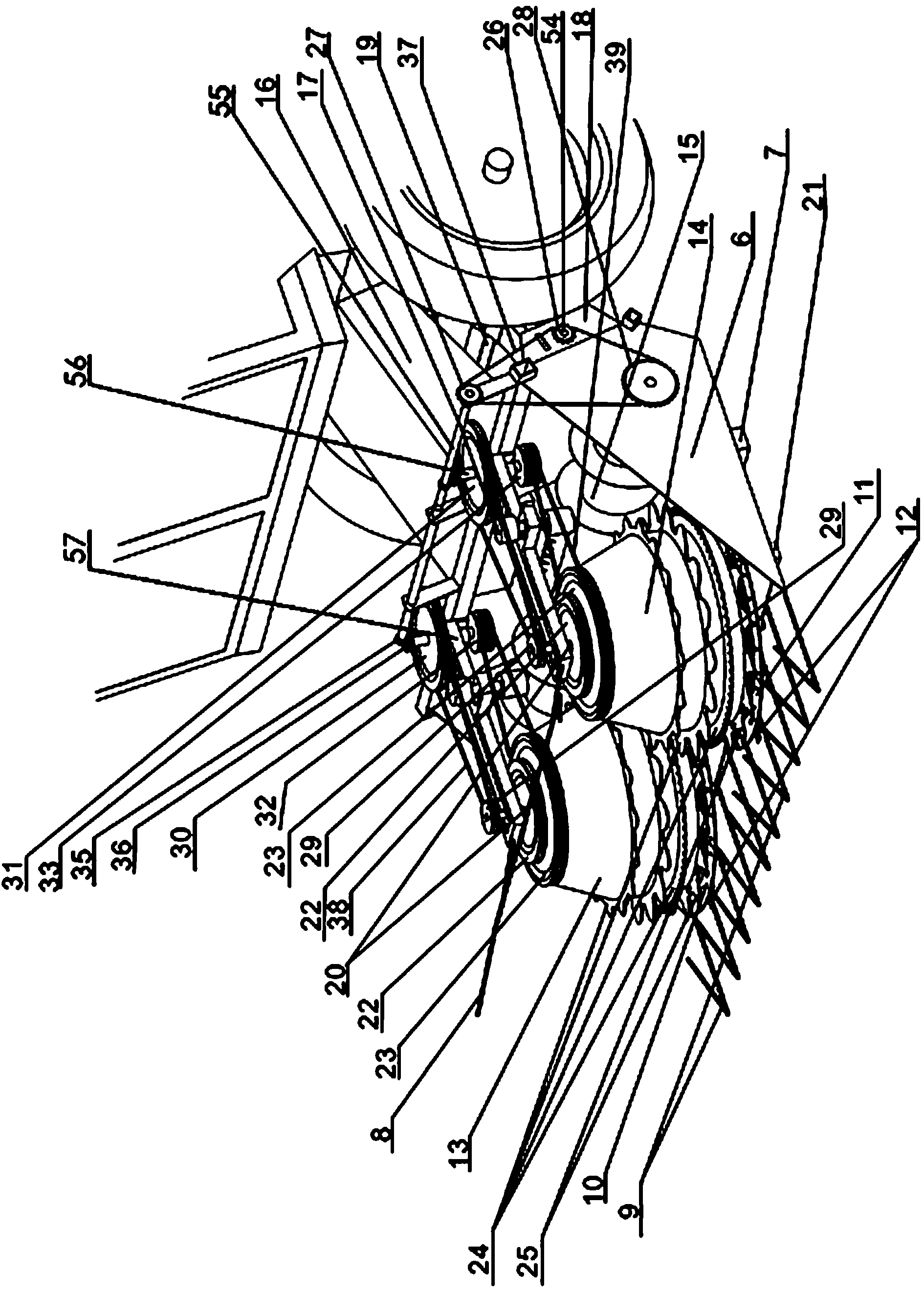

Non-lining corn stalk harvesting machine header adapting to different plant diameters

A technology adaptable to different types of corn stalks, applied in harvesting platforms, harvesters, applications, etc., can solve the problems of large force on the reel, messy straw feeding, and affecting harvesting efficiency, so as to achieve neat straw feeding and harvesting The effect of small loss and uniform arrangement of straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]Example 1 The first and second reels 13 and 14 are configured at different speeds when harvesting corn stalks with a plant diameter of 2 cm.

[0031] The design and calculation of the first and second reels 13 and 14 of the corn stalks with a diameter of 2 cm for harvesting:

[0032] According to the actual test, the harvesting speed of the harvester is:

[0033] v max =0.4963m / s

[0034] v min =0.4415m / s

[0035] Corn stalk diameter d 2 2cm

[0036] ie: d 2 =0.02m

[0037] Then: the time it takes for the harvester to cut 2cm corn stalks

[0038] t 2min =0.02 / 0.4963=0.040 (s) (the minimum time required for cutting)

[0039] t 2max =0.02 / 0.4415=0.045 (s) (the longest time required for cutting)

[0040] Calculation of the speed of the reel:

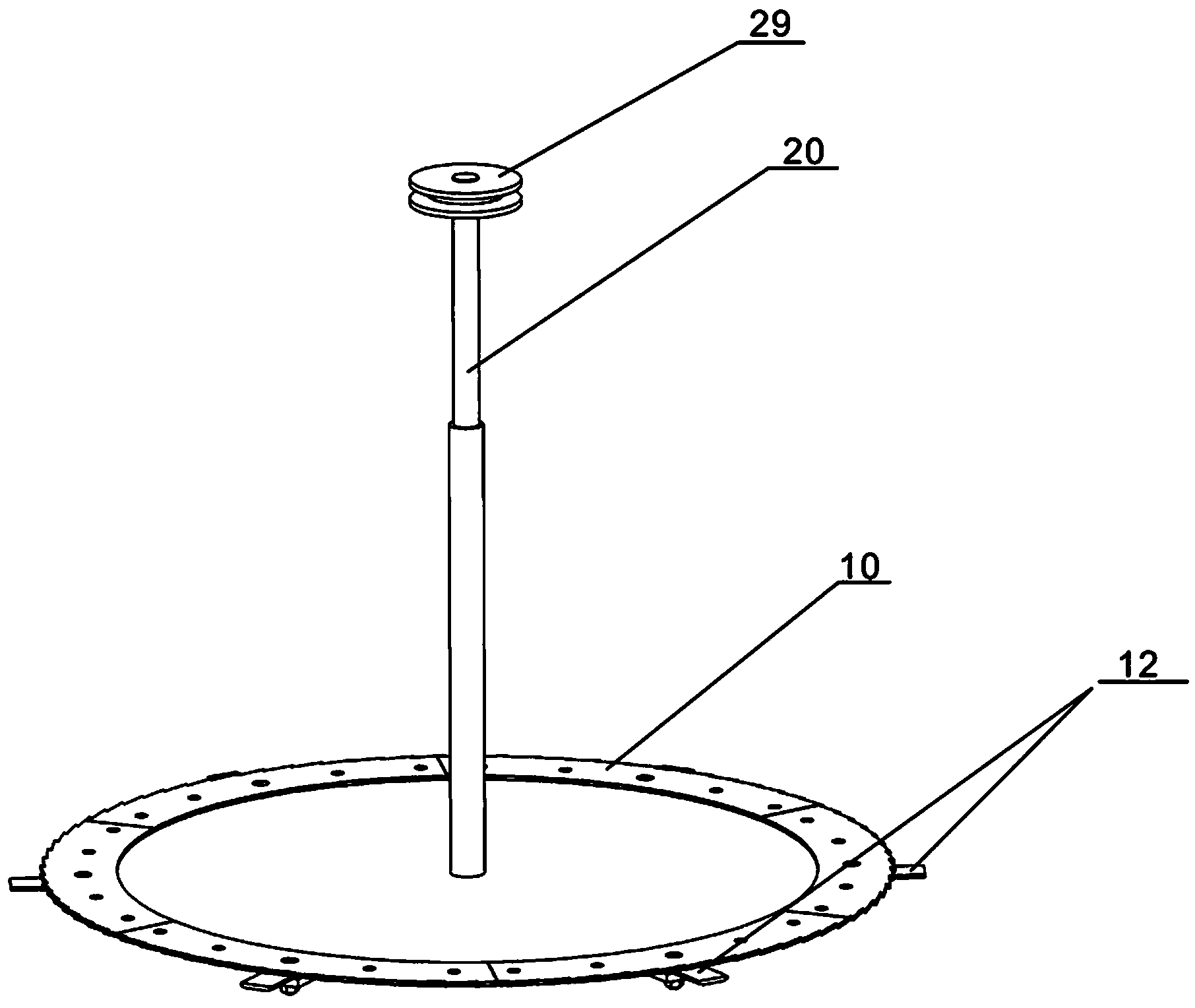

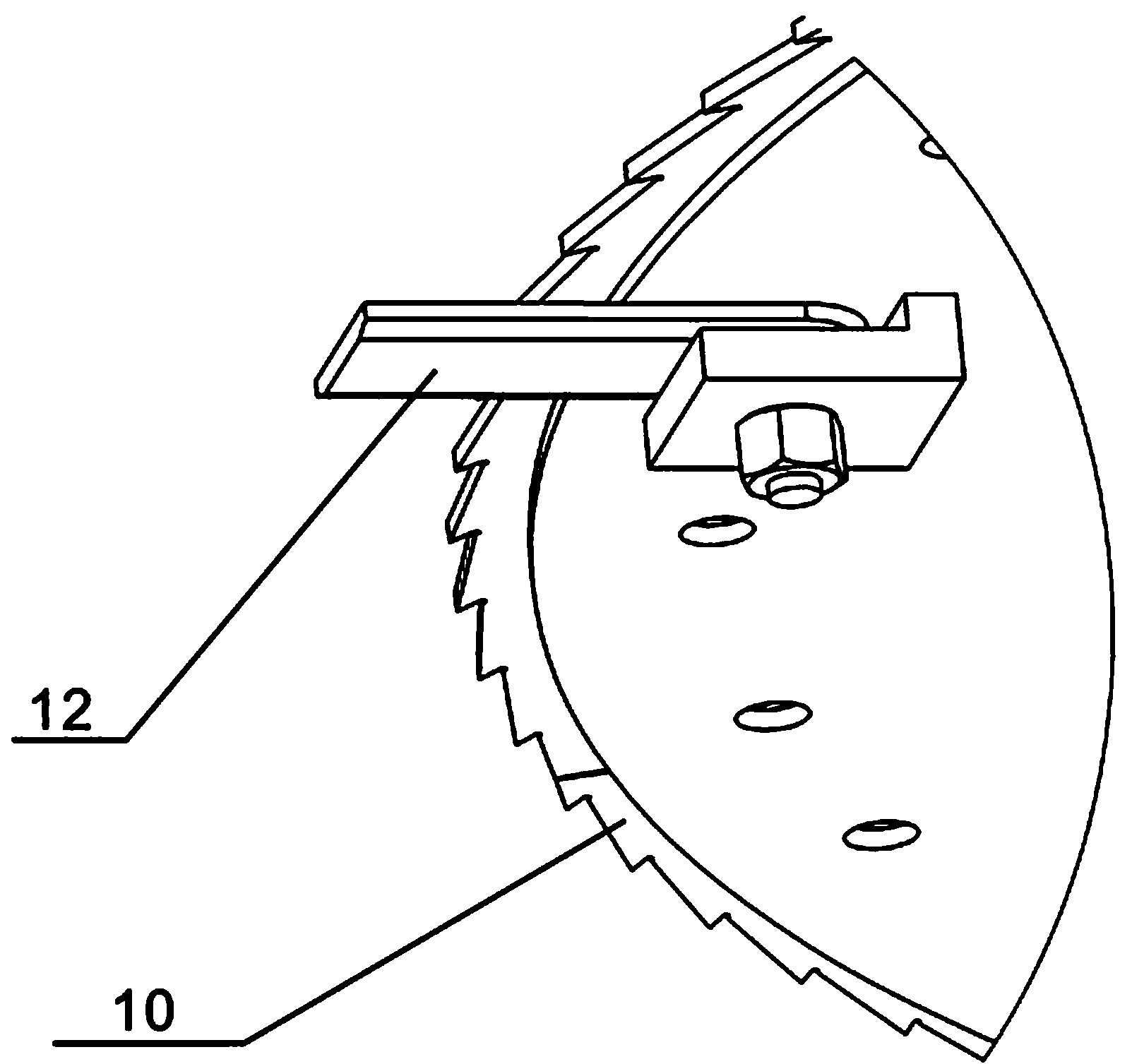

[0041] The hook-shaped reeling teeth 25 at the bottom of the first and second reeling cylinders 13 and 14 have 16 teeth. The saw blades 10, 11 completely cut the corn stalk, and the hook reel tooth 25 r...

Embodiment 2

[0051] Example 2 The rotational speed configuration of the first and second reels 13 and 14 when the diameter of corn stalks harvested by the header is 4 cm.

[0052] Design and calculation of first and second reels 13 and 14 rotating speeds when harvesting corn stalks with a plant diameter of 4 cm:

[0053] According to the actual test, the harvesting speed of the harvester is:

[0054] v max =0.4963m / s

[0055] v min =0.4415m / s

[0056] Corn stalk diameter d 4 4cm

[0057] ie: d 4 =0.04m

[0058] Then: the time it takes for the harvester to cut the corn stalk

[0059] t 4 min =0.04 / 0.4963=0.080 (s) (the minimum time required for cutting)

[0060] t 4 max =0.04 / 0.4415=0.090 (s) (the longest time required for cutting)

[0061] First and second reel 13, 14 rotational speed calculation:

[0062] The hook-shaped reeling teeth 25 at the bottom of the first and second reeling cylinders 13 and 14 have 16 teeth. The saw blades 10 and 11 completely cut ...

Embodiment 3

[0072] Example 3 The first and second reels 13 and 14 rotate speed and the configuration of the hook-shaped reels 25 when the diameter of the corn stalks harvested by the header is 4 cm to 6 cm.

[0073] Design and calculation of the rotation speed of the first and second reels 13 and 14 for harvesting corn stalks with a plant diameter of 4cm~6cm:

[0074] According to the actual test, the harvesting speed of the harvester is:

[0075] v max =0.4963m / s

[0076] v min =0.4415m / s

[0077] Corn stalk diameter d 46 4cm~6cm

[0078] ie: d 46 =0.04m~0.06m

[0079] harvester with v min = Traveling at a speed of 0.4415m / s

[0080] Then: the time it takes for the harvester to cut the corn stalk

[0081] t 46 min =0.04 / 0.4415=0.090 (s) (the minimum time required for cutting)

[0082] t 46 max =0.06 / 0.4415=0.136 (s) (the longest time required for cutting)

[0083] Adjustment of the number of teeth of the first and second reel 13, 14 bottom hook-shaped r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com