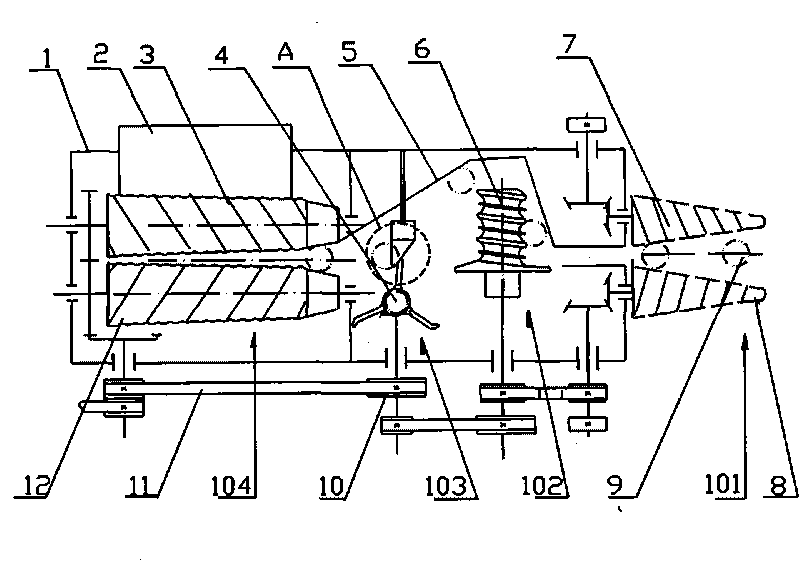

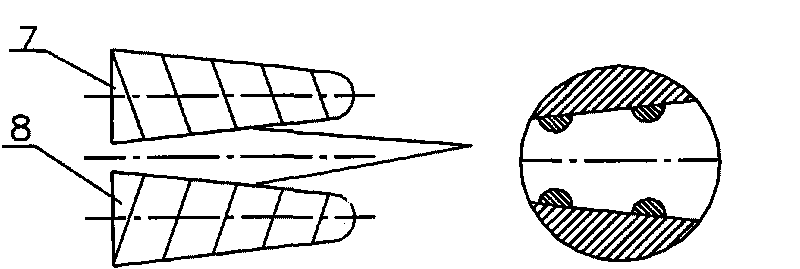

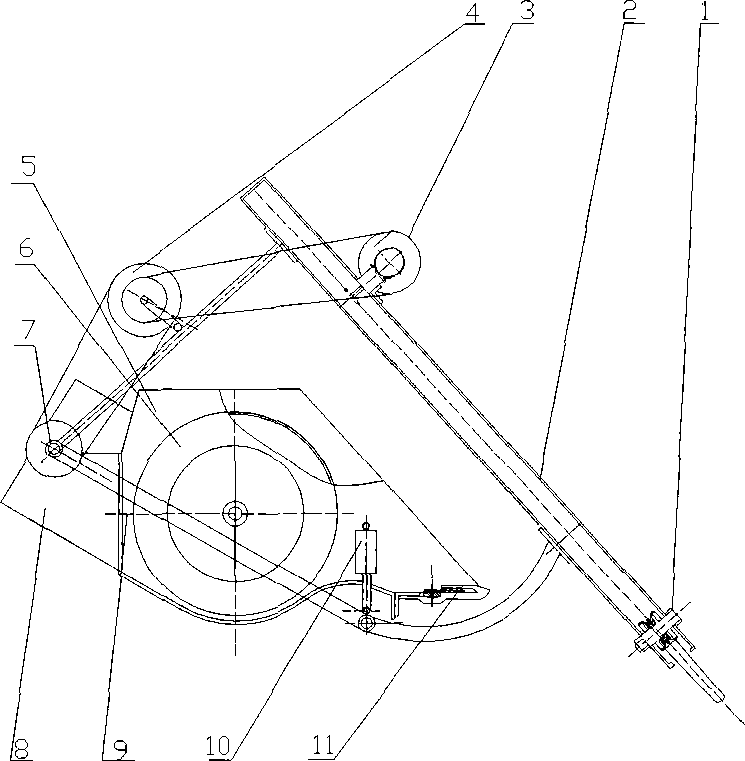

Garlic sprout harvester

InactiveCN101697677AAchieve mechanized harvestingImprove harvesting efficiencyPicking devicesProduction rateCuticle

The invention relates to a garlic sprout harvester and belongs to the field of agricultural machinery. The garlic sprout harvester can erect a single row of garlic sprout stems and gather the garlic sprout stems into a bundle, vertically gash the epidermis of each garlic sprout stem at certain height, transversely make a cut with certain depth in the gashed epidermis and draw the garlic sprouts by using a drawing device. The invention solves the problem of mechanized harvesting of garlic sprouts. The technical proposal of the invention can increase the production rate for harvesting garlic sprouts, reduce the labor intensity for harvesting garlic sprouts and enhance the mechanization level of garlic planting.

Owner:NORTHWEST A & F UNIV

Green soybean harvesting machine

Owner:QINGDAO QINGKAIYUAN ECONOMIC & TECH SERVICE

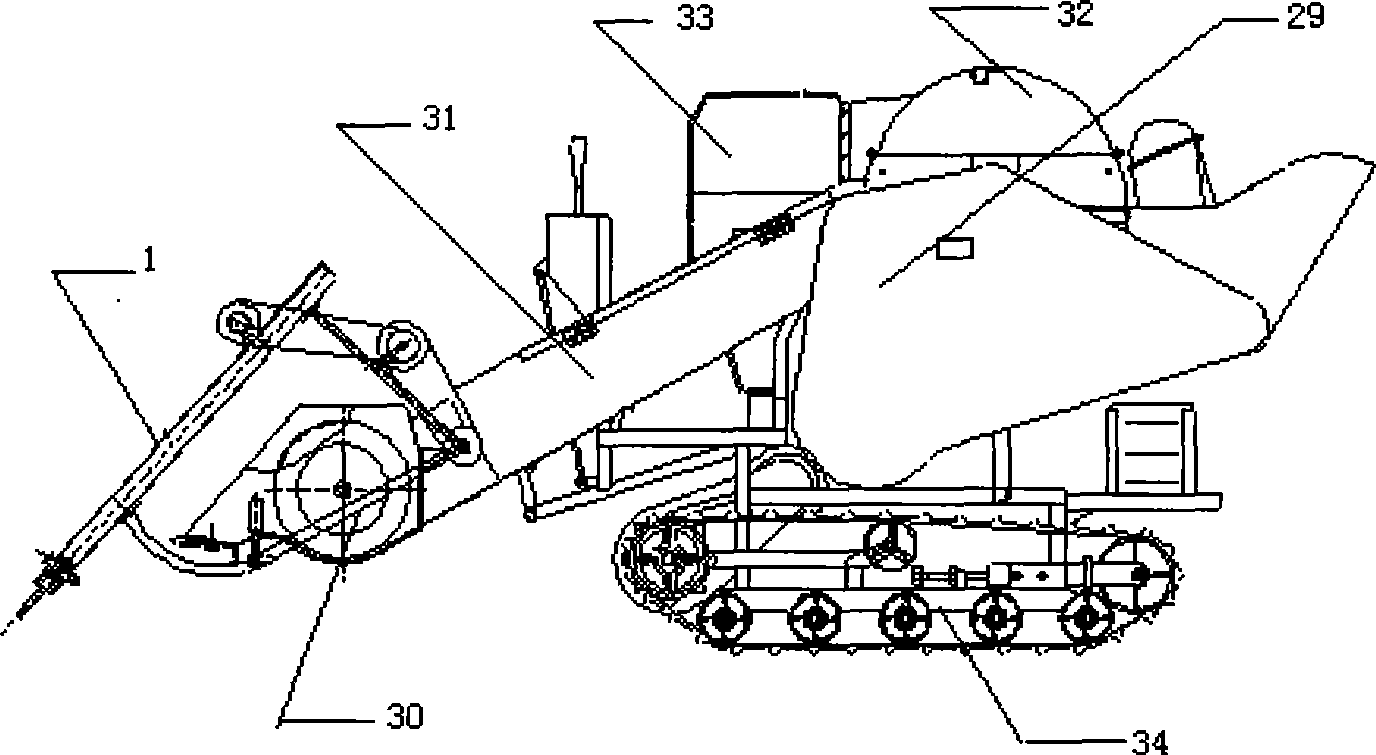

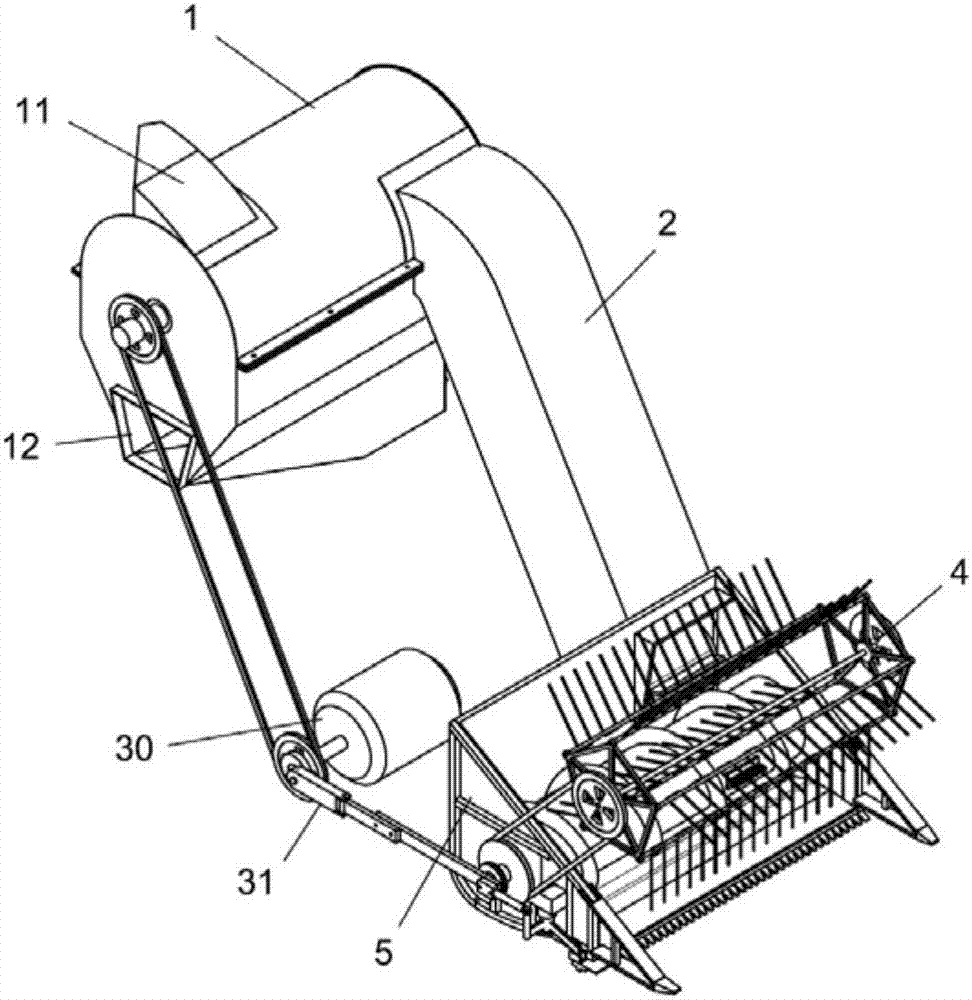

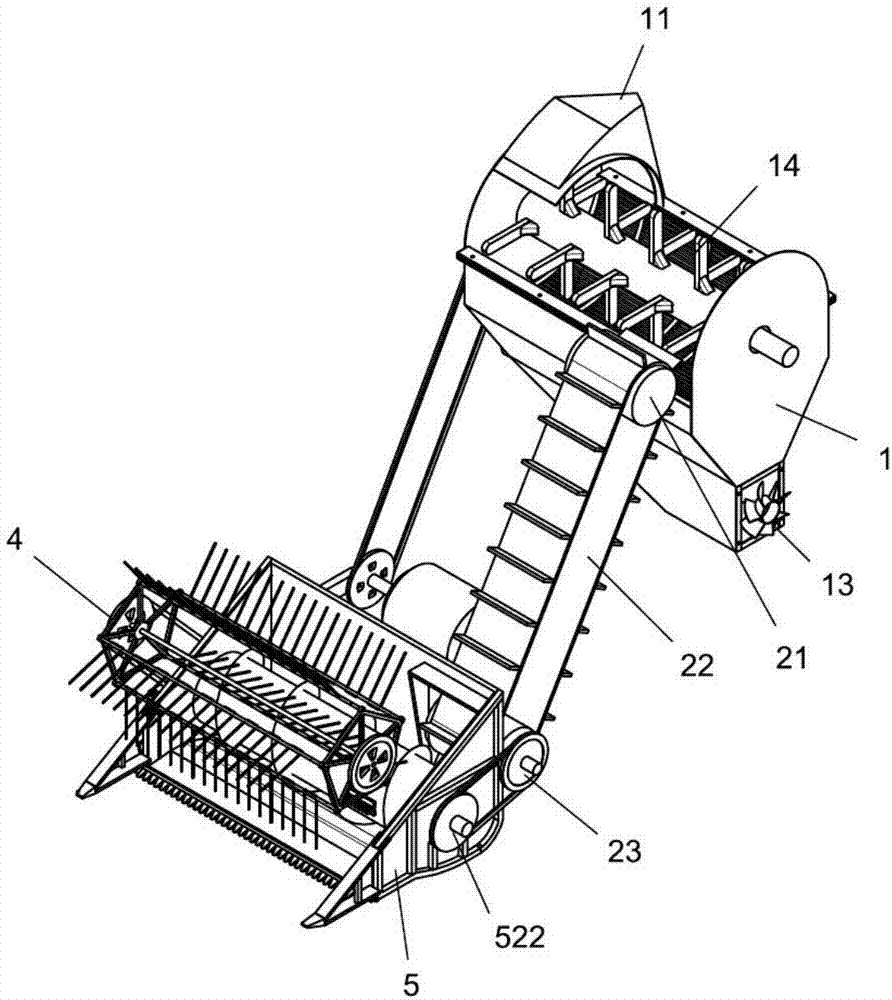

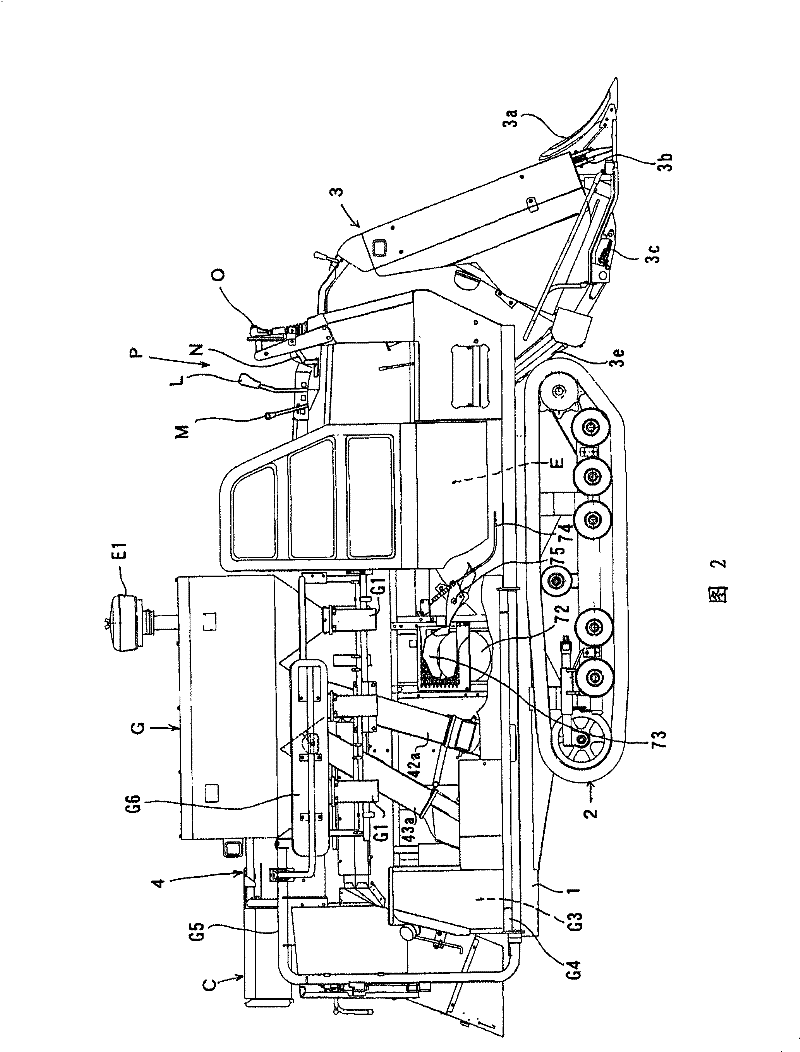

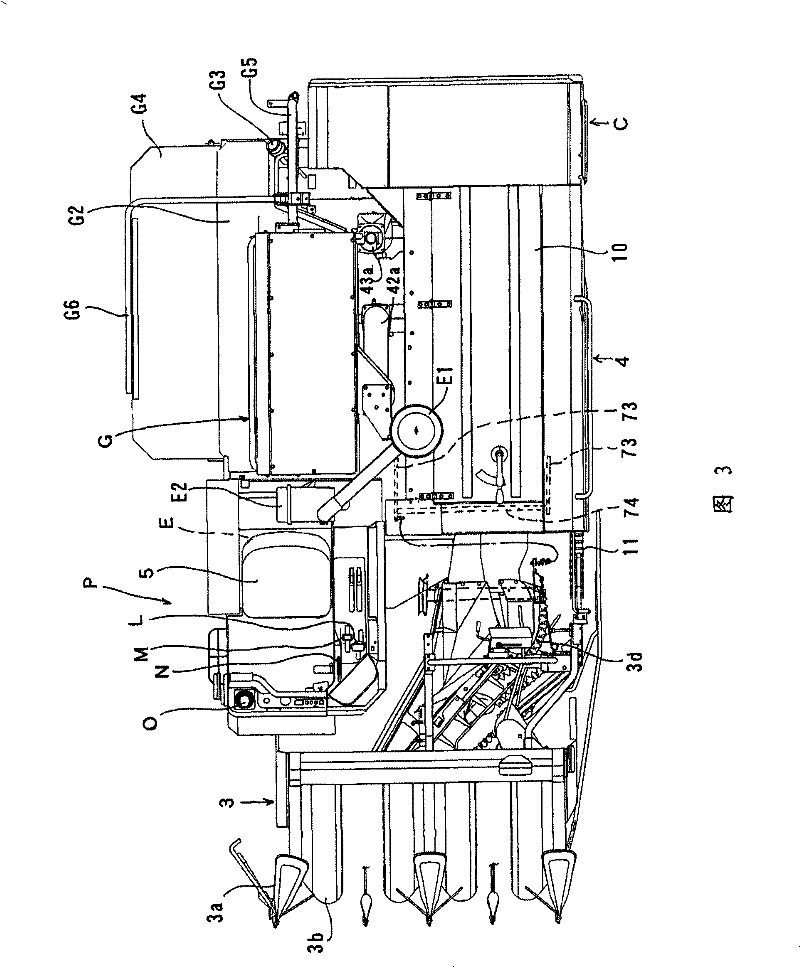

Whole-feeding combine harvester equipped with lifting device

The invention relates to a combine harvester. The combine harvester is a full-feed harvester with a lifting device and is designed to combine the advantages of full-feed harvesters and semi-feed harvesters. The combine harvester is formed by restructuring a full-feed harvester consisting of a machine frame, a header, an ear conveying device, a threshing device, a storage device, a power device and a traveling device, that is, by mounting a crop lifting device in front of a hopper of the header to form the header with the hopper, a screw feeder, a cutter, a transmission mechanism and the lifting device. The combine harvester can be used to harvest laid crops, improve working efficiency, reduce loss during harvest, effectively reduce feed quantity, reduce machine load, faults and costs, is high in efficiency and easy to popularize, and overcomes drawbacks that the full-feed harvesters can not effectively harvest laid crops .

Owner:方友祥

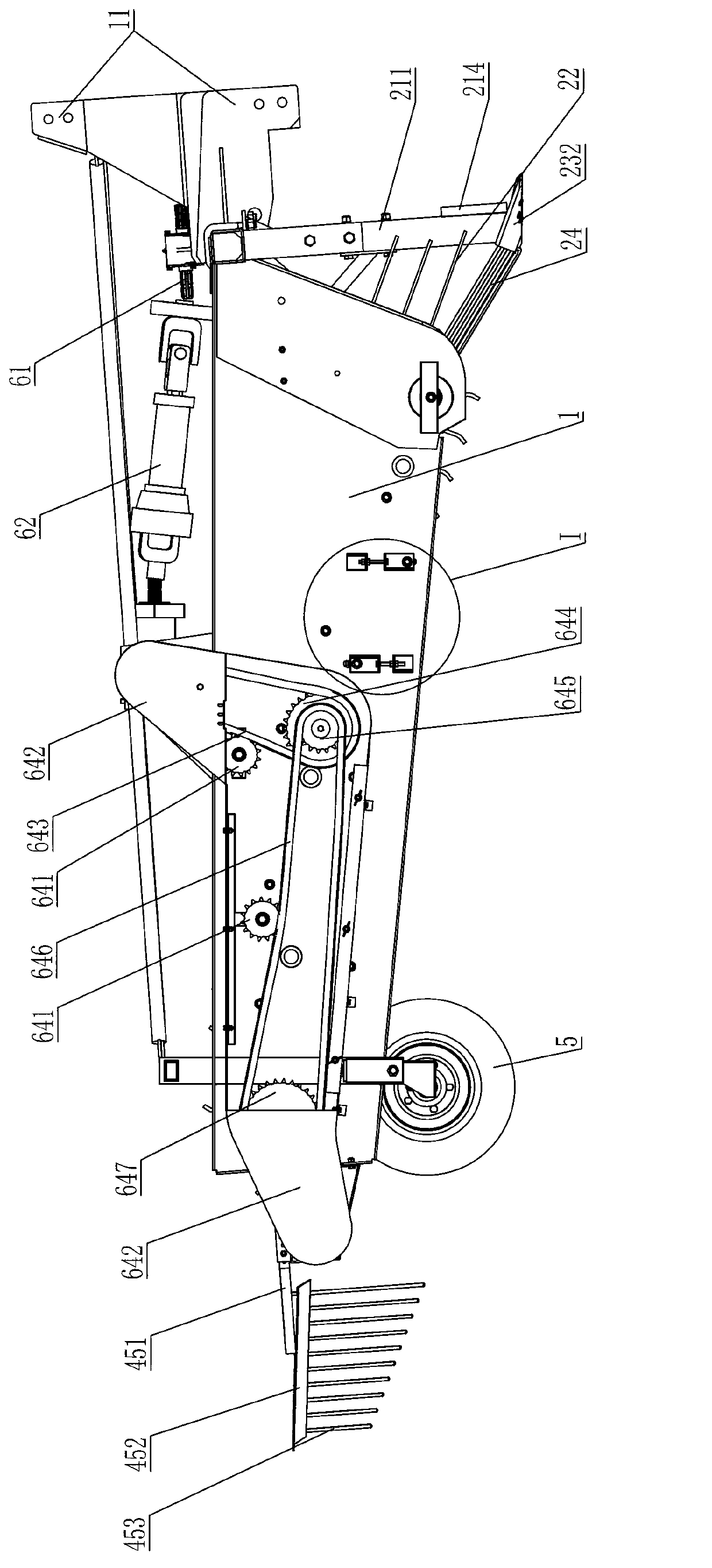

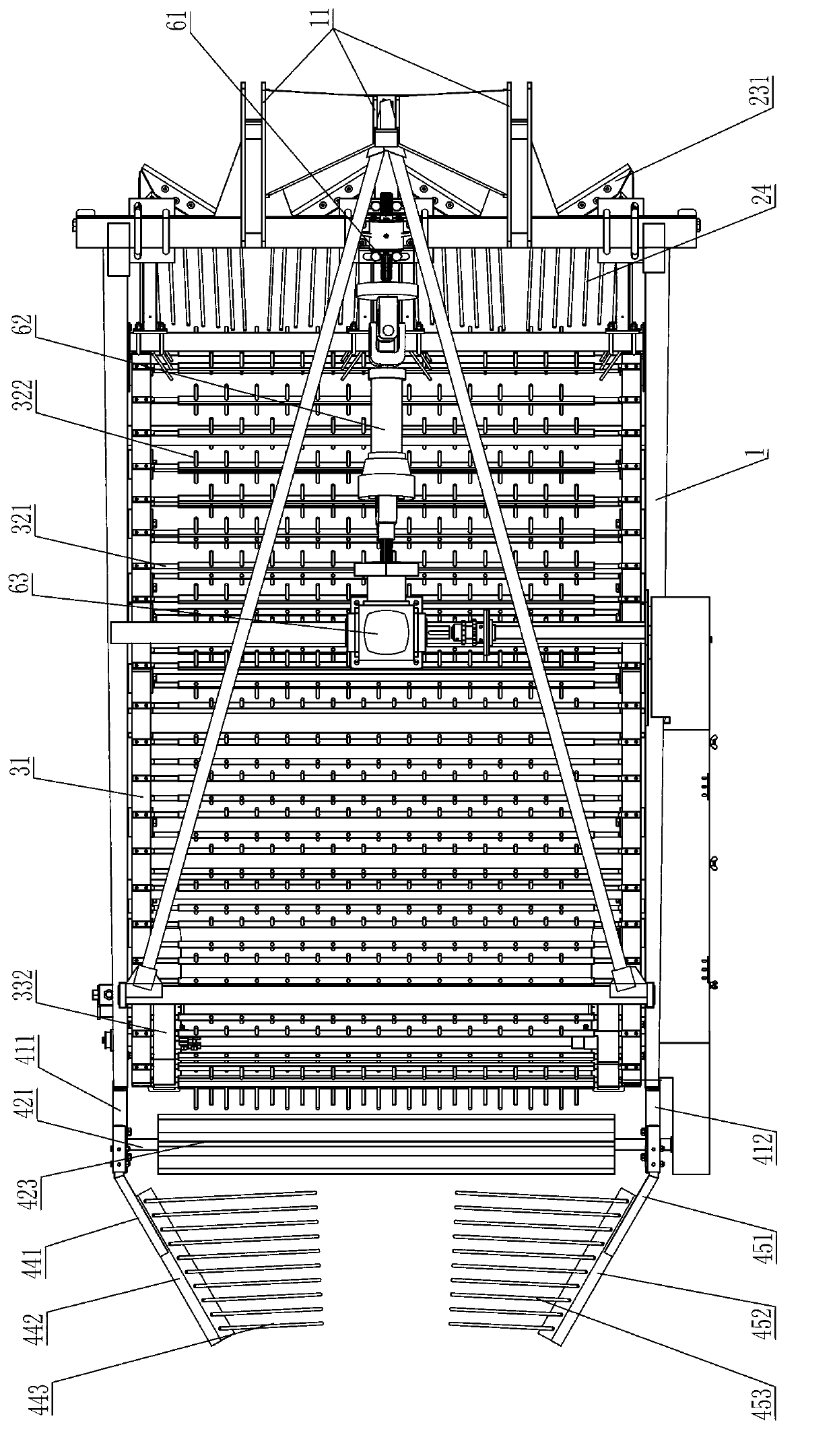

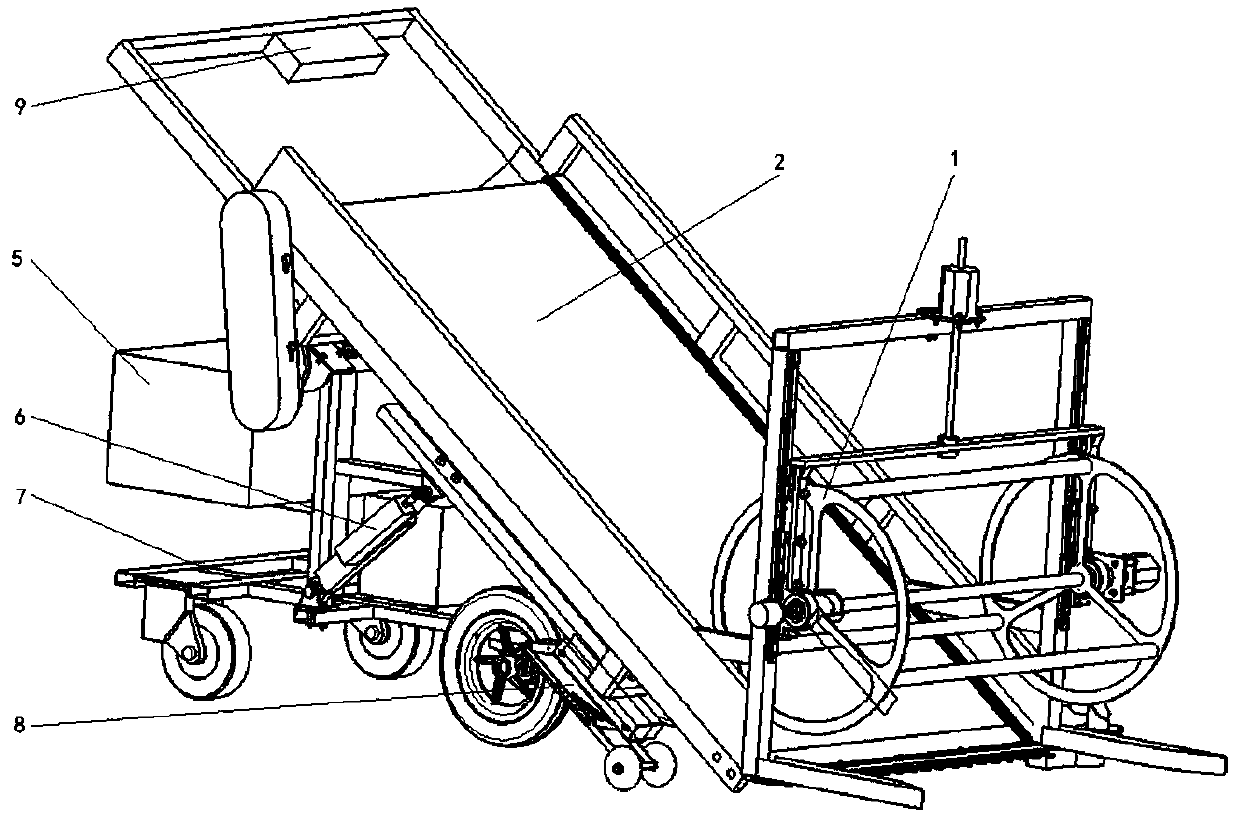

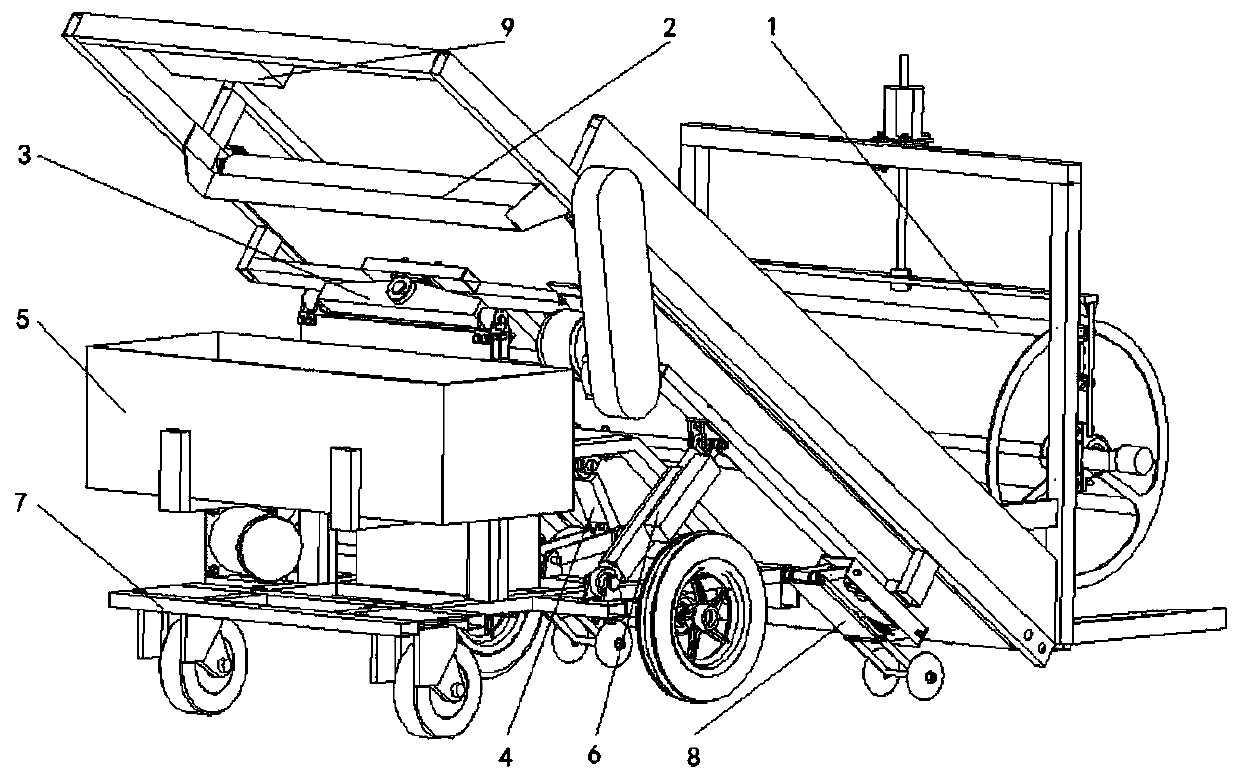

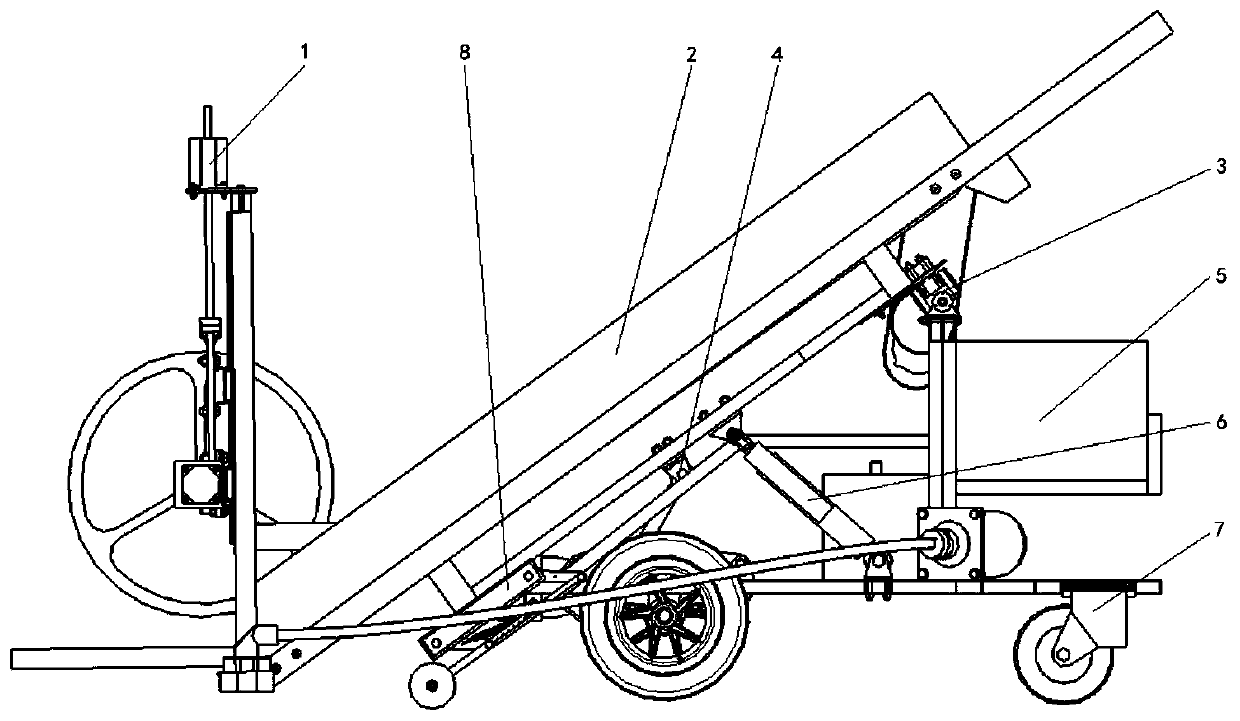

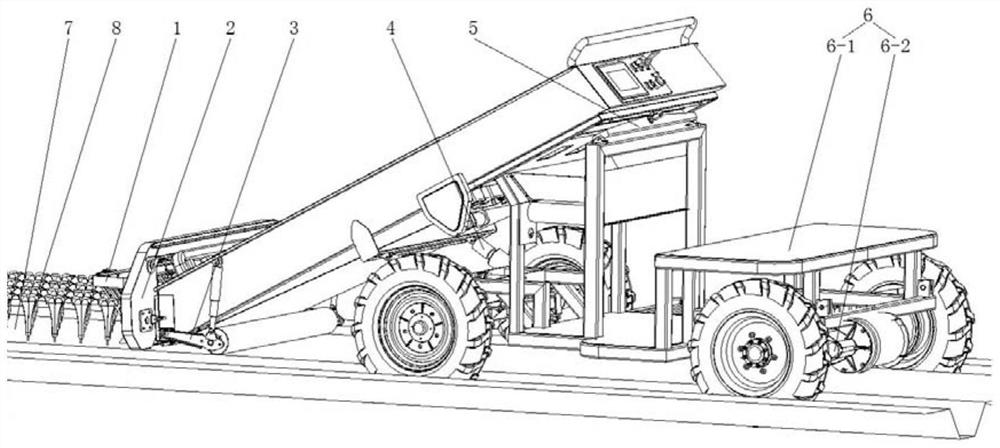

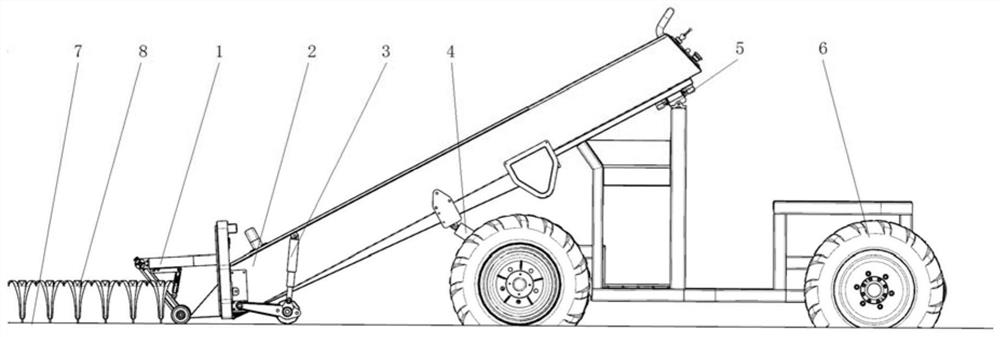

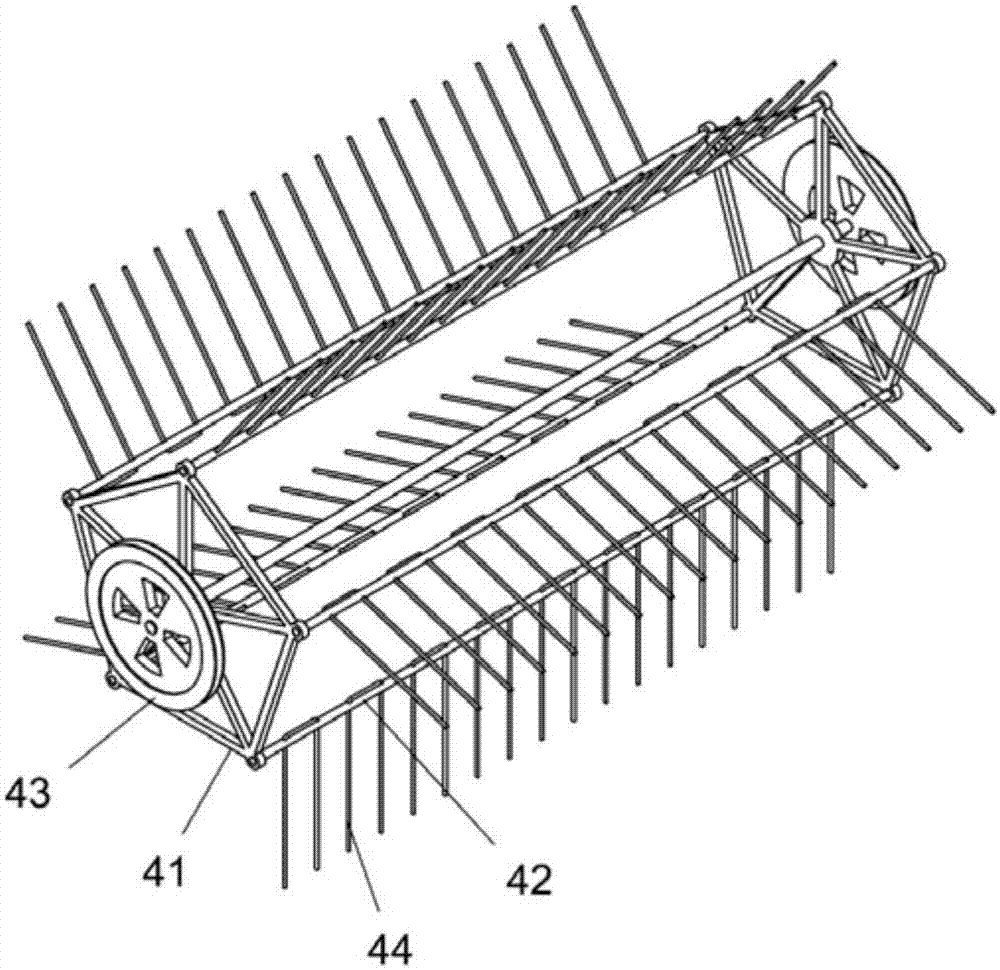

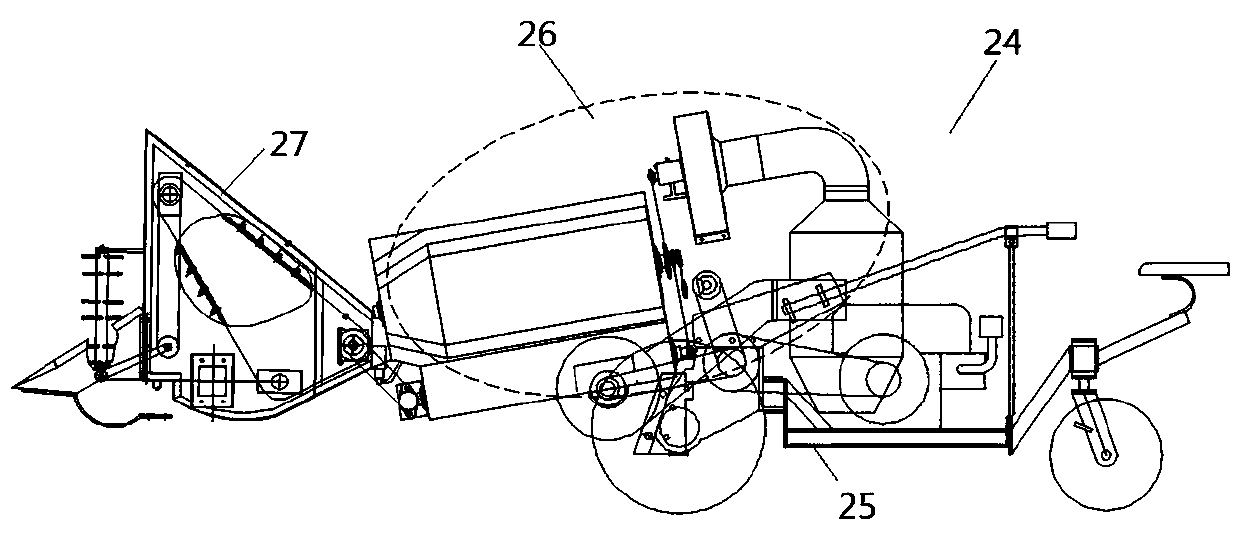

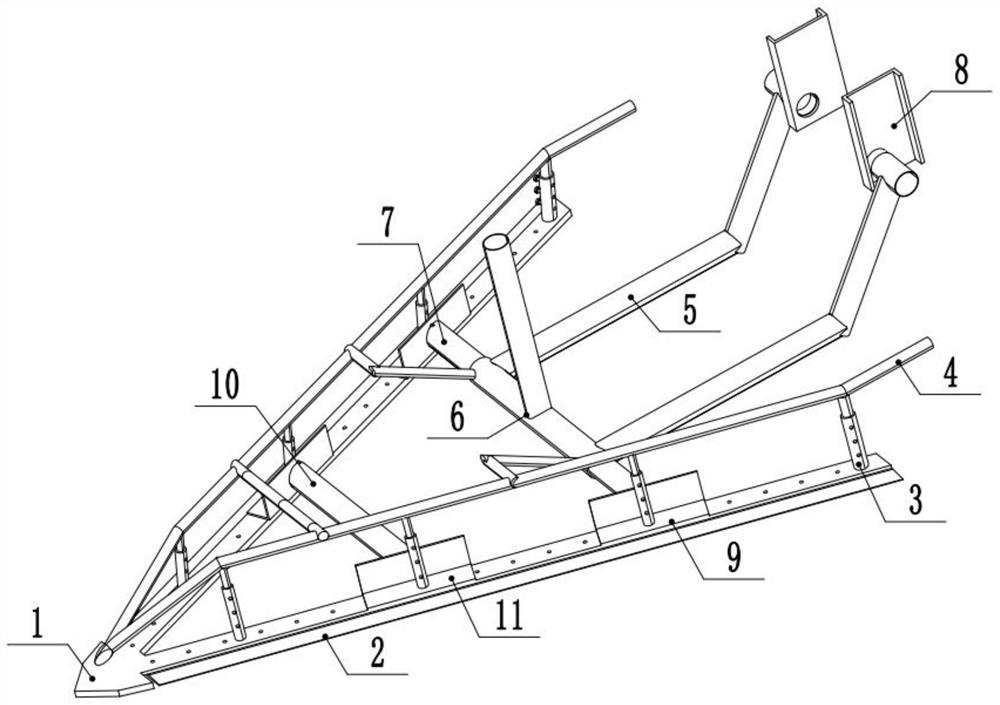

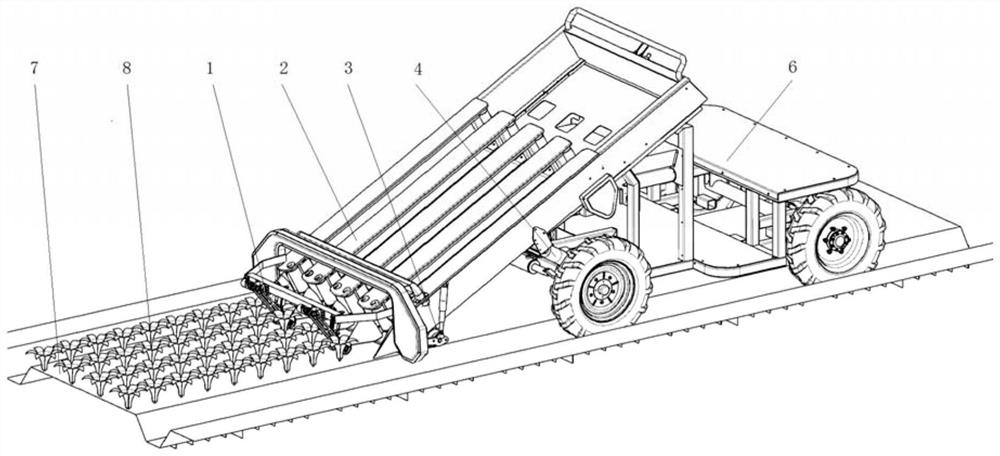

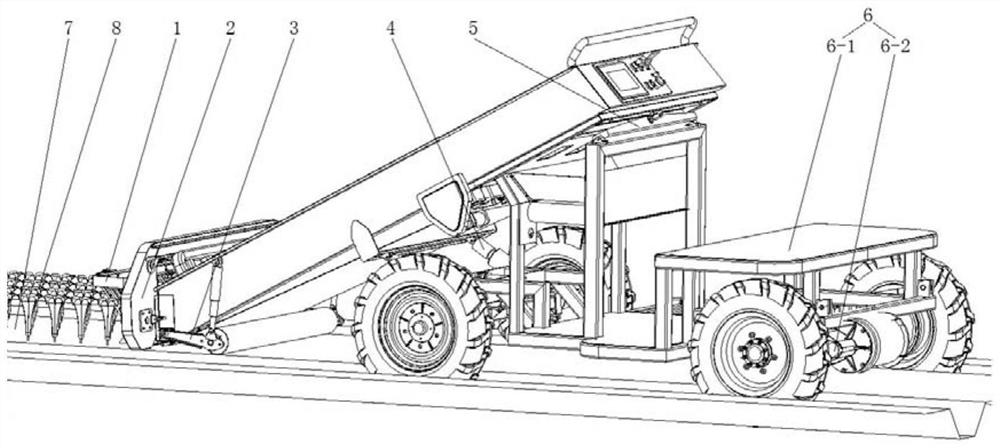

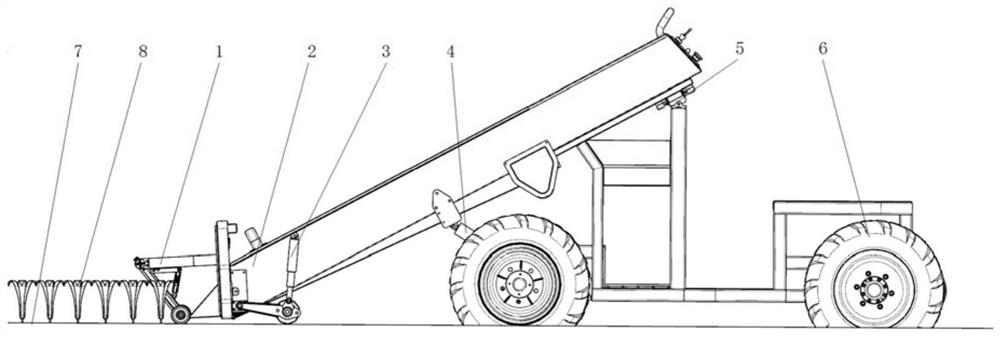

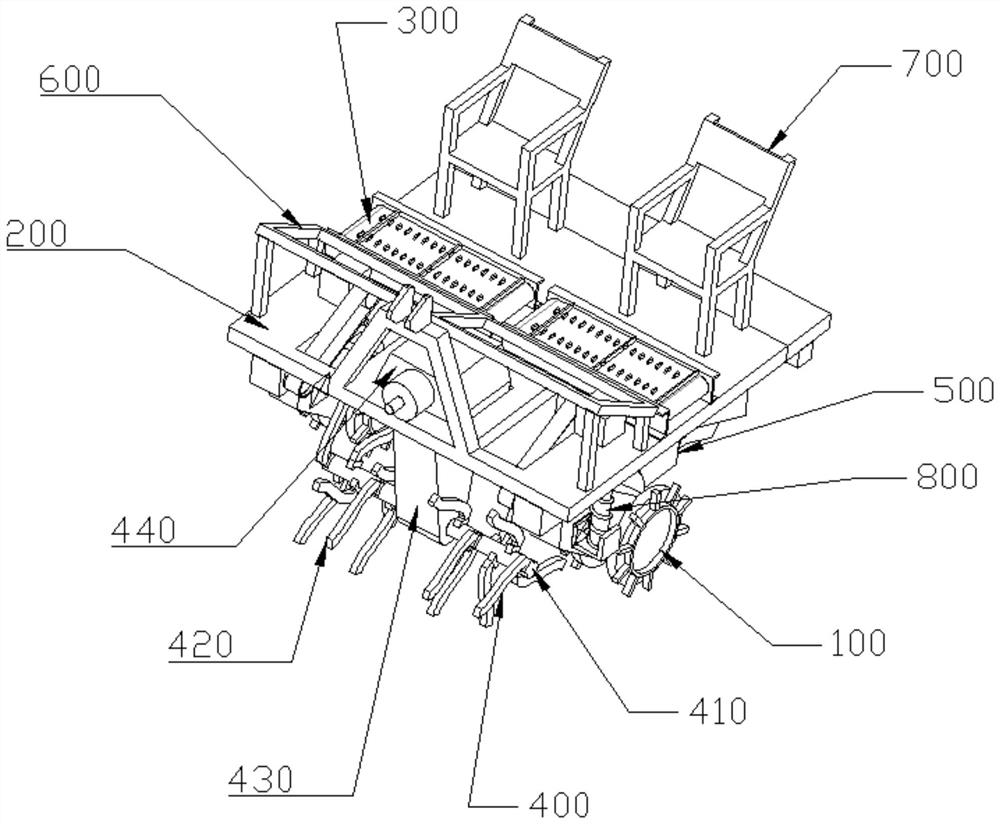

Peanut excavation windrower

The invention discloses a peanut excavation windrower which comprises a frame. A hanging frame connected with a drawing device is installed above the front end of the frame, an excavation device is installed under the front end of the frame, a lifting transportation device is installed on the frame at the back of the excavation device, a seedling laying device is installed on the frame at the back of the lifting transportation device, and a walking device is installed at the bottom at the back end of the frame. A transmission device used for transferring power to the lifting transportation device and the seedling laying device is installed on the frame. When the peanut excavation windrower is used, the hanging frame is utilized to connect the peanut excavation windrower onto the drawing device, peanut seedlings excavated by the excavation device are placed and gathered on the ground through the lifting transportation device and the seedling laying device sequentially in order, and collection of the peanut seedlings after drying is facilitated. The windrower adopts a frame structure, and is firm, reliable, even in stress, compact in structure, smooth in operation, low in cost, small in harvesting loss and high in working efficiency.

Owner:WUZHENG +1

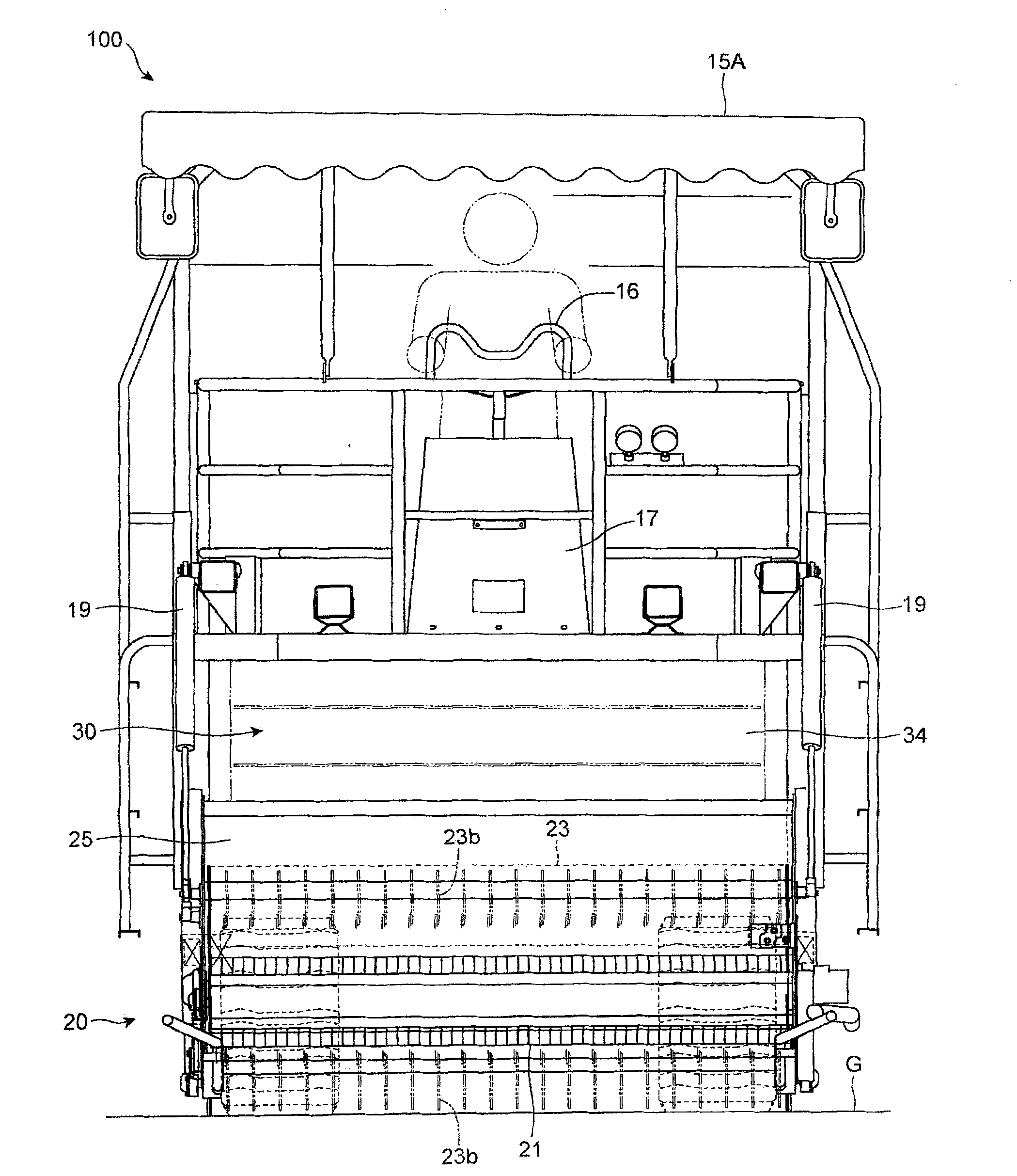

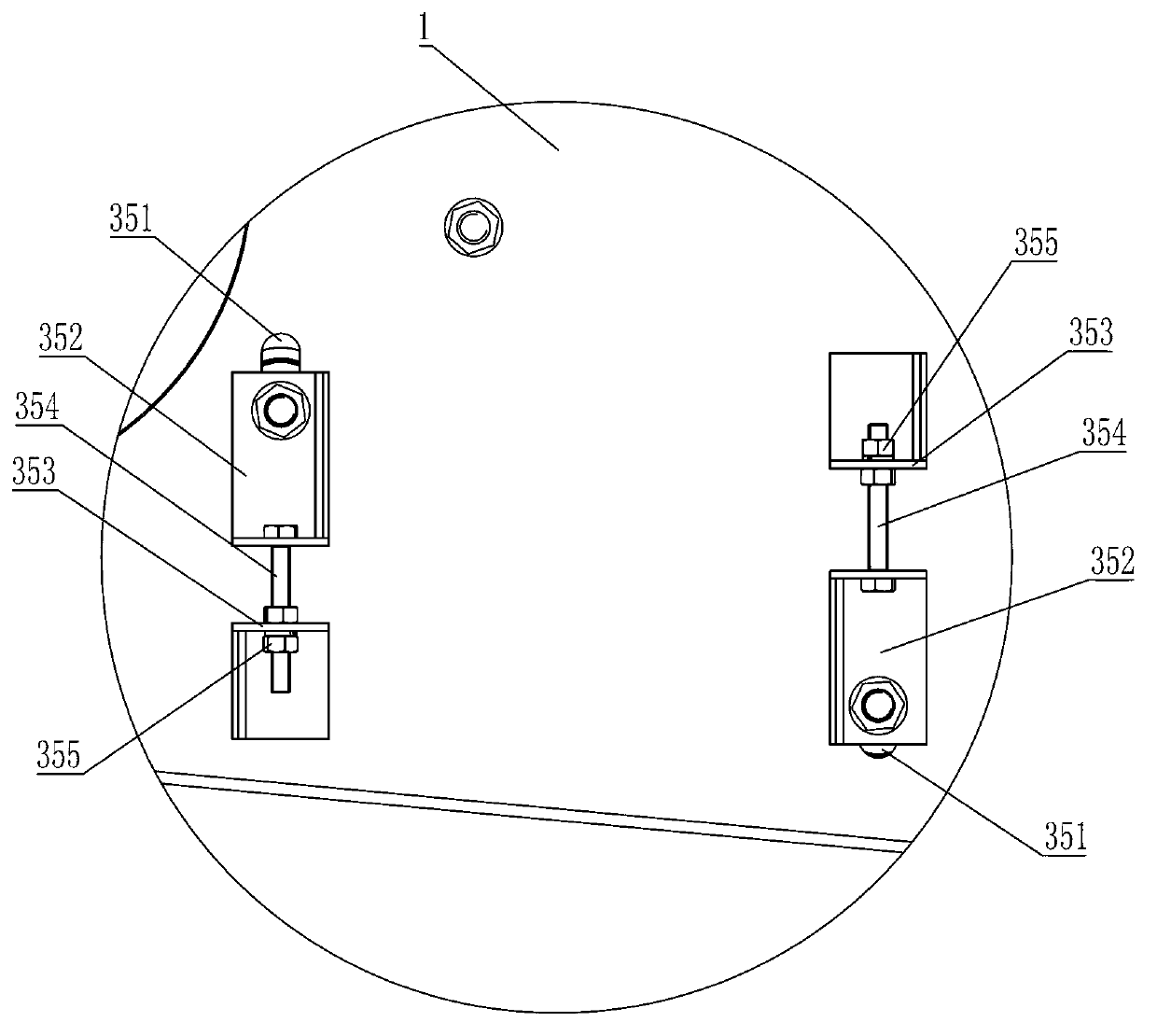

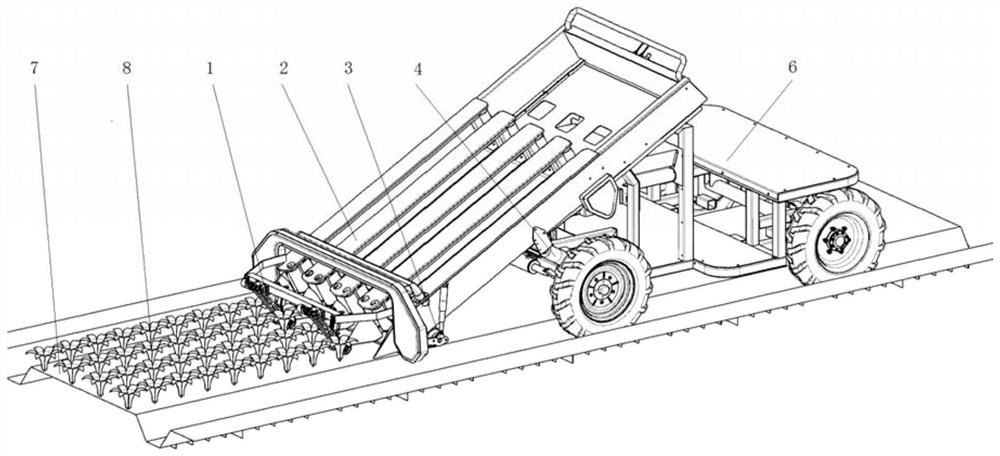

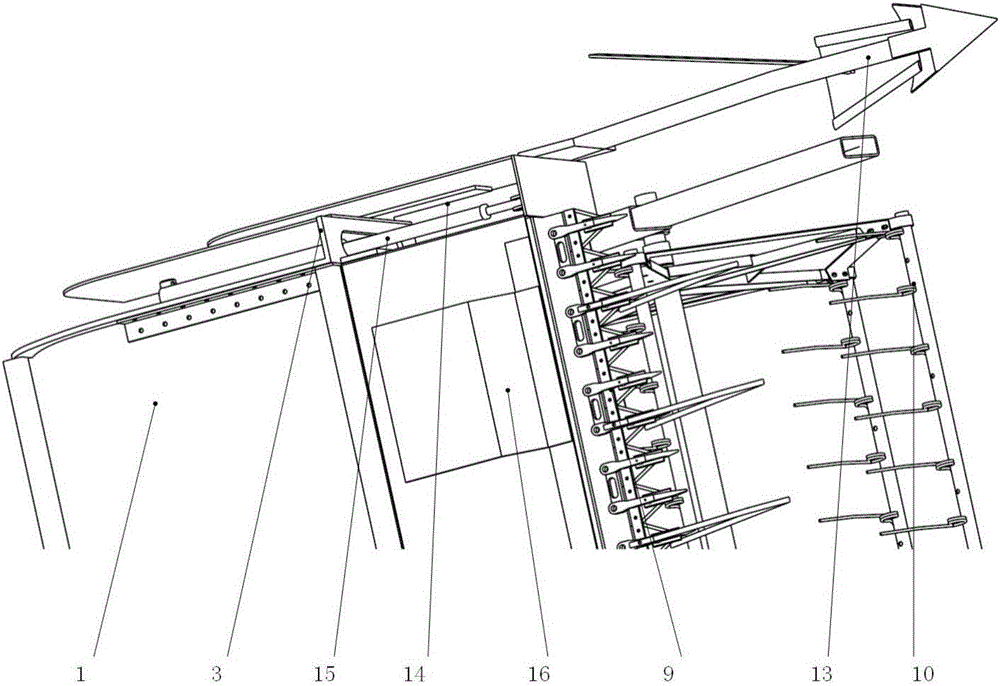

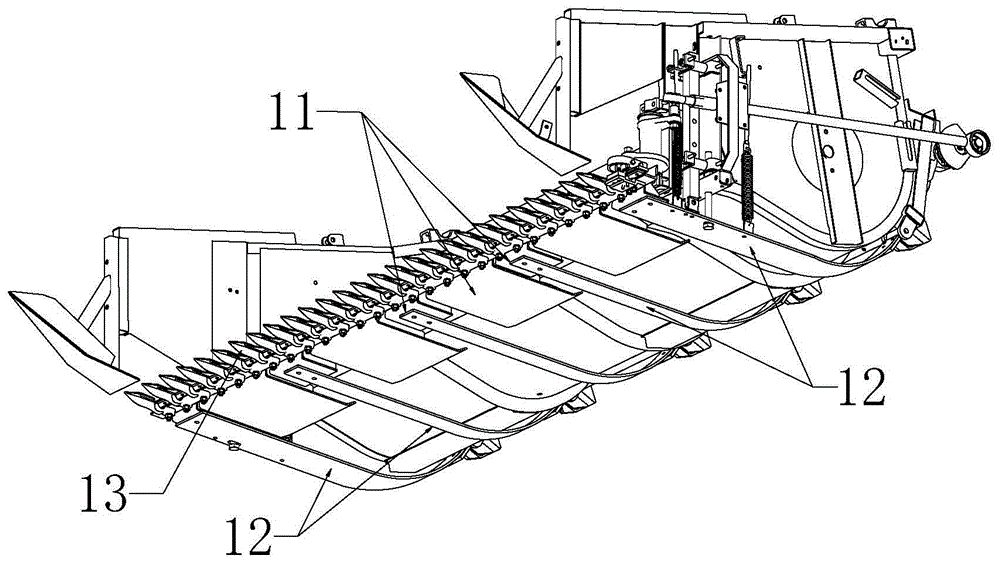

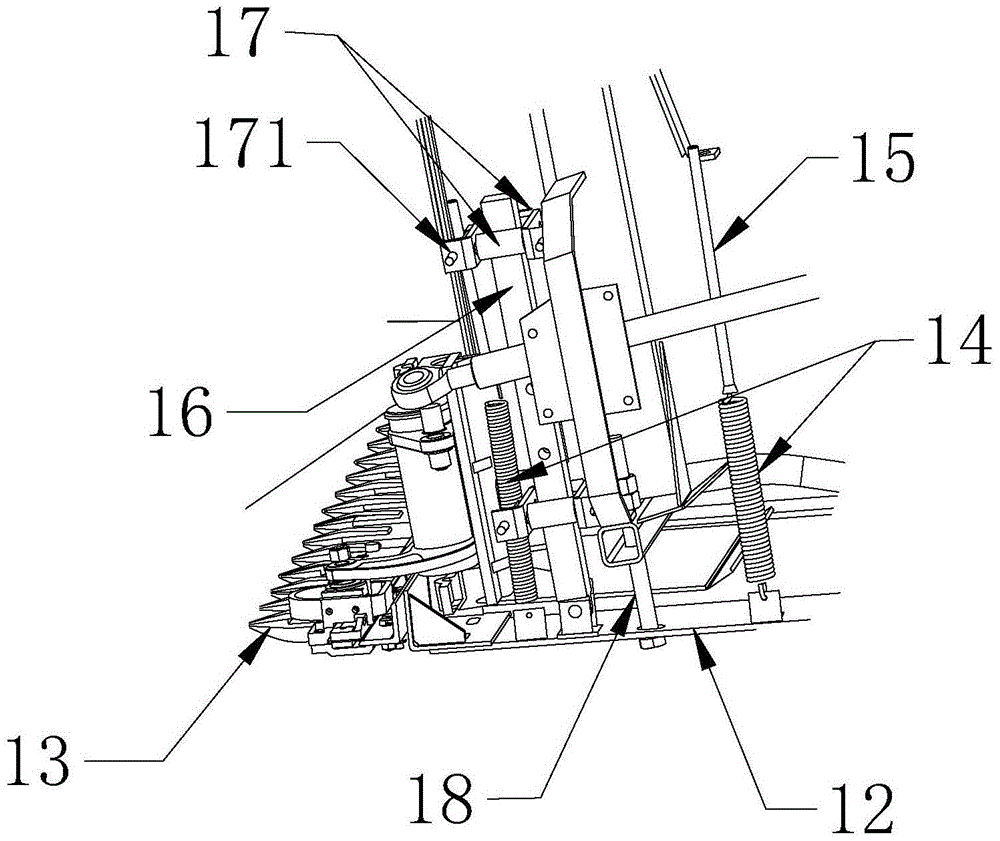

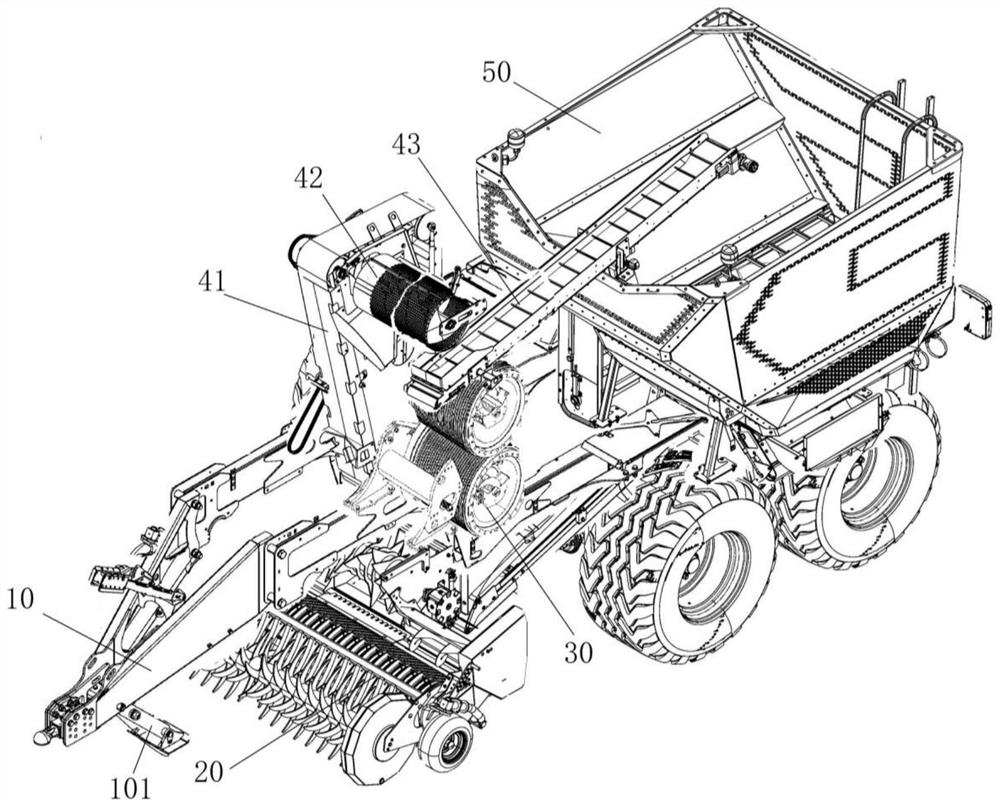

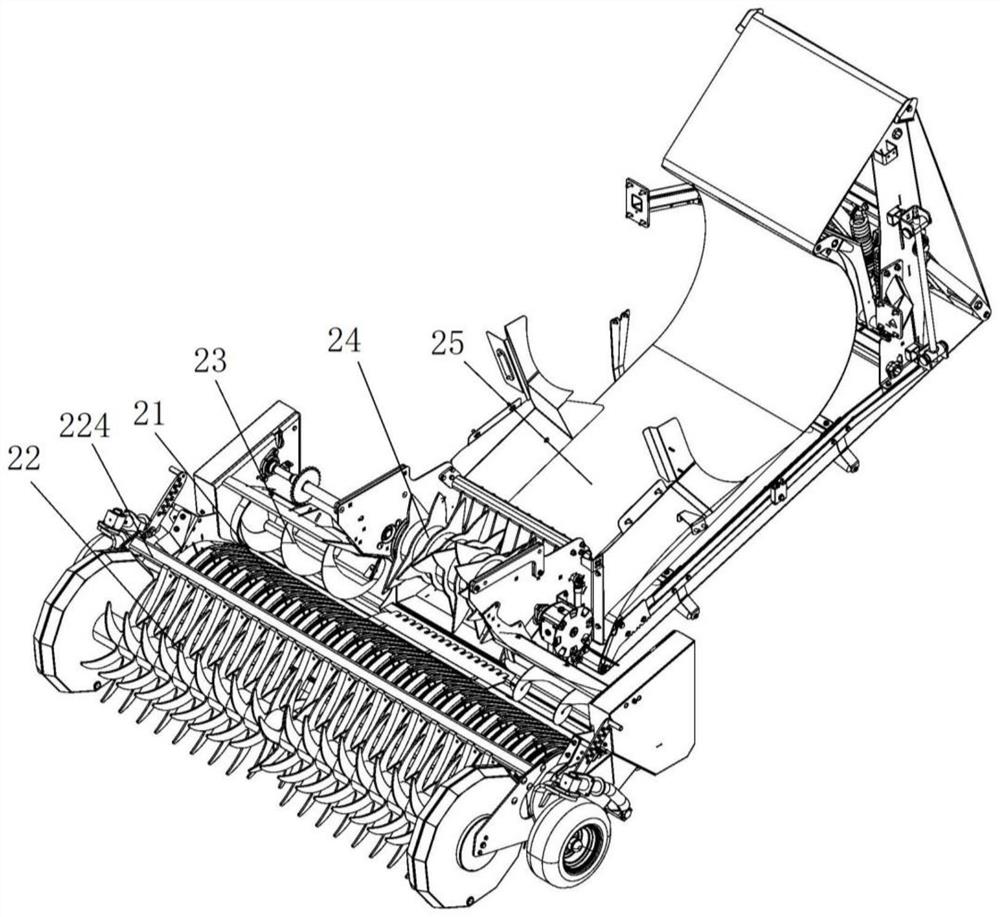

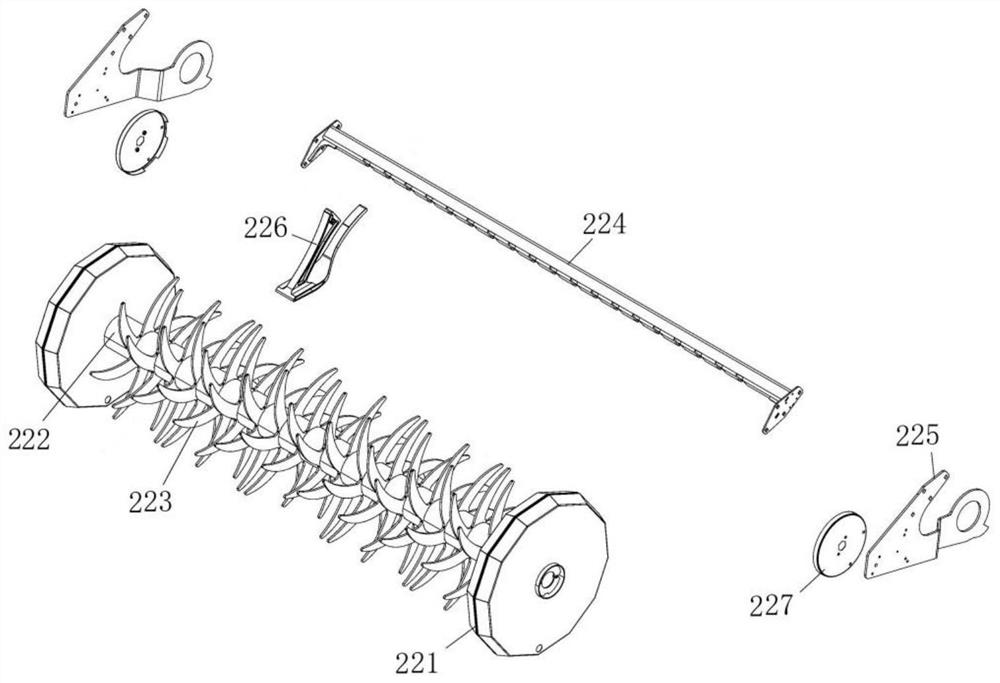

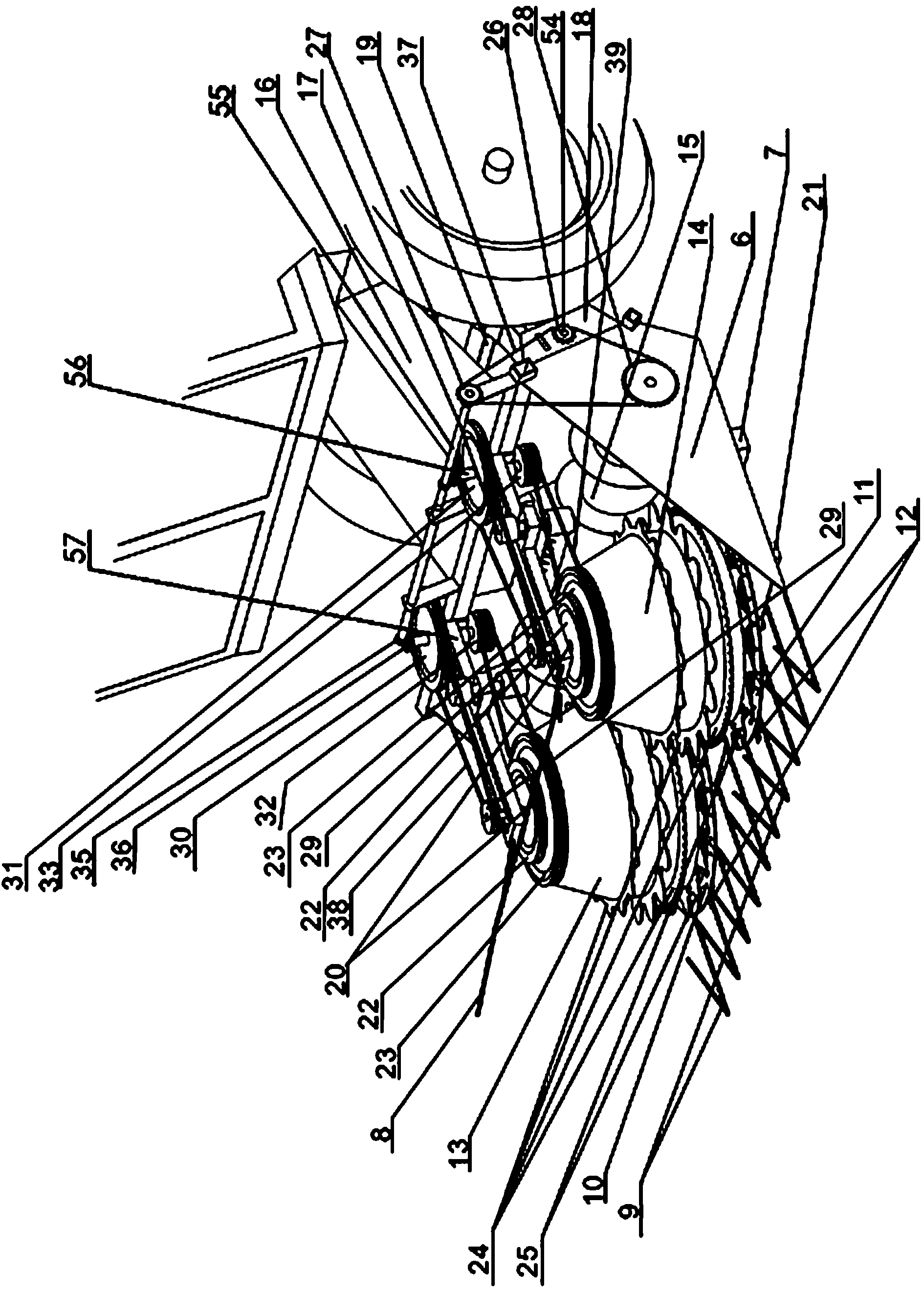

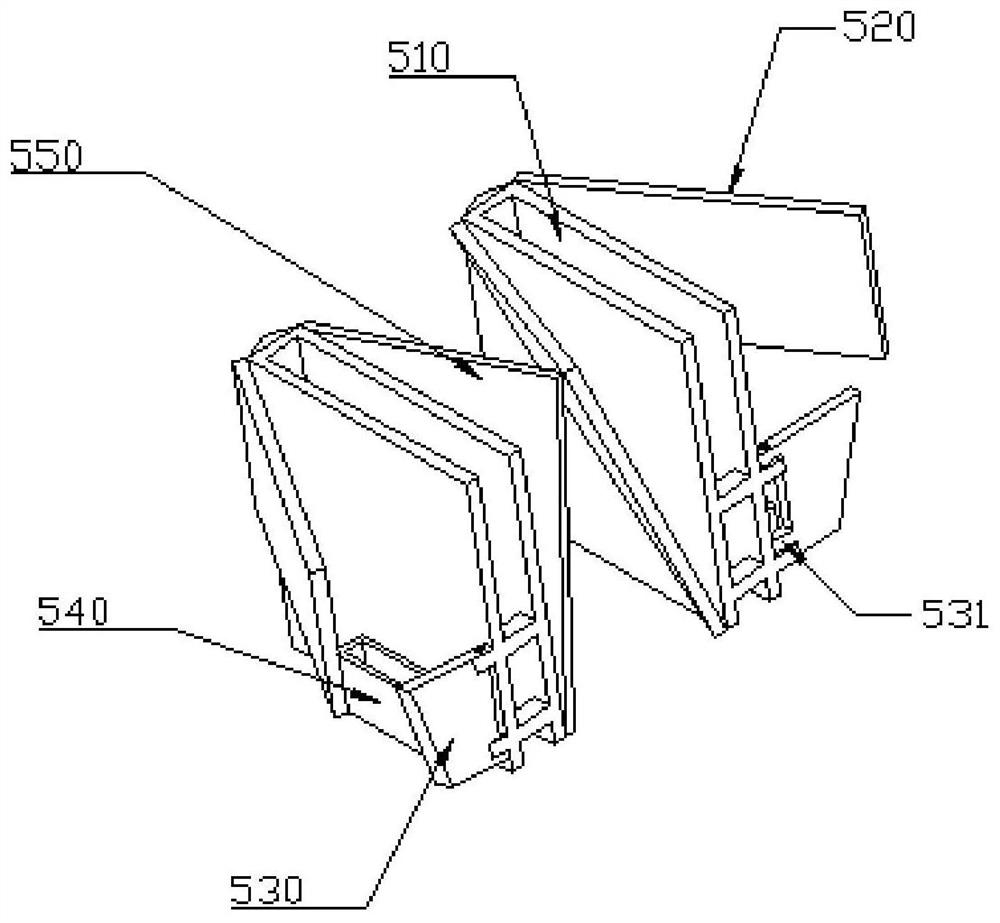

Profiling anti-blocking leaf vegetable harvester and control system and method control thereof

ActiveCN111226583AReduce Harvest LossSolve the blockageProgramme controlComputer controlControl systemAgricultural engineering

The invention belongs to the field of agricultural machinery, and relates to a profiling anti-blocking leaf vegetable harvester and a control system and a control method thereof. The profiling anti-blocking leaf vegetable harvester comprises a reel assembly, a header assembly, a header chassis connecting assembly, a header chassis limiting assembly, a collecting device, two header adjusting assemblies, a chassis assembly, two ridge surface detecting assemblies and a control system, wherein the reel assembly is installed at the front part of the header assembly; the header assembly is connectedto the chassis assembly through the header chassis connecting assembly; the header chassis limiting assembly is installed between the header assembly and the chassis assembly; the collecting device is installed at the rear part of the chassis assembly; the two header adjusting assemblies are transversely and symmetrically installed between the header assembly and the chassis assembly and are usedfor adjusting the postures of the header assembly in the transverse direction and the longitudinal direction; and the two ridge surface detecting assemblies are transversely and symmetrically installed in front of the lower part of the header assembly. The functions of ridge surface self-adaption in the transverse direction and the longitudinal direction of the cutting height, reel rotating speedself-adaption operation speed, intelligent anti-blocking regulation and the like are achieved, low loss rate of leaf vegetable harvesting is guaranteed, and the leaf vegetable harvesting quality is improved.

Owner:JIANGSU UNIV

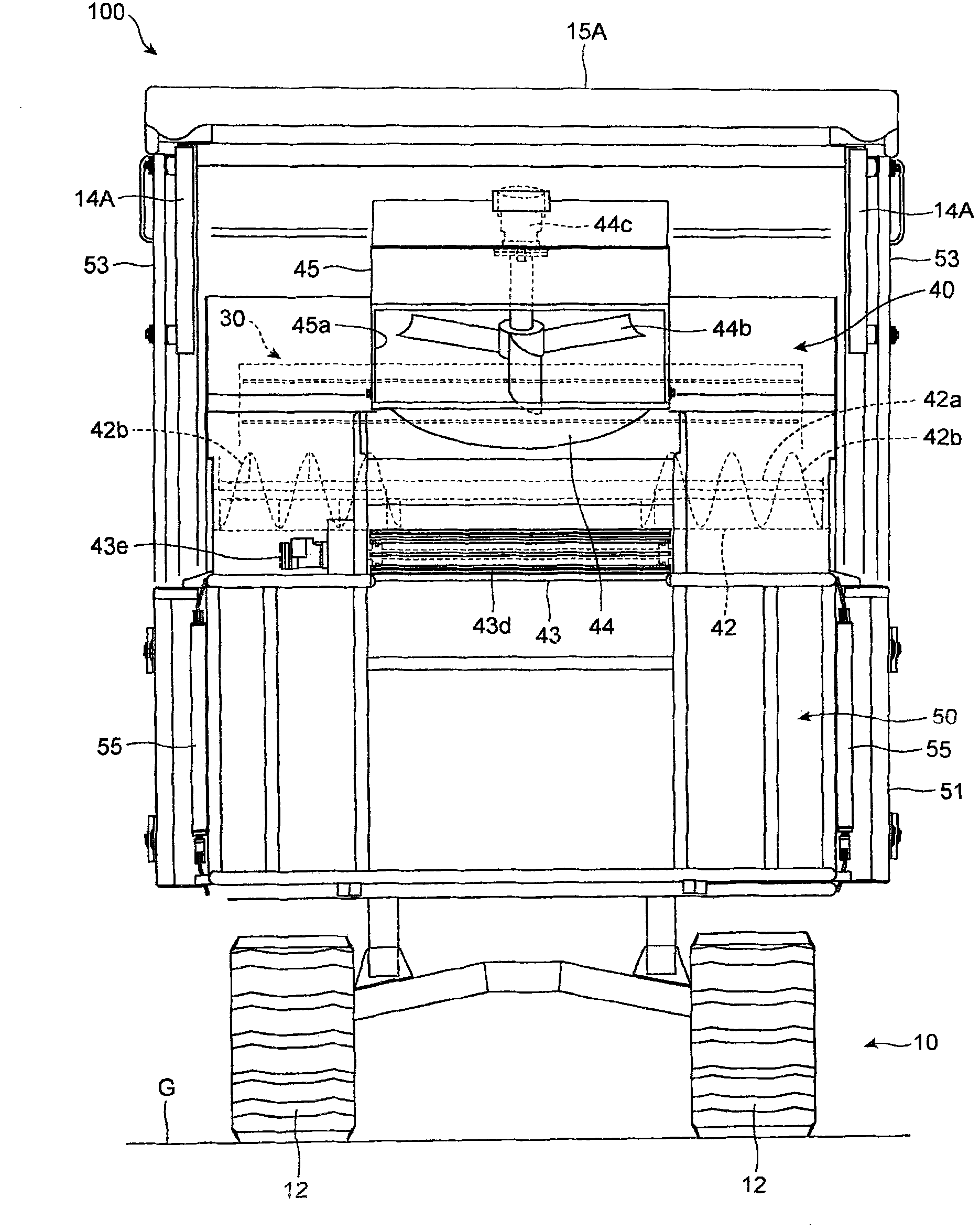

Header profiling device, control system and method thereof and harvester

ActiveCN112243682AReduce Harvest LossReduce soil damageMowersAgricultural undercarriagesControl systemMathematical model

The invention belongs to a header profiling device, a control system and method thereof and a harvester, and belongs to the field of agricultural machinery. The header profiling device comprises a profiling detection assembly, a header profiling adjustment assembly, a header lifting execution assembly, a header chassis hinge assembly and the control system. The profiling detection assembly is mounted in front of a header; the header profiling adjustment assembly is mounted at the front part of the header; the header lifting execution assembly is mounted between the header and a chassis; and the header chassis hinge assembly is arranged between the header and the chassis. Header position control in a transportation state and a header profiling harvesting operation state is realized throughthe header profiling adjustment assembly and the header lifting execution assembly; and the distance between a cutter and a ridge surface is detected by the control system for the profiling detectionassembly, the influence of the system profiling information lead amount is solved through a mathematical model, then the header profiling adjustment assembly is controlled to conduct transverse and longitudinal adjustment on the header so as to ensure that a certain distance can be kept between the cutter and the ridge surface, and the leaf vegetable harvesting loss and the cutter entering-soil damage caused by improper height adjustment of the cutter are reduced.

Owner:JIANGSU UNIV

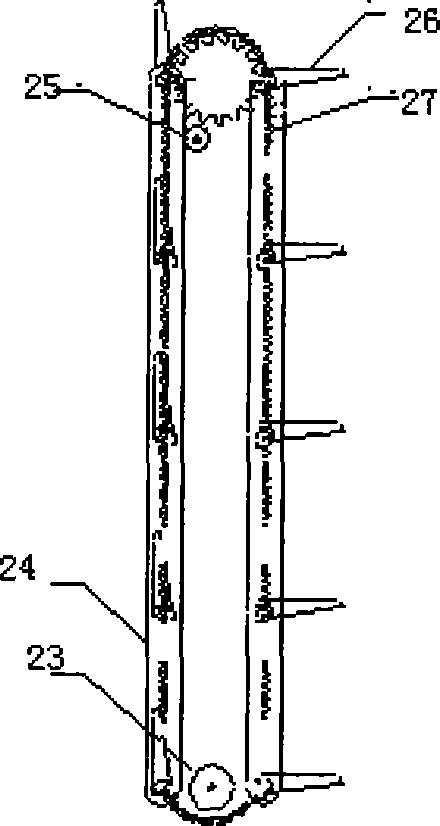

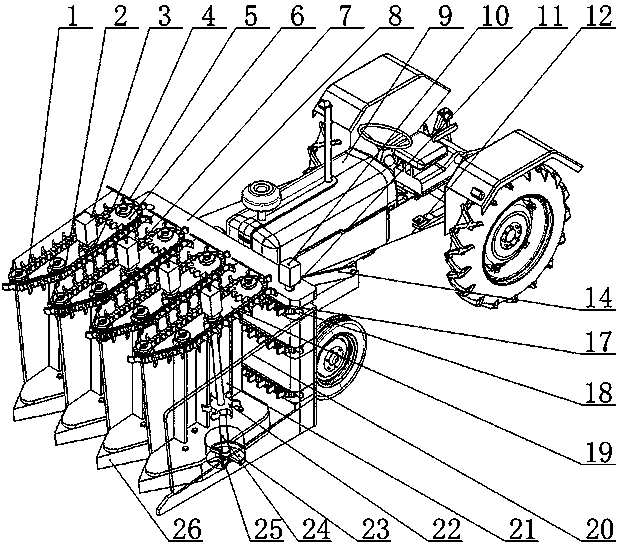

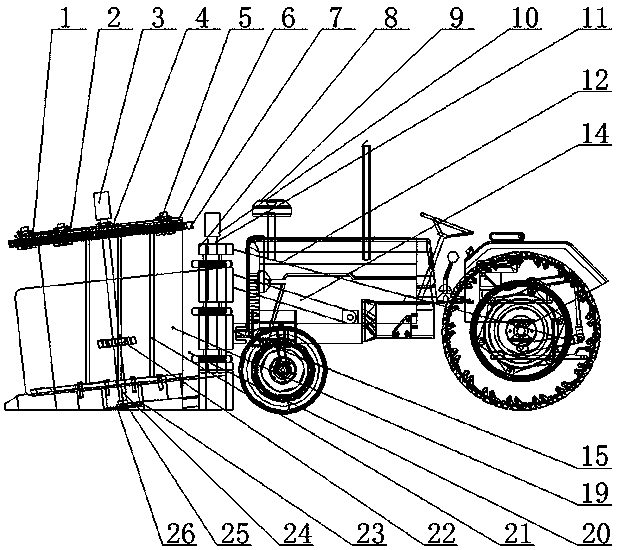

Holding chain type bast fiber crop harvester

The invention discloses a holding chain type bast fiber crop harvester. The harvester comprises a tractor, a header and a suspending frame, wherein the header comprises multiple sets of cutting devices and a horizontal conveying device; each cutting device comprises a first driven small chain wheel, a second driven small chain wheel, a driving small chain wheel, a first hydraulic motor, a driven large chain wheel, a longitudinal conveying chain, a protective cover, a stalk shifting star wheel, a semicircle fixed blade, a movable cutter shaft, a hexagonal rotary movable blade and a base; the horizontal conveying device comprises a second hydraulic motor, a driving shaft, a device mounting rack, driving chain wheels, horizontal conveying chains and driven chain wheels. After the movable cutter shafts cooperate with all cutting assemblies to perform cutting, the longitudinal conveying chains, the stalk shifting star wheels and the horizontal conveying device cooperate to complete stalk cutting and conveying operation, and the harvester has the advantages of novel design, compact structure, high universality, work stability and high efficiency.

Owner:NANJING INST OF TECH

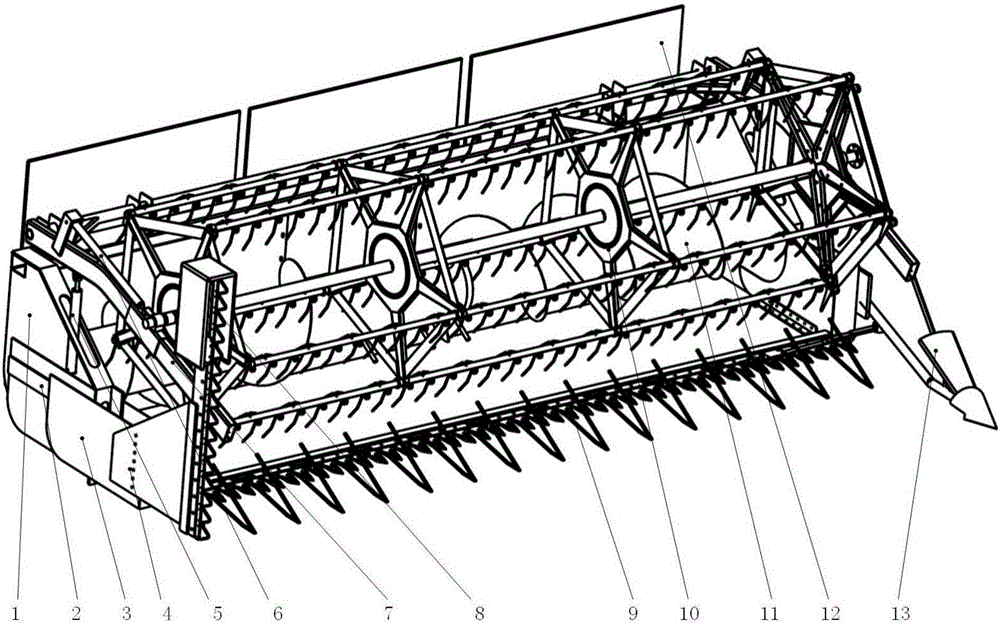

Multifunctional drawer type header for grain combine harvester

The invention relates to a multifunctional drawer type header for a grain combine harvester. Each of left and right sides of the header is provided with a drawer type rear end and a drawer type front end, and left and right ends of a conveying device are connected with the left and right drawer type rear ends respectively. Left and right ends of a cutting device are connected with the left and right drawer type front ends respectively, and a divider is connected to each drawer type front end. The drawer type rear ends and the drawer type front ends form drawer type connection through inner drawer type slide rails and outer drawer type slide rails, and extension and retraction of the left and right drawer type front ends are controlled by header depth regulation hydraulic cylinders. Rear ends of left and right reel frames are rotatably connected to a shell of the header, left and right ends of an eccentric reel are connected with the left and right reel frames respectively, and the position of the eccentric reel is adjusted through a reel horizontal position adjusting hydraulic cylinder and a reel vertical position adjusting hydraulic cylinder. The multifunctional drawer type header is applicable to harvesting of crops different in type and height, quick switching of various crop harvesting modes is realized, harvesting loss is reduced, and utilization rate of the header is increased remarkably.

Owner:CHINA AGRI UNIV

Method for judging maturity of soybeans in harvesting period based on remote sensing of unmanned aerial vehicle

PendingCN114092839AReduce Harvest LossIncrease productionKernel methodsCharacter and pattern recognitionSupport vector machineHarvest time

Disclosed is a method for judging maturity of soybeans in a harvesting period based on remote sensing of an unmanned aerial vehicle. A vegetation index of the soybean maturity period is calculated by utilizing multispectral data, a soybean maturity characterization method is established by utilizing a natural breakpoint grading algorithm and combining the vegetation index, and soybean maturity grades are divided; spectral reflectivity, color feature and texture feature parameters of the soybeans are extracted in the image, and feature screening is performed on feature difference comparative analysis; and a soybean maturity grade discrimination model of a support vector machine learning algorithm is established in combination with the soybean maturity grade. The soybean maturity can be accurately judged by combining unmanned aerial vehicle multispectrum with a machine learning technology, so that judgment of the soybean maturity in a breeding plan is facilitated, determination of the optimal harvest time of soybeans is facilitated, the soybean harvest loss is reduced, and the soybean yield is indirectly increased.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Corn reaping and threshing device

The invention discloses a corn reaping and threshing device. The corn reaping and threshing device comprises a cutting and ear guiding unit, wherein a winding roll is arranged laterally above the cutting and ear guiding unit; a guiding unit is arranged behind the cutting and ear guiding unit; the guiding unit comprises a guiding cover; the guiding cover is fixedly arranged at the periphery of a guiding belt; the lower end port of the guiding cover corresponds to an ear guiding port; the upper end port of the guiding cover is connected with a threshing unit; the threshing unit comprises a threshing cover casing; a threshing roll is mounted in the threshing cover casing; and the end part of the threshing roll is provided with a threshing roll belt wheel. The corn reaping and threshing device has the advantages of low harvesting loss and low kernel breakage rate; the corn reaping and threshing device is provided with a husk peeling device, thereby realizing thorough peeling of husks; when the stalks are returned to the field, the corn reaping and threshing device achieves a favorable pulverizing effect and realizes uniform throwing; in the stalk silage harvesting process, the corn reaping and threshing device achieves a high harvesting rate and realizes uniform cutting; the reaping and threshing device operates reliably and is high in applicability; and the reaping and threshing device can be adapted to corn of different row spacings, natural heights, yields and ripening degrees (or even lodged corn), different agricultural planting processes and the like.

Owner:DONGGUAN BEIYANG IND DESIGN CO LTD

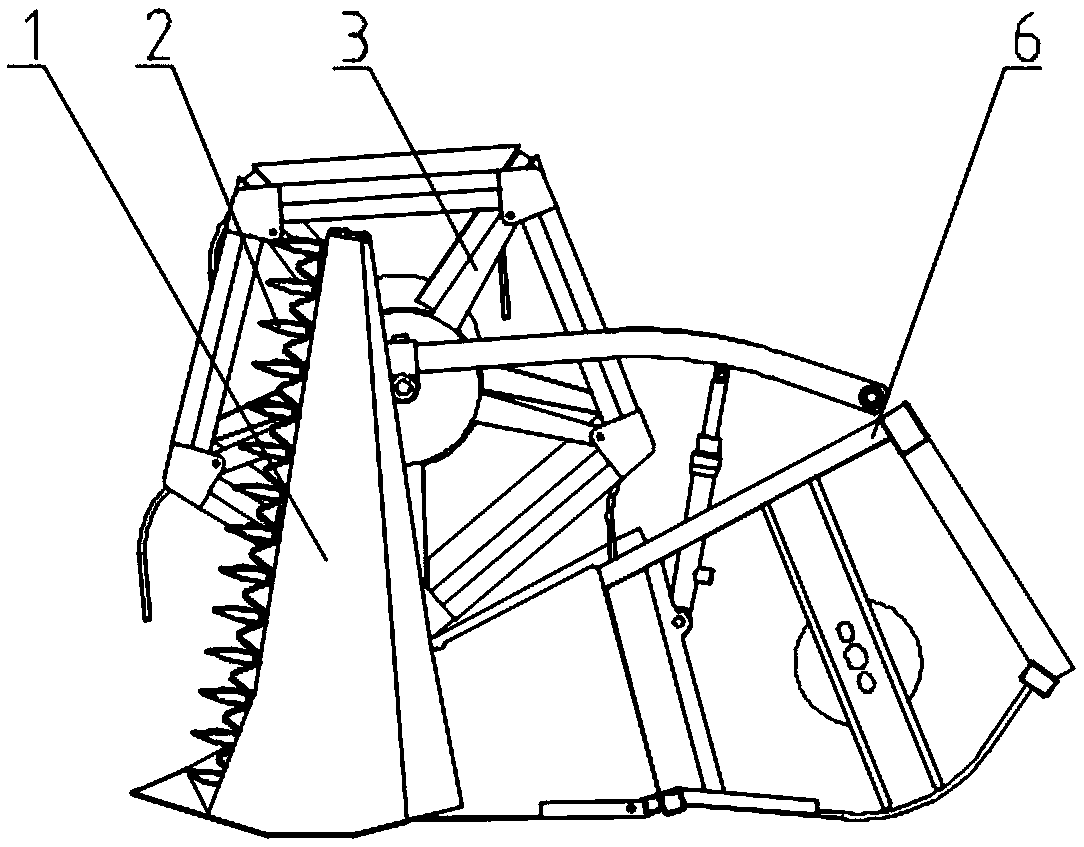

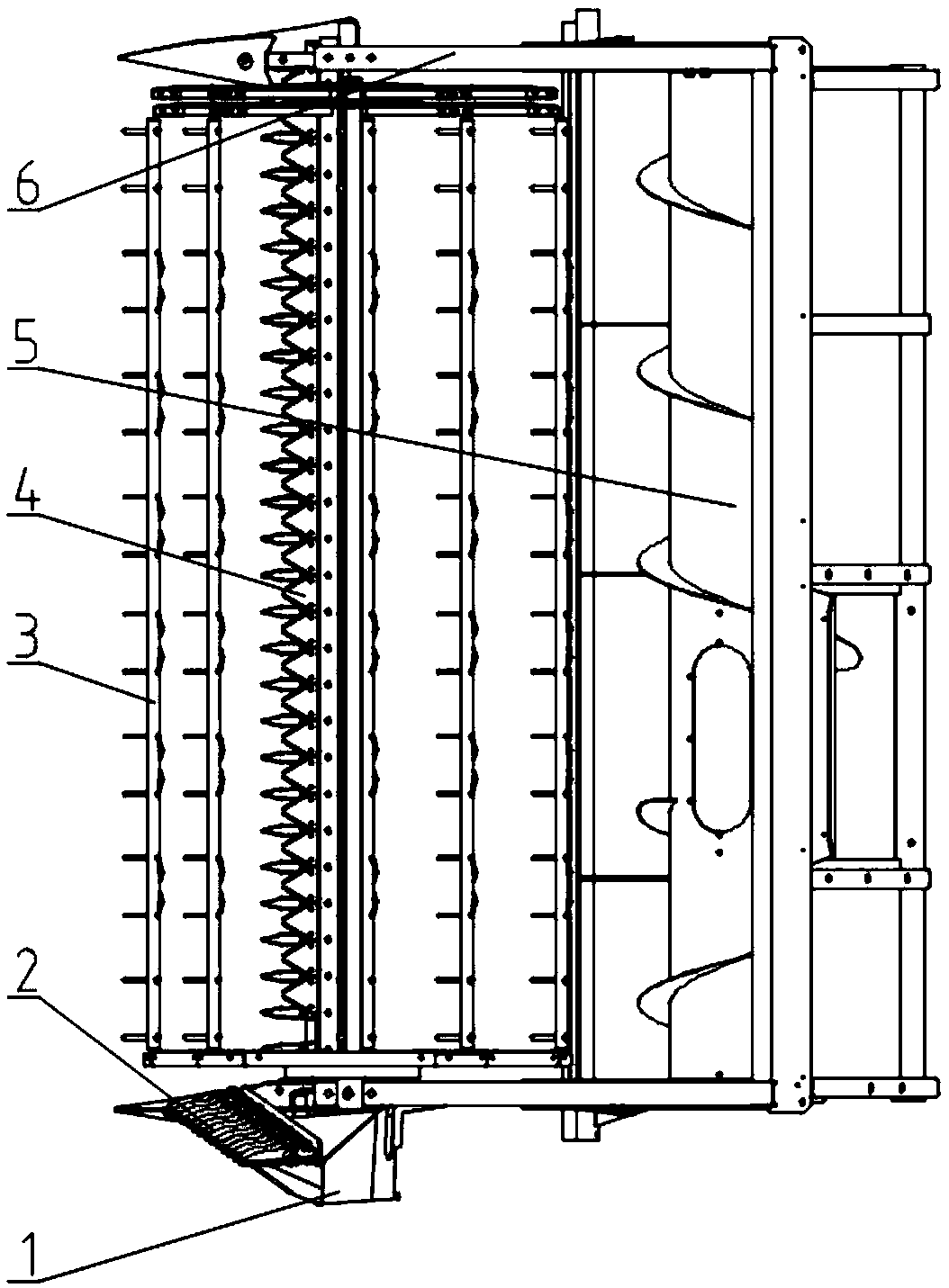

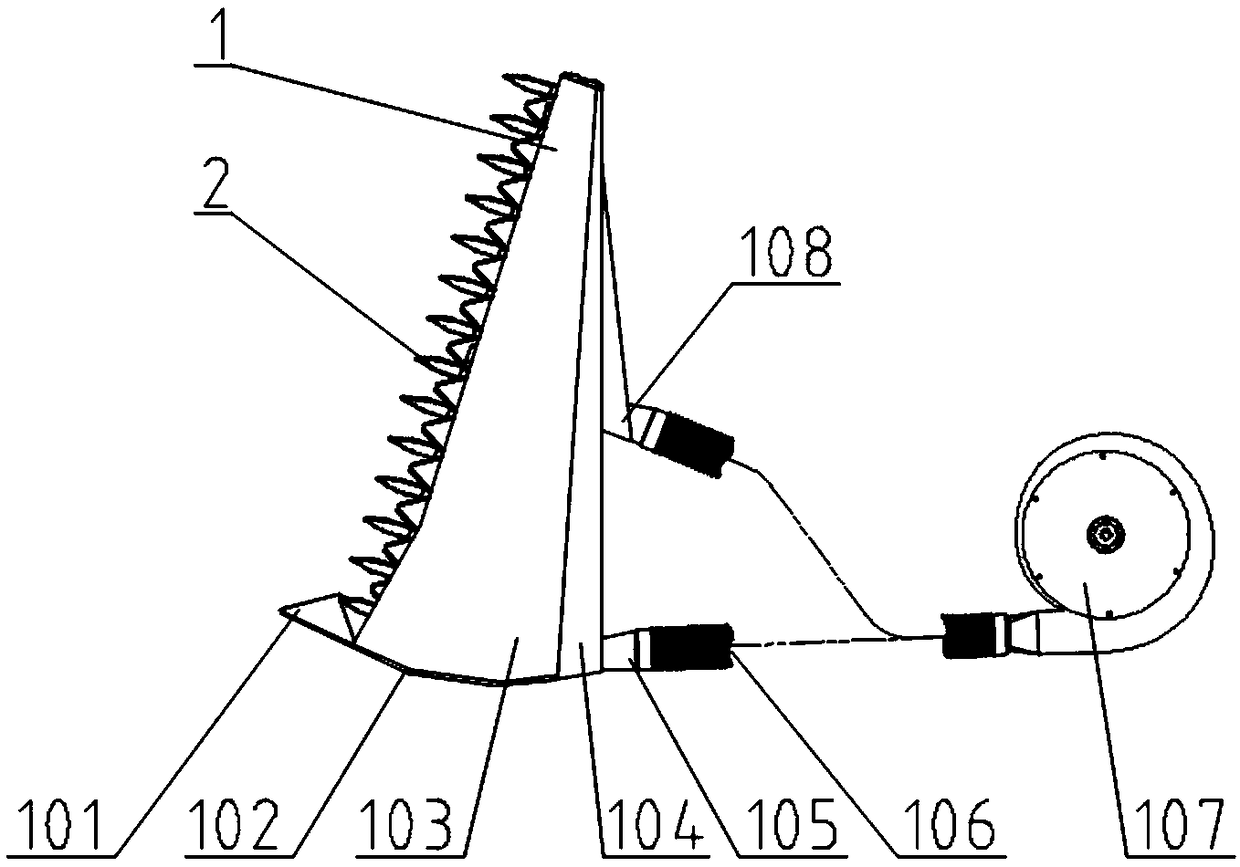

Garlic sprout harvester

InactiveCN101697677BAchieve mechanized harvestingImprove harvesting efficiencyPicking devicesProduction rateAllium sativum

The invention relates to a garlic sprout harvester and belongs to the field of agricultural machinery. The garlic sprout harvester can erect a single row of garlic sprout stems and gather the garlic sprout stems into a bundle, vertically gash the epidermis of each garlic sprout stem at certain height, transversely make a cut with certain depth in the gashed epidermis and draw the garlic sprouts by using a drawing device. The invention solves the problem of mechanized harvesting of garlic sprouts. The technical proposal of the invention can increase the production rate for harvesting garlic sprouts, reduce the labor intensity for harvesting garlic sprouts and enhance the mechanization level of garlic planting.

Owner:NORTHWEST A & F UNIV

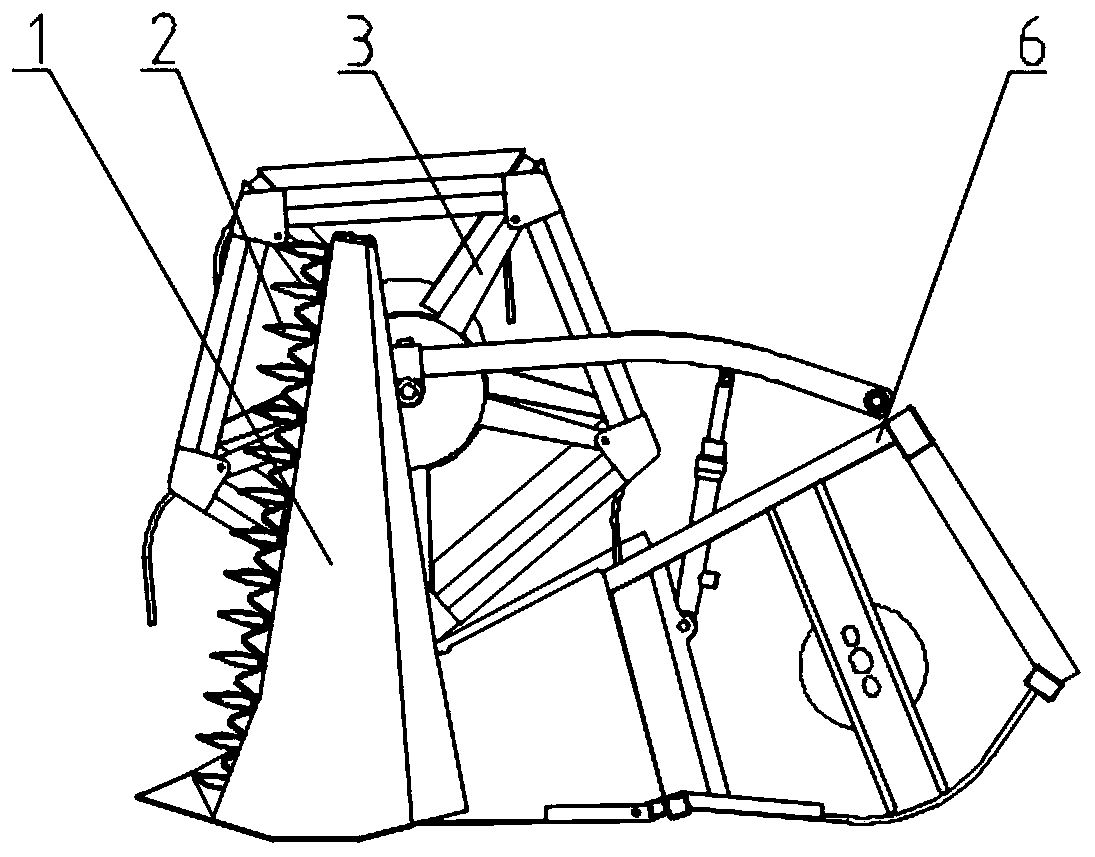

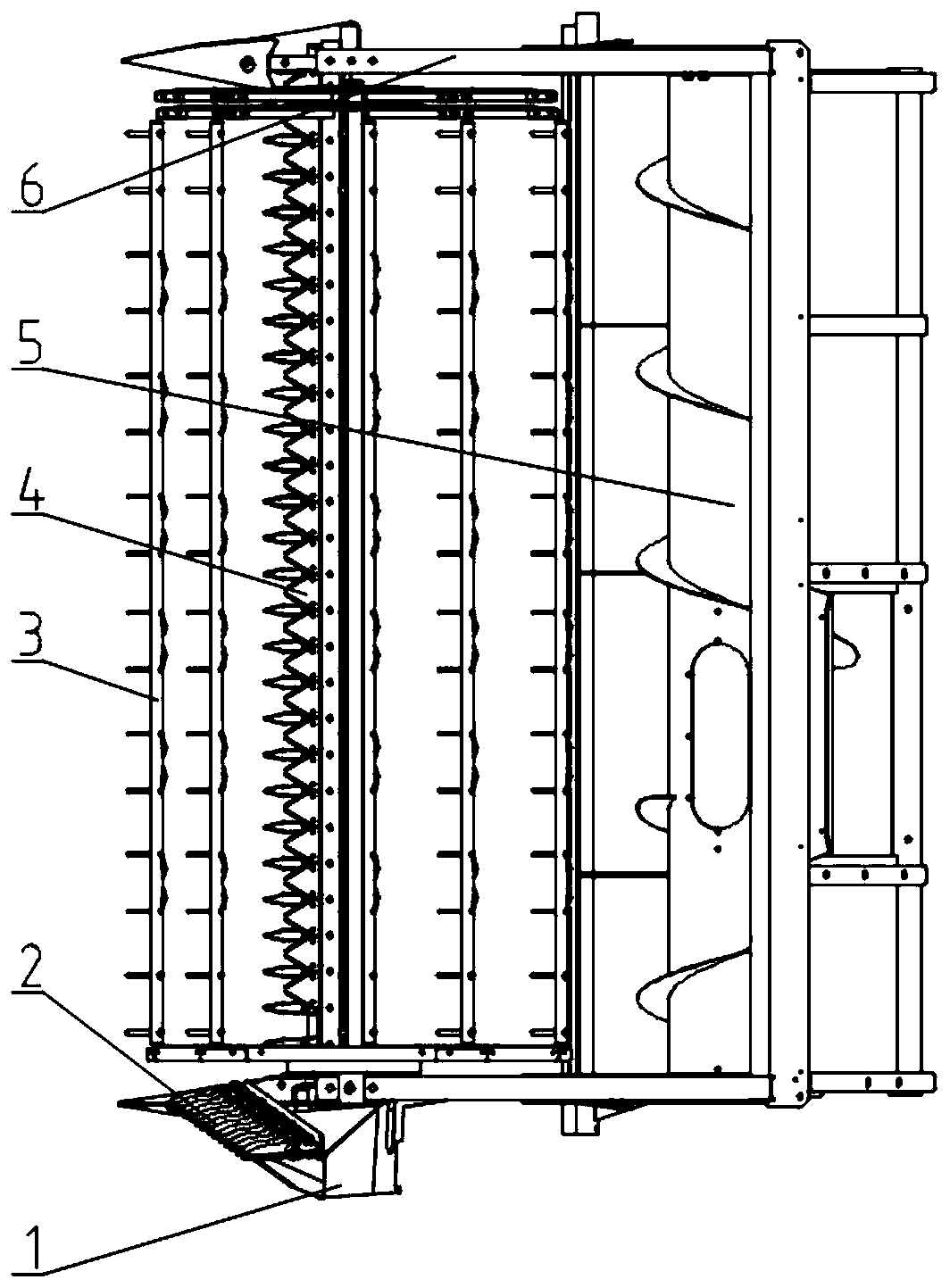

Oilseed rape harvesting header vertical cutting knife splashing grain air-aspiration type recycling device

The invention discloses an oilseed rape harvesting header vertical cutting knife splashing grain air-aspiration type recycling device. The device comprises a header frame. A pneumatic recycling deviceis arranged on the header frame. A feeding packing auger is connected to the header frame. A dividing reel is arranged on the header frame, a vertical cutter is installed on the header frame, and transverse cutters are installed among the header frame. According to the oilseed rape harvesting header vertical cutting knife splashing grain air-aspiration type recycling device, splashed oilseed rapegrains caused by cutting of the vertical cutter can be collected, the negative pressure airflow can change the motion trajectory of the splashed grains, the splashed grains can be better collected into a grain falling collecting bin, oilseed grains in the grain falling collecting bin are recycled through negative pressure airflow, and oilseed rape harvesting losses caused by the vertical cutter are reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

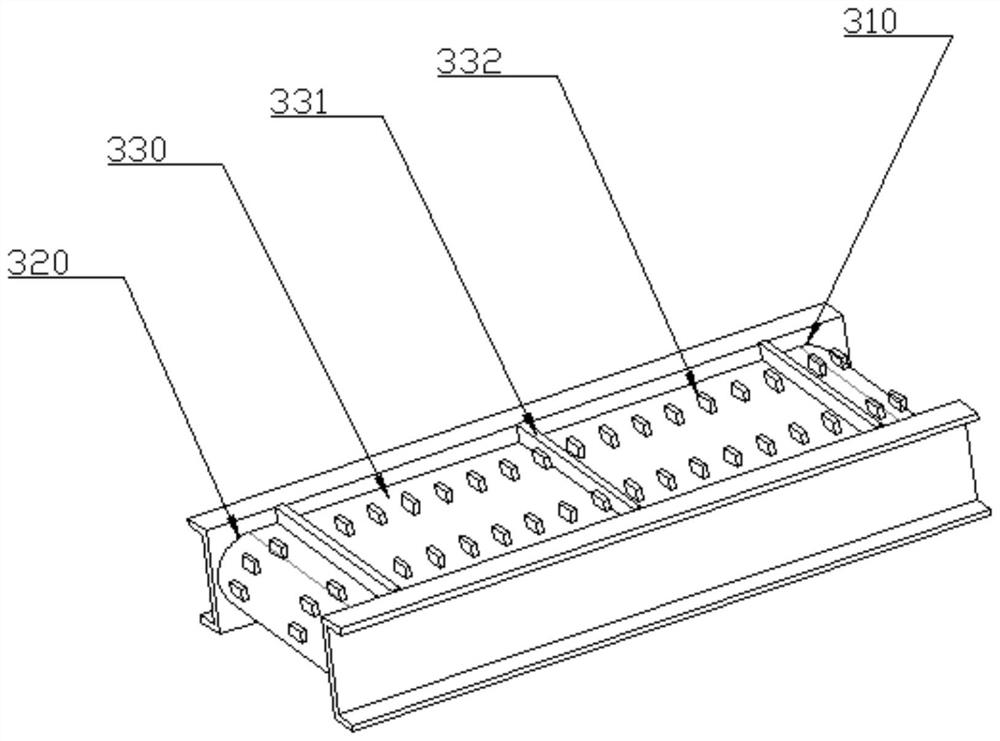

Harvesting machine and harvesting platform thereof

The invention relates to a harvesting machine and a harvesting platform thereof. The harvesting platform includes a supporting shell having a bottom support wall, a left support wall and a right support wall, a cutter assembly and a crop-pulling transportation mechanism; the crop-pulling transportation mechanism includes a driving shaft located on the lower side on the rear end of the supporting shell and an upper transmission shaft located on the upper side on the front end of the supporting shell; the driving shaft and the upper transmission shaft are rotatably installed on the left and right support walls; annular traction elements having poking members are wound on the driving shaft and the upper transmission shaft in a transmission manner; and when the annular traction elements move,the parts, close to the cutter assembly, of the annular traction elements are used for poking crops into the shell, and the parts, away from the cutter assembly, of the annular traction elements are used for backward poking and transporting the crops to the device, located on the rear side of the harvesting platform of the harvesting machine, of the harvesting machine. The front sides of the annular traction elements can achieve the effects of poking the crops, and the rear sides of the annular traction elements can achieve transportation effects; and through the combination of the functions of crop-poking wheels and conveying devices in traditional harvesting platforms of harvesting machines, the structure of the harvesting platform of the harvesting machine can be simplified, and the size of the harvesting platform of the harvesting machine can be reduced.

Owner:HENAN UNIV OF SCI & TECH

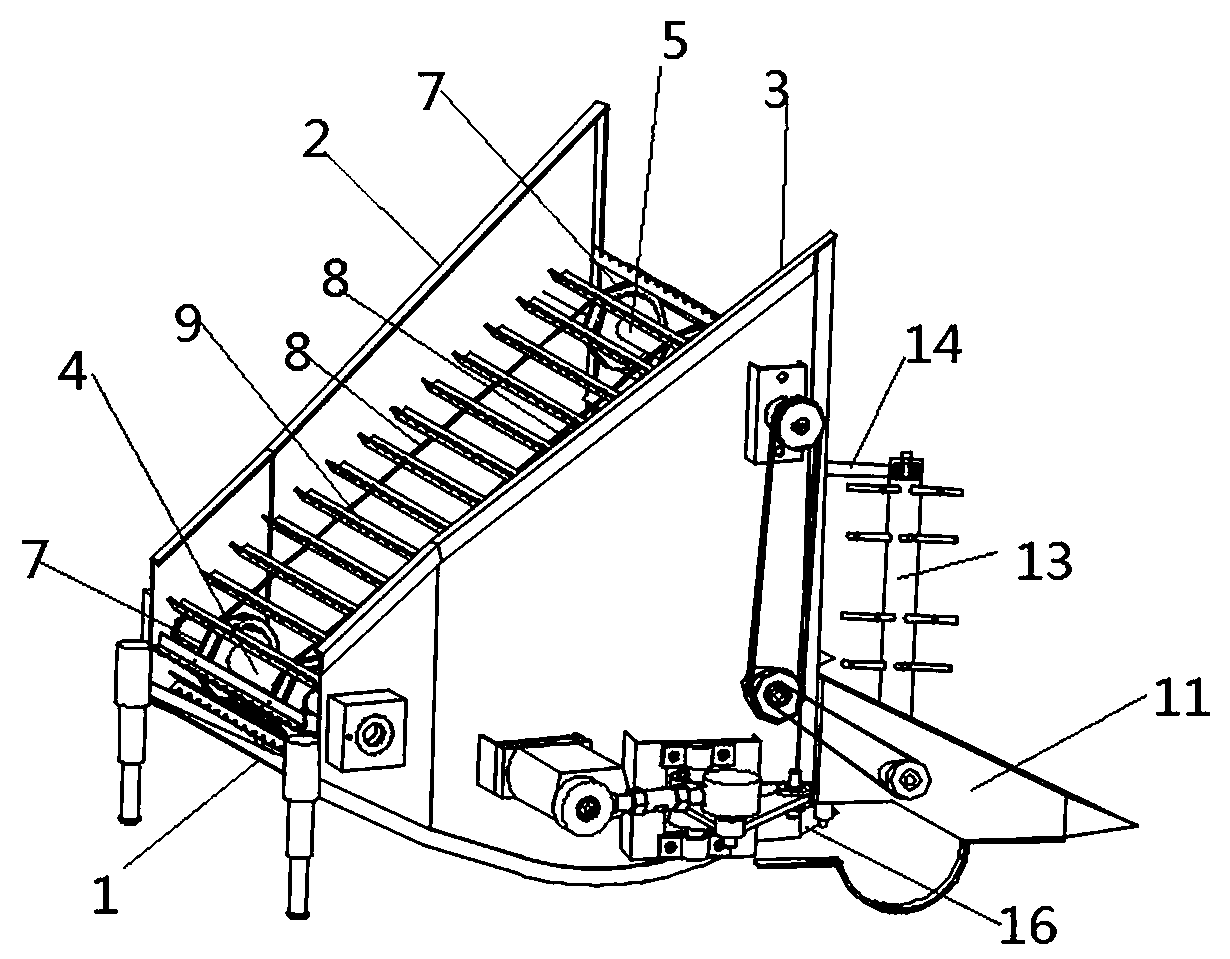

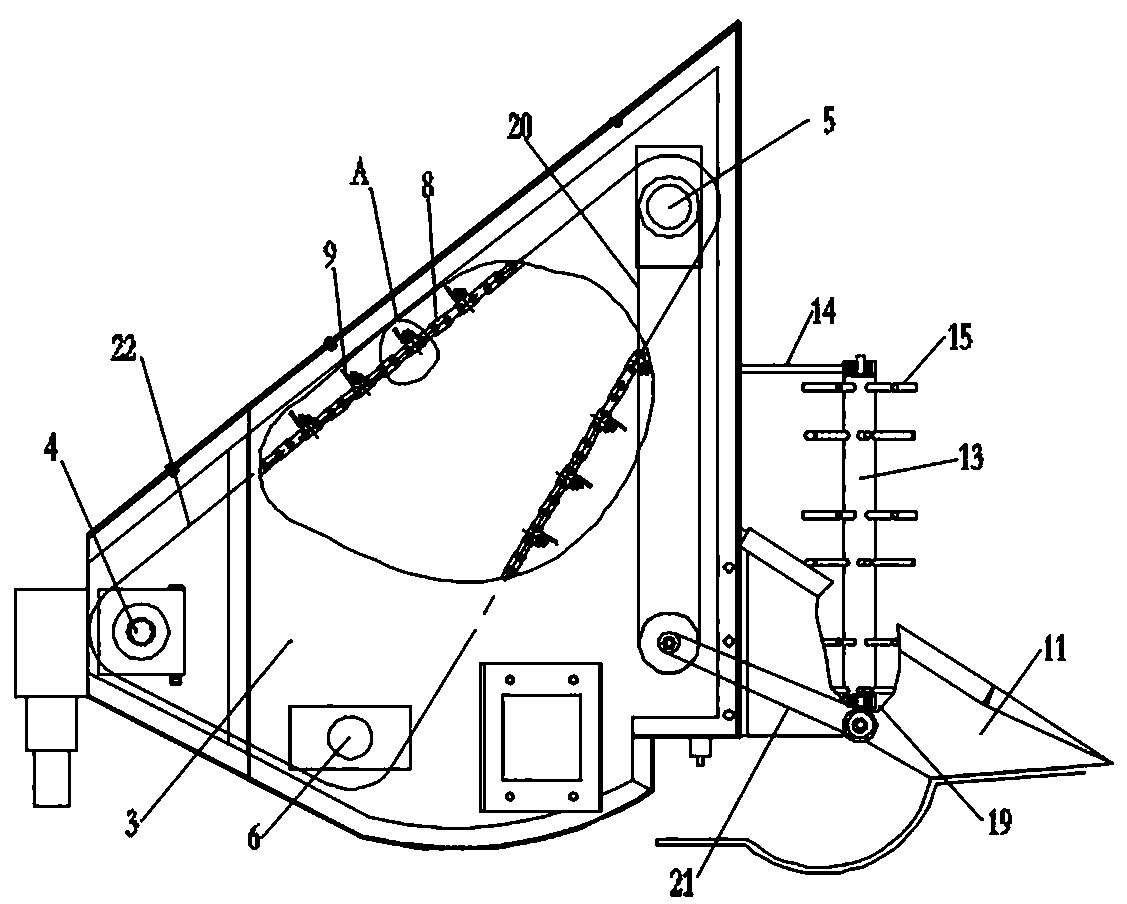

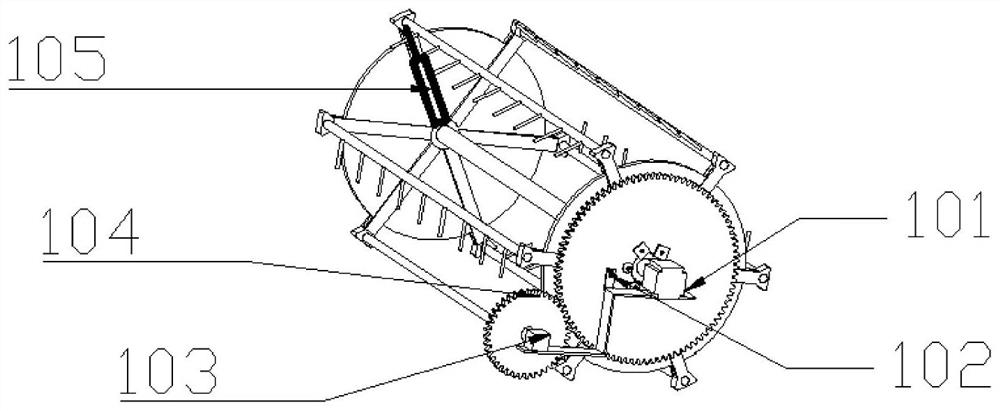

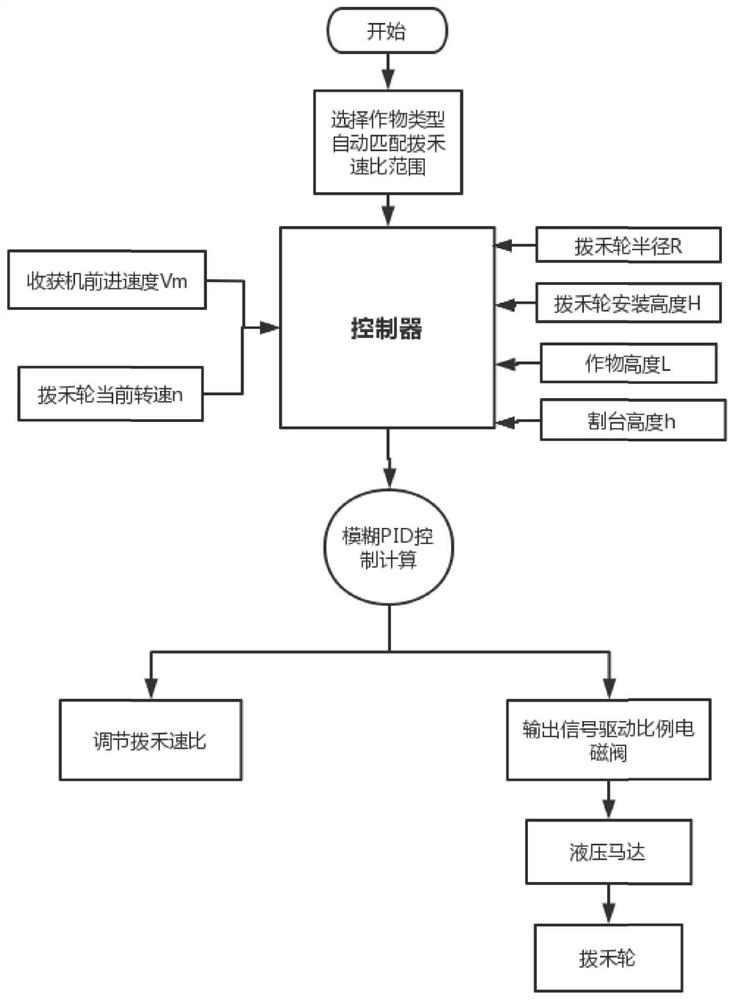

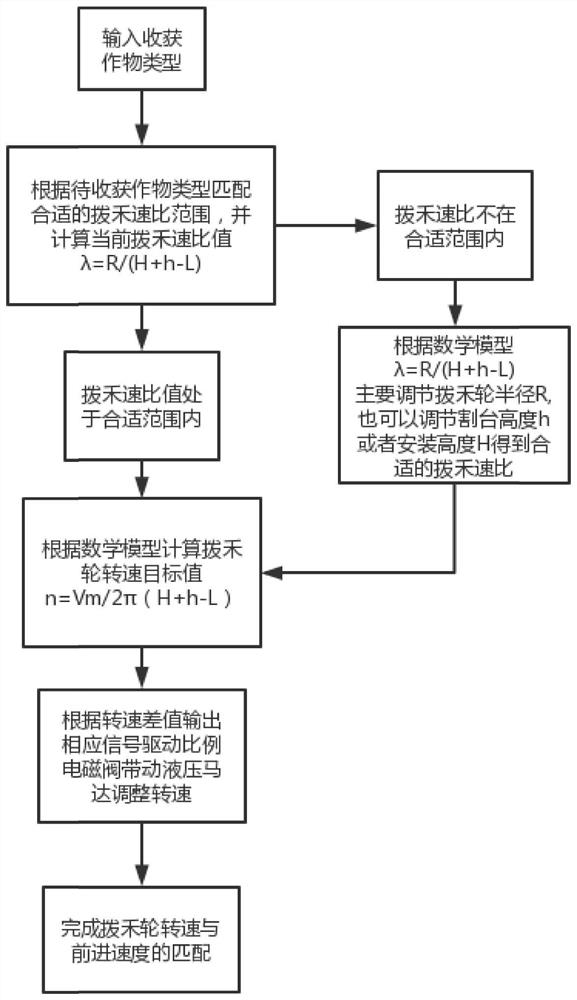

Reel rotating speed adjusting device for reducing harvesting loss and control method

ActiveCN114342665AMatch forward speedForward speed matching adjustmentOutside dividersHydraulic motorElectric machinery

The invention provides a reel rotating speed adjusting device for reducing harvesting loss and a control method, a reel is provided with a reel adjusting device, and the reel rotating speed adjusting device further comprises a sensor, a hydraulic motor, a stepping motor, a controller and a height adjusting device; the hydraulic motor is used for driving the reel turntable to rotate; the height adjusting device is used for adjusting the height of the reel; the controller determines a reel speed ratio and judges whether the radius of the reel or / and the height of the header or / and the mounting height of the reel needs to be adjusted or not according to the reel speed ratio; the controller determines a target value of the rotating speed of the reel according to the advancing speed of the header; the controller obtains the output quantity through a fuzzy PID algorithm according to the rotating speed difference between the target value and the actual rotating speed of the reel, and the controller controls the proportional electromagnetic valve to adjust the opening degree according to the output quantity. When different crops are harvested, the rotating speed of the reel is matched with the advancing speed, the failure rate of the harvester is reduced, and header loss is remarkably reduced.

Owner:JIANGSU UNIV

Linkage header of crop harvester

The invention discloses a linkage header of a crop harvester. The linkage header comprises a clamping-conveying-cutting part and a digging part, wherein the clamping-conveying-cutting part comprises a header, a clamping belt, a clamping guide wheel, an alignment seedling-cutting device, a cutter, a clamping belt motor and a cutter motor; the digging part is composed of a depth roller and a digging shovel; the header is a base support component of the linkage header, and multiple groups of clamping belt groups in parallel are arranged below the header; the alignment seedling-cutting device is arranged below the header, and is also below the clamping belt; a cutter bracket is arranged to correspond to each group of clamping belt, at the rear end of the clamping belt, below the header and above the back of the alignment seedling-cutting device; and the cutter is arranged in the cutter bracket.

Owner:SHANDONG MARIA MACHINERY

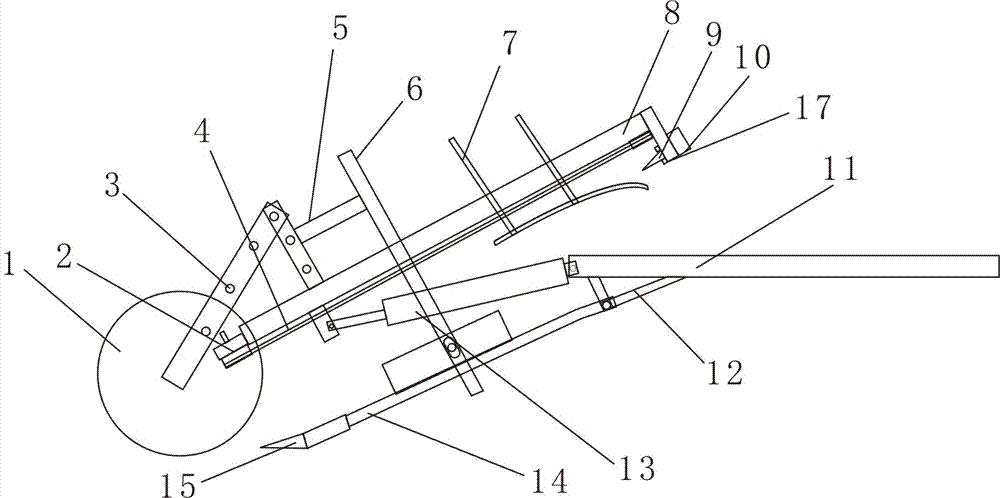

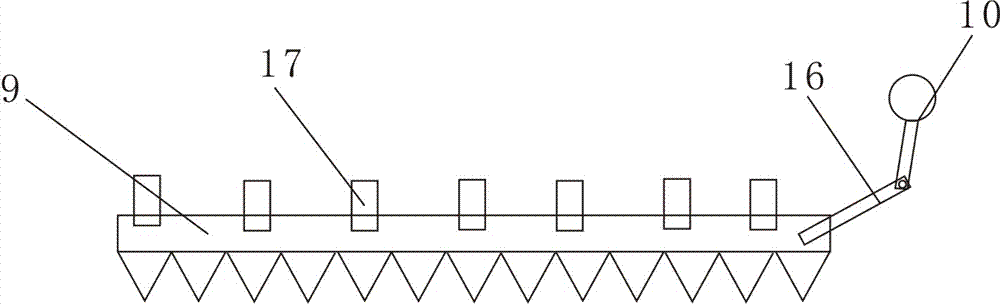

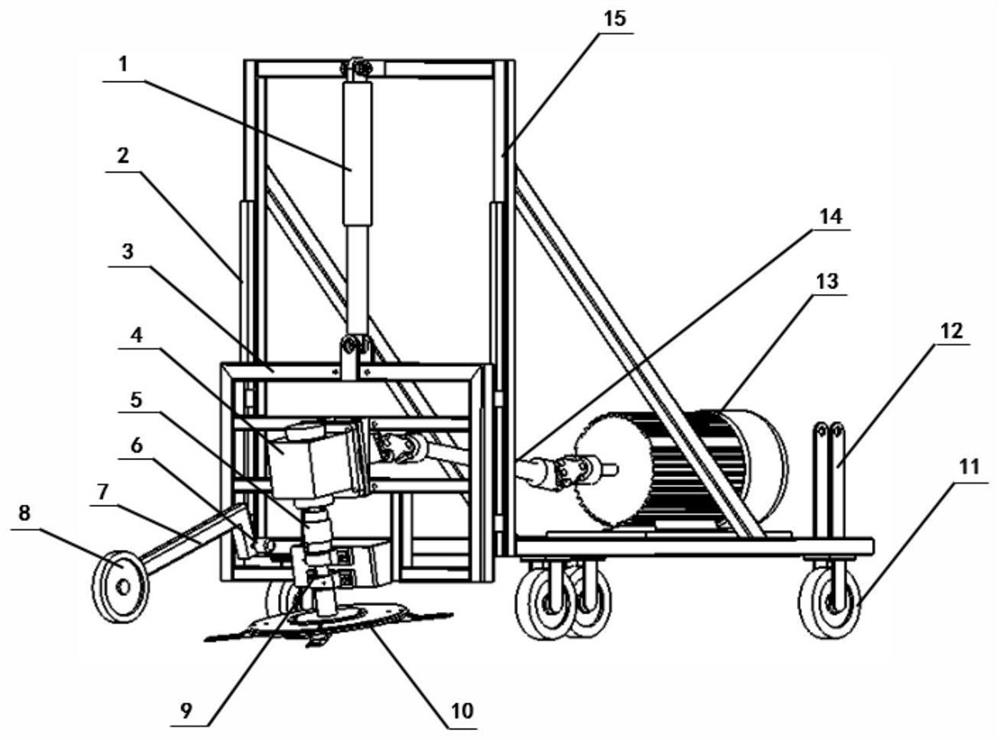

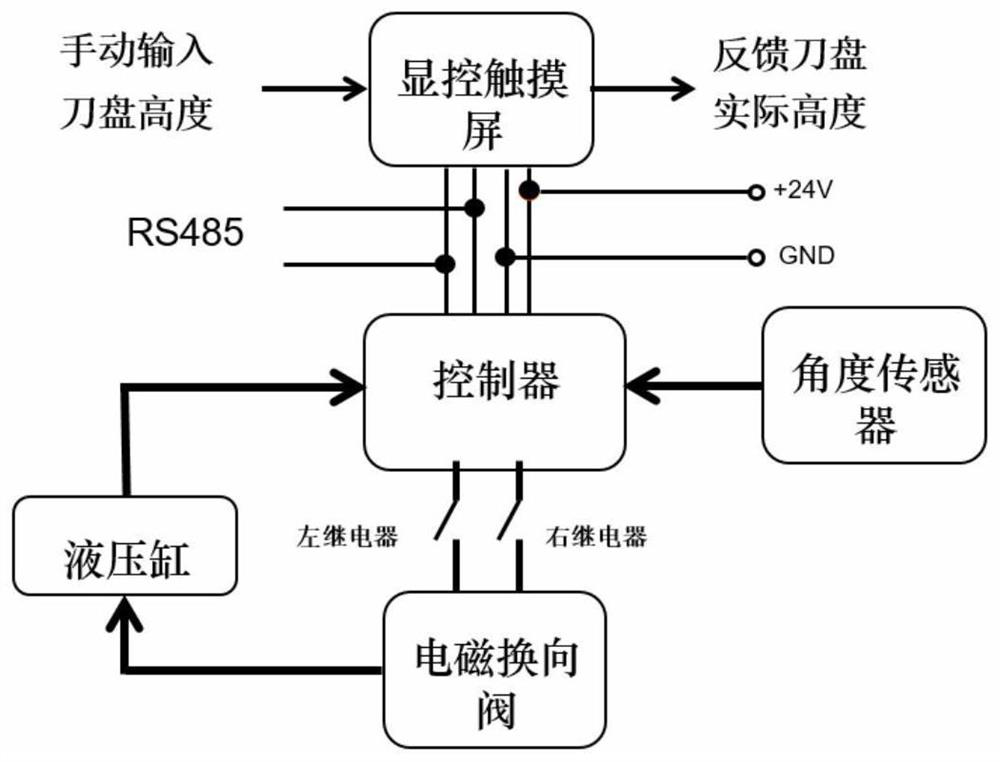

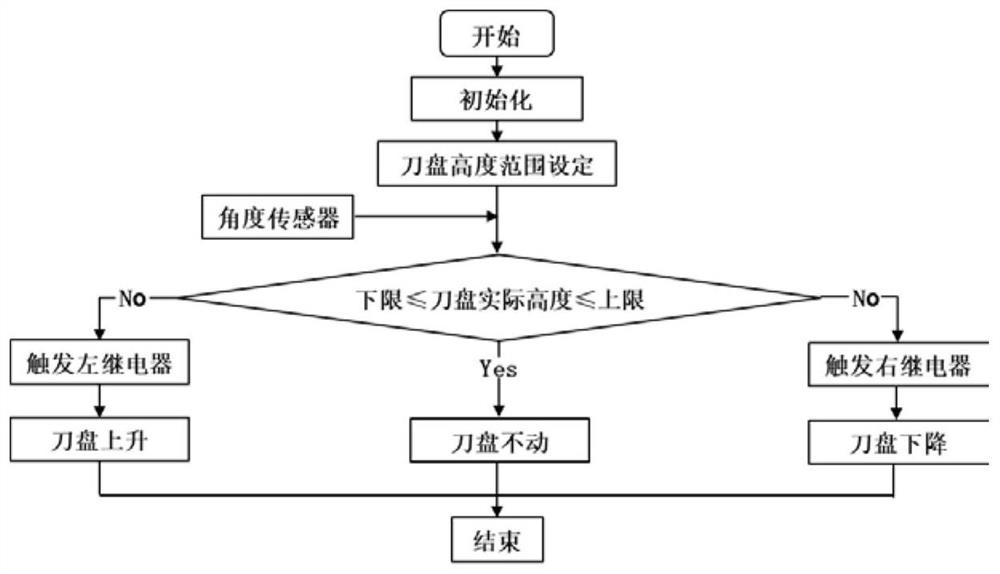

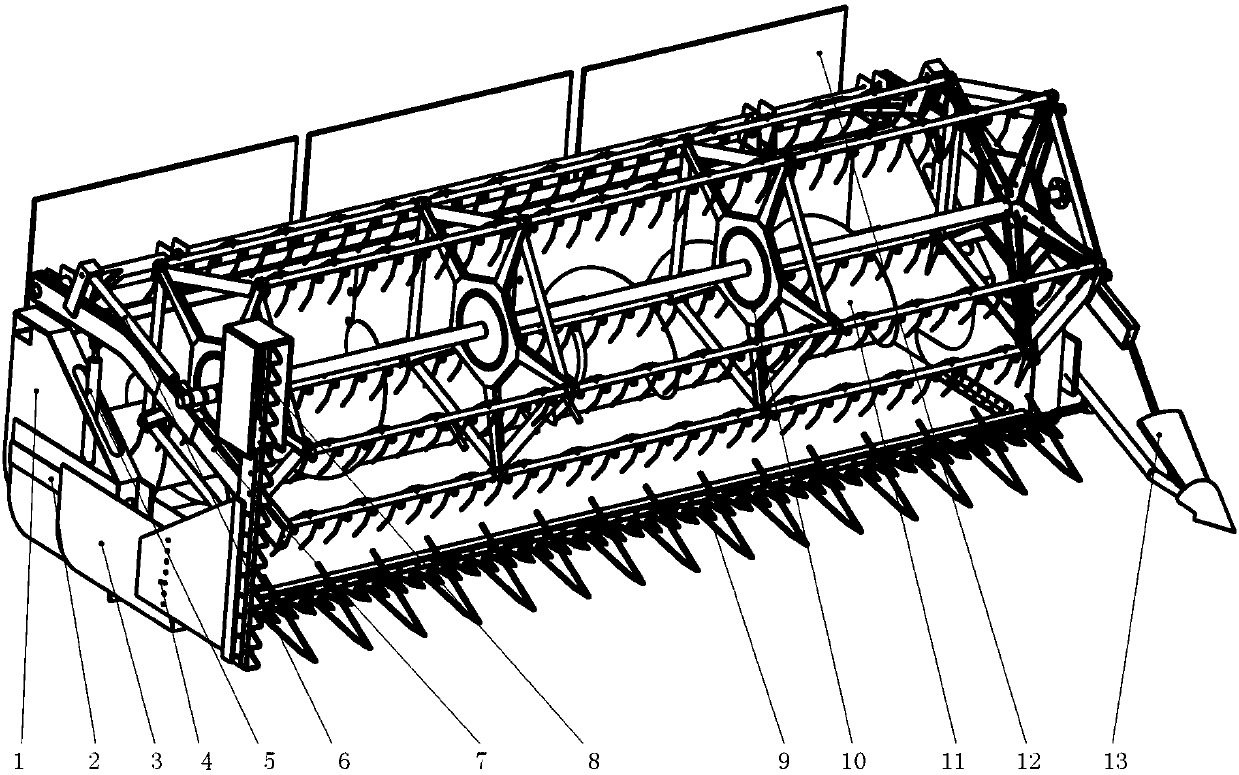

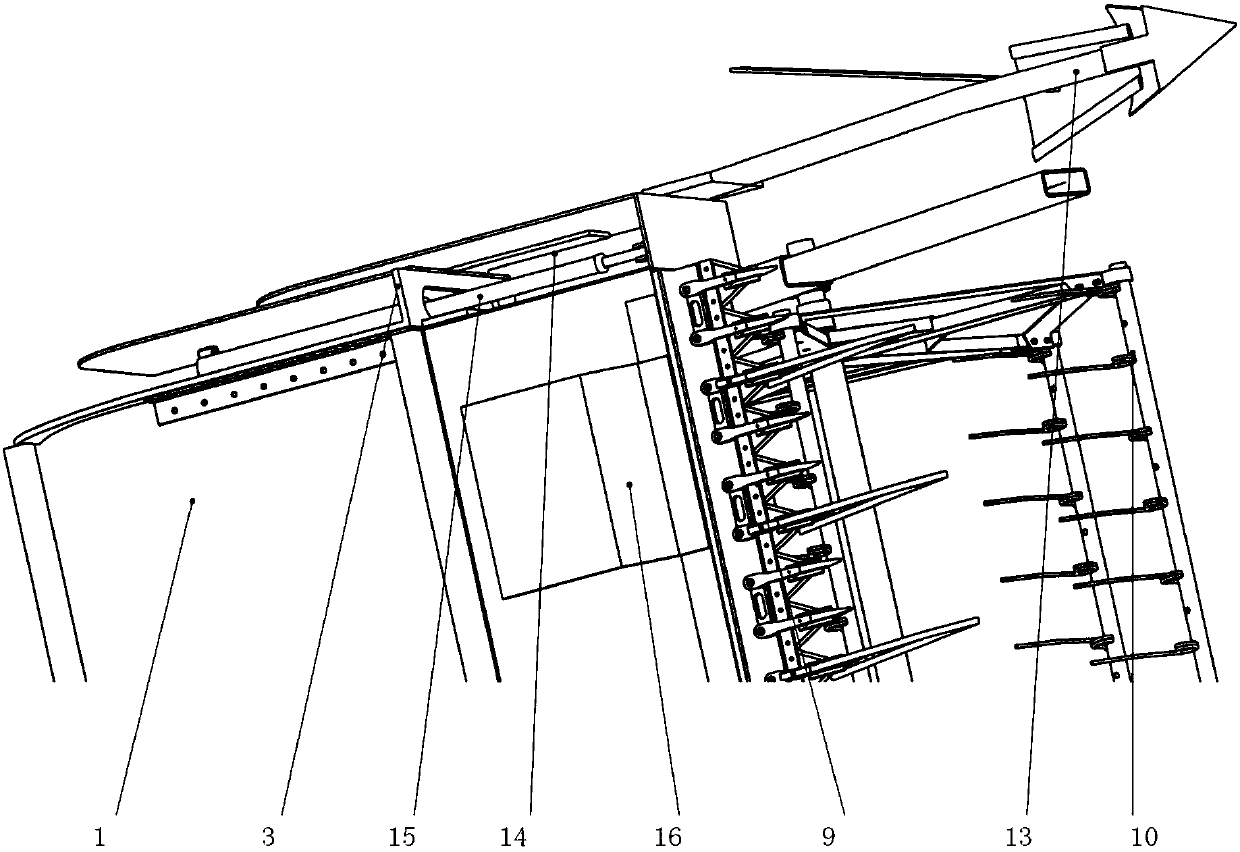

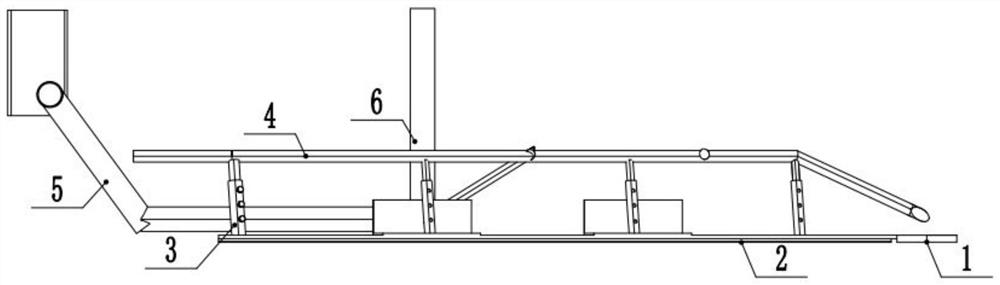

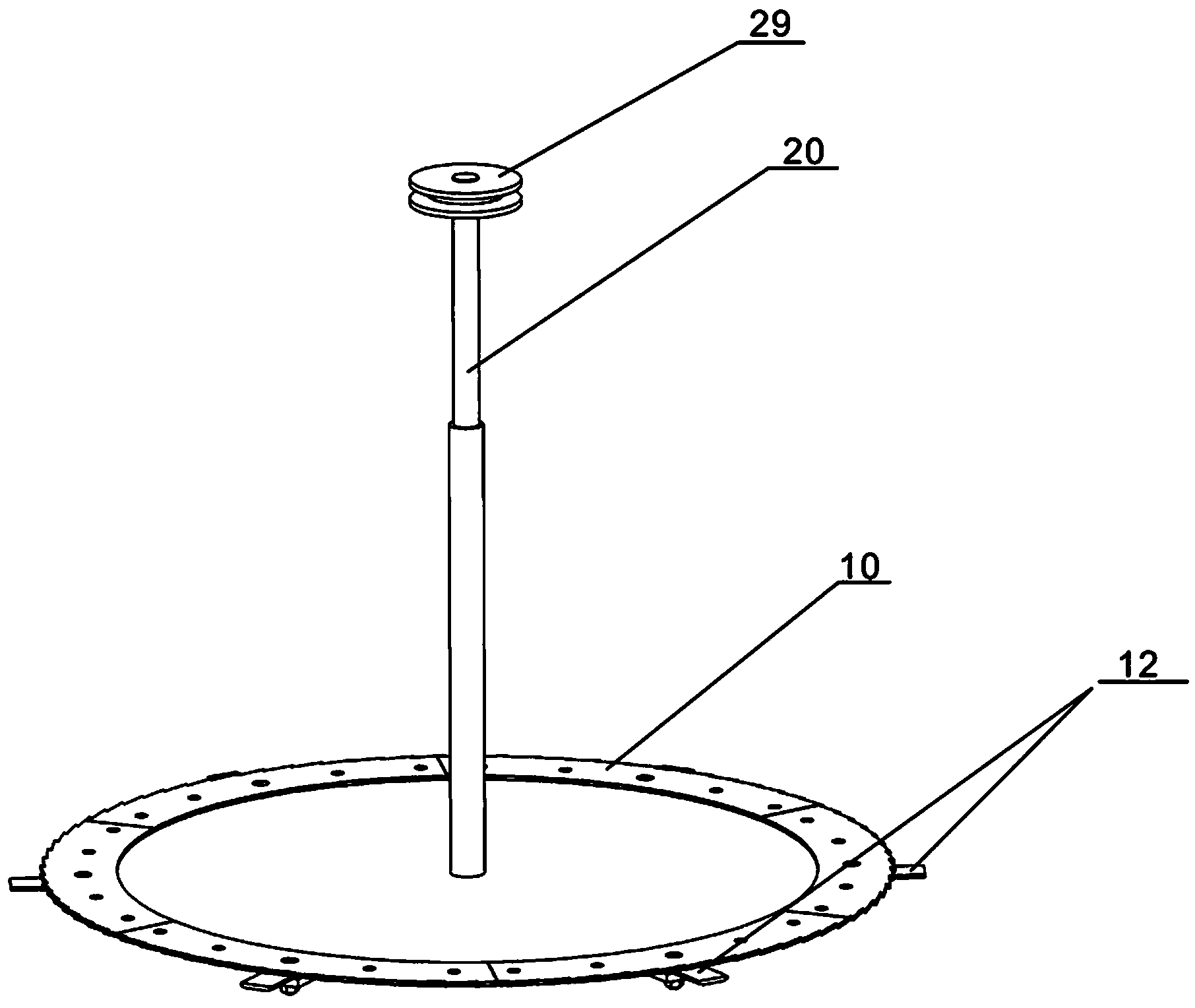

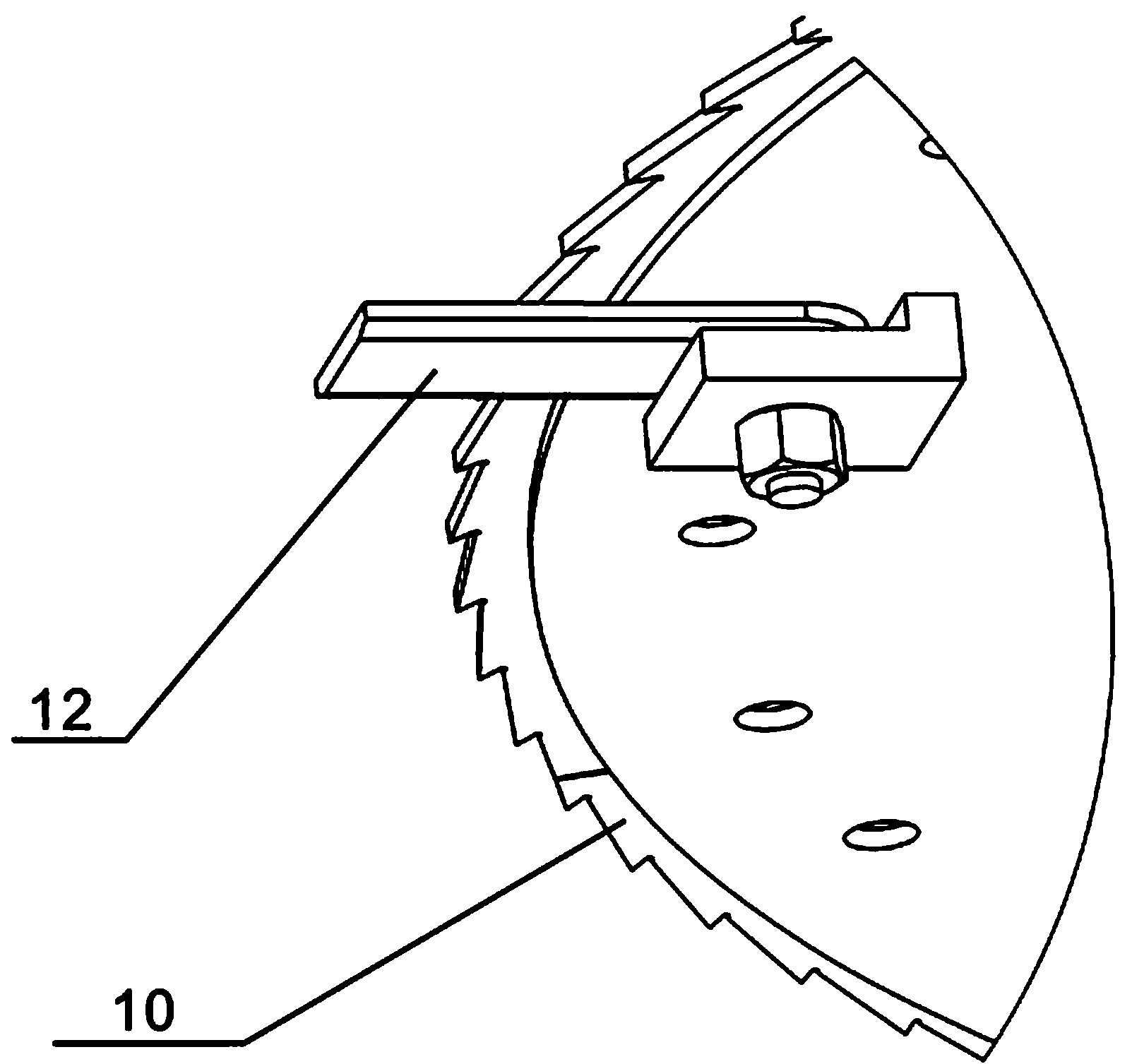

Copying cutting platform for cutterhead of sugarcane harvester

The invention relates to a copying cutting platform for a cutterhead of a sugarcane harvester. The platform comprises a cutterhead lifting system, a cutterhead driving system, a cutterhead height automatic adjusting control system and a rack. The cutterhead lifting system is arranged on two longitudinal beams at the front end of the rack. The cutterhead driving system is arranged on a bottom cross beam of the rack and is positioned at the rear end of the rack. The cutterhead height automatic adjusting control system is arranged on an inclined right cross beam of the rack. According to the platform, an angle sensor is adopted to measure the relative angle of a copying wheel and a copying rod, a controller calculates the actual height of the cutterhead through a cutterhead height mathematical model, then an electromagnetic reversing valve is controlled to be switched on and switched off, a hydraulic cylinder is controlled to stretch out and draw back, and the purpose of controlling the cutterhead height in real time is achieved. The hydraulic cylinder is used for automatically adjusting the height of the cutterhead instead of manual adjustment, the accuracy of the height of the cutterhead is greatly improved, and harvesting loss and sugarcane head breaking can be reduced. The platform is simple in structure, low in manufacturing cost, convenient to repair and maintain and high in practicability.

Owner:CHINA AGRI UNIV

A Multifunctional Drawer Header for Grain Combine Harvester

The invention relates to a multifunctional drawer type header for a grain combine harvester. Each of left and right sides of the header is provided with a drawer type rear end and a drawer type front end, and left and right ends of a conveying device are connected with the left and right drawer type rear ends respectively. Left and right ends of a cutting device are connected with the left and right drawer type front ends respectively, and a divider is connected to each drawer type front end. The drawer type rear ends and the drawer type front ends form drawer type connection through inner drawer type slide rails and outer drawer type slide rails, and extension and retraction of the left and right drawer type front ends are controlled by header depth regulation hydraulic cylinders. Rear ends of left and right reel frames are rotatably connected to a shell of the header, left and right ends of an eccentric reel are connected with the left and right reel frames respectively, and the position of the eccentric reel is adjusted through a reel horizontal position adjusting hydraulic cylinder and a reel vertical position adjusting hydraulic cylinder. The multifunctional drawer type header is applicable to harvesting of crops different in type and height, quick switching of various crop harvesting modes is realized, harvesting loss is reduced, and utilization rate of the header is increased remarkably.

Owner:CHINA AGRI UNIV

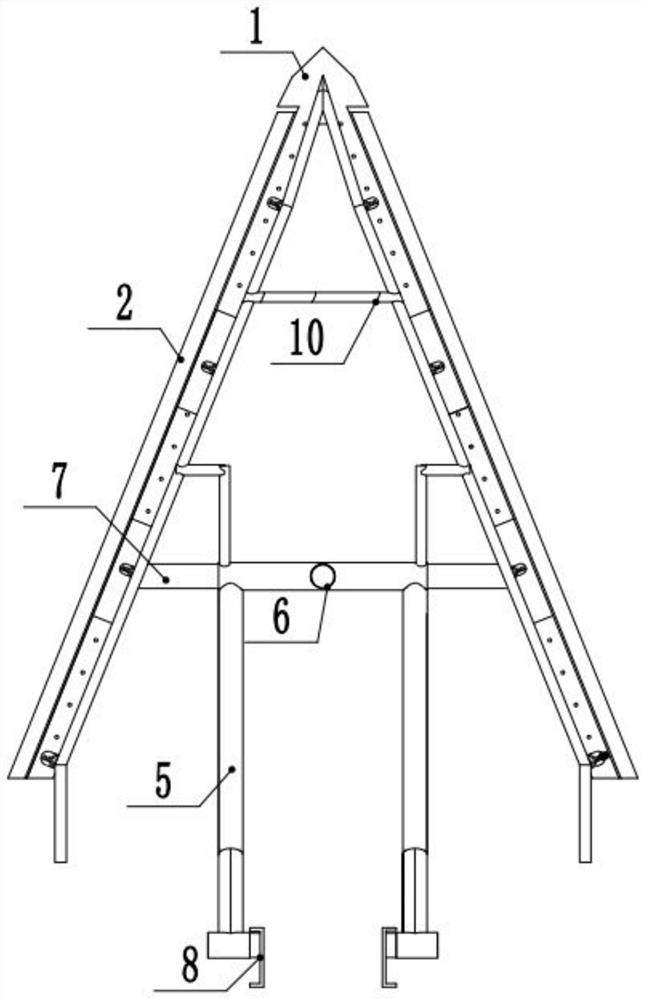

Low-stubble push-over type stevia rebaudiana harvesting and drying mechanism

The invention relates to the field of stevia rebaudiana harvesting and drying mechanisms and discloses a low-stubble push-over type stevia rebaudiana harvesting and drying mechanism. The mechanism comprises a triangular base, cutters are fixedly mounted on the surfaces of the two sides of the outer edge of the triangular base through adjusting bolts, and the cutters and the triangular base are located on the same horizontal plane. Multiple fixed cylinders are fixedly welded to the upper surface of the triangular base, fixed frames are fixedly connected in the fixed cylinders through adjustingbolts, the number of the fixed frames is two, the front ends of the two fixed frames are welded, and the two fixed frames are supported through a connecting rod. The mechanism is simple in structure,low in cost, low in stubble cutting, high in thorough cutting rate, good in using effect and capable of effectively reducing labor intensity, improving labor efficiency and reducing harvesting losses;and the mechanism is economical, practical, high in efficiency, low in stubble cutting and high in thorough cutting rate, the stevia rebaudiana harvesting cost is greatly reduced, and the mechanism is suitable for large-scale mechanized stevia rebaudiana harvesting.

Owner:HEBEI AGRICULTURAL UNIV.

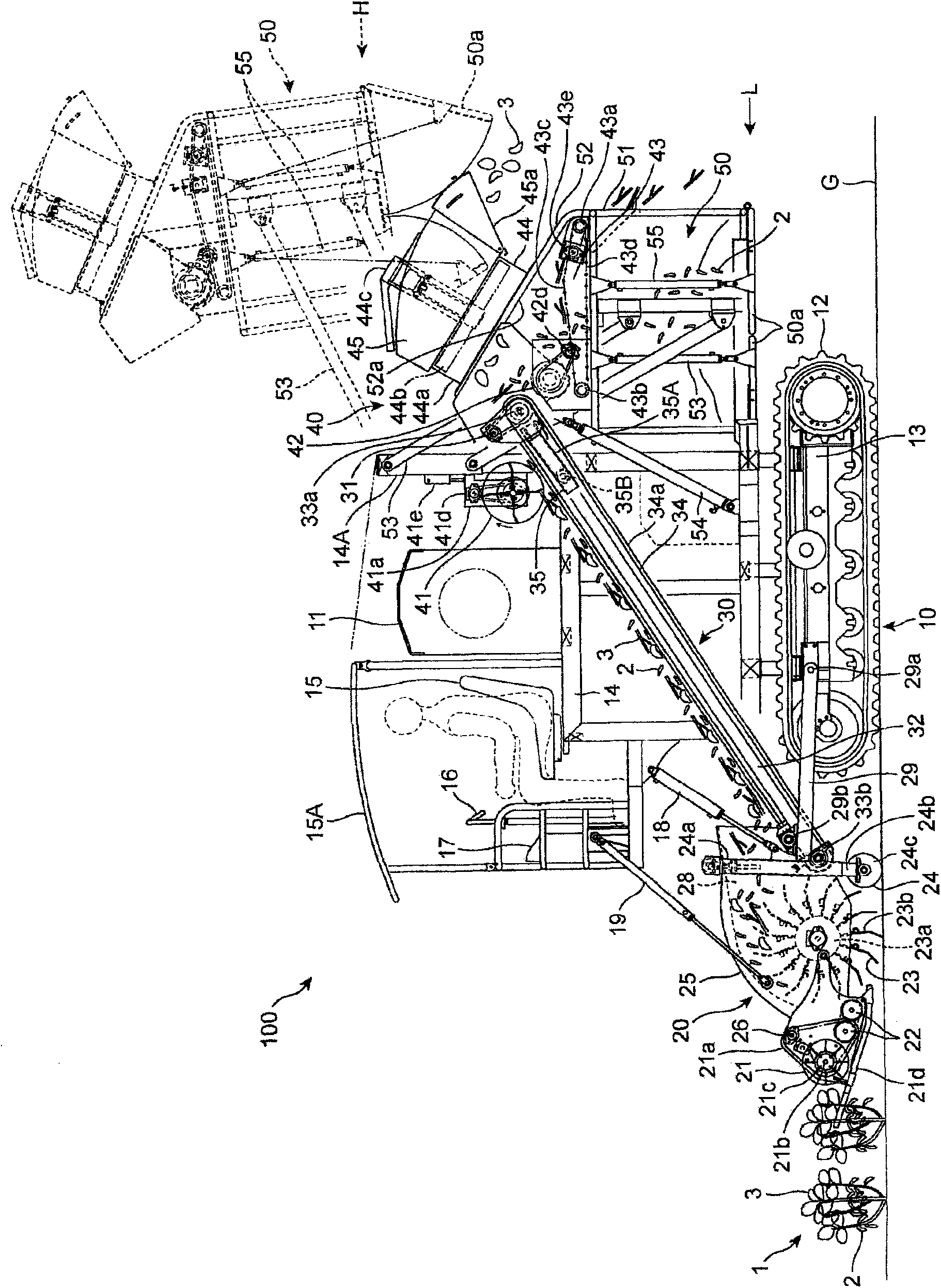

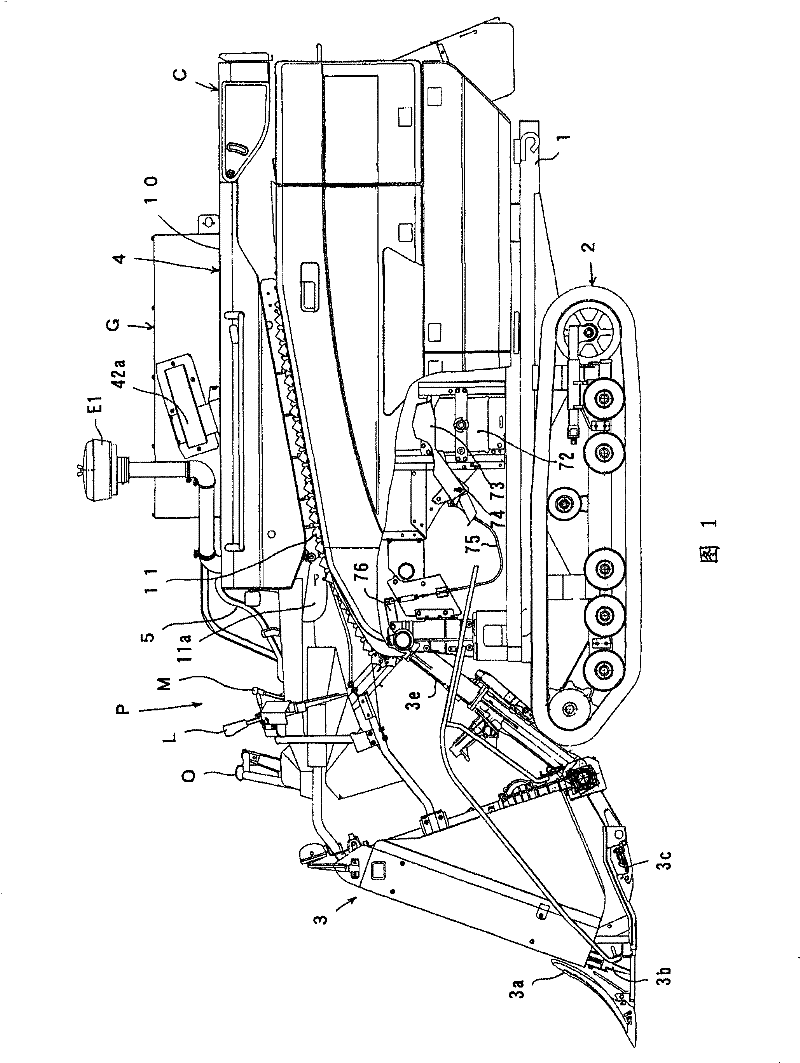

Combine harvester

The present invention relates to a combine harvester. The invention settles a problem of harvest loss caused by the discharging of grains on a swinging sorting shelf to the outside of a threshing device, and the precision and efficiency of the threshing operation are increased. On a first dust discharging opening (21) which is equipped to the back left side part of a dust discharging processing chamber (18), a first discharging guiding plate (29) which is provided with a first inclined surface (29a) that guides the dust material discharged from a first dust opening (21) to the right back flowfor falling to the surface of farmland. On a second dust discharging opening (23) which is equipped to the back right side part of the dust discharging processing chamber (18), a second discharging guiding plate (24) which is provided with a second inclined surface (24a) that guides the dust material discharged from the second dust discharging opening (23) to the right back flow for falling to the surface of the farmland and a third inclined surface (24b) that guides the dust material discharged from the second dust discharging opening (23) to the right back flow of the threshing device (4) for falling to the surface of the farmland is provided.

Owner:ISEKI & CO LTD

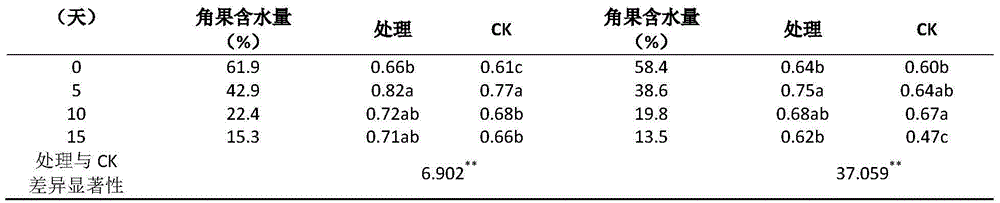

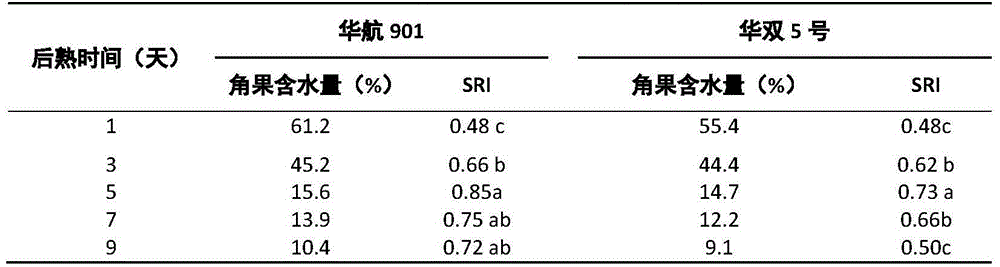

Method and application for improving silique pod-shattering resistance of cabbage type rape and method and application of mechanized harvesting of cabbage type rape

InactiveCN104663144AImprove crack resistance indexImprove grain yield and qualityHarvestersBiologyCrop

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

A kind of air suction recovery device for rapeseed harvesting table vertical cutting knife splashing seed

The invention discloses an oilseed rape harvesting header vertical cutting knife splashing grain air-aspiration type recycling device. The device comprises a header frame. A pneumatic recycling deviceis arranged on the header frame. A feeding packing auger is connected to the header frame. A dividing reel is arranged on the header frame, a vertical cutter is installed on the header frame, and transverse cutters are installed among the header frame. According to the oilseed rape harvesting header vertical cutting knife splashing grain air-aspiration type recycling device, splashed oilseed rapegrains caused by cutting of the vertical cutter can be collected, the negative pressure airflow can change the motion trajectory of the splashed grains, the splashed grains can be better collected into a grain falling collecting bin, oilseed grains in the grain falling collecting bin are recycled through negative pressure airflow, and oilseed rape harvesting losses caused by the vertical cutter are reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

A header profiling device, its control system and method, and a harvester

ActiveCN112243682BReduce Harvest LossReduce soil damageMowersAgricultural undercarriagesAgricultural scienceControl system

The invention belongs to the field of agricultural machinery and relates to a header profiling device, its control system and method, and a harvester, comprising a profiling detection assembly, a header profiling adjustment assembly, a header lifting execution assembly, and a header chassis hinge assembly and control system. The profiling detection assembly is installed in front of the header; the header profiling adjustment assembly is installed in the front of the header; the header lifting execution assembly is installed between the header and the chassis; the header chassis hinge assembly is installed in the header between the chassis. The position control of the header in the transportation state and the harvesting operation state of the header copying is realized through the header copying adjustment assembly and the header lifting execution assembly; the distance between the cutting knife and the ridge surface is detected by the control system for the copying detection assembly The mathematical model is used to solve the influence of the advanced amount of system profiling information, and then control the header profiling adjustment assembly to adjust the header horizontally and vertically to ensure a certain distance between the cutter and the ridge surface, and reduce the blade height caused by improper adjustment of the cutter height. Harvest loss of vegetables and damage of knives into the soil.

Owner:JIANGSU UNIV

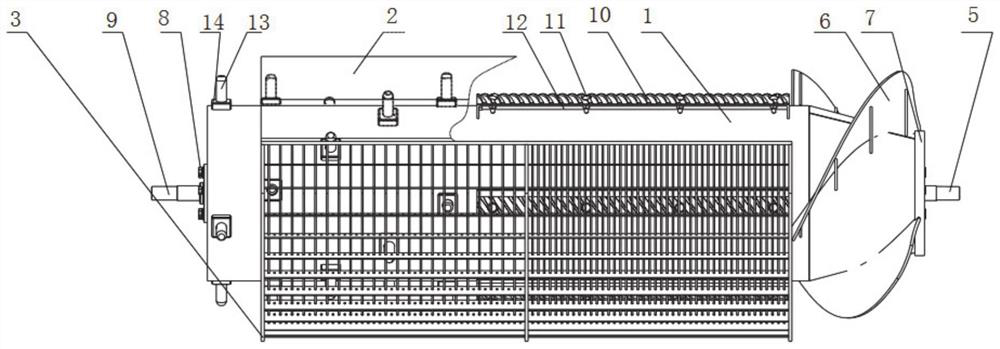

Floating header and a combine harvester comprising the same

The invention provides a floating header and a combined harvester with the same. The floating header comprises a slide plate group, a plate spring group and a fine adjustment floating mechanism. The slide plate group is positioned at the bottom of a header, and the fine adjustment floating mechanism comprises a cutter floating assembly; the fine adjustment floating mechanism comprises tension springs, a guide rod and roller trains; the slide plate group comprises a plurality of large and small slide plates; one end of each plate spring is fixed onto the corresponding slide plate, and the other end of each plate spring backwardly and downwardly extends to be hinged onto a rear main frame of the header by a hinge pin; one end of each tension spring is fixed to the end, which is close to a cutter, of the corresponding plate spring, and the other end of each tension spring is hung on a front lower main frame of the header by the aid of a long bolt; one end of the guide rod is hinged onto the plate springs, the upper portion of the guide rod is limited in the certain roller train, and the guide rod can slide up and down under the effect of the certain roller train; the roller trains are fixed onto frames on the side walls of the header. The floating header and the combined harvester have the advantages that the productivity can be effectively improved when grains are harvested by the combined harvester, and the grain harvest loss can be reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

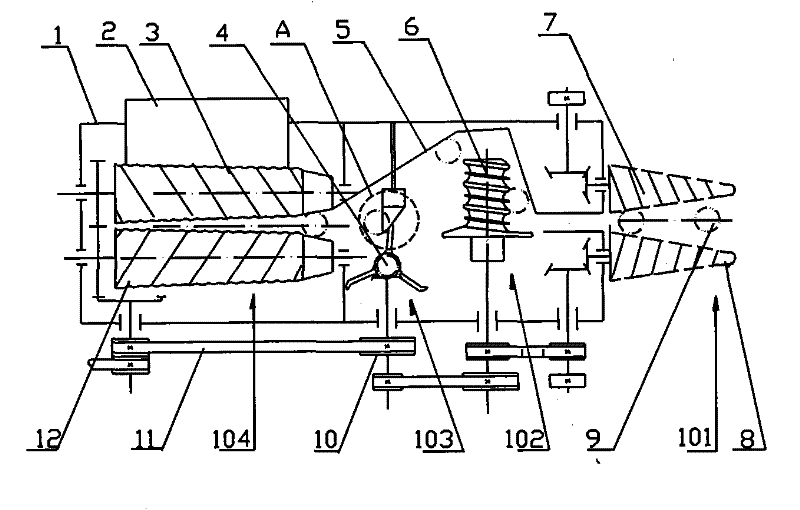

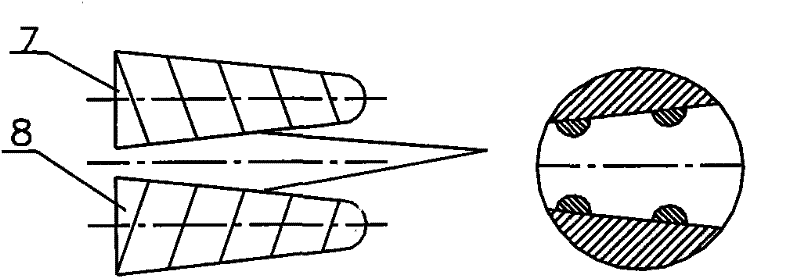

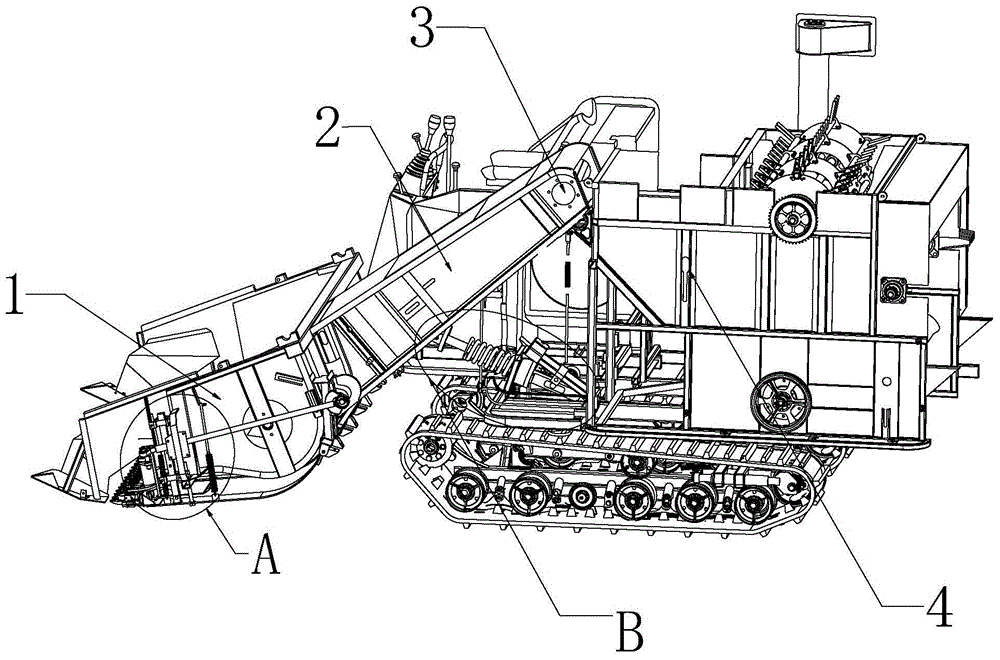

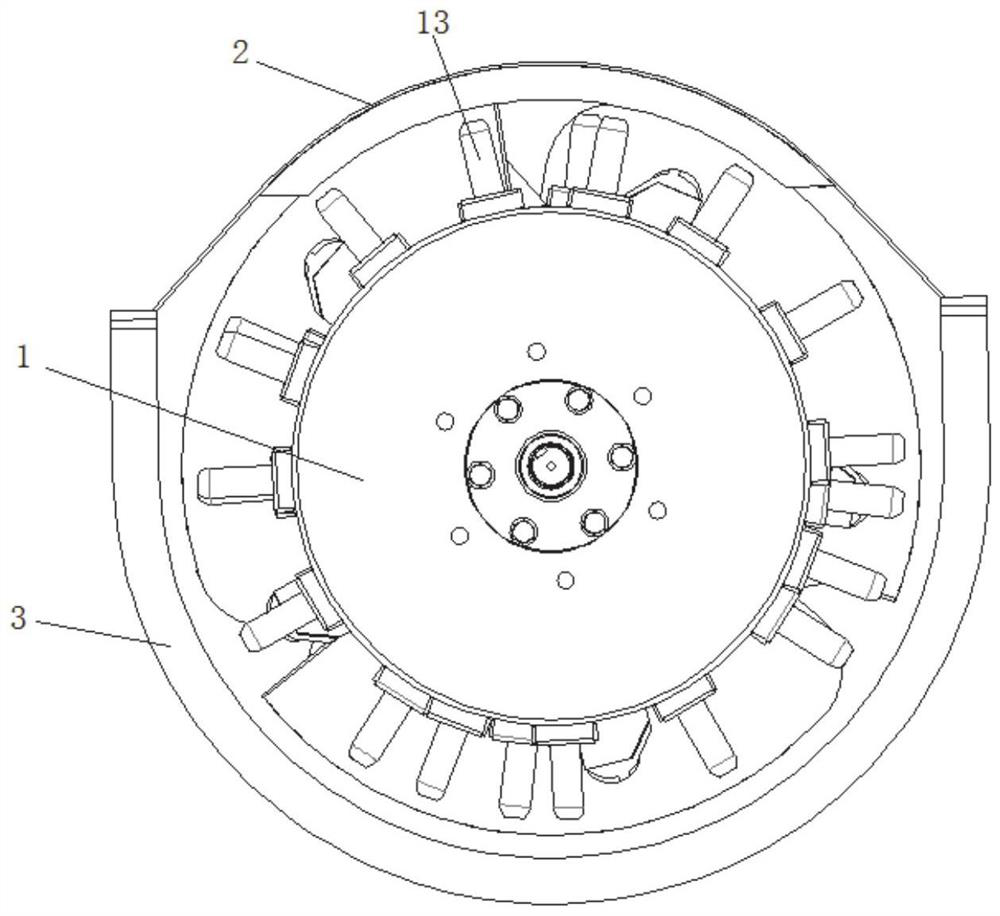

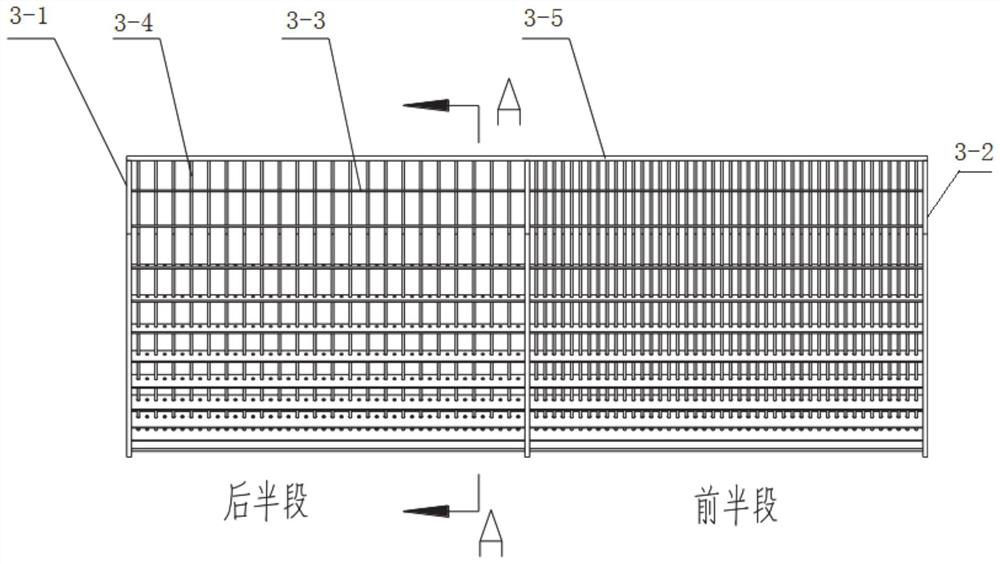

A kind of squeeze type threshing separation device and harvester

The invention relates to a squeeze-type threshing separation device and a harvester, which include a rotatable drum, a fixed grille is arranged under the drum, a plurality of grain bars are fixed on the first half of the drum, and a There are several groups of nail teeth distributed along the spiral line, and there is a fixed top cover on the top of the drum. The screw pitch of the flow plate becomes larger gradually, and the threshing and separating device of the present invention has a high removal rate and a low grain damage rate.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

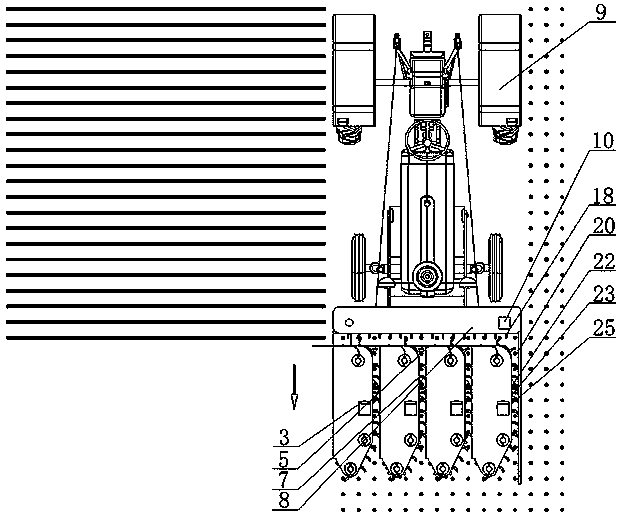

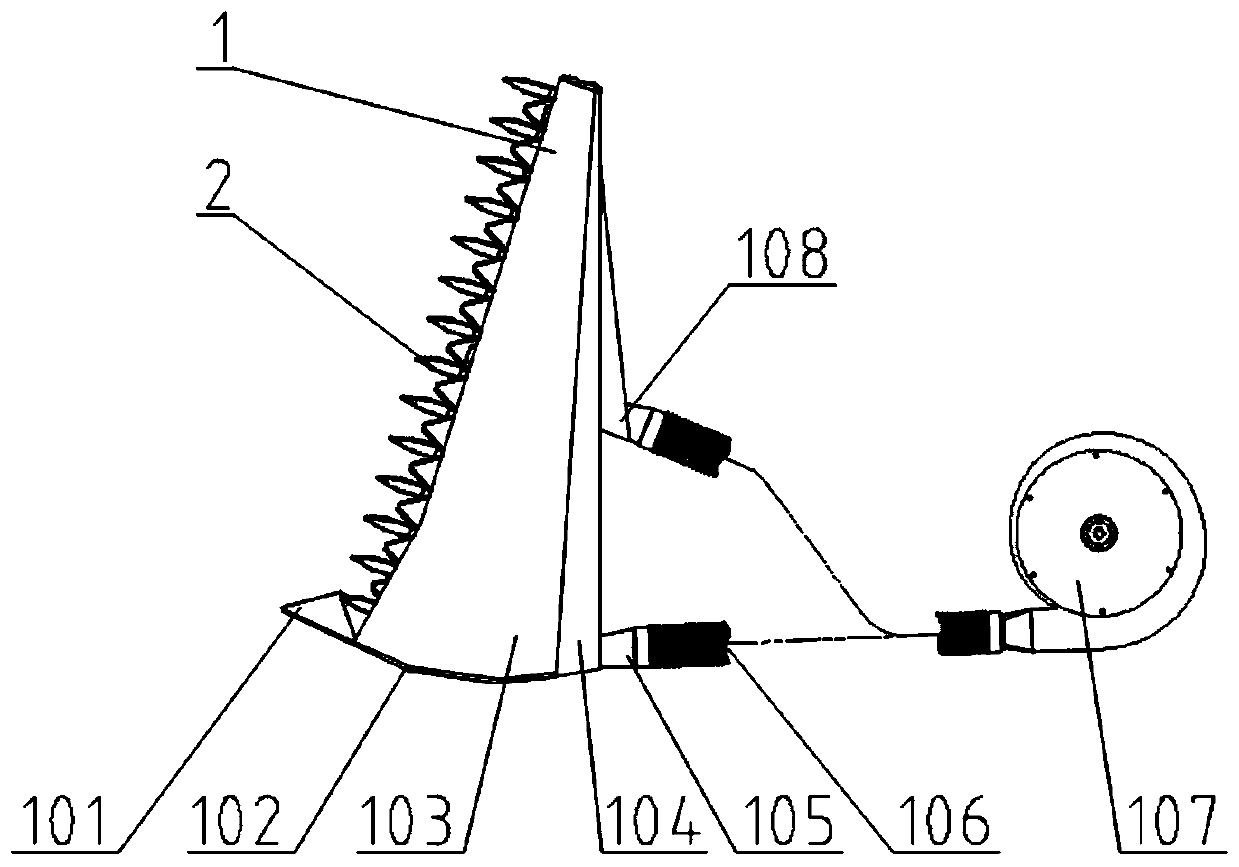

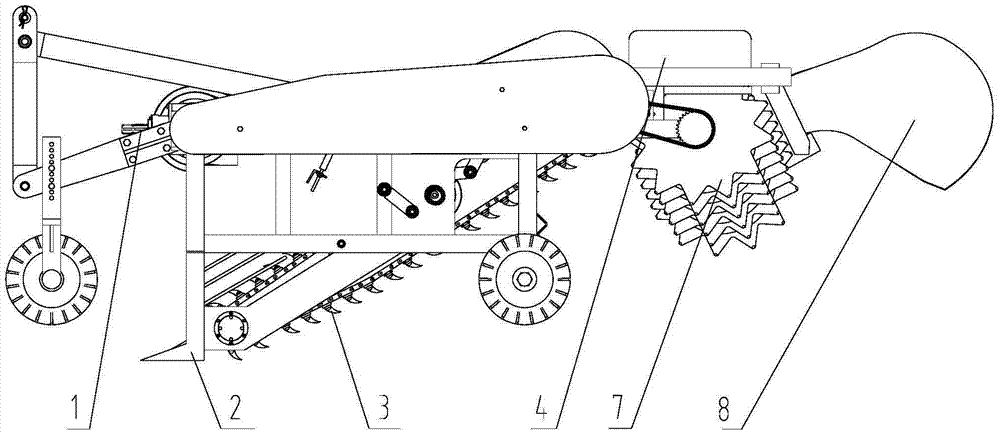

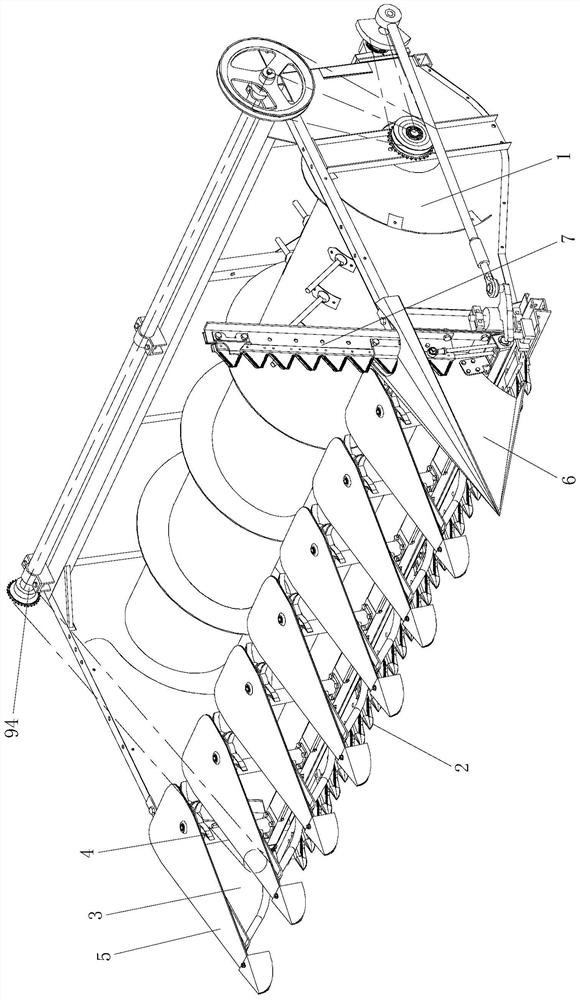

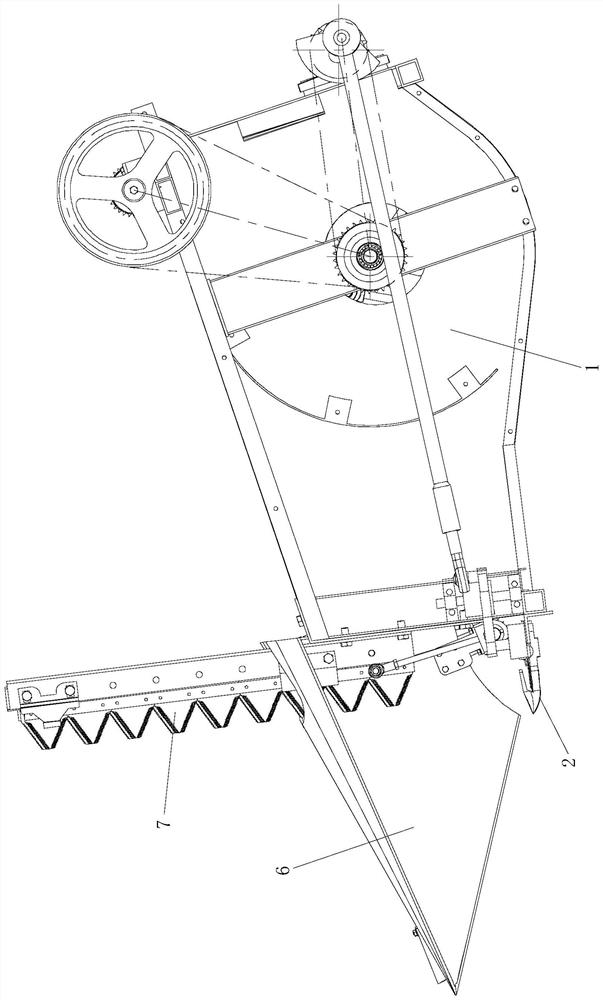

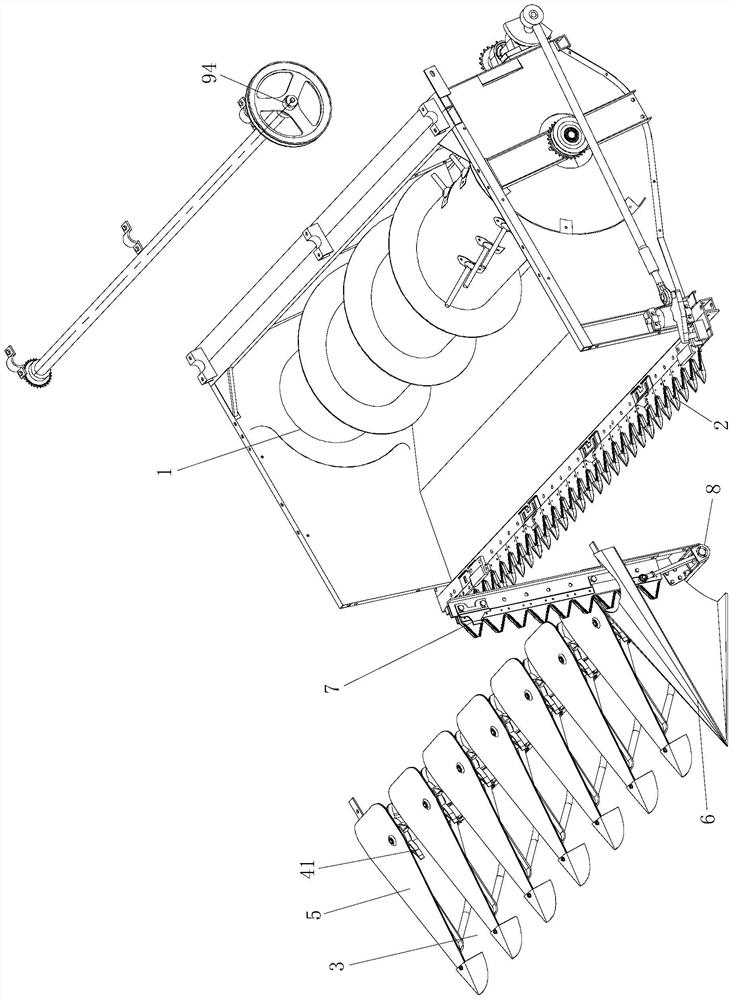

A small creeping peanut digging harvester for mulching planting

The invention relates to a peanut harvesting machine, which is a small creeping peanut digging and harvesting machine for film-covered planting. A digging shovel (2) with a pointed front is arranged horizontally at the lower end of the front end of the frame, and the excavating shovel (2) ) to the rear cross bar configuration of the rectangular frame from the lower front to the rear upper toothed conveyor chain (3); respectively configure a guide plate (4) at the both sides of the toothed conveyor chain (3); A pair of toothed rotary cylindrical cylinders (7) are arranged between the guide plates (4): the toothed rotary cylindrical cylinders (7) are a plurality of rows of metal ring gears perpendicular to the axis protruding from the outer surface of the cylindrical cylinder. It is a triangular tooth plate protruding along the circumference, and the outer surface of the gear ring is covered with rubber coating; two left and right turning plates (8) are arranged behind the toothed rotary cylindrical cylinder (7), and the upper surface of the turning plate (8) Extending opposite to each other and the upper surface goes downwards through a rotating shape and smoothly transitions to the upper surface facing downwards. The invention overcomes the drawbacks of the prior art in domestic peanut fields covered with agricultural film that are easy to be entangled, clamped rods, and clamped fruits, and can give full play to the advantages of large-scale mechanized harvesting.

Owner:山东卧龙种业有限责任公司

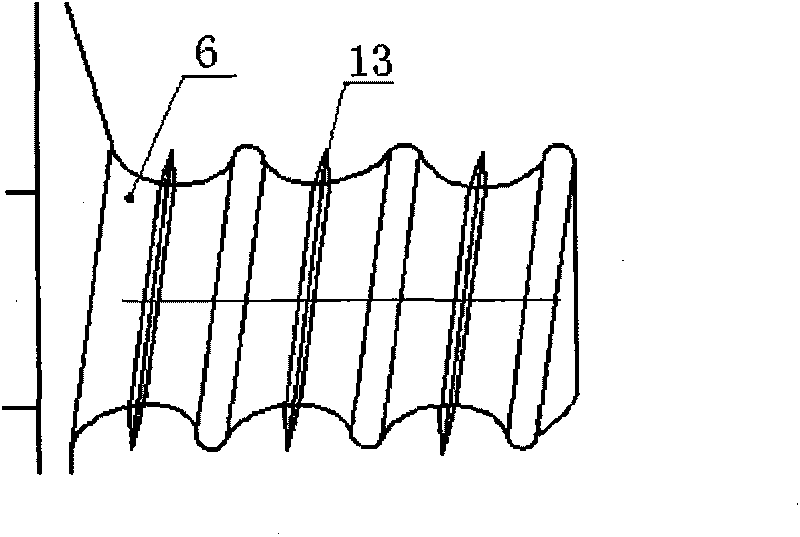

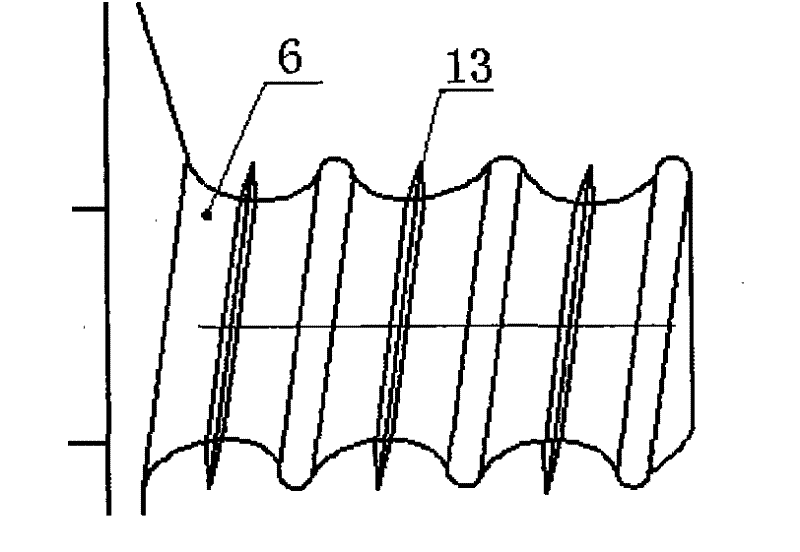

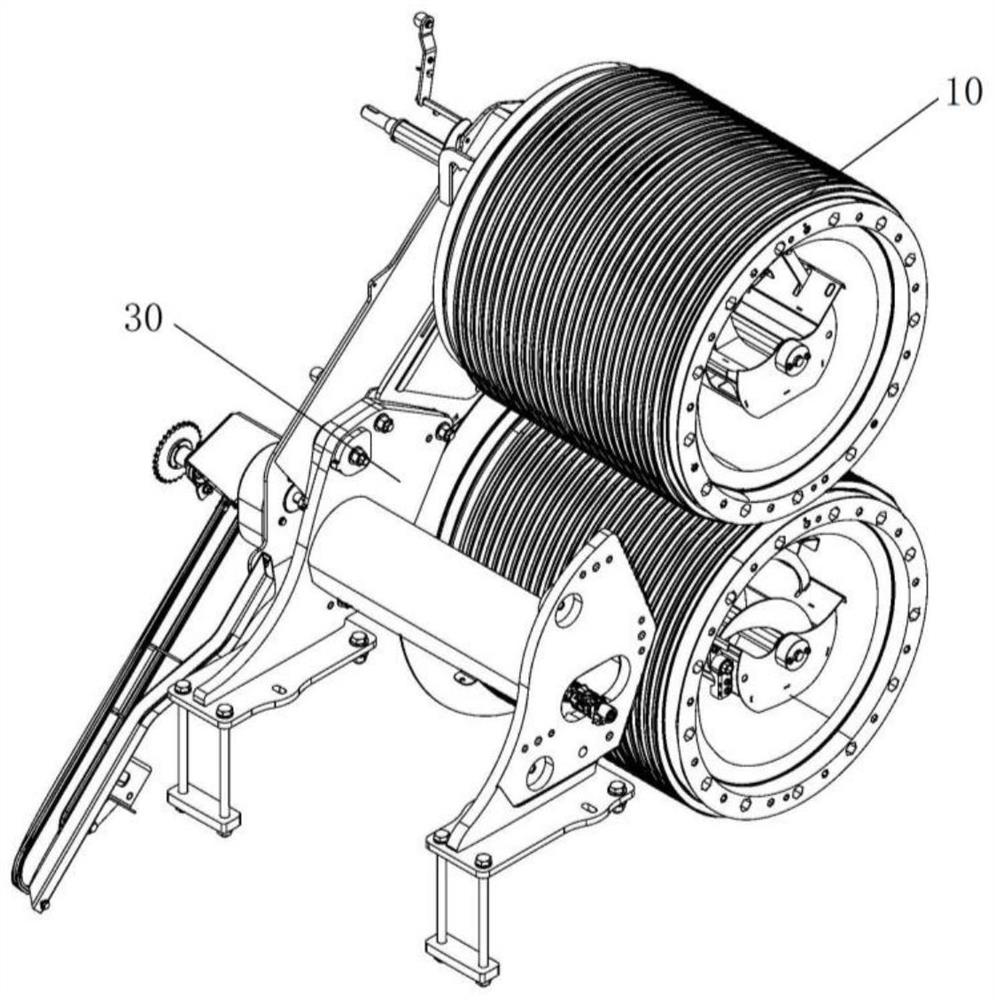

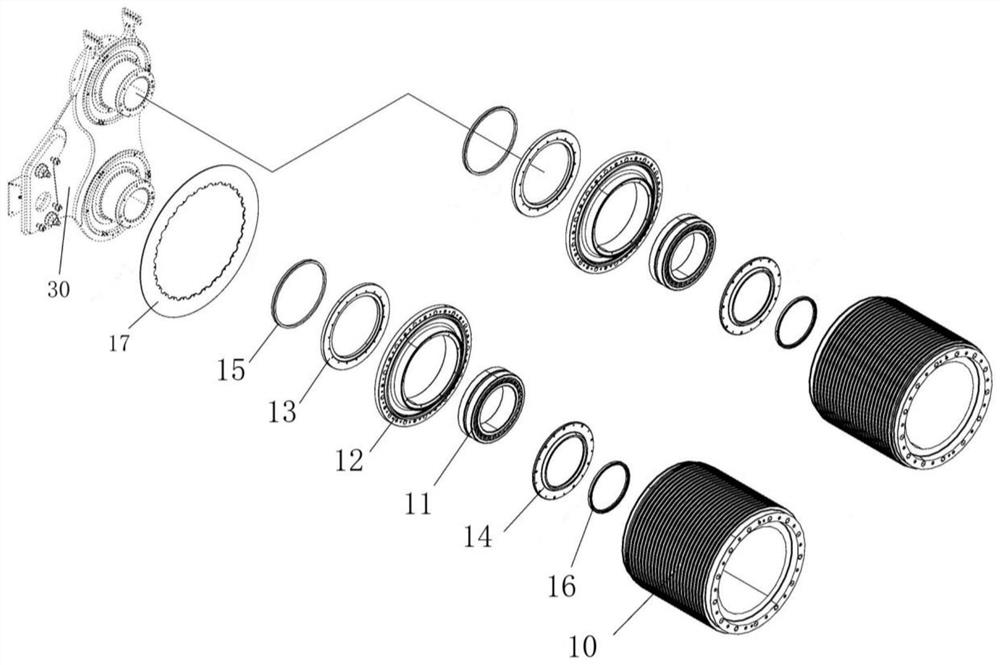

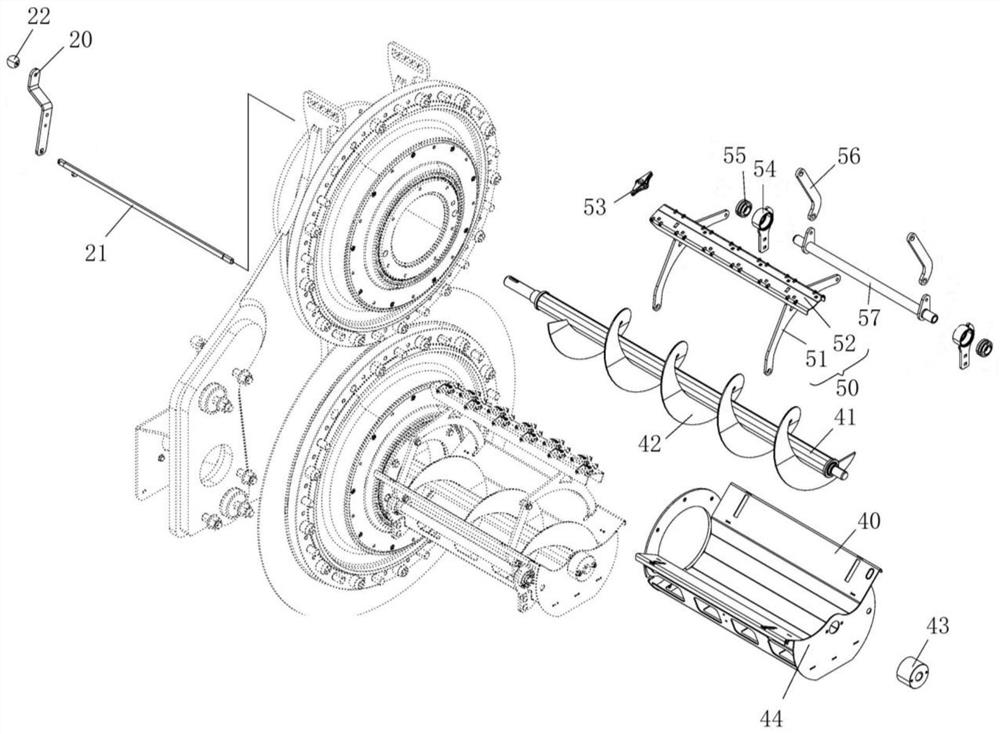

Granulator

The invention relates to a granulator which comprises a pickup device, a granulation compression roller, an upward conveying mechanism, a screening mechanism, a horizontal conveying mechanism and a granule bin. The pickup device sequentially comprises a grass pressing roller, a pickup device main body, a guide mechanism, a crusher and a feeding conveyor belt from front to back; the granulation compression roller comprises two rollers which rotate oppositely and are meshed, and holes communicated with the interiors of the rollers are distributed in the rollers in a matrix manner; a material conveying groove is formed in each roller in the axial direction of the roller, and a second spiral blade is arranged in each material conveying groove; the feeding conveyor belt extends to the position between the two rollers from the position below the crusher; and the material conveying grooves are communicated with the upward conveying mechanism, the upward conveying mechanism is communicated with the screening mechanism, the screening mechanism is communicated with the horizontal conveying mechanism, and the horizontal conveying mechanism is communicated with the granule bin. The granulator is simple in structure, straw is directly smashed and granulated after being picked up, a drying chamber is omitted, and granulated particles are conveyed to the open type granule bin.

Owner:ZOOMLION HEAVY MASCH CO LTD

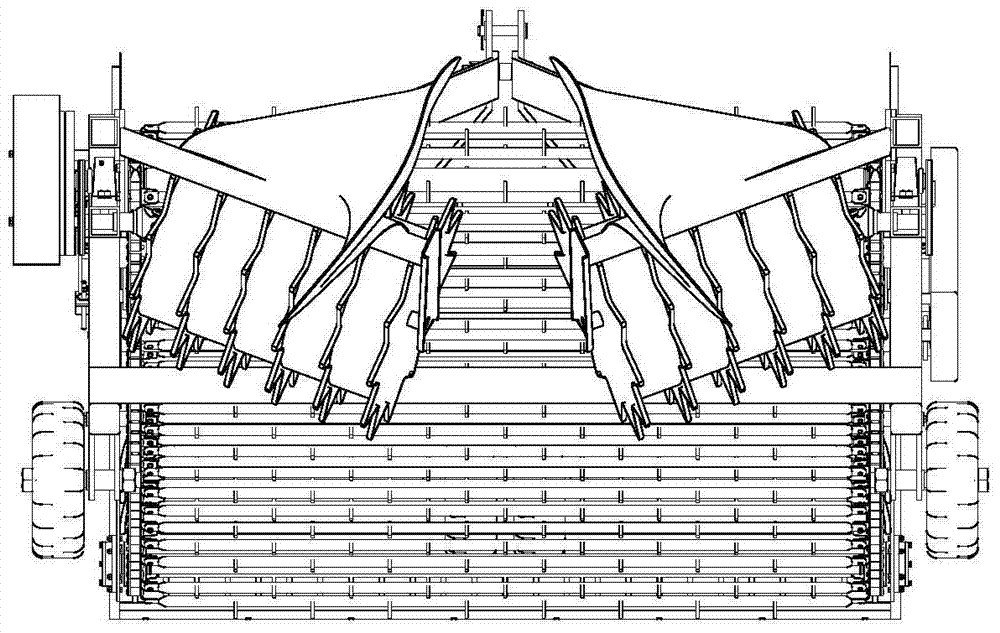

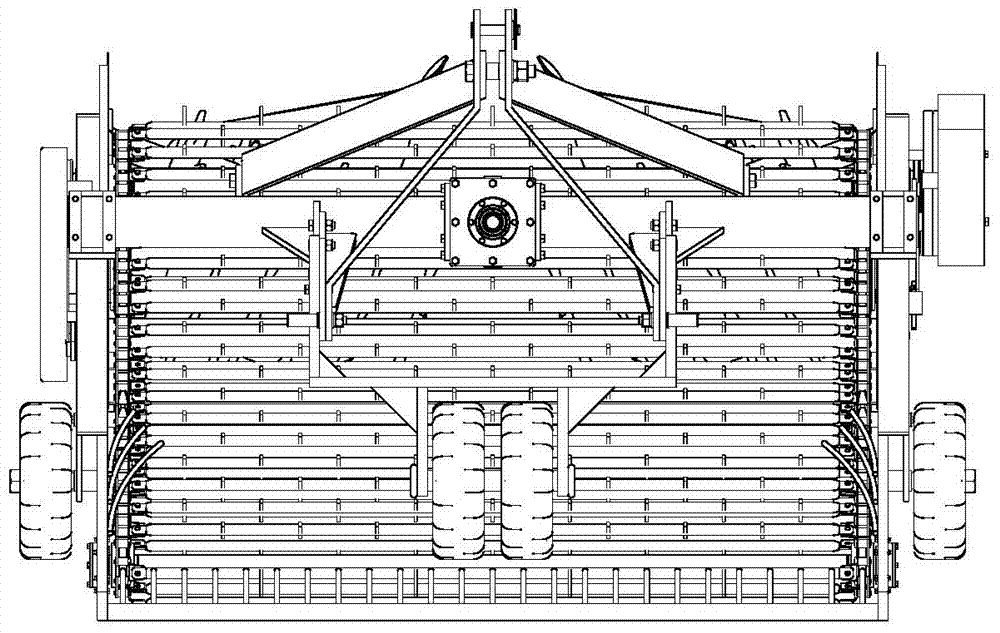

Non-lining corn stalk harvesting machine header adapting to different plant diameters

ActiveCN103004367BEvenly arrangedIncrease productivityHeadersAgricultural scienceAgricultural engineering

The invention relates to a non-lining corn stalk harvesting machine header adapting to different plant diameters. A grain gathering rod is fixedly connected with the front end of a steering shaft bracket, and grain dividing teeth are installed on the end head of a lower cross beam of the front end of a header rack in a uniformly-spaced mode; a first disk saw blade and a second disk saw blade are installed at the lower ends of inner shafts of a concentric sleeve shaft, and a first grain poking roller and a second grain poking roller are installed on outer shafts of the concentric sleeve shaft; and the inner shafts and the outer shafts of the concentric sleeve shaft are connected with each other through bearings, and the inner shafts of the concentric sleeve shaft are installed on the lower cross beam of the front end of the header rack side by side. The non-lining corn stalk harvesting machine header can harvest corn stalks with different plant diameters, different planting densities and different heights in different seasons; under the clamping delivery of the grain gathering rod at the front end of the header, the grain dividing teeth and grain poking teeth on a pair of grain poking rollers, crop stalks are cut off by the saw blades and then are fed in from the root part, the stalks are uniformly arrayed and are tidily fed in, the feeding is smooth, and the blocking is not easily generated; and the harvesting loss is small, the power consumption is low, and the production efficiency is high.

Owner:常蓬彬

Sugarcane planting and managing method for eliminating wide-narrow row craters

ActiveCN113973681AReduce Harvest LossAffect germinationSpadesBiocideAgricultural engineeringSugar cane

The invention belongs to the technical field of sugarcane planting, and particularly relates to a sugarcane planting and management method for eliminating wide-narrow row craters. The method comprises the following steps: (1) preparing soil; (2) preparing sugarcane seeds; (3) performing planting; (4) managing fields; (5) conducting harvesting. According to the application, by combining a planting mode with mechanical improvement, and by adopting a wide-narrow row planting mode, sugarcanes are planted in deep planting furrows, so that the sugarcanes are not liable to suffer from drought to influence germination; meanwhile, by improving planting machinery, when sugarcanes are planted, raised mounds are built between every two narrow rows of sugarcanes, and soil between every two narrow rows of sugarcanes is basically turtle-back-shaped through mechanical intertillage ridging, so that craters formed in the ridging process of the conventionally planted sugarcanes can be eliminated, and therefore, the lodging resistance of sugarcanes can be improved; by combining the technologies of fertilizer management optimization, coating agent adjustment, and the like, the sugarcane yield can be improved, mechanical harvesting loss is reduced, farmer income is increased, and the whole process of sugarcane mechanization planting management is promoted.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

a header

The invention discloses a header, which comprises a header body and a cutter installed at the front end of the header body. The front end of the header body is provided with several guiding passages for guiding the stalks of crop plants to the inside of the header body. The guide passages are located above the cutter and arranged at intervals in sequence, and each guide passage is provided with a dialing device for pulling the stems of the animals to make the crop plants fall along the guide passages to the inside of the header body. The invention has the advantages of greatly reducing harvest loss, reasonable design, simple and compact structure, stable and reliable operation and the like.

Owner:HUNAN AGRICULTURAL UNIV

Granulation compression roller mechanism of granulator

PendingCN112790012AImprove granulation qualityAvoid problems such as over-threshingThreshersSpiral bladeEngineering

The invention relates to a granulation compression roller mechanism of a granulator. The mechanism comprises two rollers which rotate in opposite directions and are meshed, and holes communicating with the interiors of the rollers are distributed in the rollers in a matrix manner; and each material conveying groove is formed in the corresponding roller in the axial direction of the corresponding roller, and a spiral blade is arranged in each material conveying groove. According to the granulation compression roller mechanism, extrusion threshing, radial feeding and axial discharging are performed through the double rollers opposite in rotation direction, crop grains are conveyed in the rollers after threshing, the granulation quality is improved, the problems of excessive threshing and the like are effectively solved, and the harvesting loss is reduced.

Owner:ZOOMLION HEAVY MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com